Содержание

- 2. The Ask Stage-gate approval for funds and resources to establish a commercial market entry plan

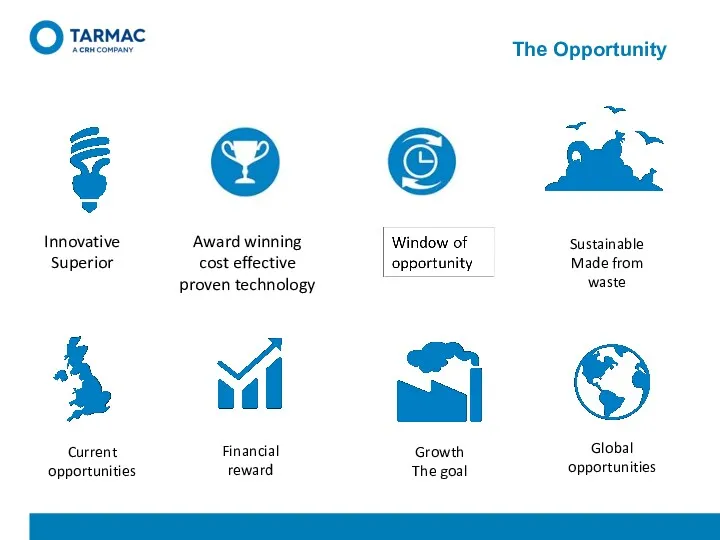

- 3. The Opportunity Award winning cost effective proven technology Innovative Superior Global opportunities Current opportunities Sustainable Made

- 4. The Vision

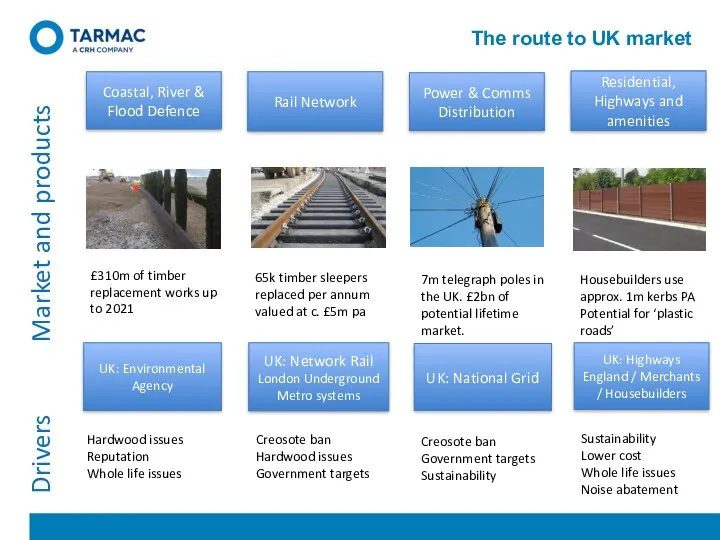

- 5. The route to UK market Coastal, River & Flood Defence Rail Network Power & Comms Distribution

