Содержание

- 2. Diffusion Welding Lesson Objectives When you finish this lesson you will understand: Diffusion Welding Definition, Characteristics,

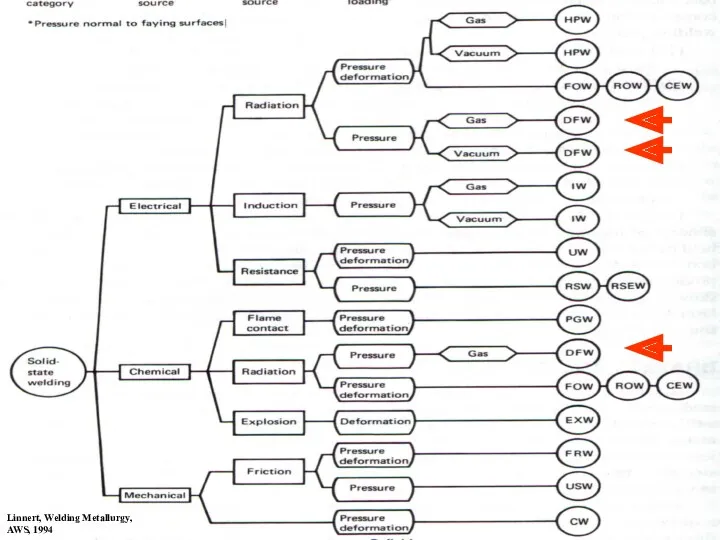

- 3. Linnert, Welding Metallurgy, AWS, 1994

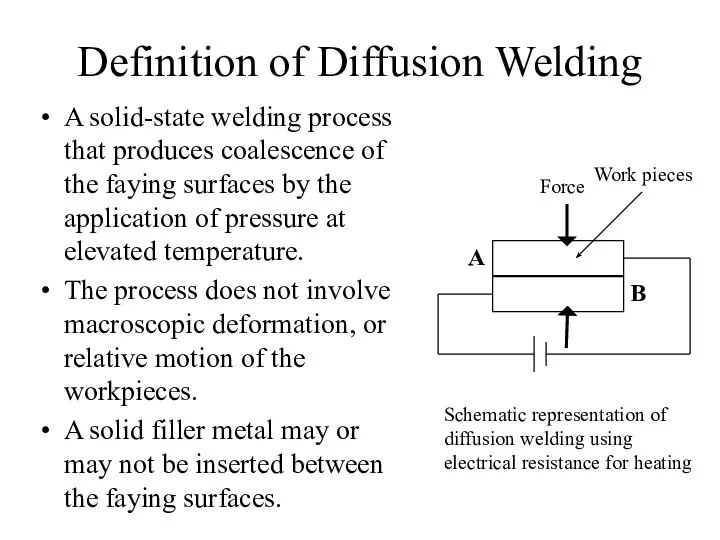

- 4. A solid-state welding process that produces coalescence of the faying surfaces by the application of pressure

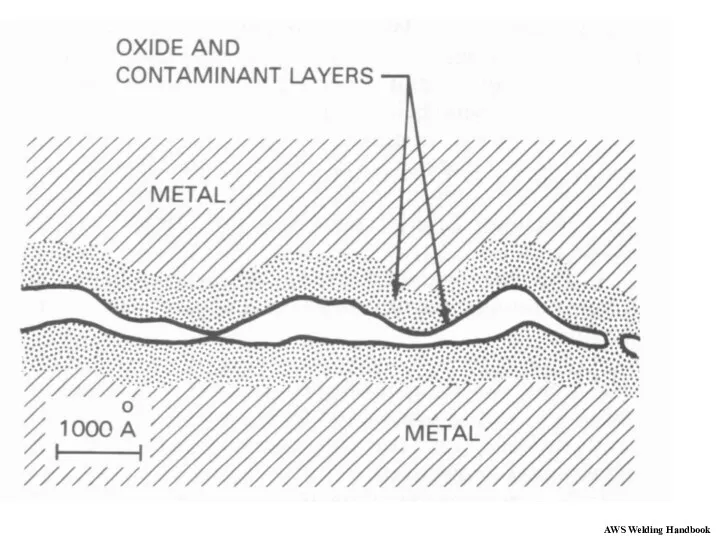

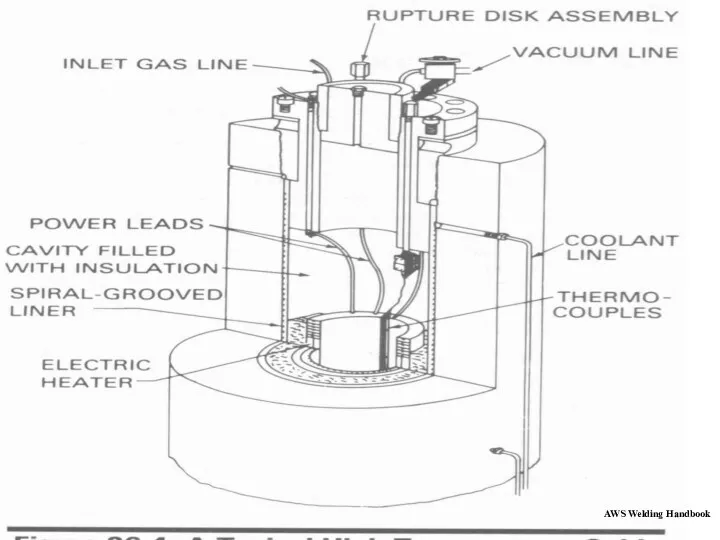

- 5. AWS Welding Handbook

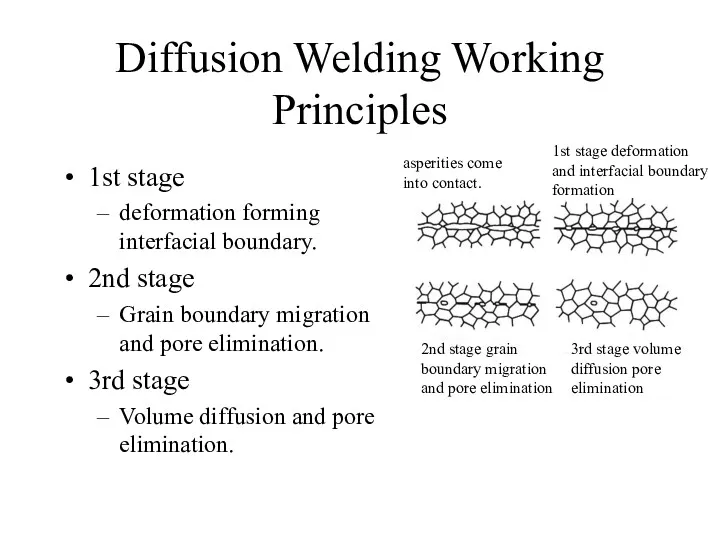

- 6. 1st stage deformation forming interfacial boundary. 2nd stage Grain boundary migration and pore elimination. 3rd stage

