Содержание

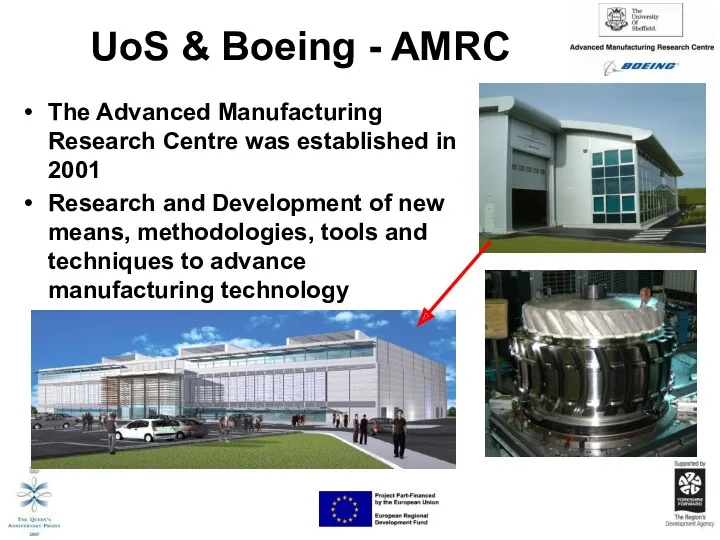

- 2. UoS & Boeing - AMRC The Advanced Manufacturing Research Centre was established in 2001 Research and

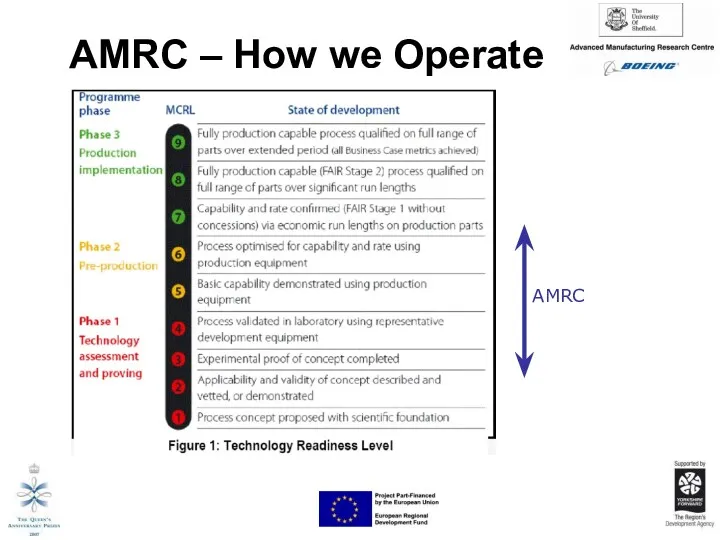

- 3. AMRC – How we Operate AMRC

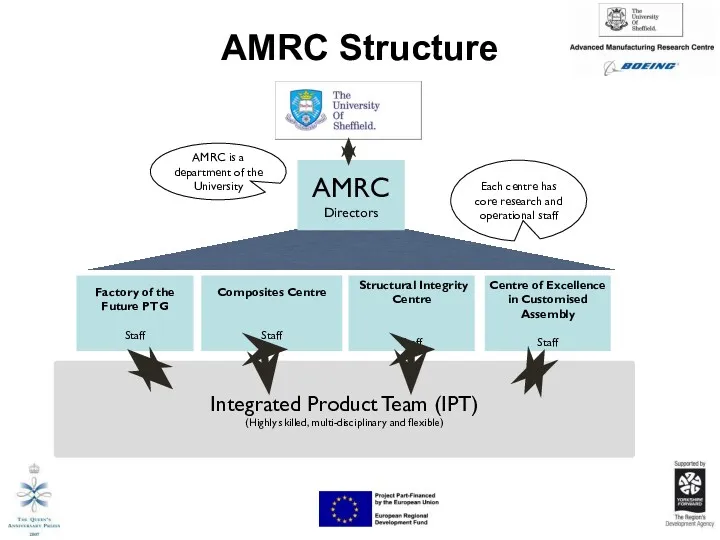

- 4. AMRC Structure Factory of the Future PTG Staff Centre of Excellence in Customised Assembly Staff Composites

