Содержание

- 2. Sakhalin Energy LNG/OET/TLU S T P Unit 6200

- 3. Process Introduction Purpose of the Unit Process description Equipment Health, Safety and Environment Routine checks The

- 4. Introduction to the unit To collect and dispose vapour and liquid in a safe manner: Types

- 5. Purpose of the unit Purpose: The purpose of the unit is to safely collect and dispose

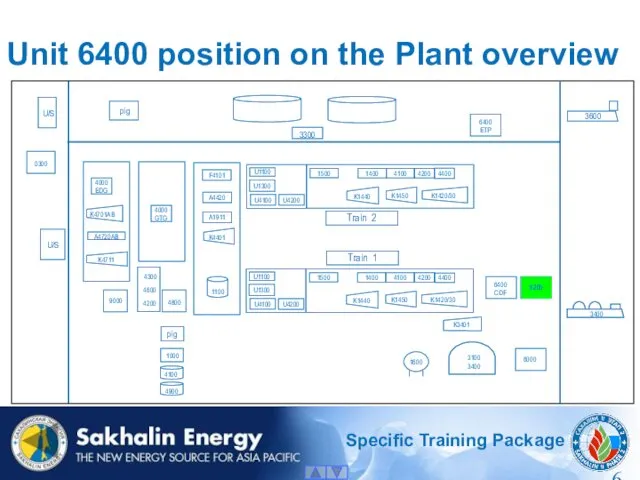

- 6. Unit 6400 position on the Plant overview 6200

- 7. Process description Warm Flare System (FWW) All the warm vapours are collected into a single 48”

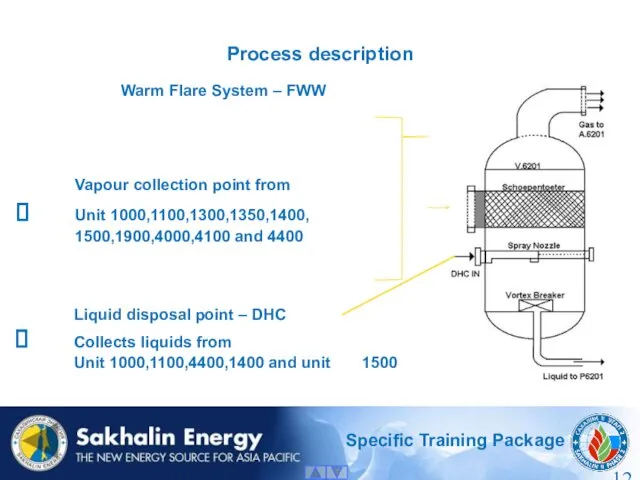

- 8. Process description Warm Liquid Disposal System (DHC) The warm liquids from manual drains are collected in

- 9. Process description Cold Flare System (FCD) Cold dry and light hydrocarbon vapours from unit 1400, 1500

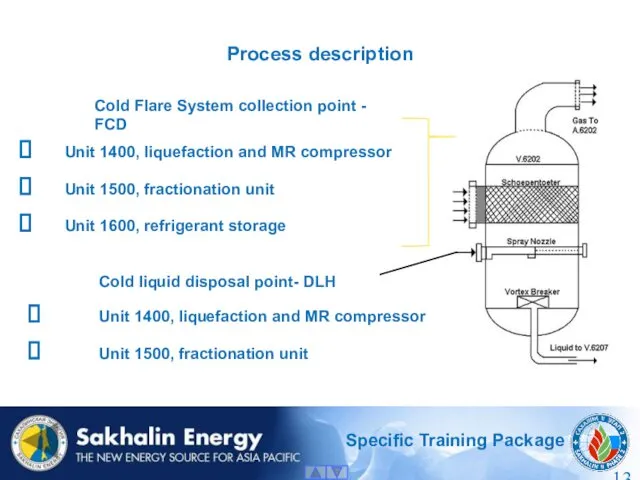

- 10. Process description Cold Liquid Disposal System (DLH) All the cold liquids are collected into two 12”

- 11. Process description Operationally initiated release is vented to separate 16” FOP header. The vented gas is