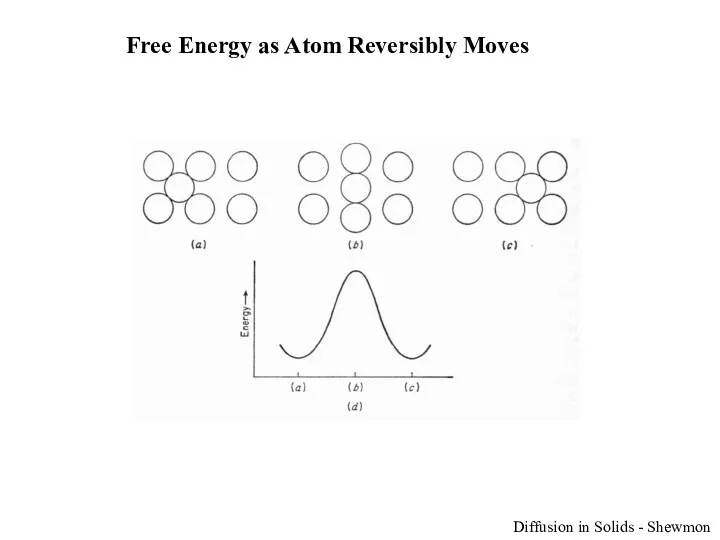

- 7. Free Energy as Atom Reversibly Moves Diffusion in Solids - Shewmon

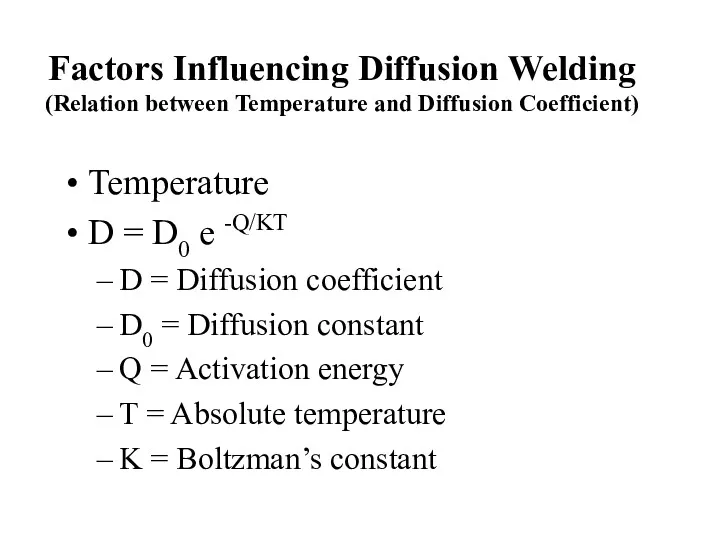

- 8. Temperature D = D0 e -Q/KT D = Diffusion coefficient D0 = Diffusion constant Q =