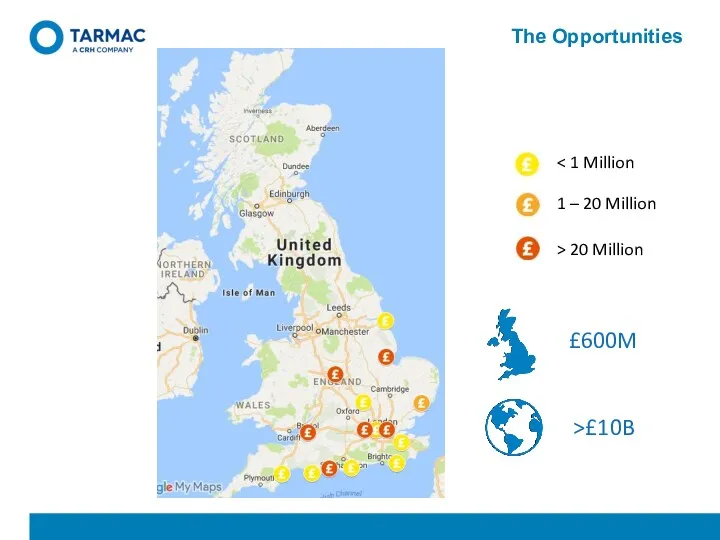

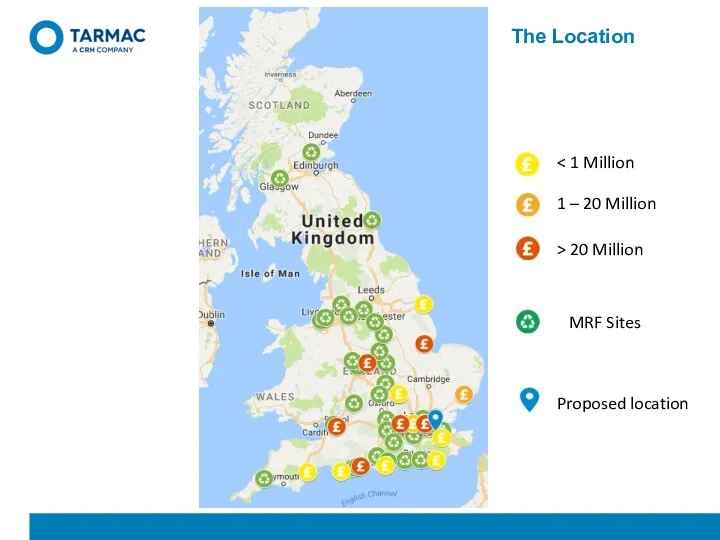

- 6. The Opportunities 1 – 20 Million > 20 Million £600M >£10B

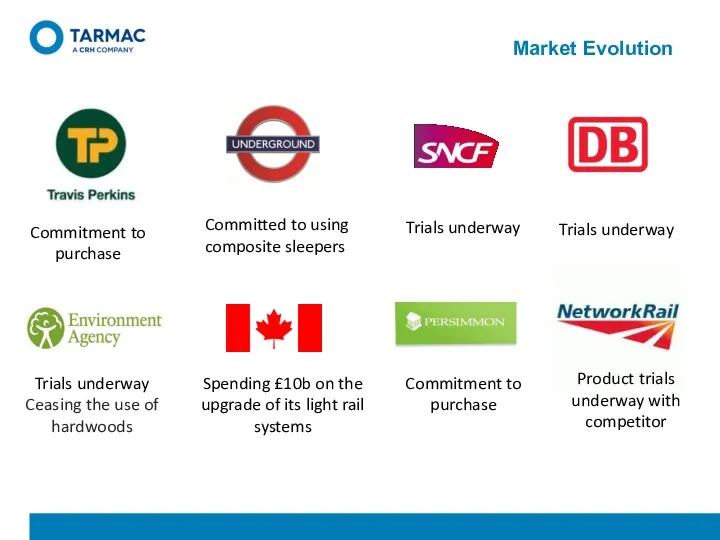

- 7. Market Evolution Product trials underway with competitor Trials underway Ceasing the use of hardwoods Committed to

