Содержание

- 2. Waste management Waste management includes the collection and transport of waste recovery of waste Separation Further

- 3. Waste Policy in Finland Is in line with the EU waste policy Sets the wider perspective

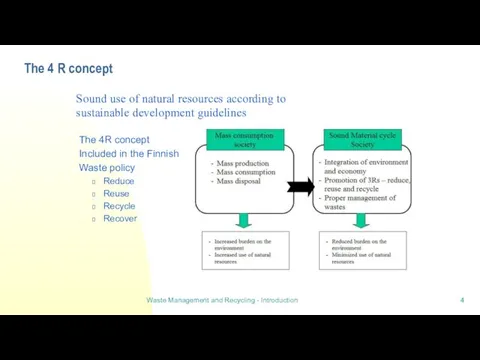

- 4. The 4 R concept The 4R concept Included in the Finnish Waste policy Reduce Reuse Recycle

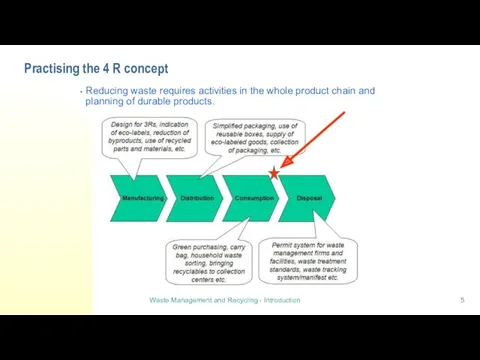

- 5. Practising the 4 R concept Reducing waste requires activities in the whole product chain and planning

- 6. Lecture 2: Collection and transport

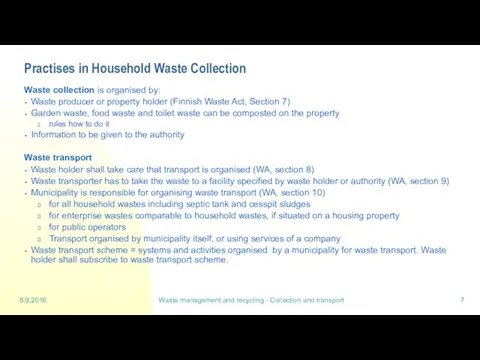

- 7. 8.9.2016 Waste management and recycling - Collection and transport Practises in Household Waste Collection Waste collection

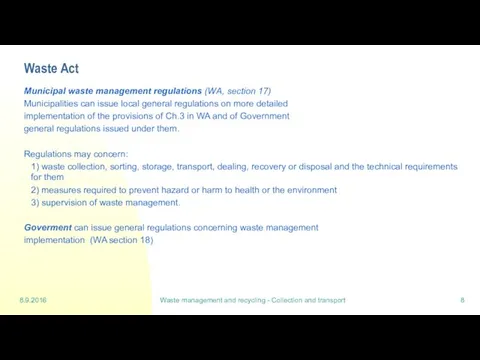

- 8. 8.9.2016 Waste management and recycling - Collection and transport Waste Act Municipal waste management regulations (WA,

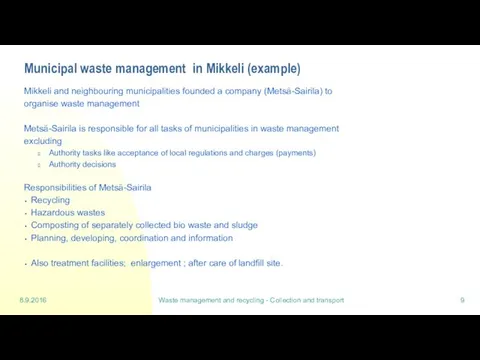

- 9. 8.9.2016 Waste management and recycling - Collection and transport Municipal waste management in Mikkeli (example) Mikkeli

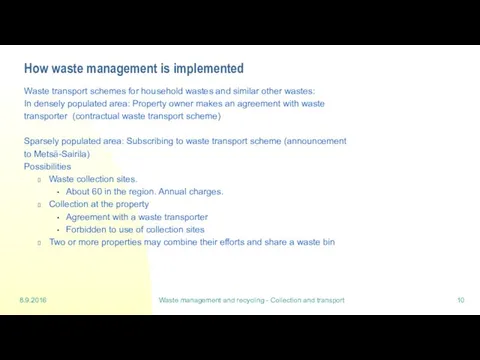

- 10. 8.9.2016 Waste management and recycling - Collection and transport How waste management is implemented Waste transport