- 12. Process description Liquid disposal point – DHC Collects liquids from Unit 1000,1100,4400,1400 and unit 1500 Warm

- 13. Process description Cold liquid disposal point- DLH Unit 1400, liquefaction and MR compressor Unit 1500, fractionation

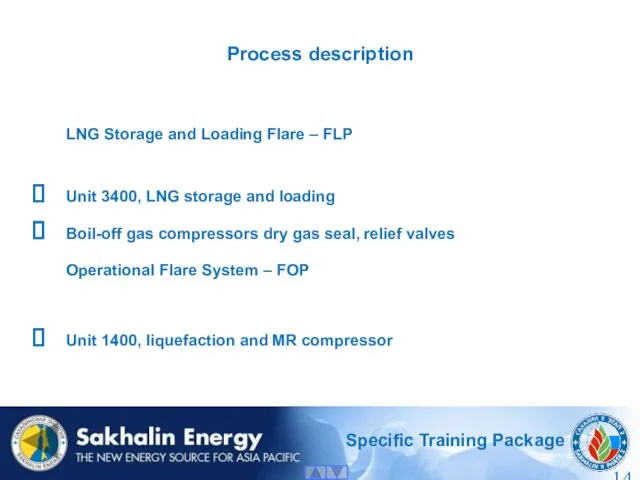

- 14. LNG Storage and Loading Flare – FLP Unit 3400, LNG storage and loading Boil-off gas compressors

- 15. Fuel Gas: High pressure fuel gas is used for: Motive gas in the blow cases V-6207A/B.

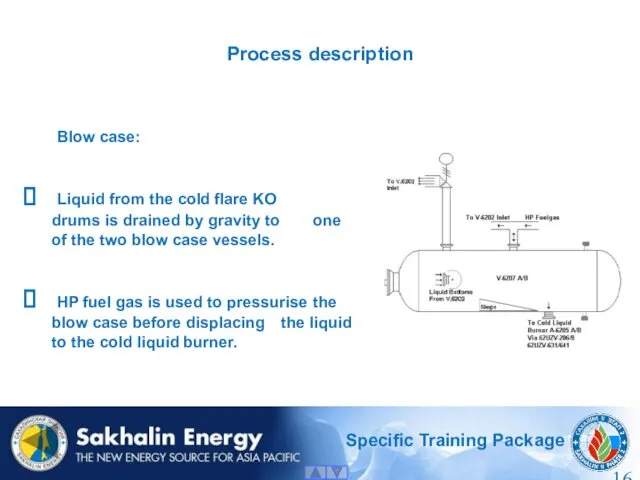

- 16. Blow case: Liquid from the cold flare KO drums is drained by gravity to one of

- 17. Flare Overview

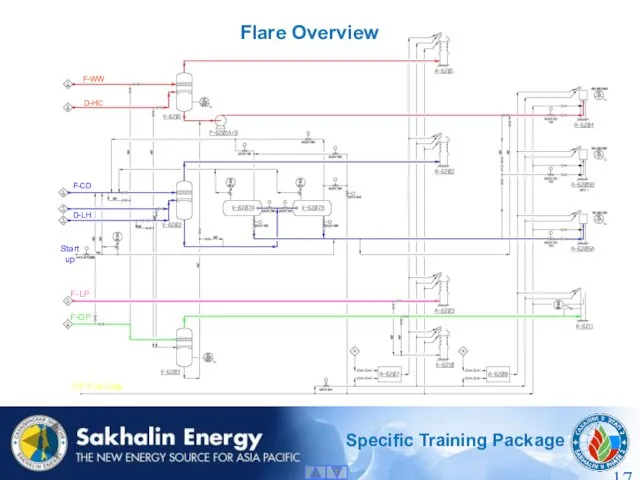

- 18. Major equipment 3 flare KO drums One blow case (two vessels) Two warm liquid disposal pumps

- 19. Health, Safety and Environment Health, Safety: Noise when the flare is operating. Radiated heat from the

- 20. Environment Controlled releases to atmosphere from the flares and liquid disposal burners pose no harm to