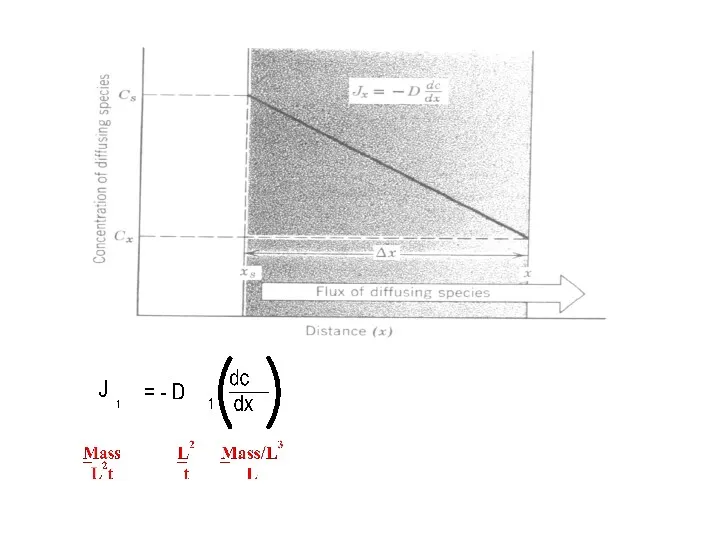

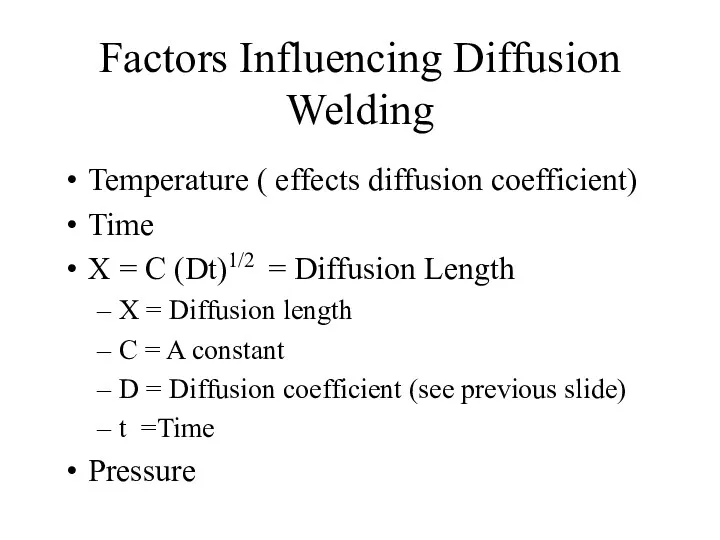

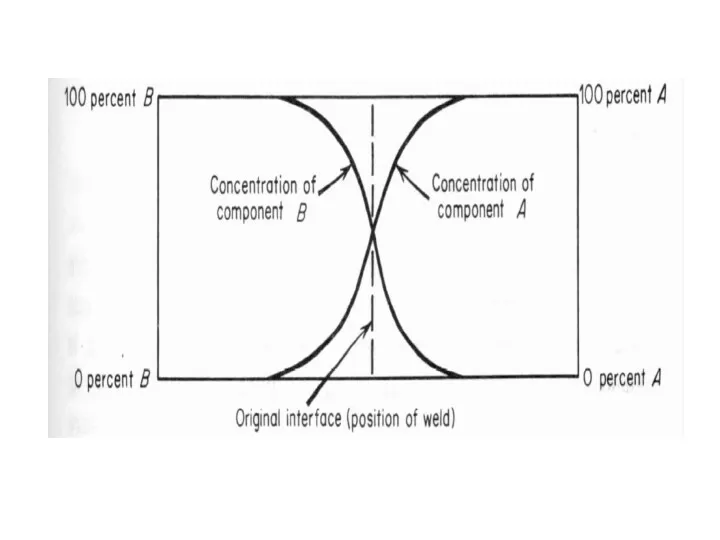

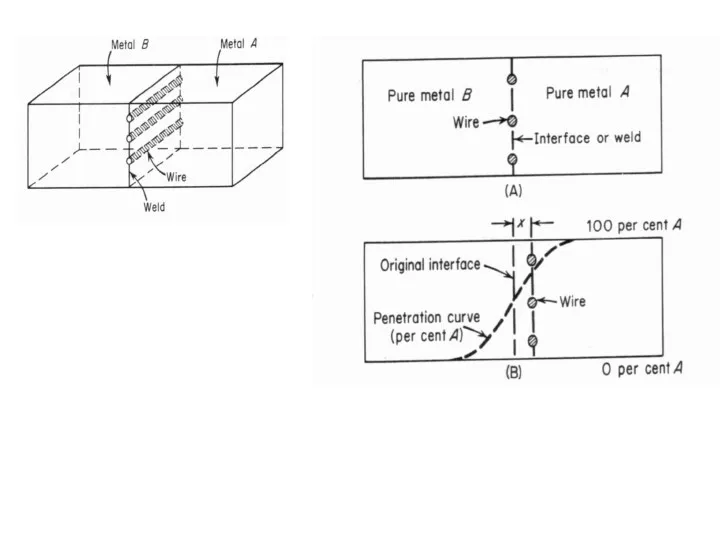

- 10. Temperature ( effects diffusion coefficient) Time X = C (Dt)1/2 = Diffusion Length X = Diffusion

- 14. AWS Welding Handbook

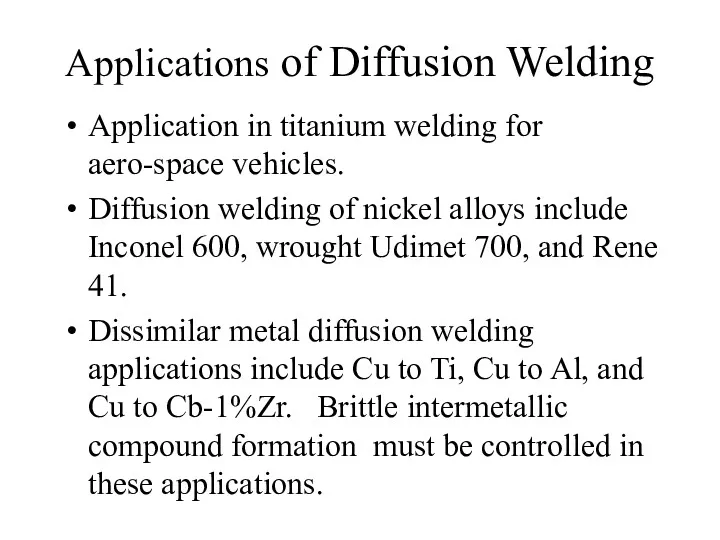

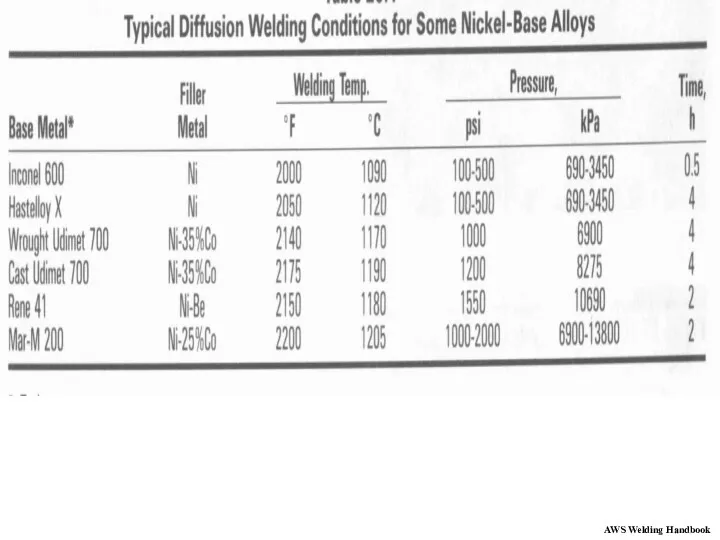

- 16. Application in titanium welding for aero-space vehicles. Diffusion welding of nickel alloys include Inconel 600, wrought