- 11. 8.9.2016 Waste management and recycling - Collection and transport Waste collection Requirements for waste bins: Durable

- 12. 8.9.2016 Waste management and recycling - Collection and transport Household waste collection Private household Biowaste has

- 13. 8.9.2016 Waste management and recycling - Collection and transport Housing company waste Mixed waste large bins

- 14. 8.9.2016 Waste management and recycling - Collection and transport Public waste collection sites Waste collection at

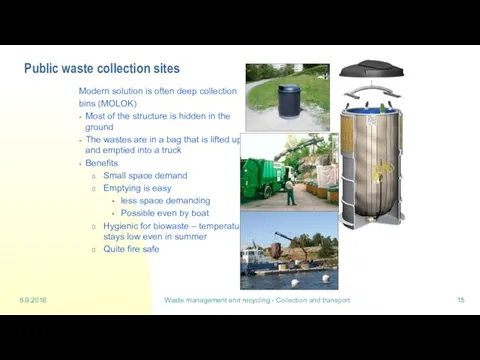

- 15. 8.9.2016 Waste management and recycling - Collection and transport Public waste collection sites Modern solution is

- 16. 8.9.2016 Waste management and recycling - Collection and transport Logistics in waste transport The waste transport

- 17. 8.9.2016 Waste management and recycling - Collection and transport Waste collection trucks for option C

- 18. 8.9.2016 Waste management and recycling - Collection and transport Logistics and transport routes

- 19. 8.9.2016 Waste management and recycling - Collection and transport Cost of waste collection and transport The

- 20. Lecture 3: Waste sorting

- 21. 8.9.2016 Waste management and recycling - Sorting Waste types Waste should be sorted for recovery In

- 22. 8.9.2016 Waste management and recycling - Sorting Waste centre in Lahti Sorted waste is collected at

- 23. 8.9.2016 Waste management and recycling - Sorting Recyclable materials sorted at source Waste paper collected separately

- 24. 8.9.2016 Waste management and recycling - Sorting Biowaste Biowaste is organic, biologically degradable waste suitable for

- 25. 8.9.2016 Waste management and recycling - Sorting Waste for energy recovery In general paper or plastic

- 26. 8.9.2016 Waste management and recycling - Sorting Waste for landfill Waste not possible to use for

- 27. 8.9.2016 Waste management and recycling - Sorting Material recovery facility MSW is not sorted at source

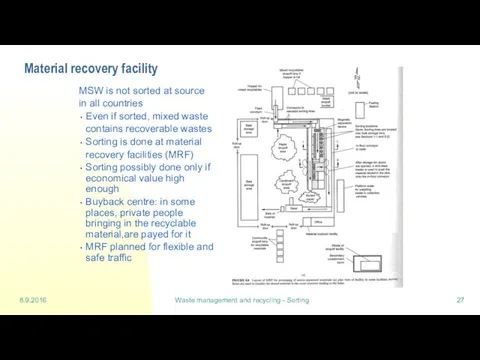

- 28. 8.9.2016 Waste management and recycling - Sorting Material prices in USA 2002

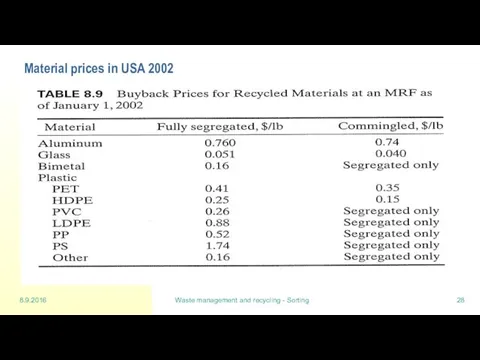

- 29. 8.9.2016 Waste management and recycling - Sorting MRF facility Commingled recyclable material is sorted into usable

