Serial production of Measurement- While-Drilling (MWD) systems with dual (electromagnetic (EM) & mud-pulse (MP)) презентация

Содержание

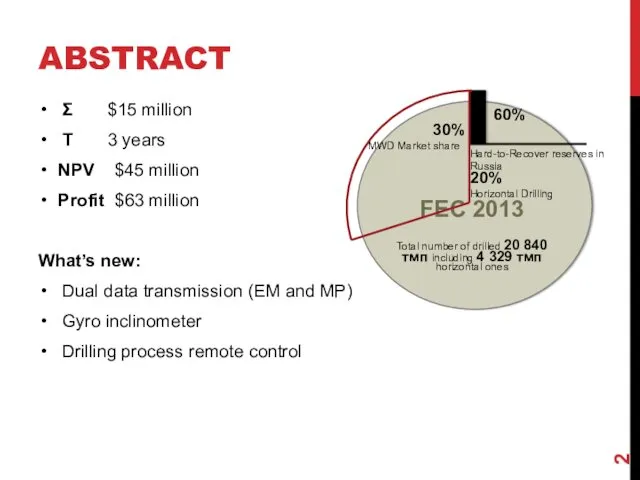

- 2. ABSTRACT Σ $15 million T 3 years NPV $45 million Profit $63 million What’s new: Dual

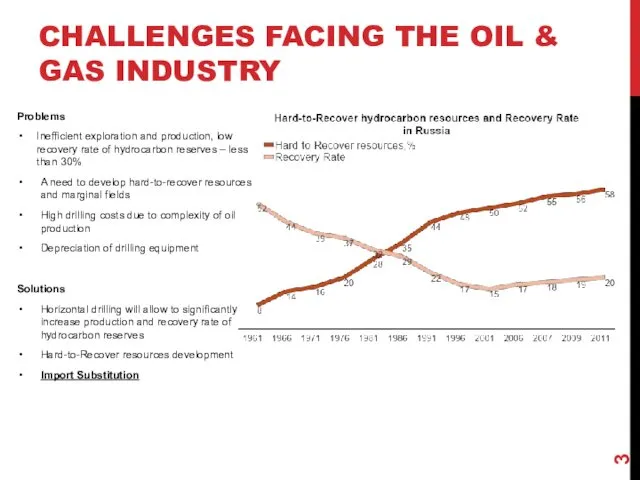

- 3. CHALLENGES FACING THE OIL & GAS INDUSTRY Problems Inefficient exploration and production, low recovery rate of

- 4. MARKET POTENTIAL Horizontal Drilling today: 20% in Russia vs. 80% Outside of Russia out of total

- 5. OUR HORIZONTAL DRILLING EQUIPMENT INCLUDES: EM & MP MWD (dual data transmission) Gyro inclinometer Geophysical survey

