Содержание

- 2. Building materials made of wood wood chips, solid wood or fiber webs of various shapes, which

- 3. Wood pulp - is a timber, which is in its properties superior to conventional standards and

- 4. By this kind of sawn solid wood are: Block house. Brus. Lining and Lining. Boards. As

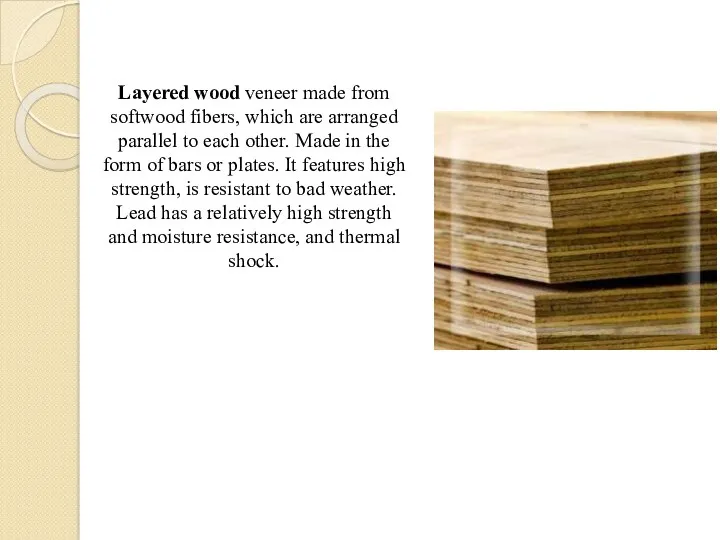

- 5. Layered wood veneer made from softwood fibers, which are arranged parallel to each other. Made in

- 6. Plywood - sheet material composed of bonded together sheets of veneer or chips, which are obtained

- 7. Plywood longitudinal called if the fibers in the facial layers oriented along the long side, otherwise

- 8. Wood-stuzhechnaya plate (DSP) - sheets of different thicknesses, obtained by mixing and compacting particles of comminuted

- 9. Fiberboard (MDF) - plates of varying thickness, made from wood fibers (obtained from Waste) with a

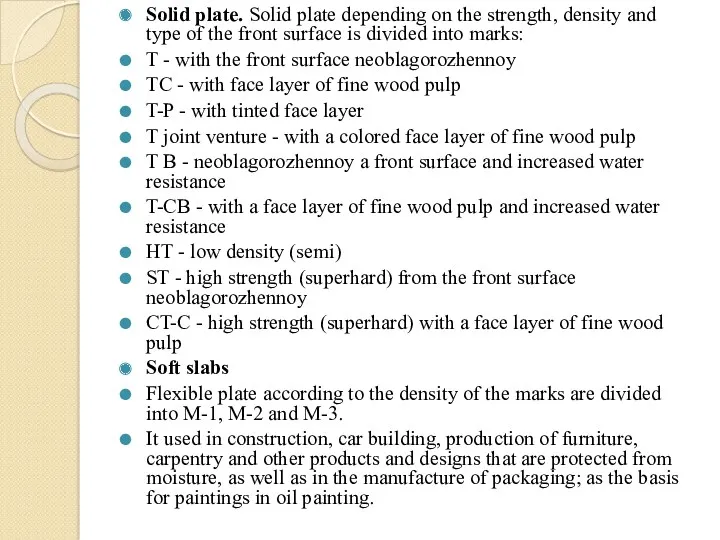

- 10. Solid plate. Solid plate depending on the strength, density and type of the front surface is

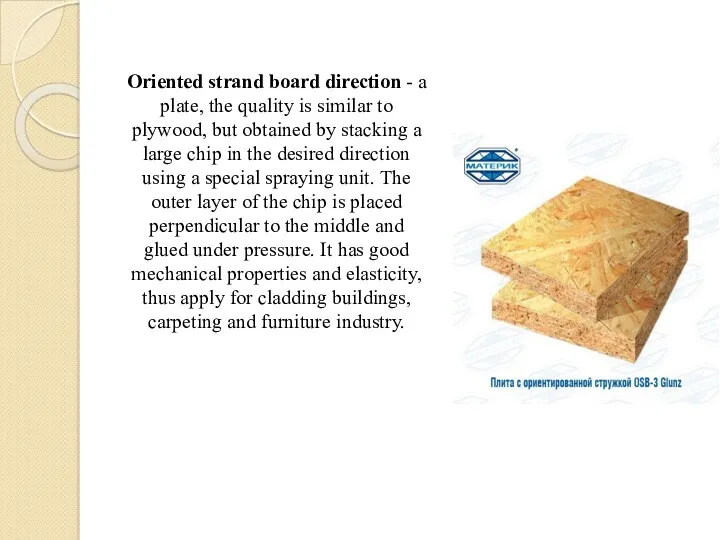

- 11. Oriented strand board direction - a plate, the quality is similar to plywood, but obtained by

- 12. Bearing structures. Characterized in that in places severe loads are enlarged cross-section. They are made of