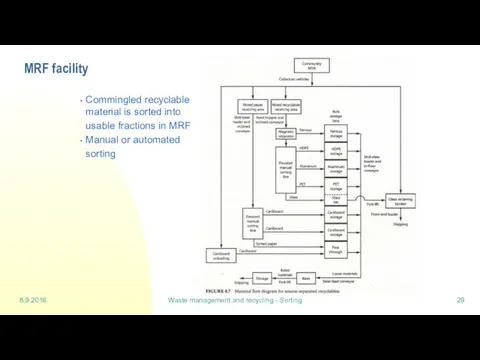

- 30. 8.9.2016 Waste management and recycling - Sorting Processing of and recovery from mixed municipal waste Manual

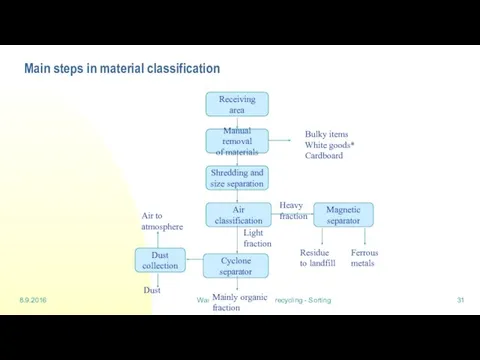

- 31. 8.9.2016 Waste management and recycling - Sorting Main steps in material classification

- 32. 8.9.2016 Waste management and recycling - Sorting Size Reduction

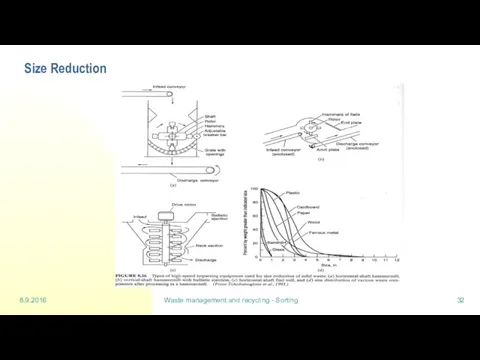

- 33. 8.9.2016 Waste management and recycling - Sorting Size separation

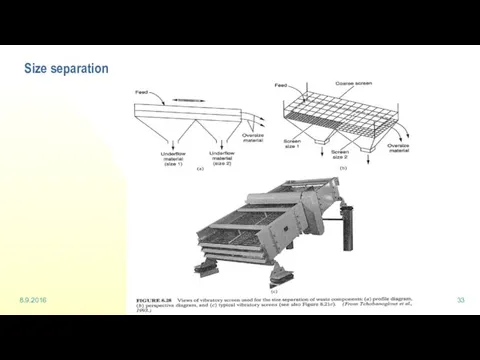

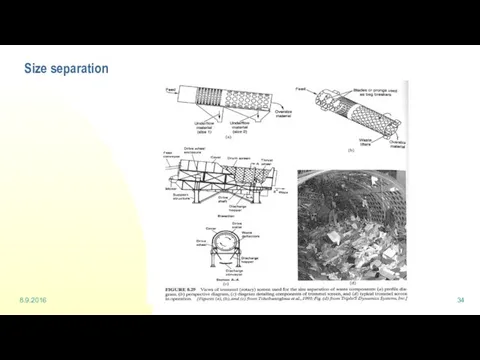

- 34. 8.9.2016 Waste management and recycling - Sorting Size separation

- 35. 8.9.2016 Waste management and recycling - Sorting Magnetic separation

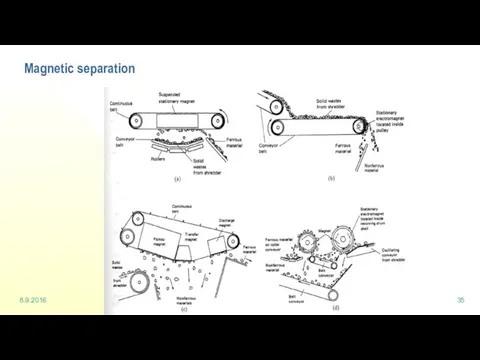

- 36. 8.9.2016 Waste management and recycling - Sorting Air classifier

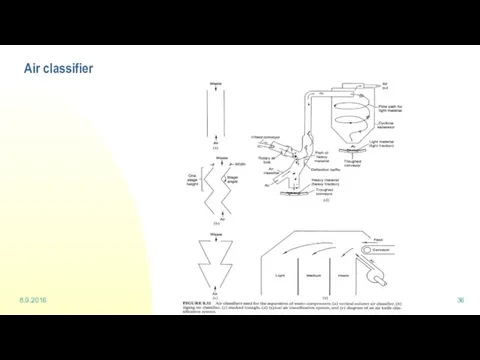

- 37. 8.9.2016 Waste management and recycling - Sorting Automated sorting system with sensors

