Содержание

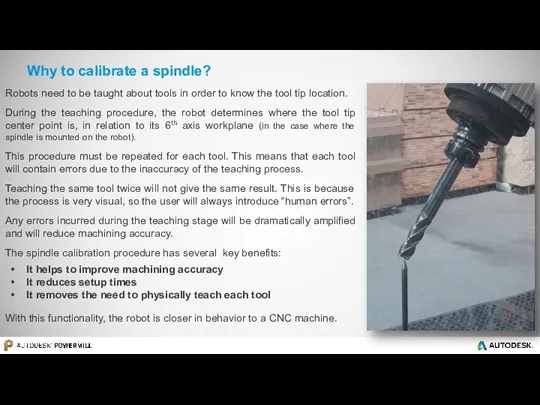

- 3. Why to calibrate a spindle? Robots need to be taught about tools in order to know

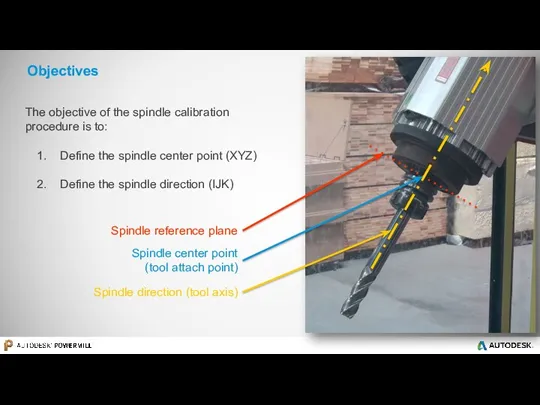

- 4. Objectives The objective of the spindle calibration procedure is to: Define the spindle center point (XYZ)

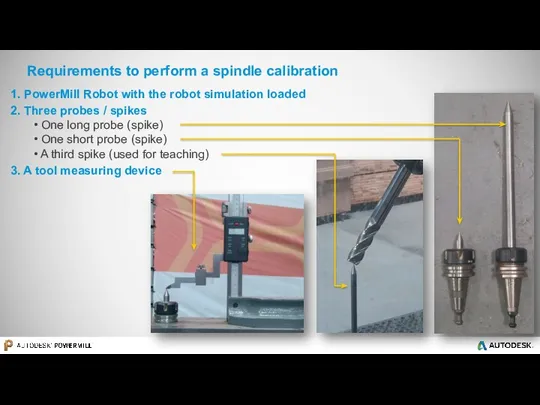

- 5. 2. Three probes / spikes One long probe (spike) One short probe (spike) A third spike

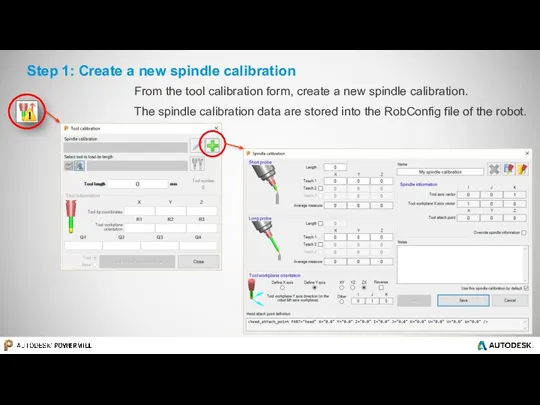

- 6. Step 1: Create a new spindle calibration From the tool calibration form, create a new spindle

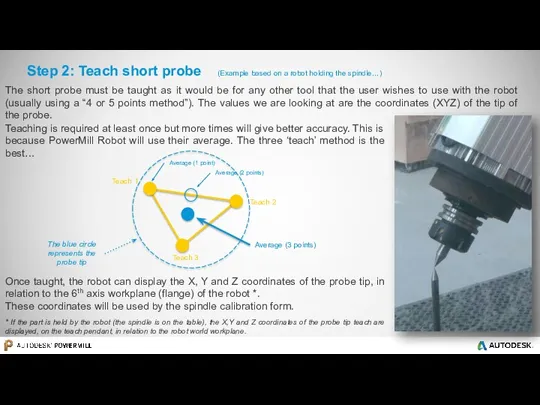

- 7. Step 2: Teach short probe (Example based on a robot holding the spindle…) Teaching is required

