Содержание

- 2. Chapter 8 Chapter Objectives Understand the concept of the supply chain, its importance, and management. Describe

- 3. Chapter 8 Supply and Value Chains Supply Chain Flows Materials flows are all physical products, new

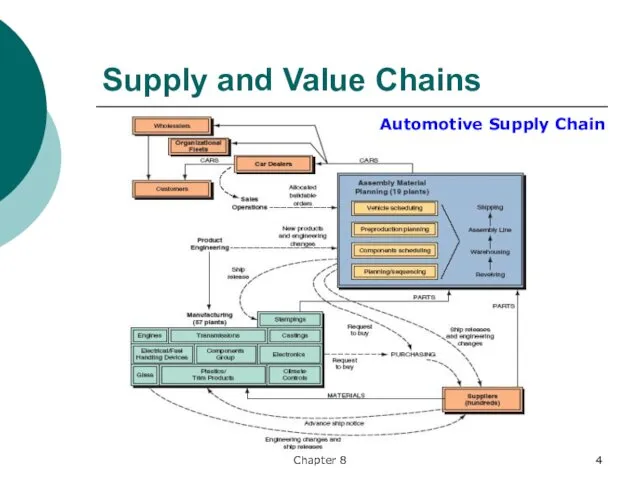

- 4. Chapter 8 Supply and Value Chains Automotive Supply Chain

- 5. Chapter 8 Supply Chains Components The supply chain involves three segments: Upstream, where sourcing or procurement

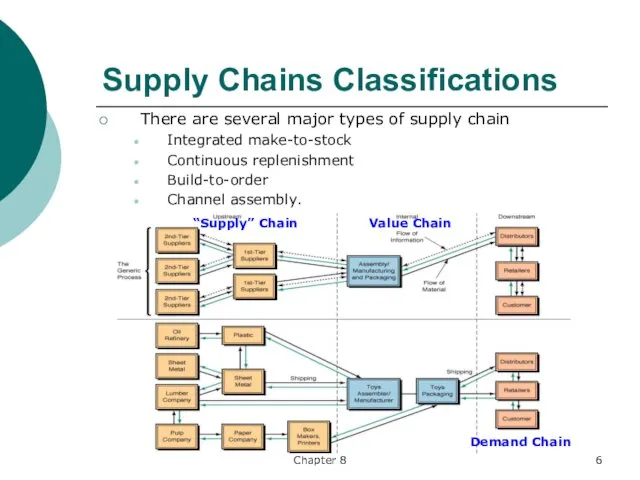

- 6. Chapter 8 Supply Chains Classifications There are several major types of supply chain Integrated make-to-stock Continuous

- 7. Chapter 8 Adding value along the chain is essential for competitiveness, however problems exist especially in

- 8. Chapter 8 The bullwhip effect refers to erratic shifts in orders up and down the supply

- 9. Chapter 8 Information sharing among supply chain partners (c-commerce) sometimes referred to as the collaboration supply

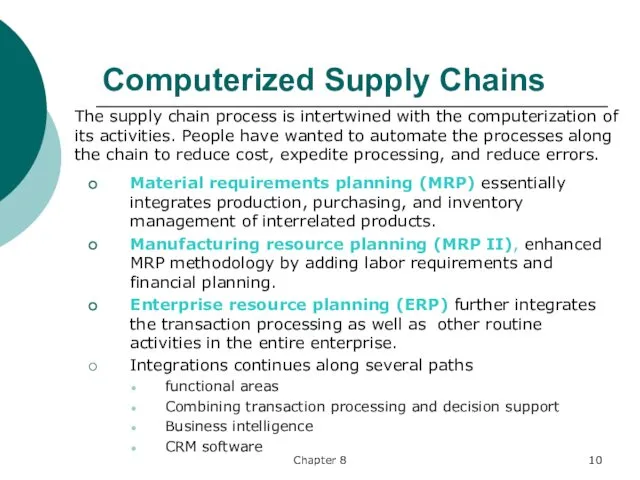

- 10. Chapter 8 The supply chain process is intertwined with the computerization of its activities. People have

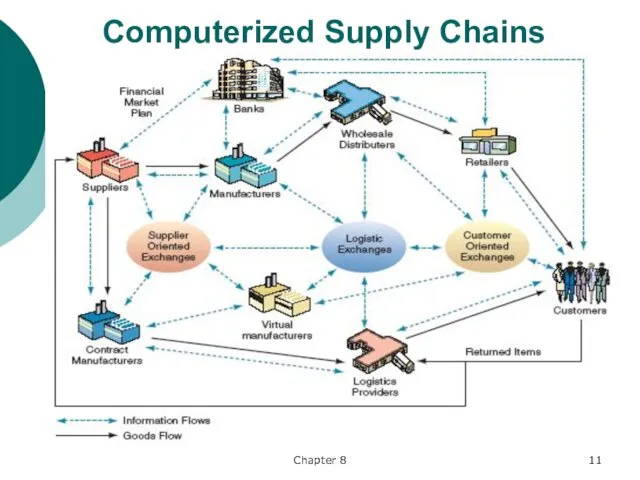

- 11. Chapter 8 Computerized Supply Chains

- 12. Chapter 8 There are many benefits to integrating functional systems. Tangible benefits: Inventory reduction Personnel reduction