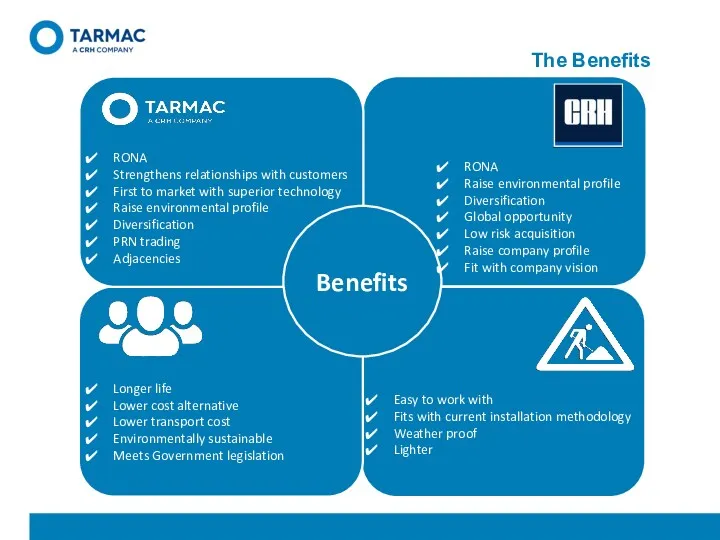

- 8. The Benefits

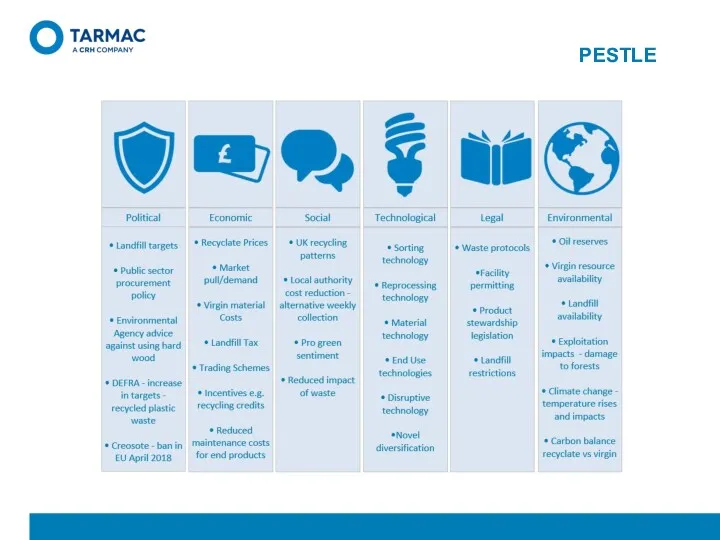

- 9. PESTLE

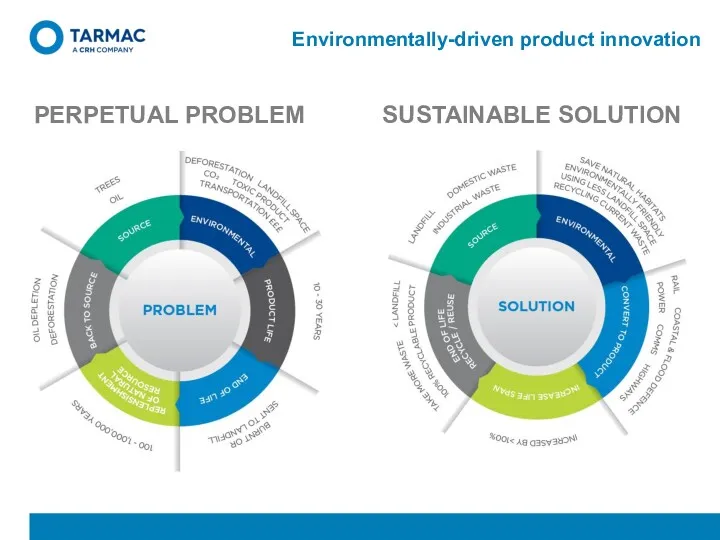

- 10. Environmentally-driven product innovation PERPETUAL PROBLEM SUSTAINABLE SOLUTION

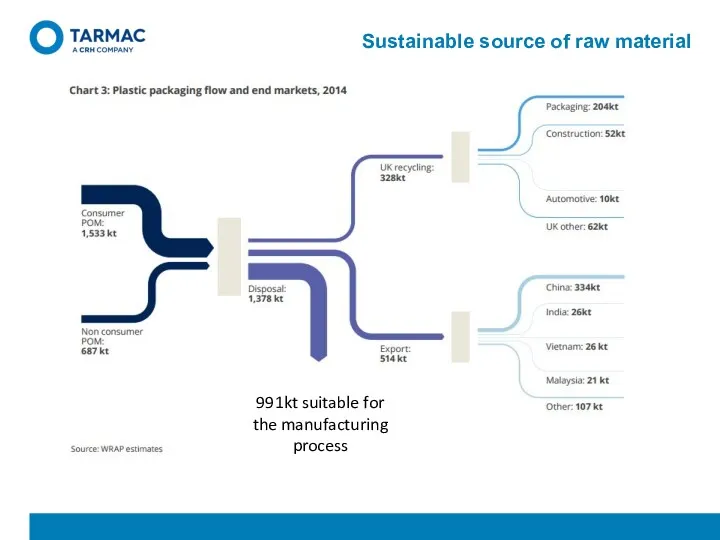

- 11. Sustainable source of raw material 991kt suitable for the manufacturing process