- 5. Partners

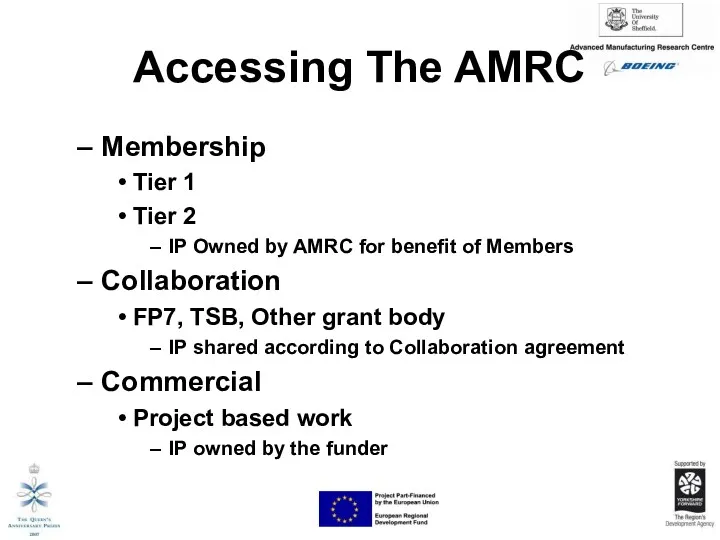

- 6. Accessing The AMRC Membership Tier 1 Tier 2 IP Owned by AMRC for benefit of Members

- 7. Funding Source of Funds Tier 1 Members £200,000 per Year Tier 2 Members £30,000 per Year

- 8. Factory of the Future PTG

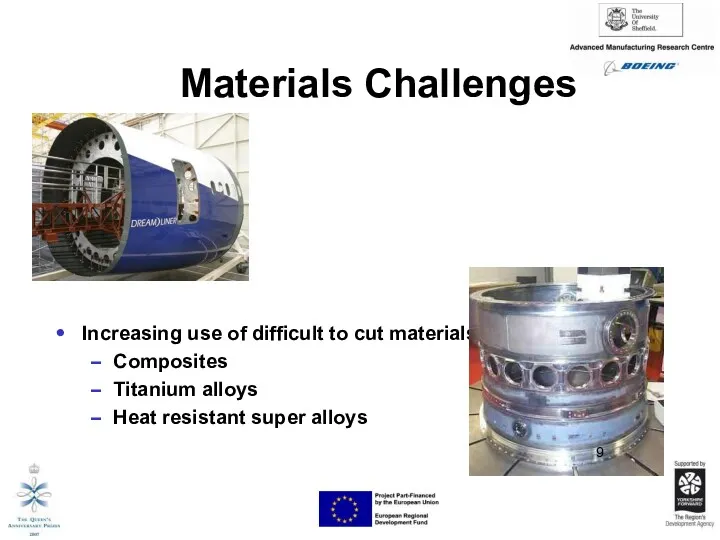

- 9. Materials Challenges Increasing use of difficult to cut materials Composites Titanium alloys Heat resistant super alloys

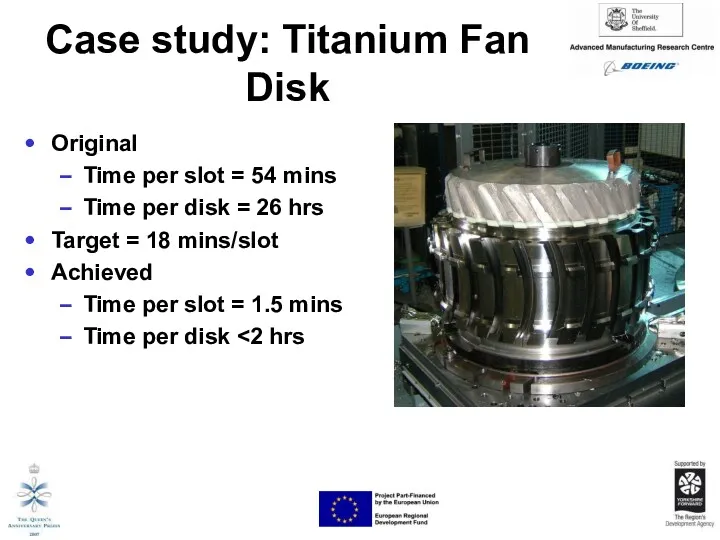

- 10. Case study: Titanium Fan Disk Original Time per slot = 54 mins Time per disk =