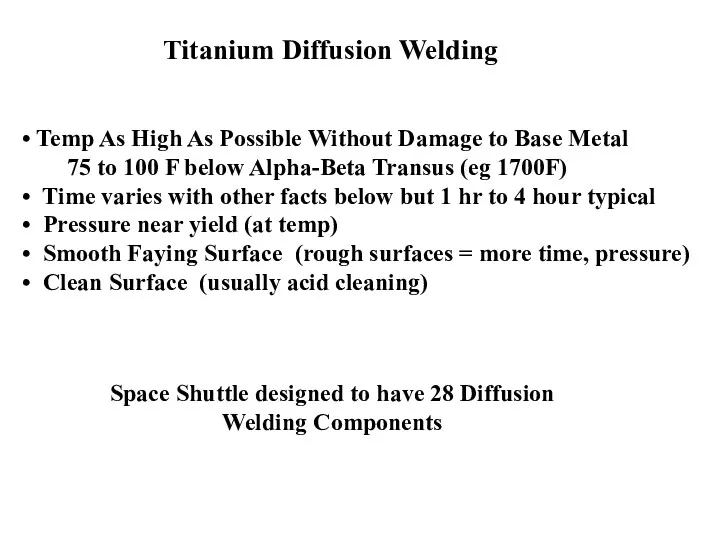

- 17. Titanium Diffusion Welding Temp As High As Possible Without Damage to Base Metal 75 to 100

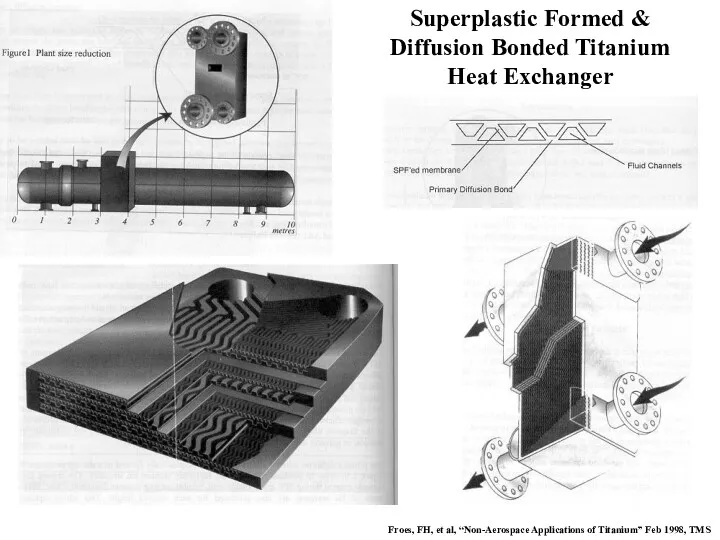

- 18. Froes, FH, et al, “Non-Aerospace Applications of Titanium” Feb 1998, TMS Superplastic Formed & Diffusion Bonded

- 19. Nickel Diffusion Welding (More Difficult to Weld) Temp close to MP High Pressure (because High hot

- 20. AWS Welding Handbook

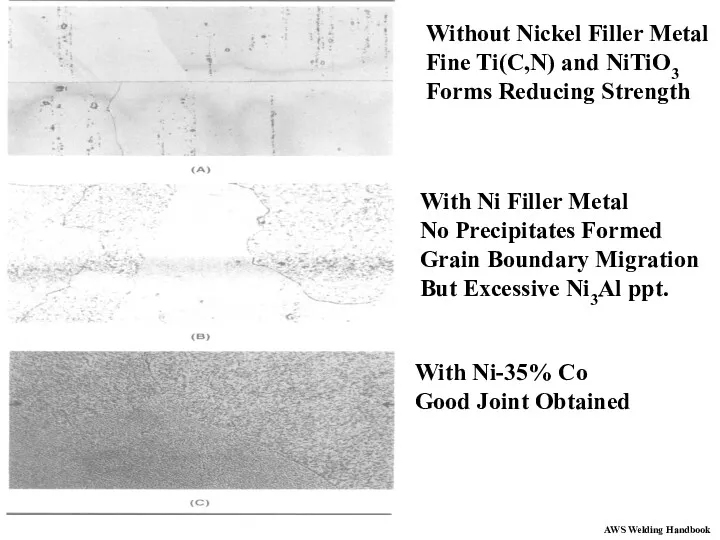

- 21. AWS Welding Handbook Without Nickel Filler Metal Fine Ti(C,N) and NiTiO3 Forms Reducing Strength With Ni

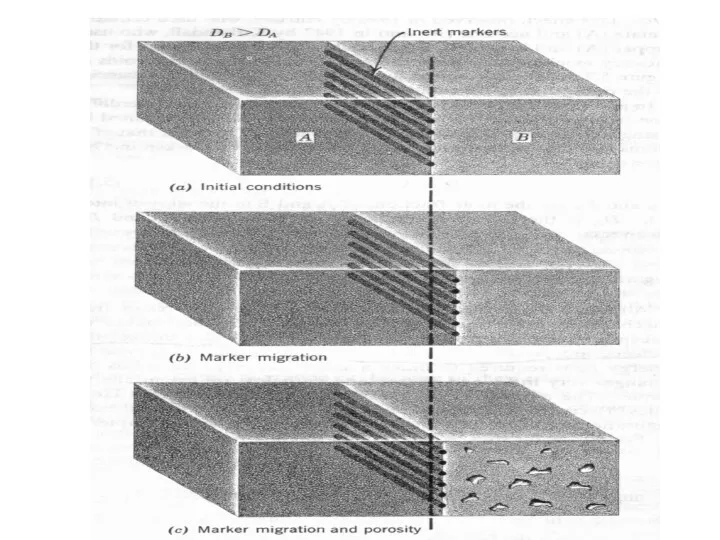

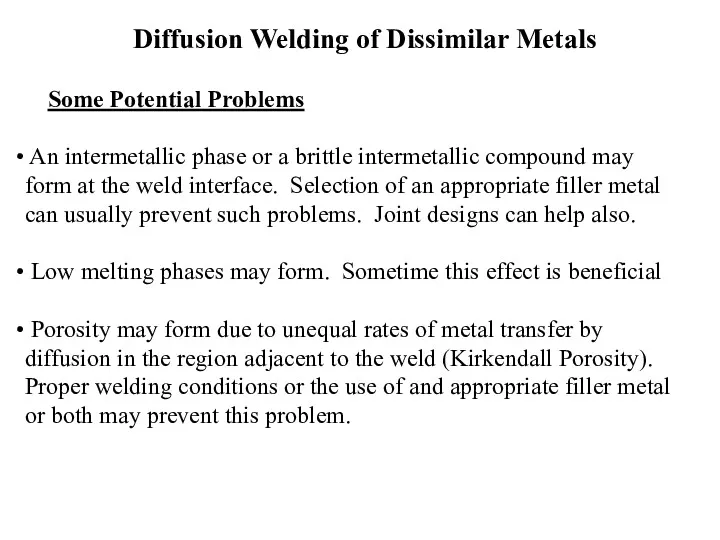

- 22. Diffusion Welding of Dissimilar Metals Some Potential Problems An intermetallic phase or a brittle intermetallic compound