- 22. Скачать презентацию

ПРЕЗЕНТАЦИЯ: РАЗВИТИЕ ИГРОВОЙ ДЕЯТЕЛЬНОСТИ ДЕТЕЙ ДОШКОЛЬНОГО ВОЗРАСТА

ПРЕЗЕНТАЦИЯ: РАЗВИТИЕ ИГРОВОЙ ДЕЯТЕЛЬНОСТИ ДЕТЕЙ ДОШКОЛЬНОГО ВОЗРАСТА Строение периферического отдела скелета животных

Строение периферического отдела скелета животных Описание климата по климатограммам

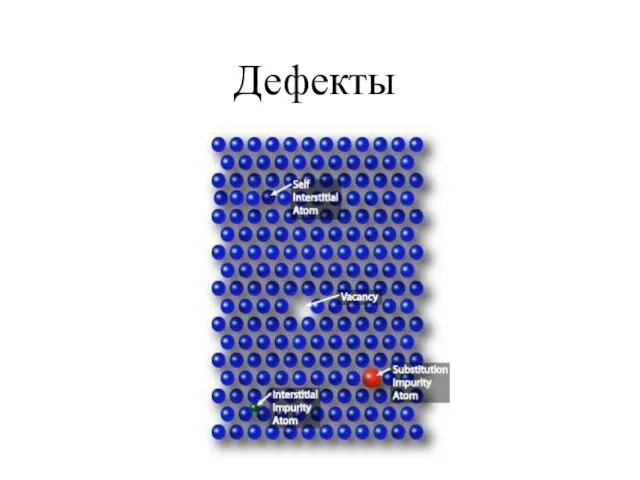

Описание климата по климатограммам Кристаллизация Осмия. Дефекты. Поликристаллы

Кристаллизация Осмия. Дефекты. Поликристаллы Обструктивные уропатии

Обструктивные уропатии Строение атома

Строение атома 12 ИЮНЯ ДЕНЬ РОССИИ

12 ИЮНЯ ДЕНЬ РОССИИ Предмет и метод экономической теории

Предмет и метод экономической теории Урок естествознания 10 класс Традиции и революции в естествознании. Религиозная традиция

Урок естествознания 10 класс Традиции и революции в естествознании. Религиозная традиция Школы менеджмента

Школы менеджмента Взаимодействие с родителями в процессе обучения ребёнка мелкой моторики.

Взаимодействие с родителями в процессе обучения ребёнка мелкой моторики. Классификация инноваций

Классификация инноваций Минералы Урала

Минералы Урала презентация Реакции обмена

презентация Реакции обмена Атмосфера. Ветер

Атмосфера. Ветер Презентация Фосфор

Презентация Фосфор Электропитание и электроснабжение нетяговых потребителей

Электропитание и электроснабжение нетяговых потребителей Презентация Трудности адаптации ребенка в 5 классе

Презентация Трудности адаптации ребенка в 5 классе Северная война 1700-1721

Северная война 1700-1721 Разработка мобильных приложений на 1С и организация взаимодействия через Интернет

Разработка мобильных приложений на 1С и организация взаимодействия через Интернет Второстепенные члены предложения. Повторение и систематизация материала

Второстепенные члены предложения. Повторение и систематизация материала Развитию речи у детей старшего дошкольного возраста на тему: Здравствуй, лето!

Развитию речи у детей старшего дошкольного возраста на тему: Здравствуй, лето! Кільватерне прискорення частинок в плазмі (plasma wakefield acceleration)

Кільватерне прискорення частинок в плазмі (plasma wakefield acceleration) Апаптоз патофизилогиясы

Апаптоз патофизилогиясы Презентация Кабинет педагога-психолога

Презентация Кабинет педагога-психолога Трипілля – Кукутені. Загадки унікальної культури

Трипілля – Кукутені. Загадки унікальної культури Русская архитектура XVI - XVII веков

Русская архитектура XVI - XVII веков Портфолио Натальи Рудяковой. Маркетолог

Портфолио Натальи Рудяковой. Маркетолог