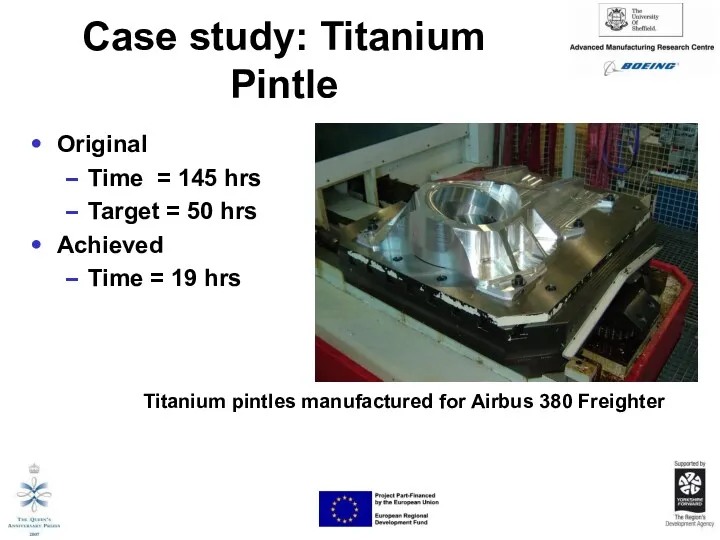

- 11. Case study: Titanium Pintle Original Time = 145 hrs Target = 50 hrs Achieved Time =

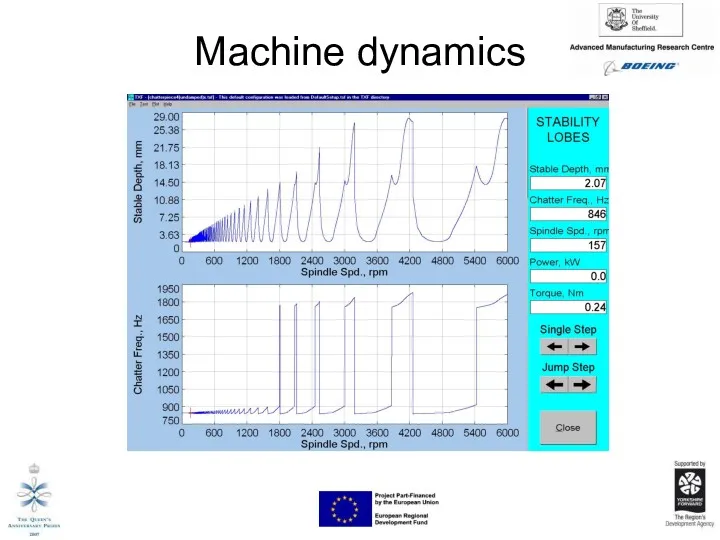

- 12. Machine dynamics

- 13. Process Technology Projects Machining aluminum, titanium and nickel alloy components reducing time by a factor of

- 14. University of Sheffield Structural Integrity Centre SIC

- 15. Status UKAS accreditation for tension, compression and fatigue testing. Work Package 4 on Airbus Integrated Wing