- 12. Raw materials availability

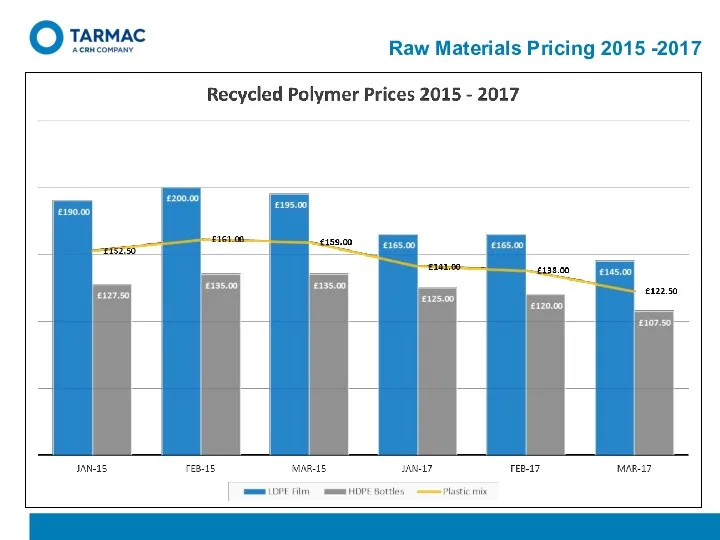

- 13. Raw Materials Pricing 2015 -2017

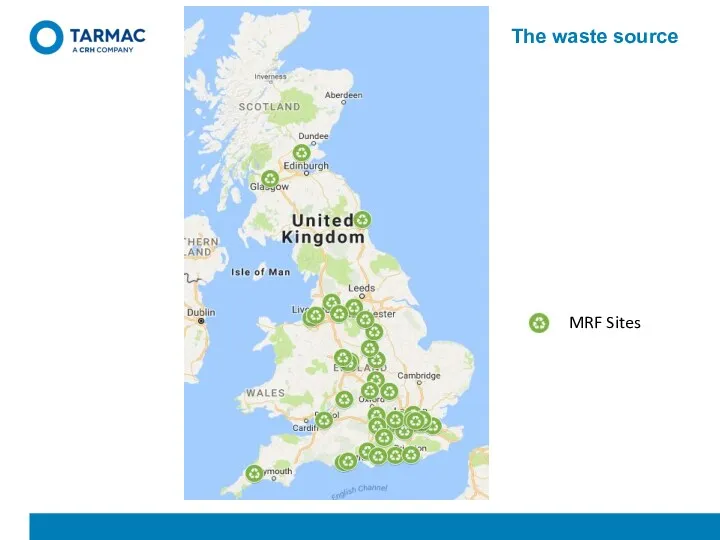

- 14. The waste source MRF Sites

- 15. The Location 1 – 20 Million > 20 Million MRF Sites Proposed location

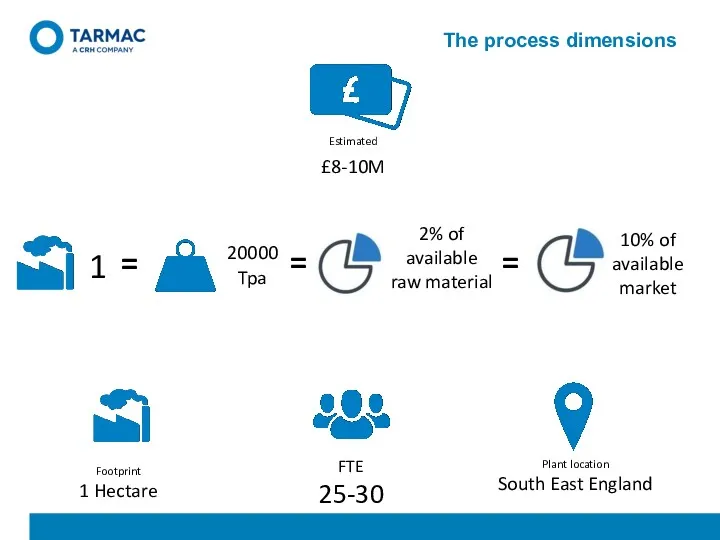

- 16. The process dimensions Estimated £8-10M Plant location South East England FTE 25-30 Footprint 1 Hectare 1

- 17. Process – recycling / polymer separation Inbound raw materials are shredded Shredded material loaded into hopper