- 15. Скачать презентацию

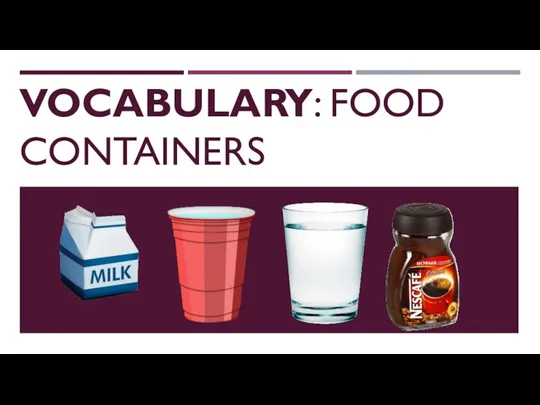

Food containers. Vocabulary

Food containers. Vocabulary Possessive pronouns. Притяжательные местоимения

Possessive pronouns. Притяжательные местоимения Чтение. Английский язык

Чтение. Английский язык Toys flashcards

Toys flashcards Do or does

Do or does Австралийский английский язык

Австралийский английский язык The infinitive and the gerund

The infinitive and the gerund Technology

Technology Simple present: questions

Simple present: questions Verbals – non-finite forms of the Verb

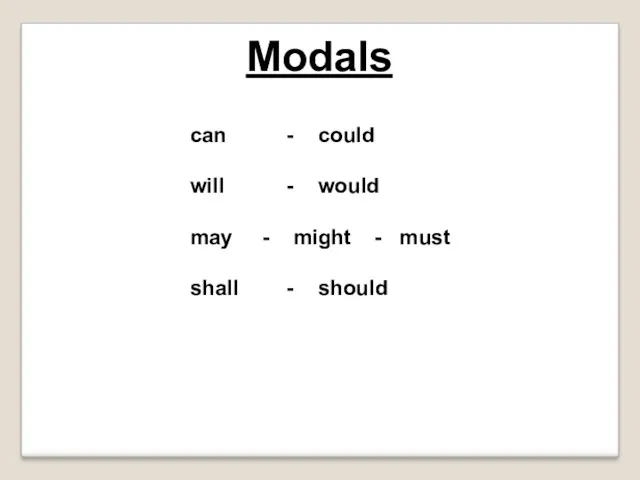

Verbals – non-finite forms of the Verb Modal Verbs

Modal Verbs Wish and regrets. Fill in the blanks with one word

Wish and regrets. Fill in the blanks with one word Final control work. Form 8

Final control work. Form 8 Эффективные технологии подготовки учащихся к ОГЭ и ЕГЭ по английскому языку 2019. Устная часть

Эффективные технологии подготовки учащихся к ОГЭ и ЕГЭ по английскому языку 2019. Устная часть Музей мадам Тюссо

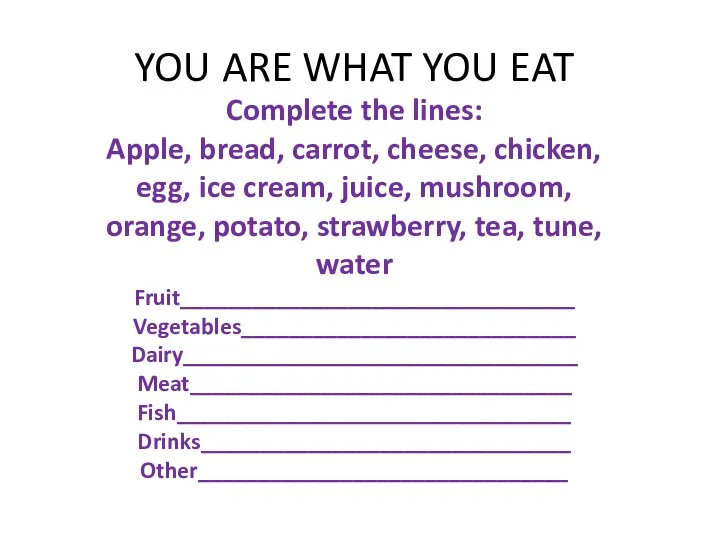

Музей мадам Тюссо You are what you eat

You are what you eat Quiz household items furniture

Quiz household items furniture English online. Lesson 2

English online. Lesson 2 Skunks

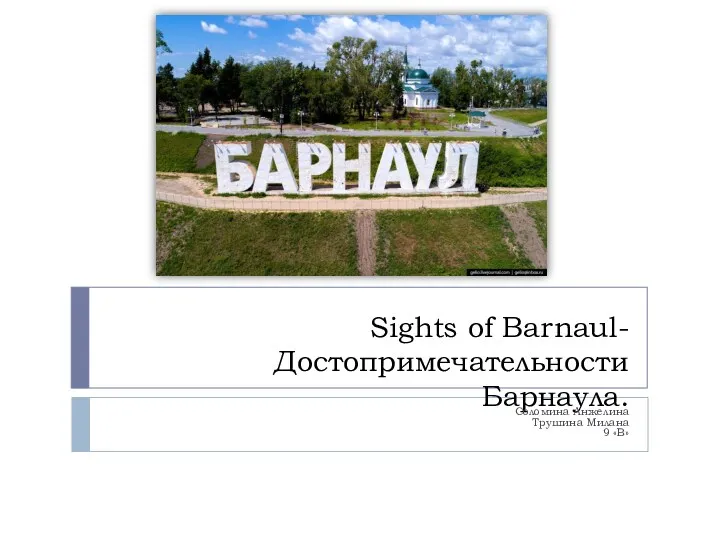

Skunks Sights of Barnaul

Sights of Barnaul Life and living

Life and living My favourite celebrity singer is Robyn Rihanna Fenty

My favourite celebrity singer is Robyn Rihanna Fenty Passive voice

Passive voice H, b, f, l. Initial sounds

H, b, f, l. Initial sounds London and its places of interest

London and its places of interest What are they doing?

What are they doing? Clothes

Clothes The Republic of Kenya

The Republic of Kenya