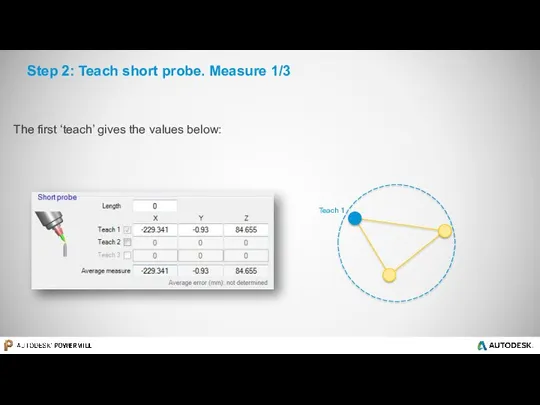

- 8. Step 2: Teach short probe. Measure 1/3 The first ‘teach’ gives the values below:

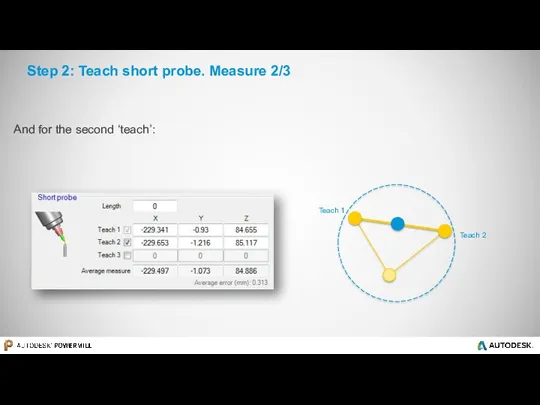

- 9. Step 2: Teach short probe. Measure 2/3 And for the second ‘teach’:

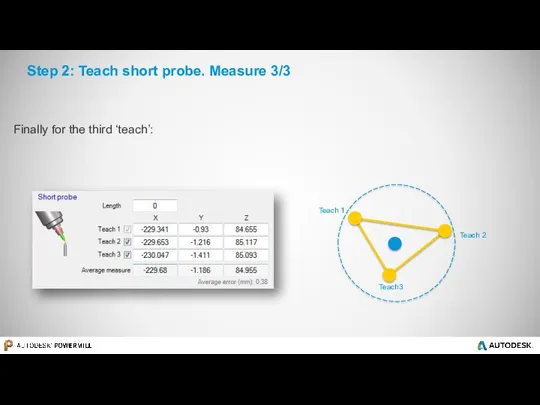

- 10. Step 2: Teach short probe. Measure 3/3 Finally for the third ‘teach’:

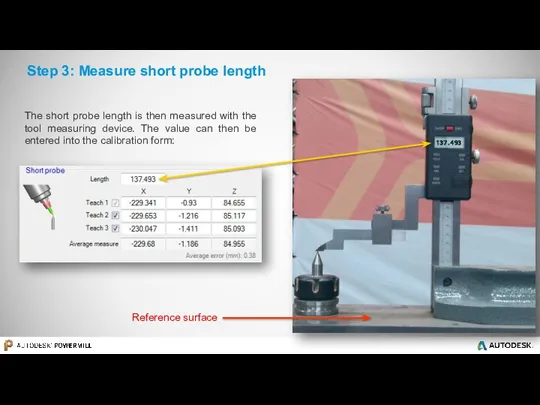

- 11. Step 3: Measure short probe length The short probe length is then measured with the tool

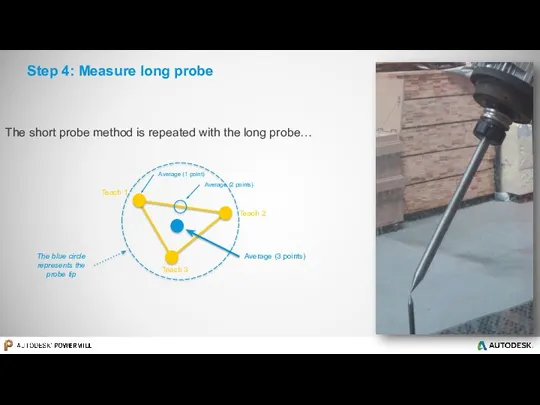

- 12. Step 4: Measure long probe The short probe method is repeated with the long probe…