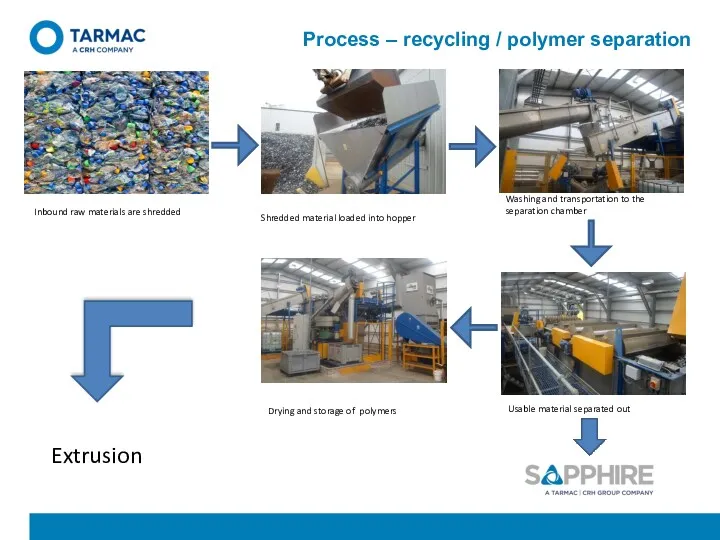

- 18. Structural formulation technology Structural extrusion technology The Process

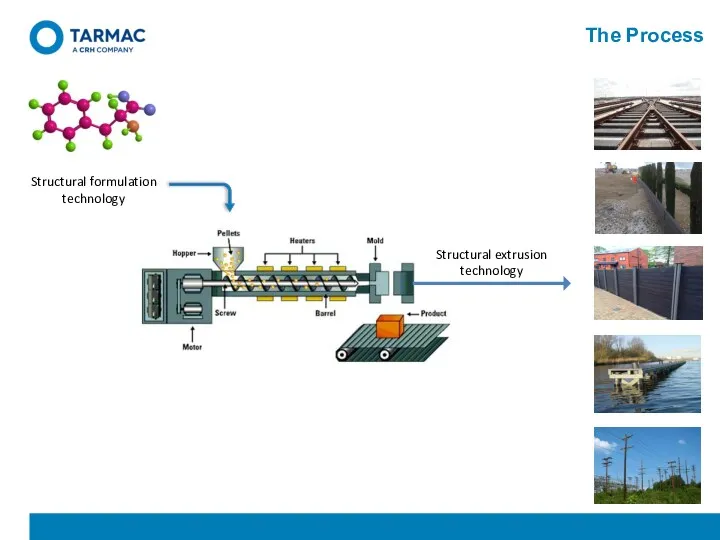

- 19. Innovation through collaboration

- 20. Where we are

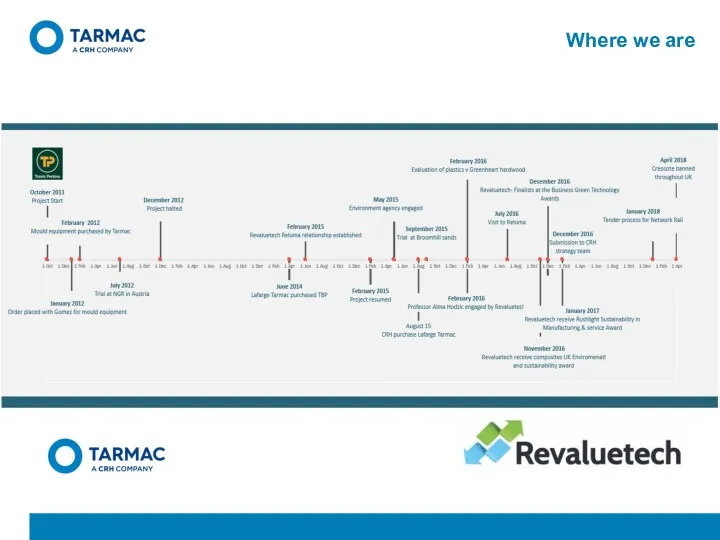

- 22. What is Reluma? Reluma currently distributing in the following countries Germany Austria The Netherlands Sweden UAE

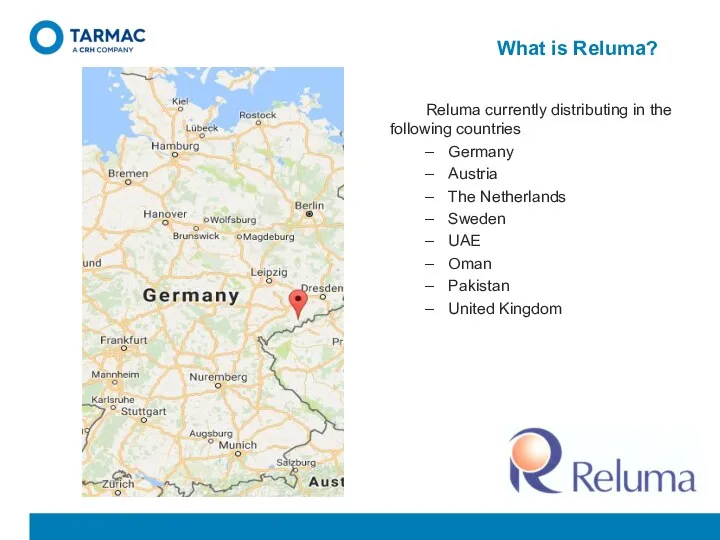

- 23. Our first step to success ?

