Содержание

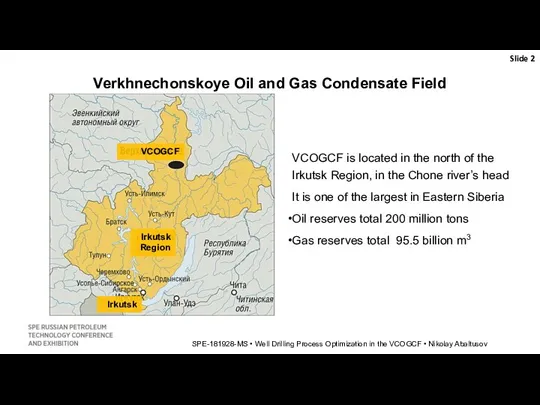

- 2. Verkhnechonskoye Oil and Gas Condensate Field VCOGCF is located in the north of the Irkutsk Region,

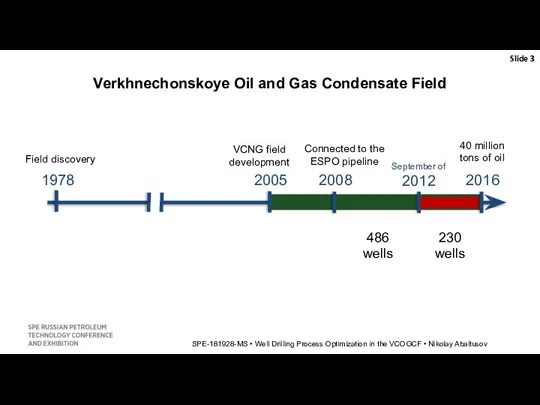

- 3. Verkhnechonskoye Oil and Gas Condensate Field Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF

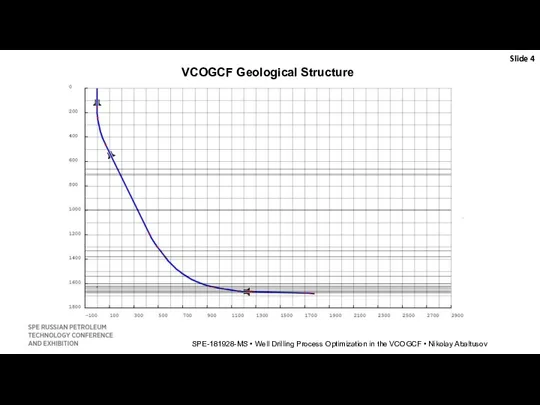

- 4. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov VCOGCF Geological Structure