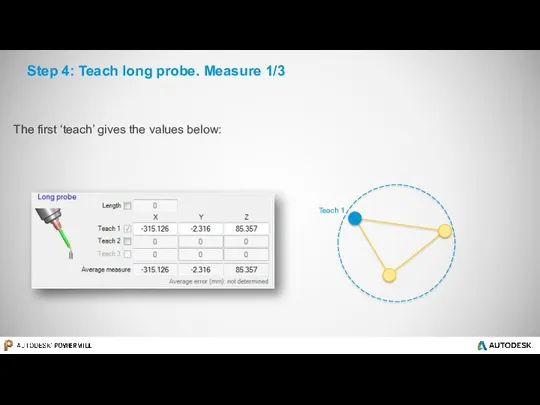

- 13. Step 4: Teach long probe. Measure 1/3 The first ‘teach’ gives the values below:

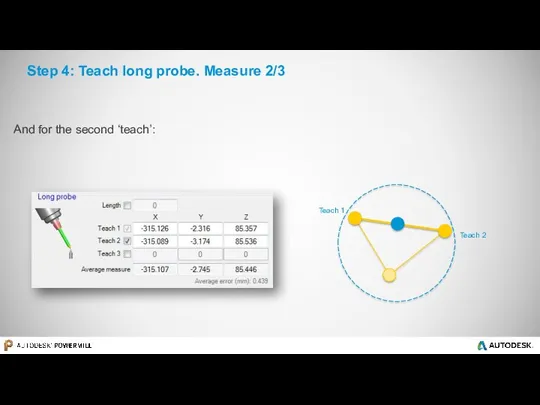

- 14. Step 4: Teach long probe. Measure 2/3 And for the second ‘teach’:

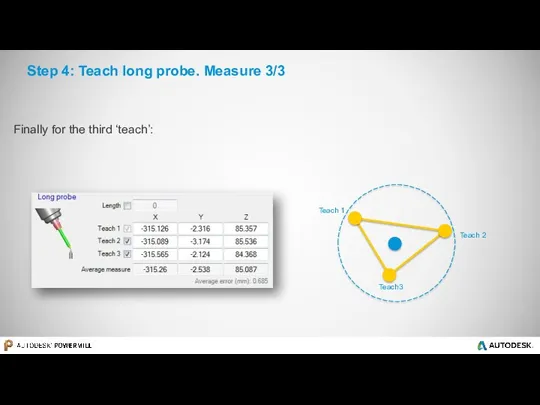

- 15. Step 4: Teach long probe. Measure 3/3 Finally for the third ‘teach’:

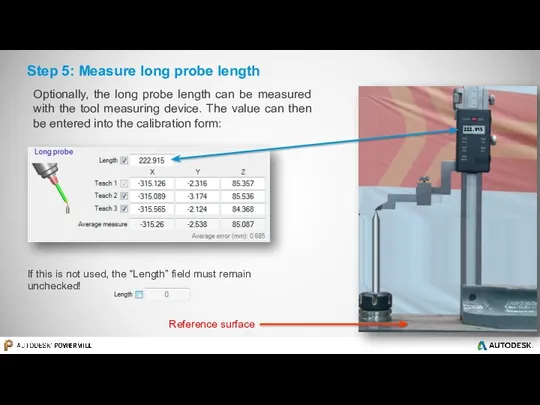

- 16. Step 5: Measure long probe length 222.915 If this is not used, the “Length” field must

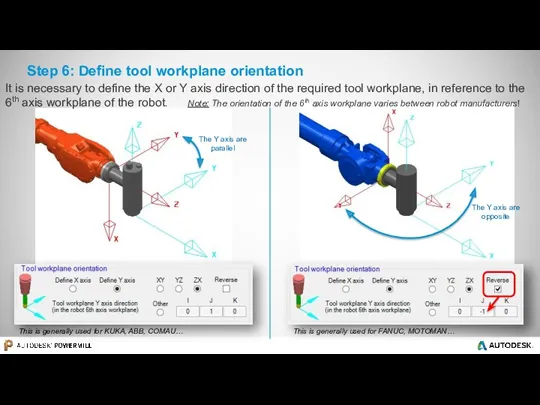

- 17. Step 6: Define tool workplane orientation This is generally used for KUKA, ABB, COMAU… This is