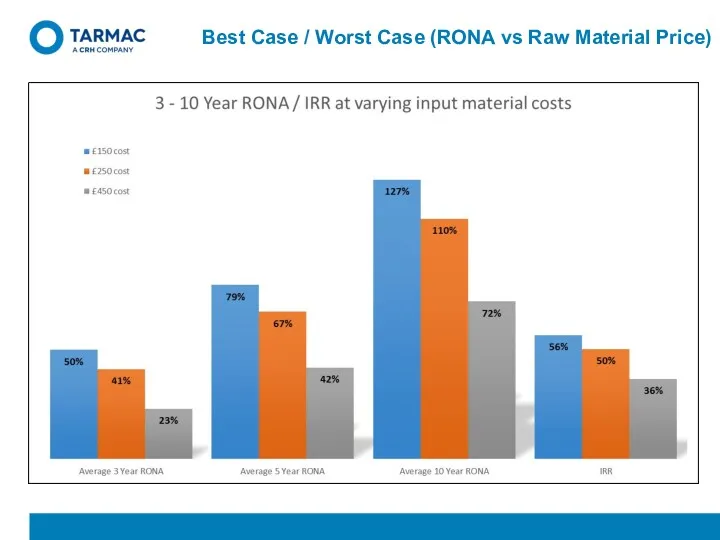

- 24. Best Case / Worst Case (RONA vs Raw Material Price)

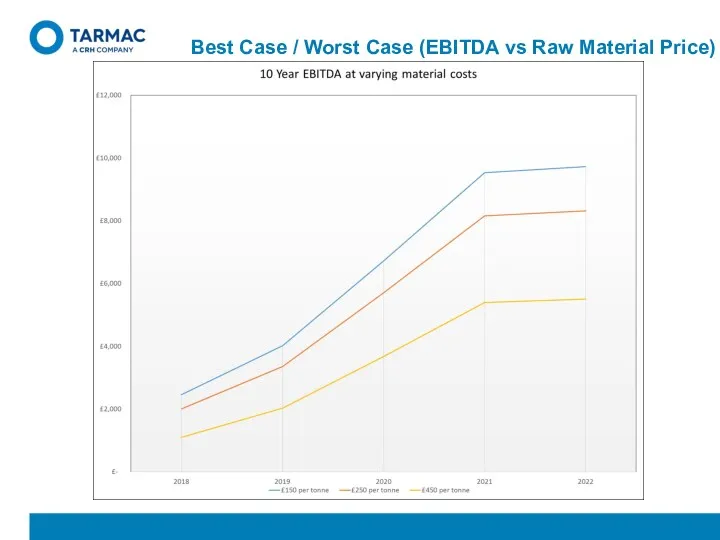

- 25. Best Case / Worst Case (EBITDA vs Raw Material Price)

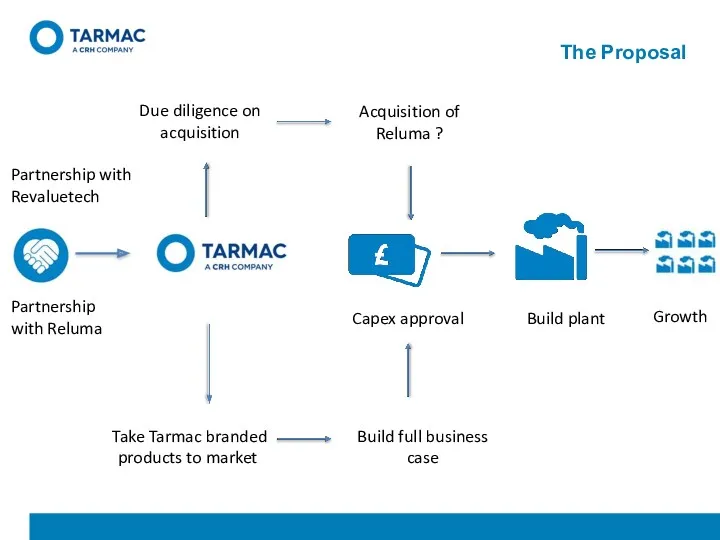

- 26. The Proposal Partnership with Reluma Acquisition of Reluma ? Due diligence on acquisition Capex approval Build