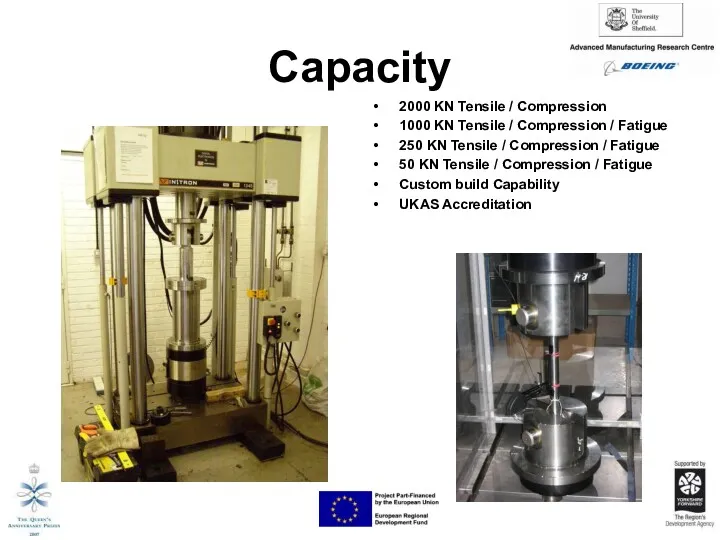

- 16. Capacity 2000 KN Tensile / Compression 1000 KN Tensile / Compression / Fatigue 250 KN Tensile

- 17. Centre of Excellence in Customised Assembly (CECA)

- 18. Purpose To develop a centre of Excellence in High value assembly High value manufacturing needs to

- 19. Developing expertise in high accuracy metrology, … ATOS

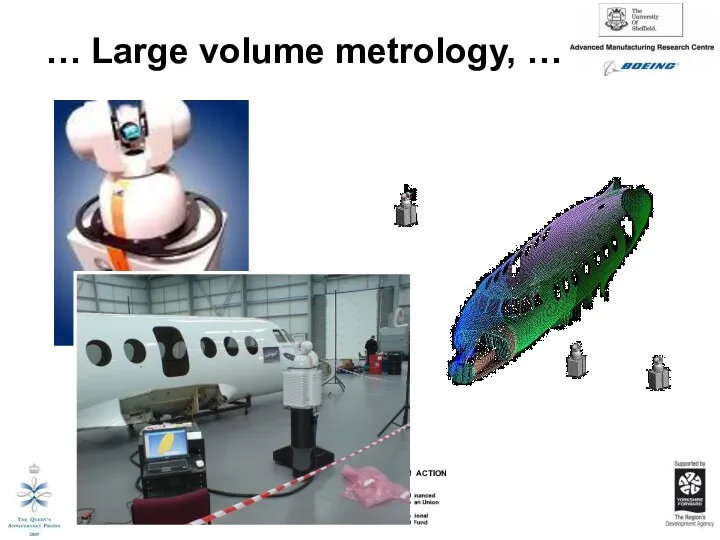

- 20. … Large volume metrology, … LASER RADAR IN ACTION

- 21. … Robotics and automation, …

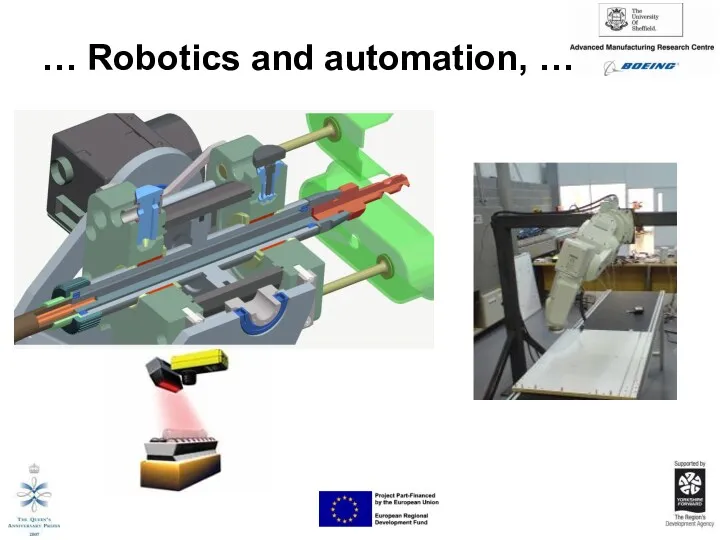

- 22. … and simulation.