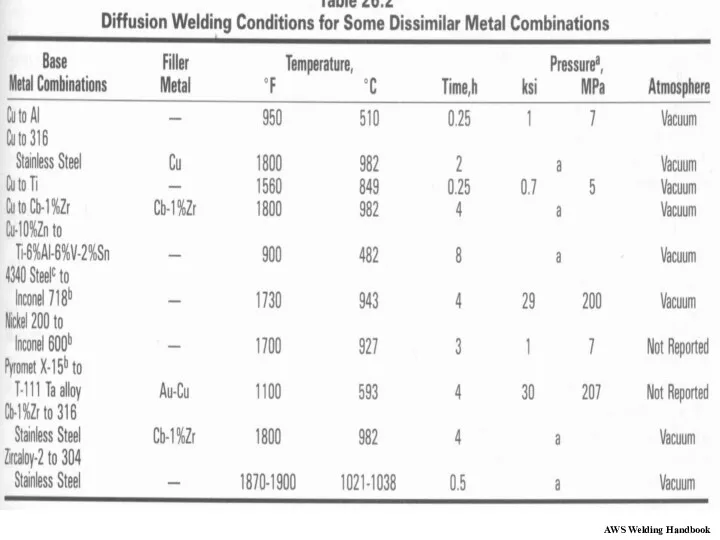

- 23. AWS Welding Handbook

- 24. Questions

- 25. Some Specific Applications Of Diffusion Welding

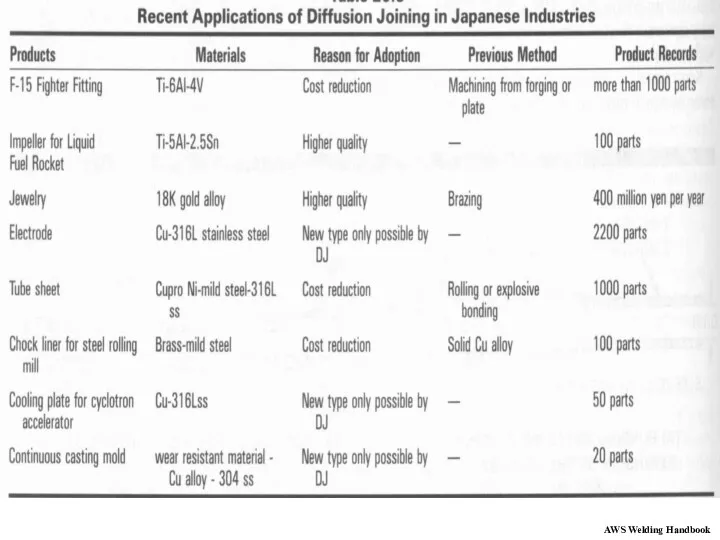

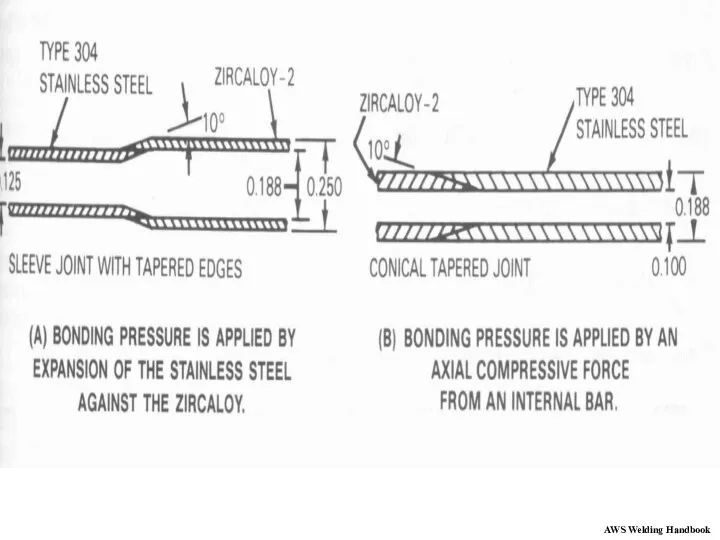

- 26. AWS Welding Handbook

- 27. AWS Welding Handbook

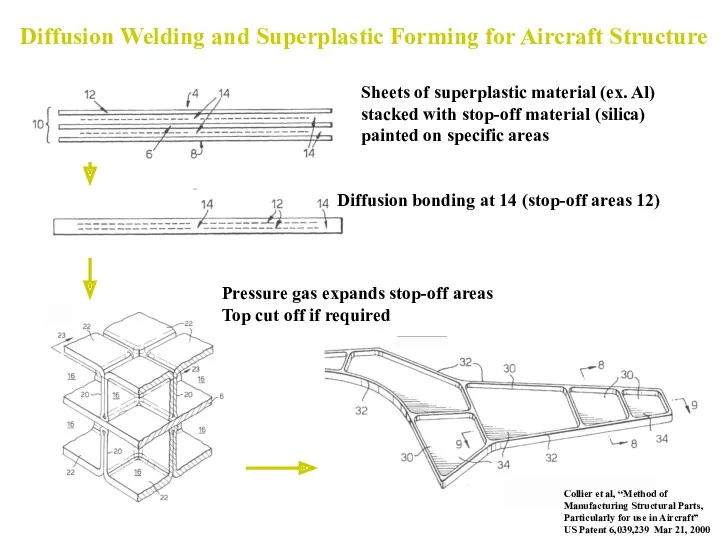

- 28. Diffusion Welding and Superplastic Forming for Aircraft Structure Sheets of superplastic material (ex. Al) stacked with