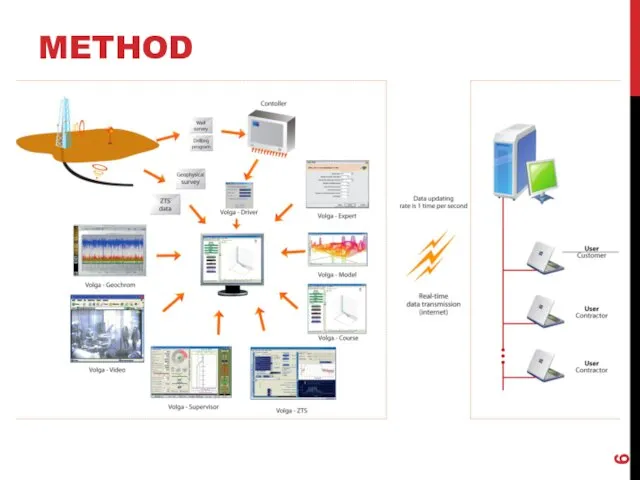

- 6. METHOD

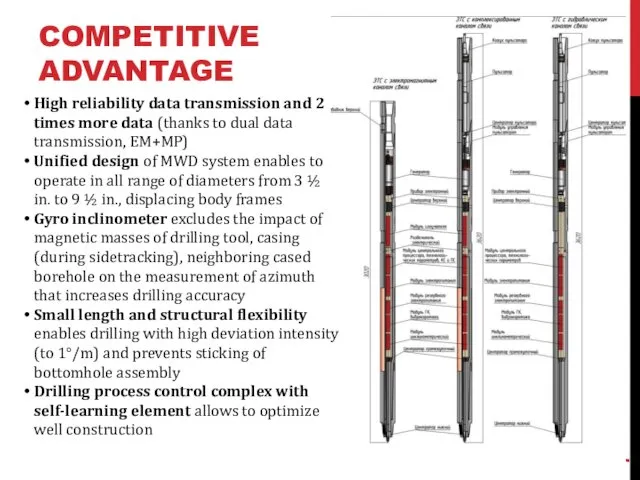

- 7. COMPETITIVE ADVANTAGE High reliability data transmission and 2 times more data (thanks to dual data transmission,

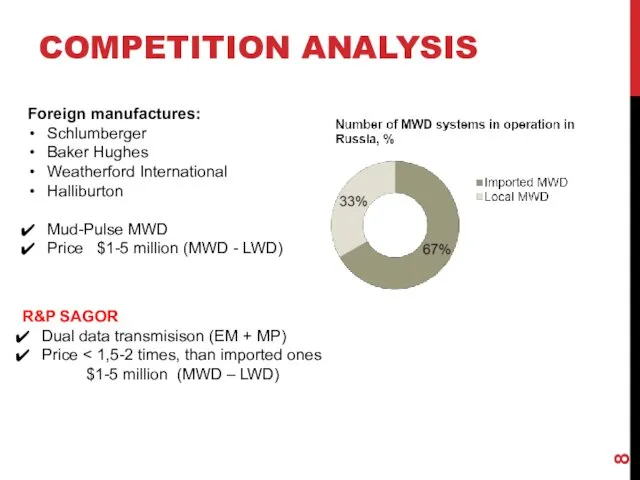

- 8. COMPETITION ANALYSIS Foreign manufactures: Schlumberger Baker Hughes Weatherford International Halliburton Mud-Pulse MWD Price $1-5 million (MWD

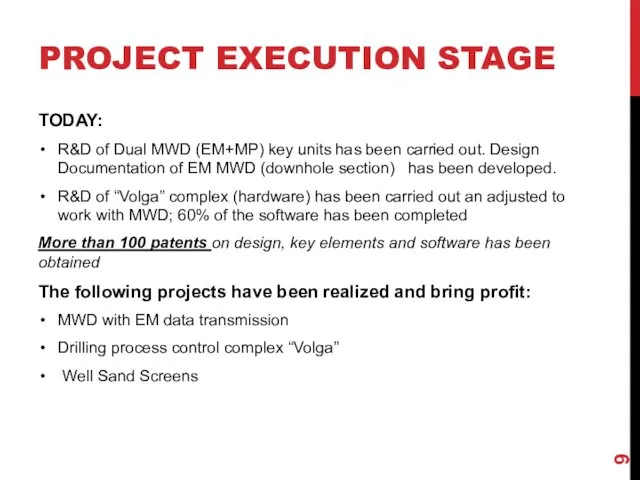

- 9. PROJECT EXECUTION STAGE TODAY: R&D of Dual MWD (EM+MP) key units has been carried out. Design

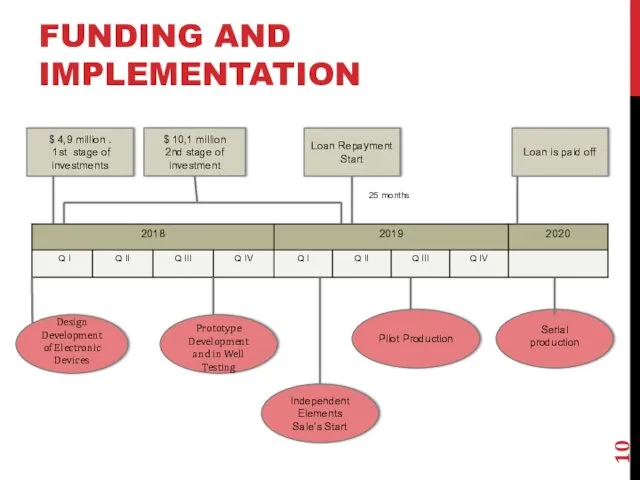

- 10. FUNDING AND IMPLEMENTATION $ 4,9 million . 1st stage of investments $ 10,1 million 2nd stage