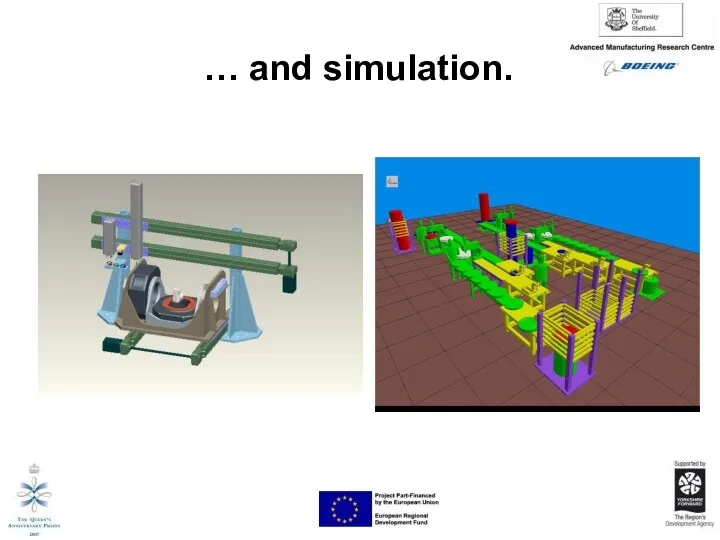

- 23. Assembly Projects Design for assembly Assembly of aero-engine components Assembly of aero structures Assembly of composite

- 24. Virtual Reality Projects Virtual modeling of landing gear, engines and aero structures

- 25. The Composite Centre

- 26. Available Technologies Hand Layup In / Out of Autoclave Automated Fibre Placement In / Out of

- 27. Core Technologies Fibre placement Thermoset Insitu Thermoplastic Microwave Thermoset Thermoplastic Co cure Joining Automated Layup Filament

- 28. Supporting Technology Areas Out Of Autoclave Materials Filament Winding Tooling development Application of multi axial fibre

- 29. Equipment ADC automated fiber placement machine 2.75 x 1.4m. Heads: ¼” / ½ “ thermoplastic, 3”

- 30. ATP/AFP Equipment ADC Automated Tape / Fibre Placement Machine complete with: ¼” & ½” Thermo Plastic

- 31. Equipment ISO Class 7 Clean Room Facility Eastman Ply Cutter

- 32. Equipment 3m x 5m Autoclave Thermoset Materials 1m x 2m Autoclave Thermoplastic Capability