- 13. Chapter 8 Intangible benefits: Information visibility New/improved processes Customer responsiveness Standardization Flexibility Globalization Business performance Reduction

- 14. Chapter 8 ERP and Supply Chains It is comprised of a set of applications that automate

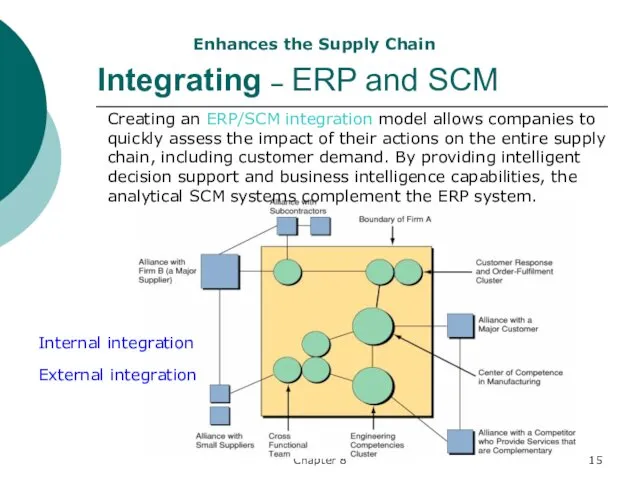

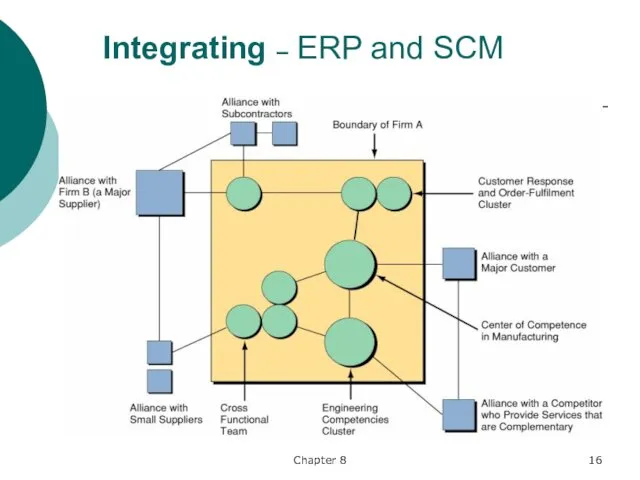

- 15. Chapter 8 Integrating – ERP and SCM Creating an ERP/SCM integration model allows companies to quickly

- 16. Integrating – ERP and SCM Chapter 8

- 17. Chapter 8 E-Commerce and Supply Chains E-commerce can digitize some products can replace all paper documents

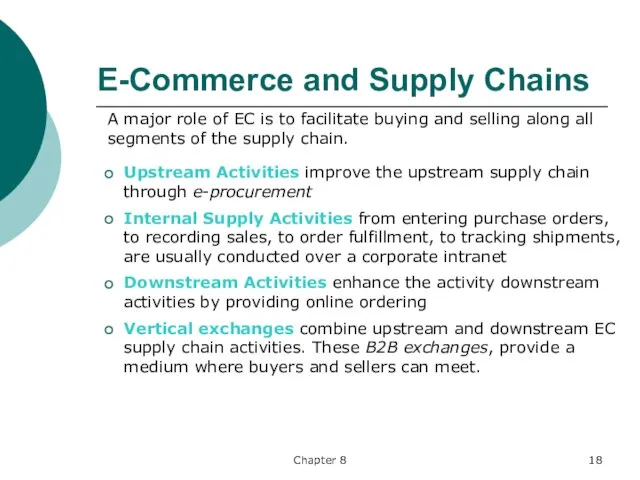

- 18. Chapter 8 E-Commerce and Supply Chains Upstream Activities improve the upstream supply chain through e-procurement Internal