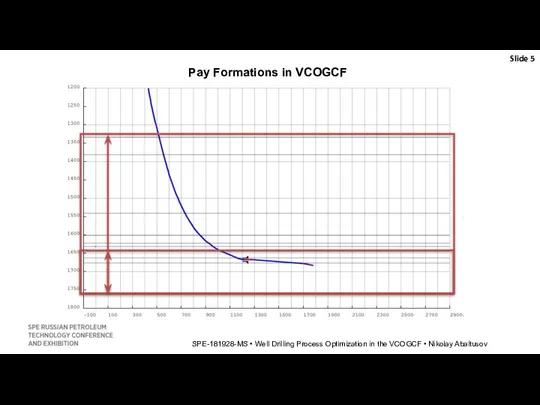

- 5. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Pay Formations in

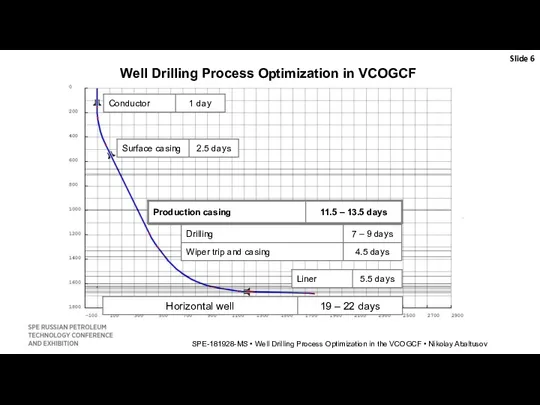

- 6. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Well Drilling Process

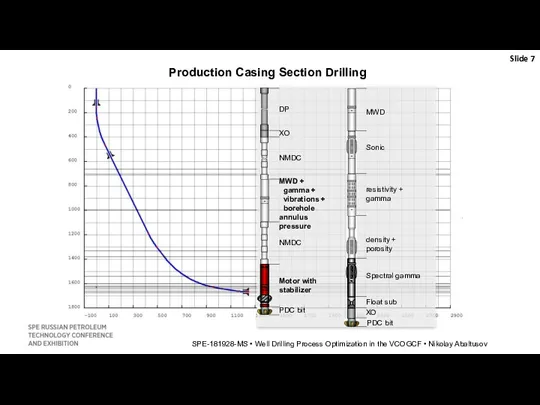

- 7. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Production Casing Section

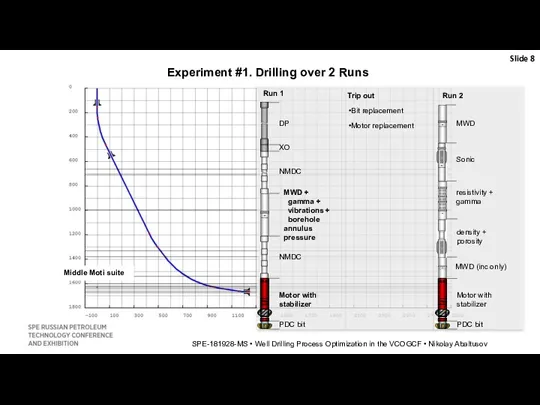

- 8. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Experiment #1. Drilling

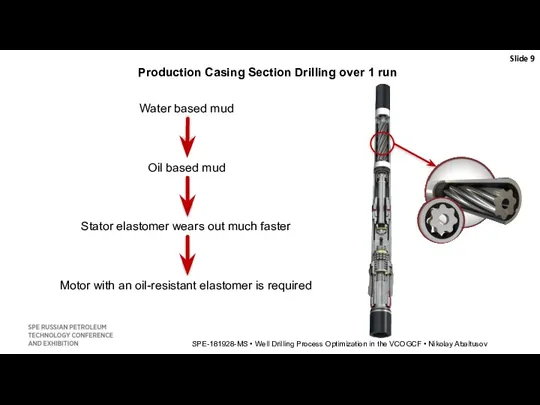

- 9. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Production Casing Section

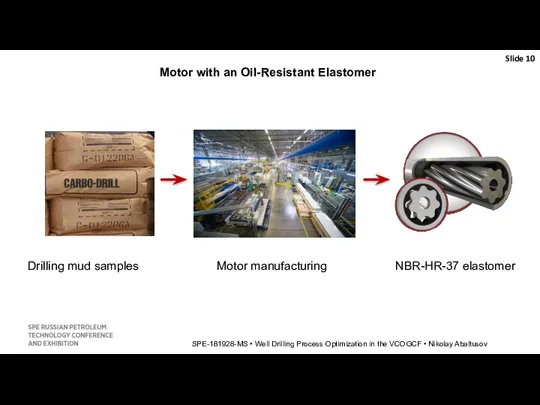

- 10. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Motor with an

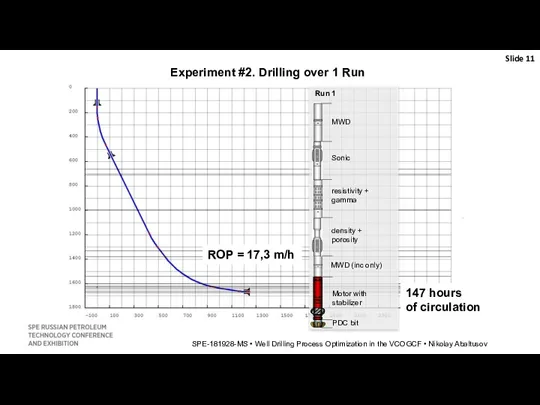

- 11. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Experiment #2. Drilling