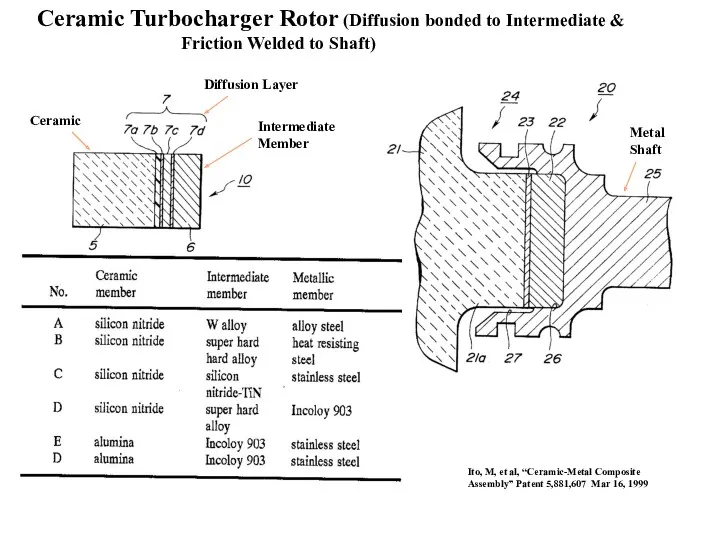

- 29. Ceramic Turbocharger Rotor (Diffusion bonded to Intermediate & Friction Welded to Shaft) Ceramic Intermediate Member Diffusion

- 30. Questions

- 31. Diffusion Brazing Low Melting inter-layer Melts & then diffuses into substrate Generally more rapid diffusion Some

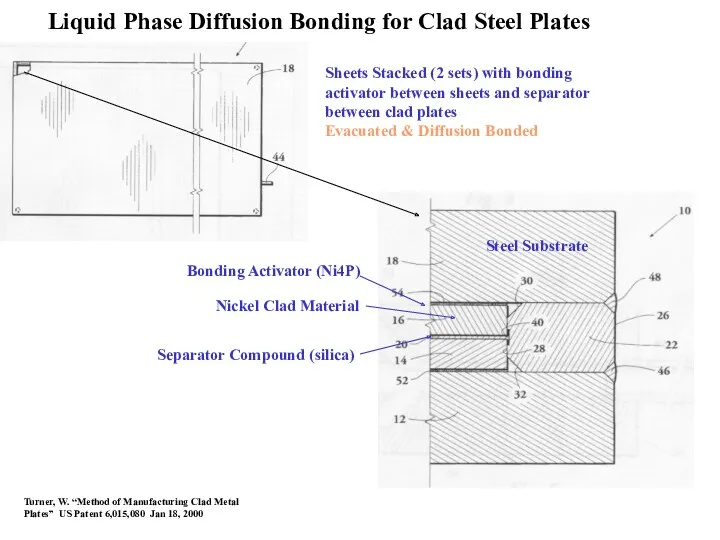

- 32. Liquid Phase Diffusion Bonding for Clad Steel Plates Sheets Stacked (2 sets) with bonding activator between

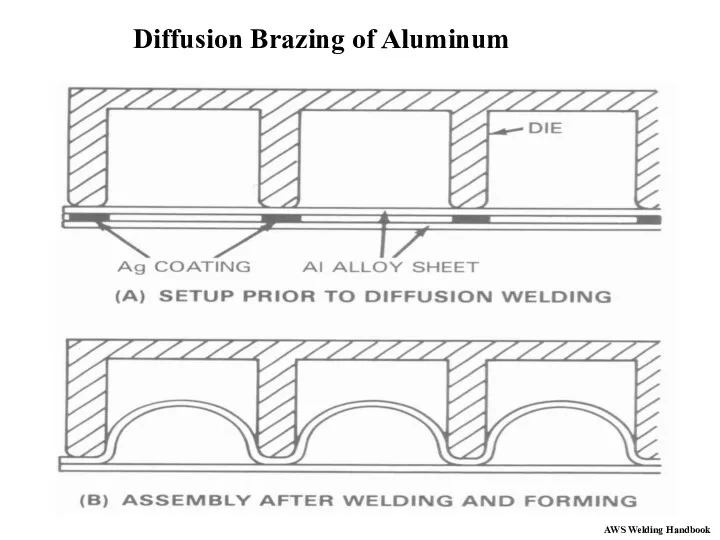

- 33. AWS Welding Handbook Diffusion Brazing of Aluminum

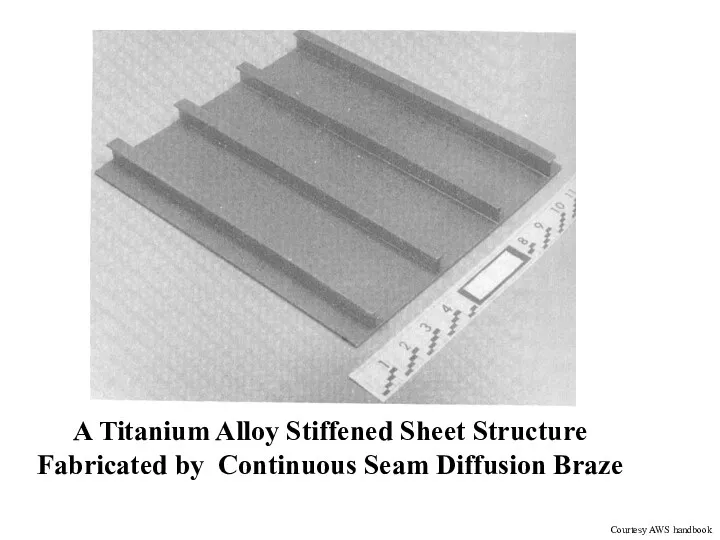

- 34. A Titanium Alloy Stiffened Sheet Structure Fabricated by Continuous Seam Diffusion Braze Courtesy AWS handbook