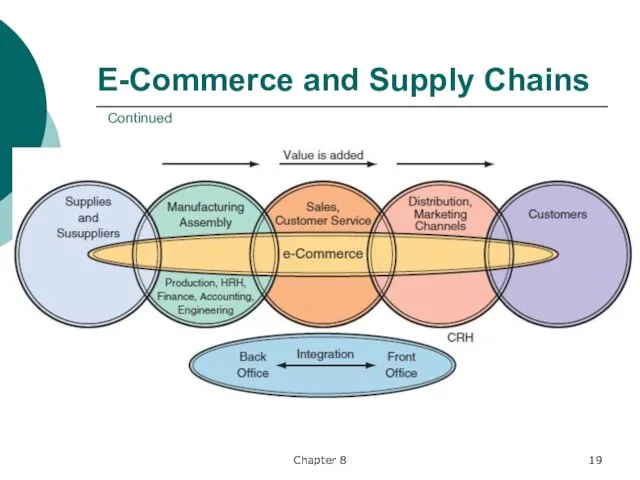

- 19. Chapter 8 E-Commerce and Supply Chains Continued

- 20. Chapter 8 Partner Relationship Management Manual methods include; phone, fax, and mail EDI is typically used

- 21. Chapter 8 Partner Relationship Management Continued

- 22. Chapter 8 Global Supply Chains Companies go global (disperse the value chain) for a variety of

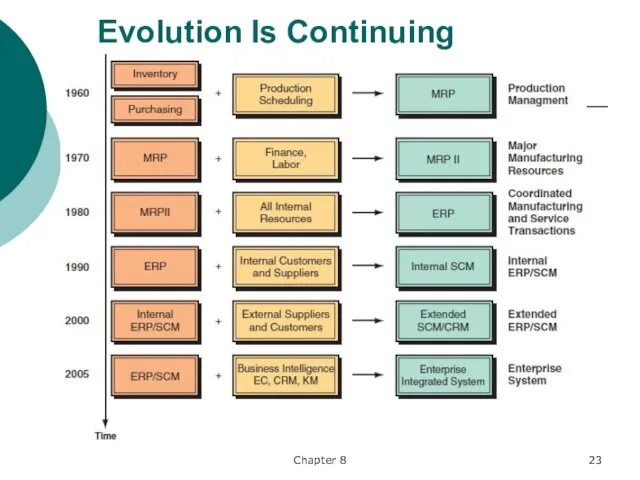

- 23. Chapter 8 Evolution Is Continuing

- 24. Chapter 8 MANAGERIAL ISSUES Ethical issues. Conducting a supply chain management project may result in the

- 26. Скачать презентацию

Оценка технического состояния скважин

Оценка технического состояния скважин изучение результативности обучения

изучение результативности обучения Дошкільний навчальний заклад комбінованого типу №7 Орлятко Білоцерківської міської ради

Дошкільний навчальний заклад комбінованого типу №7 Орлятко Білоцерківської міської ради Среднее арифметическое. Среднее значение величины

Среднее арифметическое. Среднее значение величины История правовых и политических учений

История правовых и политических учений Архитектура Санкт-Петербурга 18 века

Архитектура Санкт-Петербурга 18 века Тінтуір

Тінтуір Бабушкин юбилей

Бабушкин юбилей Презентация2

Презентация2 Материальная база обучения биологии

Материальная база обучения биологии Проект межевания территории

Проект межевания территории Ремонт и реконструкция газонефтепроводов и газонефтехранилищ

Ремонт и реконструкция газонефтепроводов и газонефтехранилищ Конституция Российской Федерации. Государственные символы России.

Конституция Российской Федерации. Государственные символы России. Презентация по образовательной программе Правильное питание тема: Овощи, ягоды и фрукты - витаминные продукты

Презентация по образовательной программе Правильное питание тема: Овощи, ягоды и фрукты - витаминные продукты Хобби игра в футбол

Хобби игра в футбол Бег на короткие дистанции. Начальная школа

Бег на короткие дистанции. Начальная школа Концепция экологического менеджмента. Система экологического менеджмента. Требования к системе экологического менеджмента

Концепция экологического менеджмента. Система экологического менеджмента. Требования к системе экологического менеджмента История развития акушерства

История развития акушерства Наследственные заболевания и генетические синдромы

Наследственные заболевания и генетические синдромы Информационная безопасность

Информационная безопасность Презентация Активизация познавательной деятельности учащихся на уроках русского языка и литературы

Презентация Активизация познавательной деятельности учащихся на уроках русского языка и литературы Хоровое искусство

Хоровое искусство Учебная ситуация, как способ реализации деятельностного подхода.

Учебная ситуация, как способ реализации деятельностного подхода. Средневековье: время рыцарей и замков

Средневековье: время рыцарей и замков Художественный мир Ф.М. Достоевского

Художественный мир Ф.М. Достоевского Волейбол

Волейбол Творческий проект

Творческий проект Комплексно-тематическое планирование в ДОУ

Комплексно-тематическое планирование в ДОУ