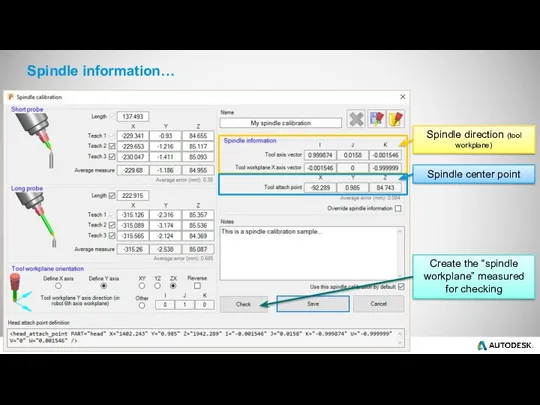

- 18. Spindle information… Spindle direction (tool workplane) Spindle center point Create the “spindle workplane” measured for checking

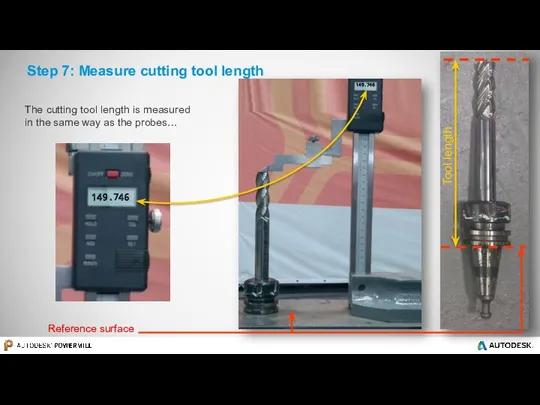

- 19. Step 7: Measure cutting tool length The cutting tool length is measured in the same way

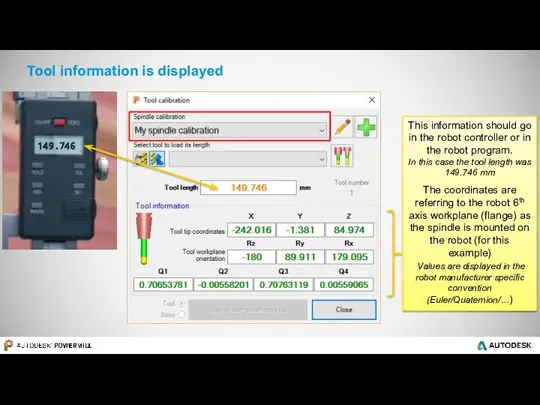

- 20. Tool information is displayed 149.746 This information should go in the robot controller or in the

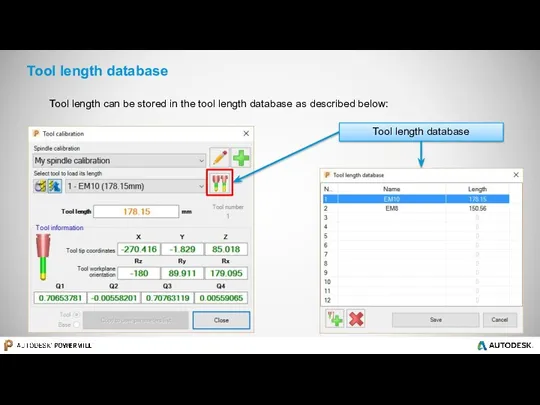

- 21. Tool length database Tool length can be stored in the tool length database as described below:

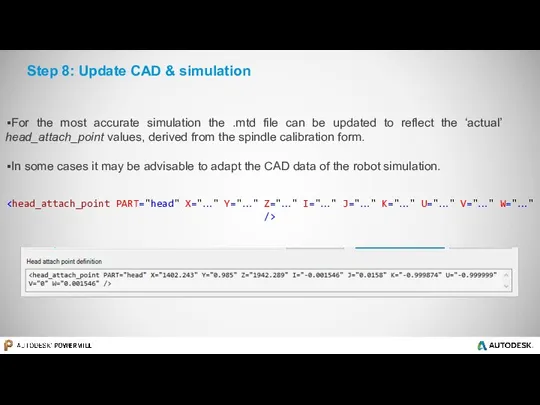

- 22. Step 8: Update CAD & simulation For the most accurate simulation the .mtd file can be

- 23. Autodesk ® PowerMill ® Robot Part on robot / External static spindle

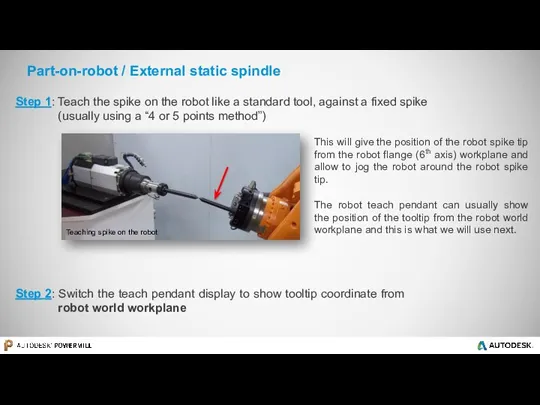

- 24. Part-on-robot / External static spindle This will give the position of the robot spike tip from

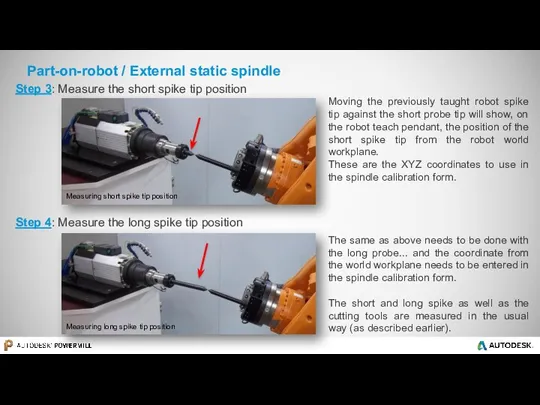

- 25. The same as above needs to be done with the long probe... and the coordinate from

- 27. Скачать презентацию

Презентация Путешествие в страну Здоровья

Презентация Путешествие в страну Здоровья Физиология внешней нервной деятельности. Торможение условных рефлексов. Типы ВНД

Физиология внешней нервной деятельности. Торможение условных рефлексов. Типы ВНД Инженерно-геологические изыскания

Инженерно-геологические изыскания Программа СОЦИАЛЬНО - ПЕДАГОГИЧЕСКАЯ ПОДДЕРЖКА УЧАЩИХСЯ В ОБРАЗОВАТЕЛЬНОМ УЧРЕЖДЕНИИ

Программа СОЦИАЛЬНО - ПЕДАГОГИЧЕСКАЯ ПОДДЕРЖКА УЧАЩИХСЯ В ОБРАЗОВАТЕЛЬНОМ УЧРЕЖДЕНИИ Инструкция по работе с дилерскими подсайтами

Инструкция по работе с дилерскими подсайтами Презентация От благодарных читателей

Презентация От благодарных читателей Кредитная и банковская системы

Кредитная и банковская системы Роль иероглифов в китайской культуре

Роль иероглифов в китайской культуре Вымирание горбатых китов

Вымирание горбатых китов Отчет по неделе игры и игрушки (подготовительная группа)

Отчет по неделе игры и игрушки (подготовительная группа) Отчет о работе НОУ 2014/15

Отчет о работе НОУ 2014/15 Аналитический отчёт

Аналитический отчёт Презентации учащихся 4 класса о космосе к дням науки

Презентации учащихся 4 класса о космосе к дням науки Электродвигатели постоянного тока

Электродвигатели постоянного тока Конституционное право

Конституционное право Теория фотоэффекта

Теория фотоэффекта Надзор прокурора за исполнением судебных решений о применении принудительных мер медицинского характера

Надзор прокурора за исполнением судебных решений о применении принудительных мер медицинского характера Презентация1