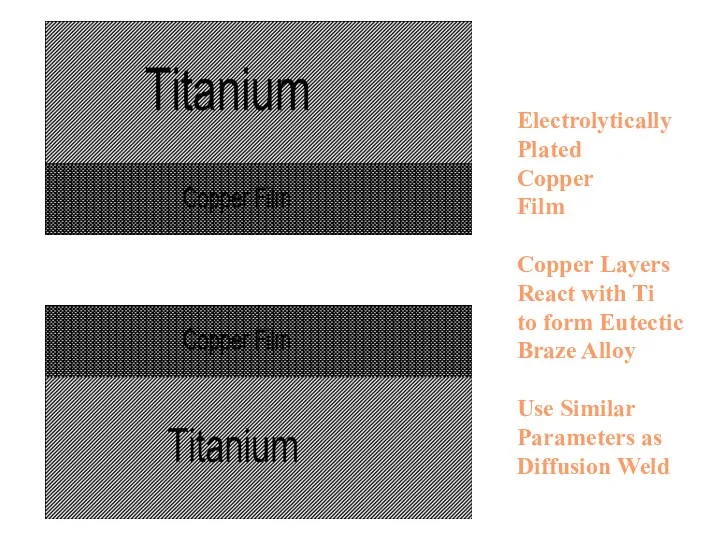

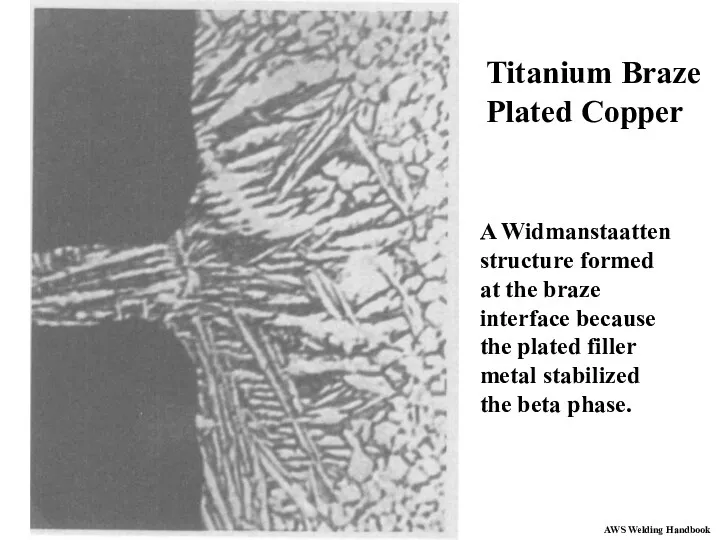

- 35. Electrolytically Plated Copper Film Copper Layers React with Ti to form Eutectic Braze Alloy Use Similar

- 36. AWS Welding Handbook Titanium Braze Plated Copper A Widmanstaatten structure formed at the braze interface because

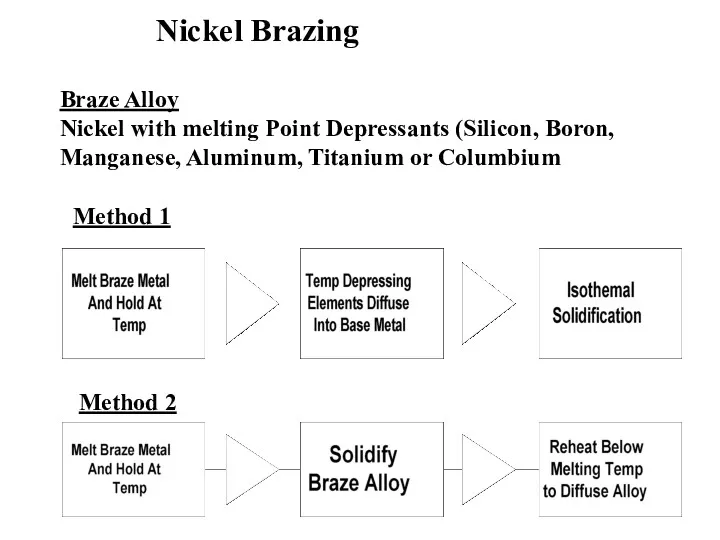

- 37. Nickel Brazing Braze Alloy Nickel with melting Point Depressants (Silicon, Boron, Manganese, Aluminum, Titanium or Columbium