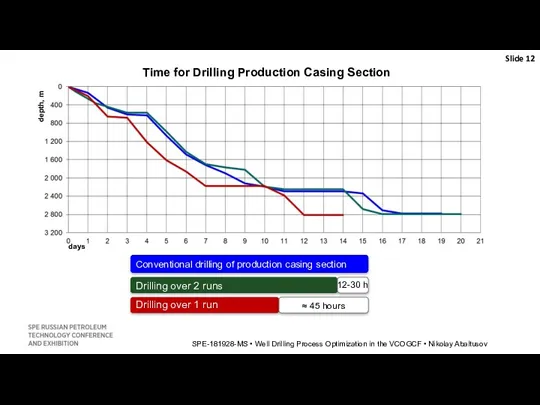

- 12. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Time for Drilling

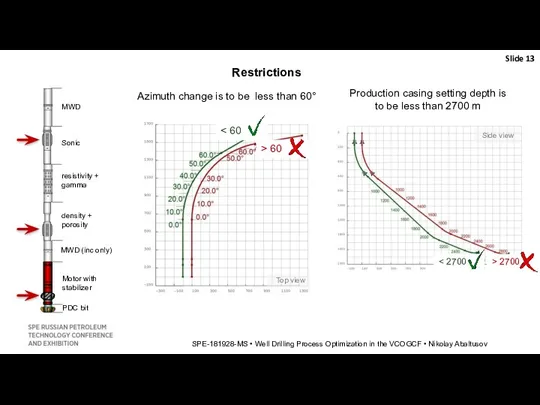

- 13. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Restrictions Azimuth change

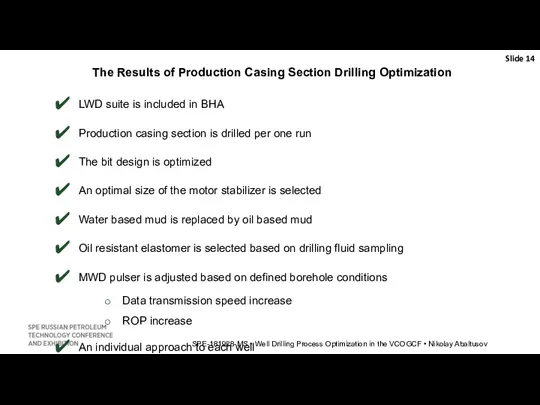

- 14. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov The Results of

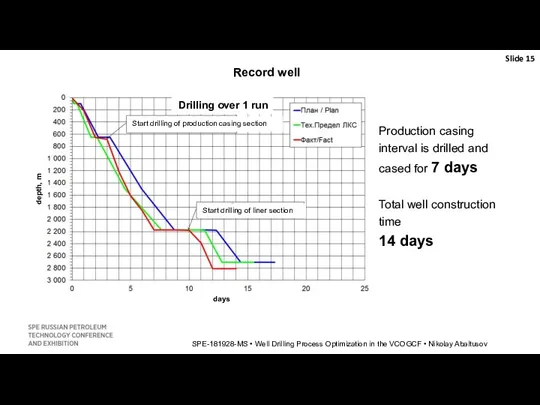

- 15. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov Record well Production

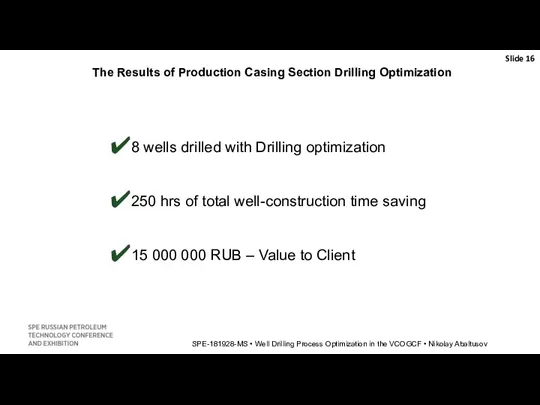

- 16. Slide SPE-181928-MS • Well Drilling Process Optimization in the VCOGCF • Nikolay Abaltusov The Results of