- 33. Equipment CMS 5 Axis Machining Centre

- 34. Equipment Caltherm 3m x 3m x 3m Oven ISOJET Resin Transfer Moulding

- 35. ATP / AFP Facility

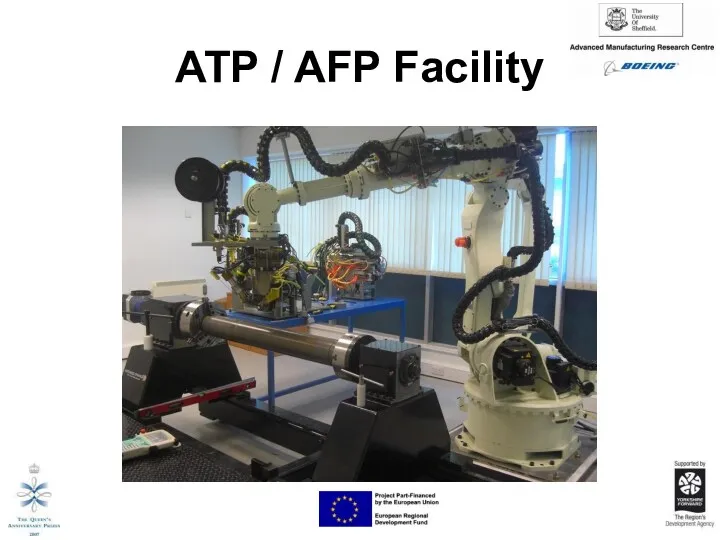

- 36. 12 Tow Thermoset Head

- 37. Thermoplastic Head

- 38. 3” Thermoset Tape Head

- 39. Wing Spar Development

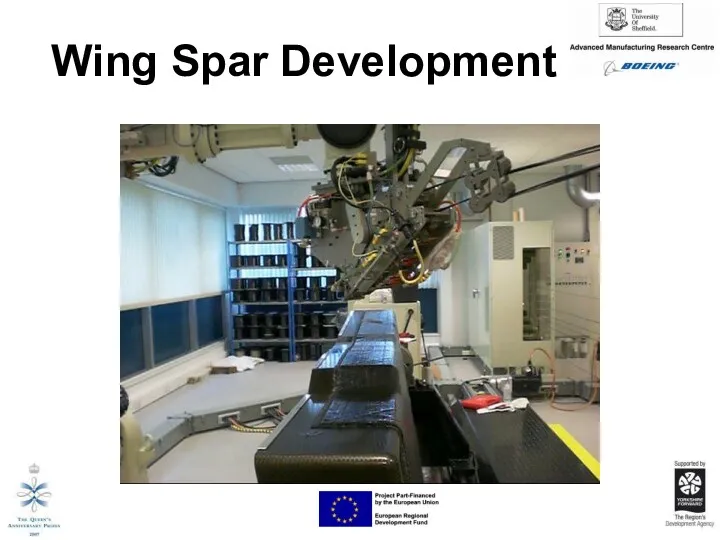

- 40. Generic Projects Generic Flap ( Technology Development ) Machining of Composites Phase 1 Drilling Machining of

- 41. Directed Generic Multi Axial Woven Structures for the Construction of Composite Fittings (Boeing) Phase 1 and

- 42. Current Industrial Projects Product Design and Manufacture Kingkraft Disabled living aids - Sports wheelchairs Hybrid pressure

- 43. Airbus Integrated Wing Project TSB funded Technology Validation Programme Working on a Messier Dowty package 3

- 44. Current Industrial Projects Process Development TSB Funded Grand Challenge- AFP development of aircraft fuel tanks TSB

- 45. Composite Centre & The NCN Low energy Low cycle time Textiles Accuracy Consistency of NDT methods

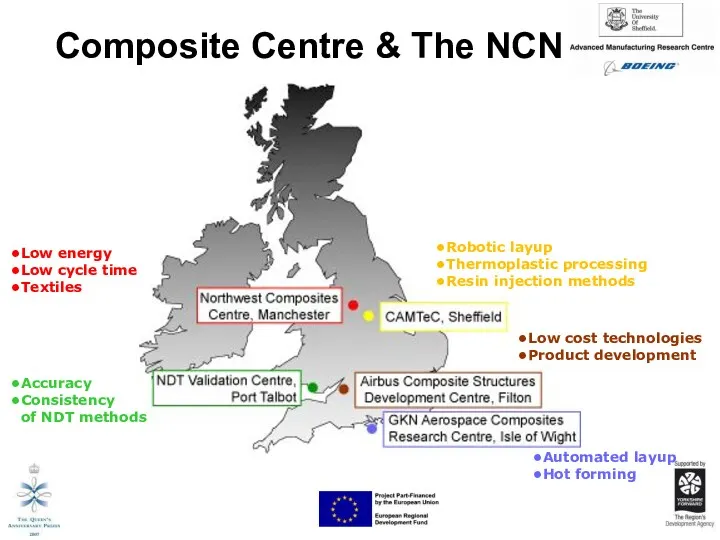

- 46. AMRC Composite Centre Regional Impact So Far 180 Jobs Created or Safeguarded 83 knowledge collaborations with

- 47. MANTRA

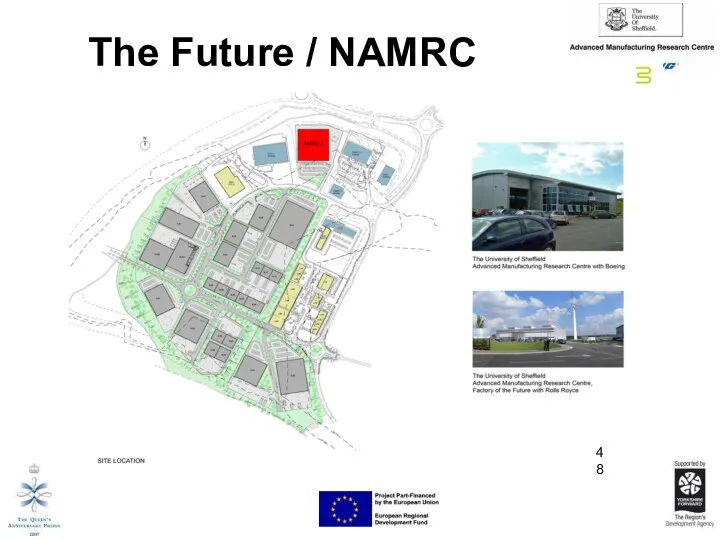

- 48. The Future / NAMRC

- 50. Скачать презентацию

Семинар для воспитателей Интонационная сторона речи дошкольников

Семинар для воспитателей Интонационная сторона речи дошкольников Интеллектуальная игра Брей-ринг

Интеллектуальная игра Брей-ринг Компьютерно -игровая зависимость и её профилактика.