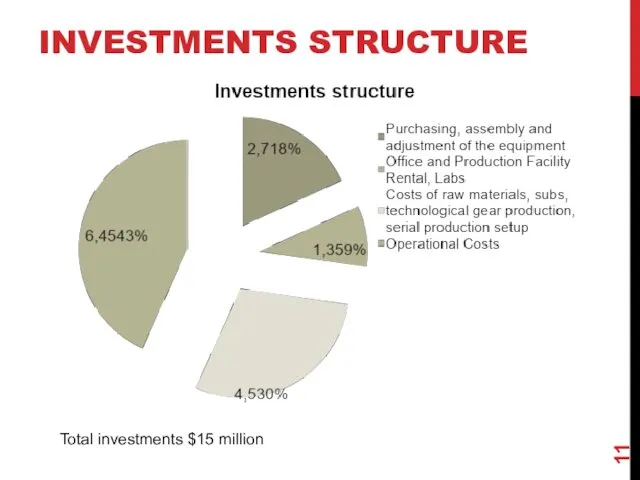

- 11. INVESTMENTS STRUCTURE Total investments $15 million

- 13. Скачать презентацию

Трудные дыхательные пути

Трудные дыхательные пути Наследование. Классы в С++

Наследование. Классы в С++ Классификация холодильных машин

Классификация холодильных машин Учебная презентация по теме Знакомимся с Коломной

Учебная презентация по теме Знакомимся с Коломной КТО СПИТ ЗИМОЙ

КТО СПИТ ЗИМОЙ Добро пожаловать в ИГНиУ МГПУ

Добро пожаловать в ИГНиУ МГПУ Мера длины дециметр

Мера длины дециметр Қазақ қызы-ұлттық тәрбие бастауы

Қазақ қызы-ұлттық тәрбие бастауы Объект недвижимости

Объект недвижимости Искусство Фландрии

Искусство Фландрии Inventions that shook the world

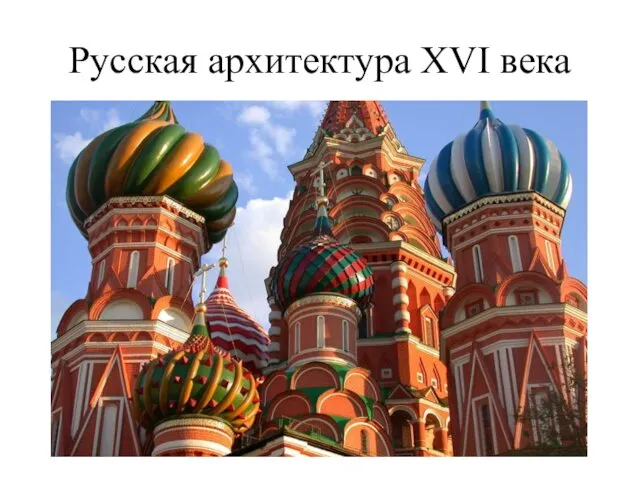

Inventions that shook the world Русская архитектура XVI века

Русская архитектура XVI века Чуковский Загадки

Чуковский Загадки Кадровое дело

Кадровое дело Дорога и её элементы Диск

Дорога и её элементы Диск Рельеф России

Рельеф России Презентация Поклонимся Великим тем годам

Презентация Поклонимся Великим тем годам Психологические особенности детей с умственной отсталостью

Психологические особенности детей с умственной отсталостью Формирование современной городской среды (проект правил благоустройства территории города Череповца)

Формирование современной городской среды (проект правил благоустройства территории города Череповца) Условия горения сварочной дуги

Условия горения сварочной дуги Обратная пропорциональность

Обратная пропорциональность Дезинфекция уборочного инвентаря, предметов ухода, медицинского инструментария

Дезинфекция уборочного инвентаря, предметов ухода, медицинского инструментария Чудеса на песке

Чудеса на песке КАСКО ФЛ Продуктовая линейка Dealer (на базе правил 171.1)

КАСКО ФЛ Продуктовая линейка Dealer (на базе правил 171.1) Теории возникновения психики

Теории возникновения психики Family of Аntonov’s regional jet passenger and transport aircraft

Family of Аntonov’s regional jet passenger and transport aircraft Процессуальное право: гражданский и арбитражный процесс

Процессуальное право: гражданский и арбитражный процесс Модель использования ИКТ на уроках иностранного языка.

Модель использования ИКТ на уроках иностранного языка.