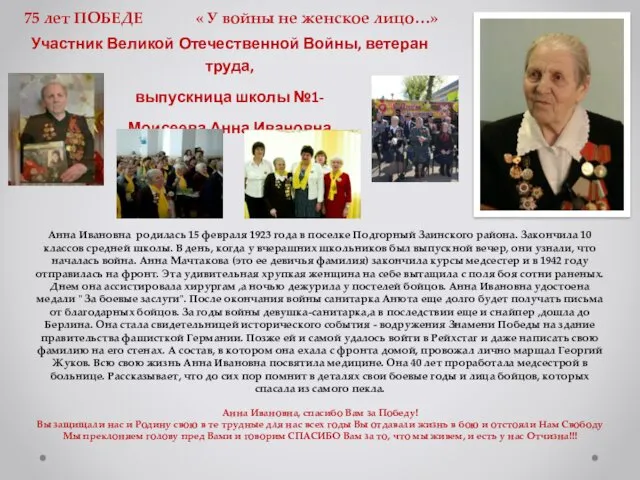

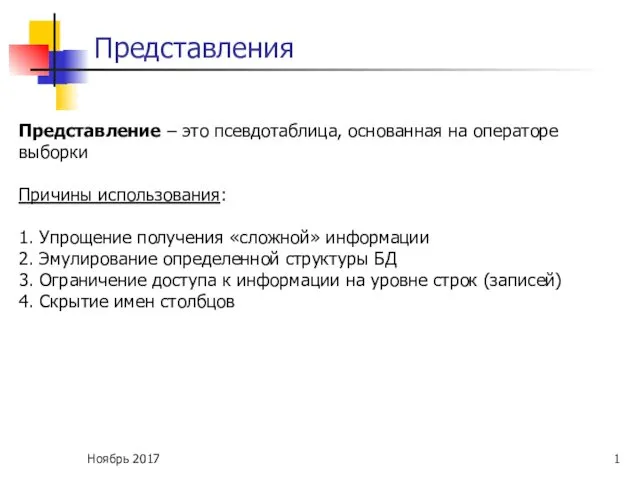

Презентация1 Презентация Принципы построения предметно-развивающей среды

Презентация Принципы построения предметно-развивающей среды 8 Марта

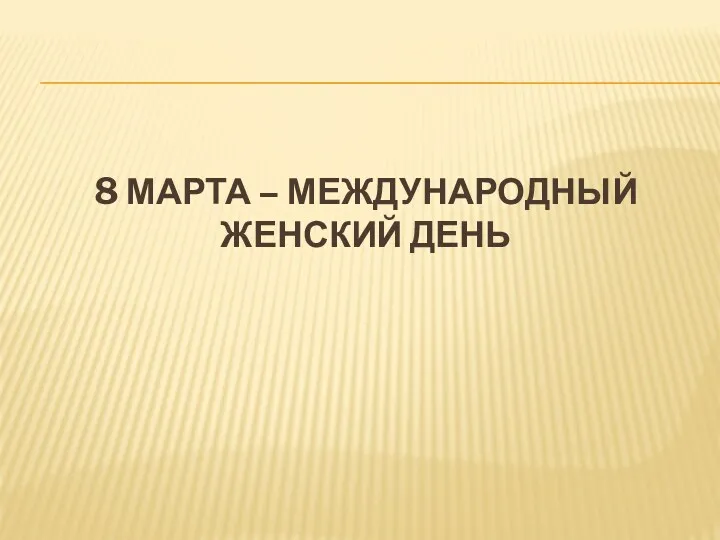

8 Марта Представления

Представления Презентация к уроку по теме Алкены

Презентация к уроку по теме Алкены Курорт на черном море город Анапа

Курорт на черном море город Анапа Классный уголок

Классный уголок Средства физического воспитания

Средства физического воспитания Интеллектуальная игра по географии Путешествие по странам и континентам

Интеллектуальная игра по географии Путешествие по странам и континентам Все вокруг-геометрия! Мастер-класс. Элементы Пентамино

Все вокруг-геометрия! Мастер-класс. Элементы Пентамино Системный анализ. (Лекция 2)

Системный анализ. (Лекция 2)