Компьютерно -игровая зависимость и её профилактика. Игра-викторина. Вопросики

Игра-викторина. Вопросики Теплоэнергетика технологии обжига известняка во вращающихся печах

Теплоэнергетика технологии обжига известняка во вращающихся печах Direkt Subjekt + Prädikat + Nebenglieder Ich lerne Deutsch nicht lange

Direkt Subjekt + Prädikat + Nebenglieder Ich lerne Deutsch nicht lange Человек и домашние животные

Человек и домашние животные Электрооборудование общепромышленных установок

Электрооборудование общепромышленных установок Родительское собрание №1. 2 класс

Родительское собрание №1. 2 класс Разработка и исследование регулируемого электропривода механизма подъема лебедки мостового крана грузоподъемностью 50 т

Разработка и исследование регулируемого электропривода механизма подъема лебедки мостового крана грузоподъемностью 50 т Система сбалансированных показателей. Показатели стратегических финансовых направлений

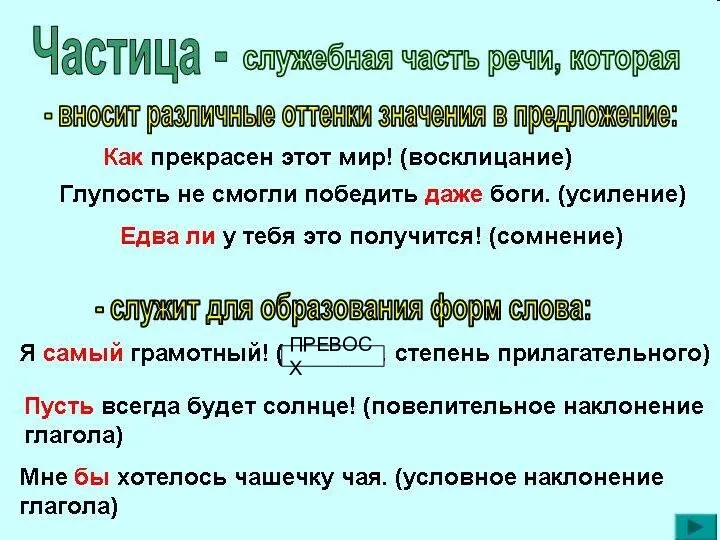

Система сбалансированных показателей. Показатели стратегических финансовых направлений Формообразующие частицы

Формообразующие частицы Эдуард Анатольевич Стрельцов,

Эдуард Анатольевич Стрельцов, Острый и хронический синусит

Острый и хронический синусит Буквы Е, Ё, Ю, Я и их функции в словах

Буквы Е, Ё, Ю, Я и их функции в словах Поверхностное упрочнение стальных деталей

Поверхностное упрочнение стальных деталей Гликоген. Структура. Физические и химические свойства

Гликоген. Структура. Физические и химические свойства Презентація

Презентація Художник и театр

Художник и театр Ванты. вантовые конструкции

Ванты. вантовые конструкции Снятие мерок с фигуры человека

Снятие мерок с фигуры человека История обыкновенных дробей

История обыкновенных дробей Забытая война, посвященный 100-летию начала Первой мировой войны

Забытая война, посвященный 100-летию начала Первой мировой войны Особенности ВНД человека. Познавательные процессы

Особенности ВНД человека. Познавательные процессы Фосфор

Фосфор Совет Лицеистов

Совет Лицеистов Работы учащихся 9 классов ГБОУ СОШ 599 (презентации к уроку)

Работы учащихся 9 классов ГБОУ СОШ 599 (презентации к уроку) Защита у организмов

Защита у организмов