- 18. Скачать презентацию

Культура Эллинизма

Культура Эллинизма 1С Парфюм Логистик

1С Парфюм Логистик Применение нетрадиционных источников энергии в Чувашской Республике

Применение нетрадиционных источников энергии в Чувашской Республике zanyatie_10_pro_zaychat_i_zaychihu

zanyatie_10_pro_zaychat_i_zaychihu Джон Эверетт Милле (John Everett Millais)

Джон Эверетт Милле (John Everett Millais) Мои земляки - труженики полей

Мои земляки - труженики полей Перу. План описания страны Латинской Америки

Перу. План описания страны Латинской Америки Имя прилагательное.Суффиксы прилагательных

Имя прилагательное.Суффиксы прилагательных Культура ислама. Основы духовно – нравственной культуры народов России

Культура ислама. Основы духовно – нравственной культуры народов России Что такое дисграфия и как с ней бороться?

Что такое дисграфия и как с ней бороться? Секреты семейного воспитания

Секреты семейного воспитания Презентация Игра в жизни ребенка

Презентация Игра в жизни ребенка E-learning и дистанционные технологии

E-learning и дистанционные технологии Microsoft Office Power Point

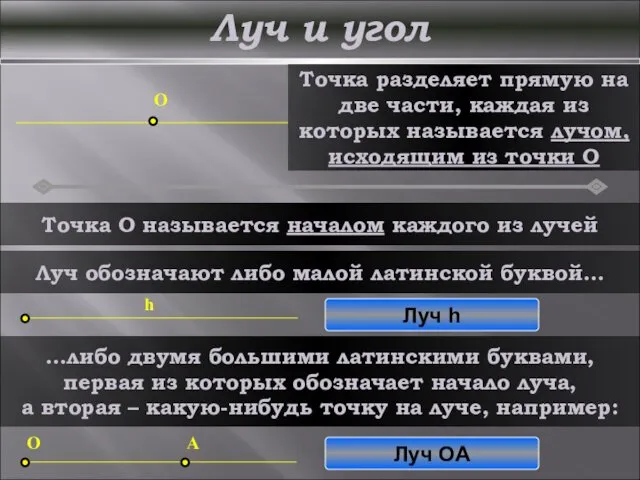

Microsoft Office Power Point Луч и угол

Луч и угол Глобальная энергетическая и сырьевая проблема

Глобальная энергетическая и сырьевая проблема Система мотивации за инновационные проекты

Система мотивации за инновационные проекты Тема поэта и поэзии в лирике А.С. Пушкина

Тема поэта и поэзии в лирике А.С. Пушкина Шляпный этикет, как правильно вписать аксессуар из прошлого в современный образ

Шляпный этикет, как правильно вписать аксессуар из прошлого в современный образ Кабинет географии

Кабинет географии Кроссворд Что мы знаем о пчёлах

Кроссворд Что мы знаем о пчёлах Органы растений. Побег

Органы растений. Побег Газообразное состояние вещества

Газообразное состояние вещества Гидроэлектростанции. Типы ГЭС

Гидроэлектростанции. Типы ГЭС Жигули. ОАО АвтоВАЗ

Жигули. ОАО АвтоВАЗ Отчет по искусствоведческой практике. Шаблон

Отчет по искусствоведческой практике. Шаблон Презентация Интеллектуальное развитие дошкольников

Презентация Интеллектуальное развитие дошкольников Винсент Ван Гог - краткая биография и картины художника

Винсент Ван Гог - краткая биография и картины художника