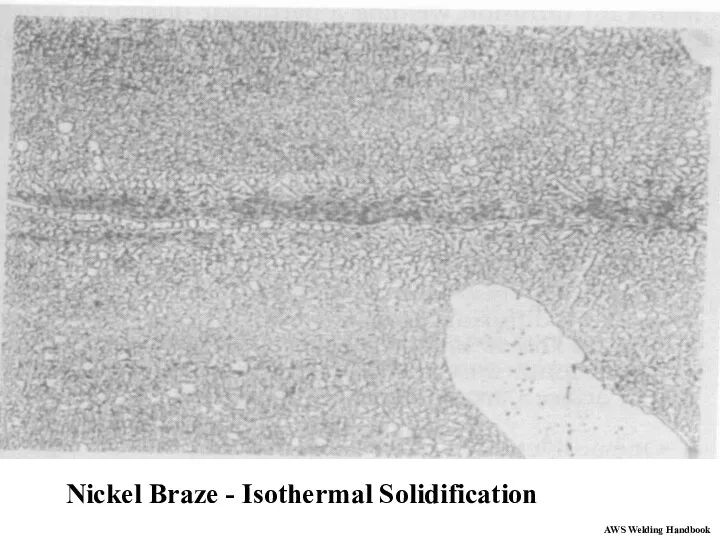

- 38. Nickel Braze - Isothermal Solidification AWS Welding Handbook

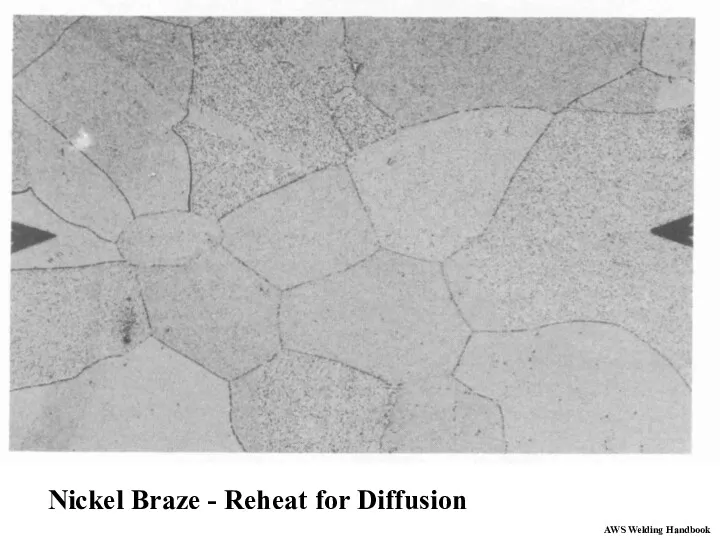

- 39. AWS Welding Handbook Nickel Braze - Reheat for Diffusion

- 41. Скачать презентацию

Ecological problems of the Black Sea. Экологические проблемы Черного моря

Ecological problems of the Black Sea. Экологические проблемы Черного моря Подготовка экспертов ГИА-11 по английскому языку 2017

Подготовка экспертов ГИА-11 по английскому языку 2017 The UK of Great Britain and Northern Ireland

The UK of Great Britain and Northern Ireland Emotions in group

Emotions in group Happy Easter

Happy Easter Thanksgiving day. Poems and songs

Thanksgiving day. Poems and songs mind verb

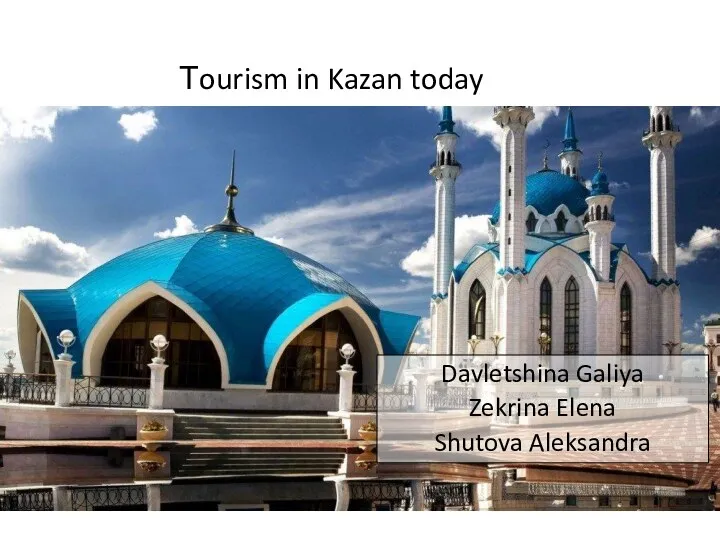

mind verb Тourism in Kazan today

Тourism in Kazan today Funny animals. Game

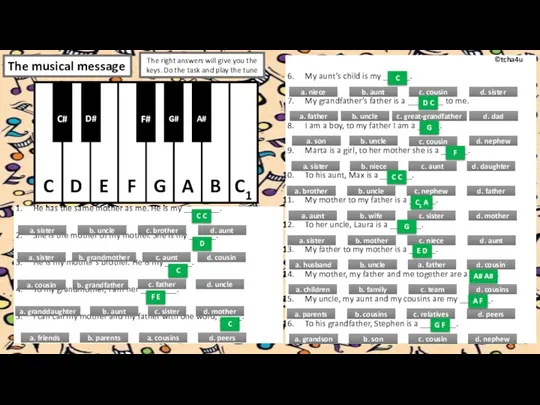

Funny animals. Game Musical message (Family)

Musical message (Family) The topic of the English lesson:… Class: 6

The topic of the English lesson:… Class: 6 Adjectives. Personality activities promoting classroom dynamics group form

Adjectives. Personality activities promoting classroom dynamics group form Reading and Speaking

Reading and Speaking Future Perfect

Future Perfect Условные предложения. Conditionals

Условные предложения. Conditionals Drought. Interesting facts

Drought. Interesting facts My favorite writer A.S. Pushkin

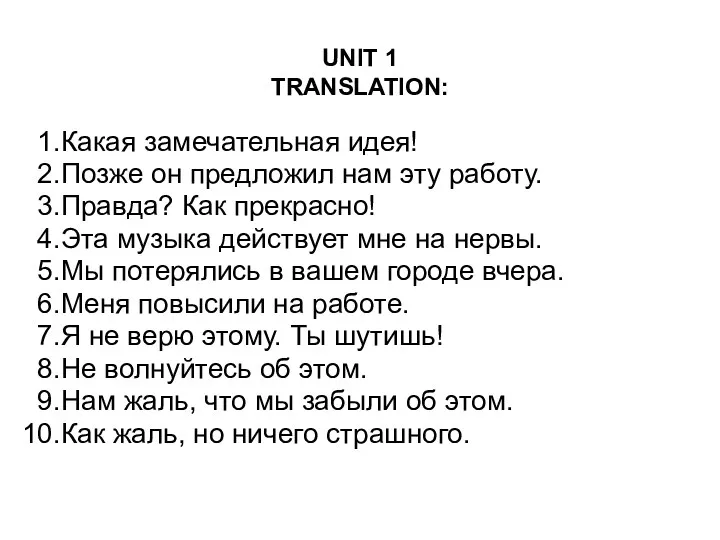

My favorite writer A.S. Pushkin Unit 1 translation

Unit 1 translation Indian national embelem

Indian national embelem Creamy mushroom soup

Creamy mushroom soup My dream house

My dream house This Is London

This Is London Research methods of lexico-phraseological level of the language

Research methods of lexico-phraseological level of the language Raccoon lesson 3 kidsb1+

Raccoon lesson 3 kidsb1+ Present Continuous Tense

Present Continuous Tense English Presentation. Music in our Life

English Presentation. Music in our Life Literature of renaissance period in Italy

Literature of renaissance period in Italy Подготовка к сдаче ЕГЭ по английскому языку. Раздел Говорение. Задание 44

Подготовка к сдаче ЕГЭ по английскому языку. Раздел Говорение. Задание 44