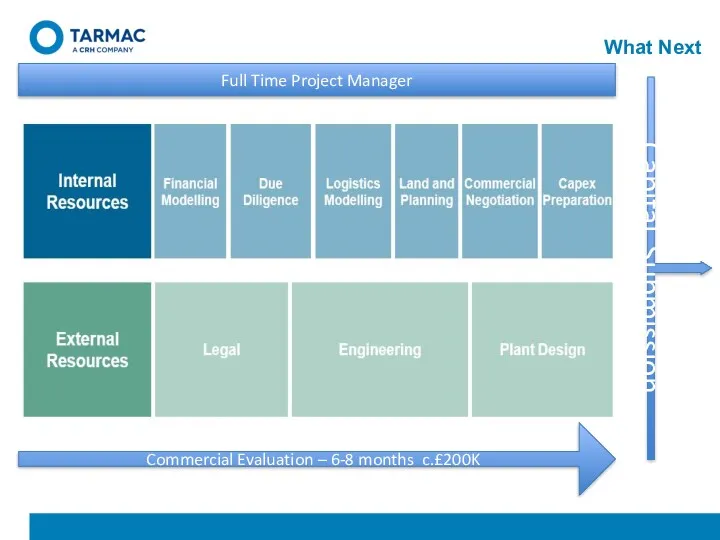

- 27. What Next Commercial Evaluation – 6-8 months c.£200K Capital Submission Full Time Project Manager

- 29. Скачать презентацию

Фонд по содействию кредитованию субъектов малого и среднего предпринимательства Республики

Фонд по содействию кредитованию субъектов малого и среднего предпринимательства Республики Основы системного бизнес-анализа

Основы системного бизнес-анализа SYLVATICA - Школа Дополнительного образования

SYLVATICA - Школа Дополнительного образования Створення інтернет-магазину

Створення інтернет-магазину Бизнес как проект

Бизнес как проект Бизнес-план. Салон обуви

Бизнес-план. Салон обуви Бизнес-план. Структура бизнес-плана

Бизнес-план. Структура бизнес-плана 5 самых мощных бесплатных способов трафика в ваш бизнес

5 самых мощных бесплатных способов трафика в ваш бизнес Бизнес план кафе SteakHouse

Бизнес план кафе SteakHouse Бизнес-план малого предприятия Мини-пекарня <<Счастье есть>>

Бизнес-план малого предприятия Мини-пекарня <<Счастье есть>> Мини-кондитерская по изготовлению пончиков. Бизнес-план

Мини-кондитерская по изготовлению пончиков. Бизнес-план Семейная компания Bandi. Профессиональная косметика

Семейная компания Bandi. Профессиональная косметика Бизнес Идея. Салон красоты и здоровья

Бизнес Идея. Салон красоты и здоровья Готельно-ресторанний комплекс Tree House. Архітектурний проект

Готельно-ресторанний комплекс Tree House. Архітектурний проект Бизнес-план. Понятие и функции

Бизнес-план. Понятие и функции Генерация идей и методы их оценки

Генерация идей и методы их оценки Партнерская программа FMC Мегафон

Партнерская программа FMC Мегафон Дух предпринимательства

Дух предпринимательства Бизнес-план Кролиководство

Бизнес-план Кролиководство Управление и организация командировок

Управление и организация командировок Моделювання бізнес-процесів вирощування та реалізації зернових та зернобобових культур

Моделювання бізнес-процесів вирощування та реалізації зернових та зернобобових культур Кондитерская BAKERY lab

Кондитерская BAKERY lab Органы инфраструктуры поддержки предпринимательства

Органы инфраструктуры поддержки предпринимательства Готельна інфраструктура Єгипту

Готельна інфраструктура Єгипту Концепція десерт-бару

Концепція десерт-бару Центр Мой бизнес

Центр Мой бизнес Business-planning system

Business-planning system Кафе на 50 місць

Кафе на 50 місць