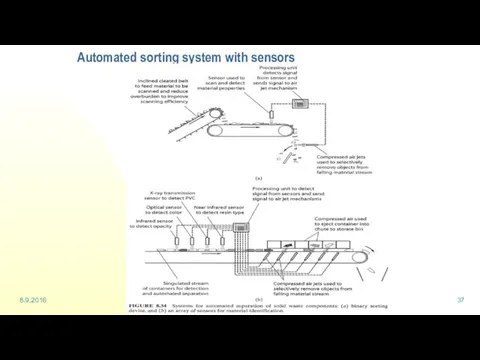

- 38. Lecture 4: Landfill

- 39. 22.9.2016 Waste management and recycling - Landfill Gas collection and utilization system Gas collection system contains

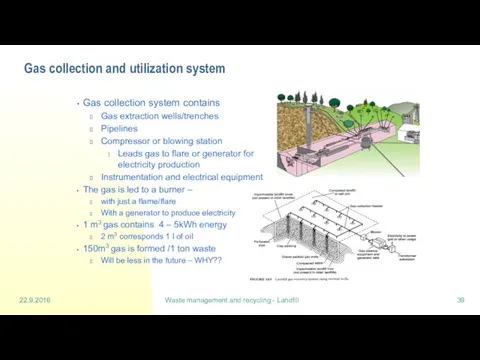

- 40. 22.9.2016 Waste management and recycling - Landfill Planning of a landfill Siting is a problem: ”not

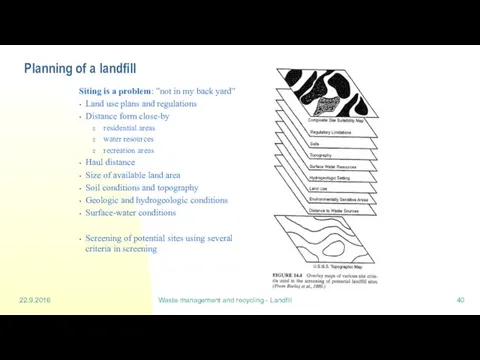

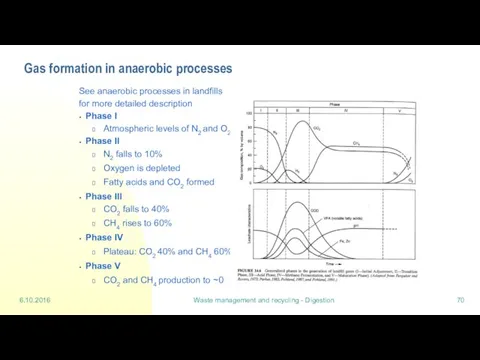

- 41. 22.9.2016 Waste management and recycling - Landfill Gas formation in anaerobic processes Micro-organisms come from daily

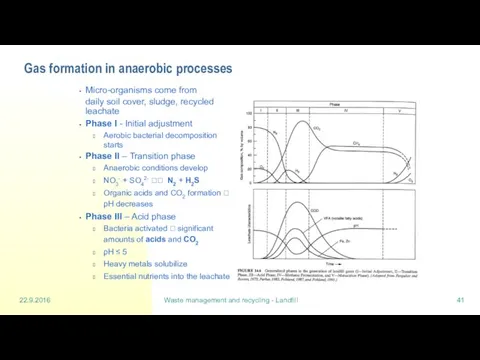

- 42. 22.9.2016 Waste management and recycling - Landfill Gas formation… Phase IV – methane fermentation phase Bacteria

- 43. 22.9.2016 Waste management and recycling - Landfill Formation of leachate Amount of leachate varies and depends

- 44. 22.9.2016 Waste management and recycling - Landfill Leachate Quality of leachate depends on the phase of

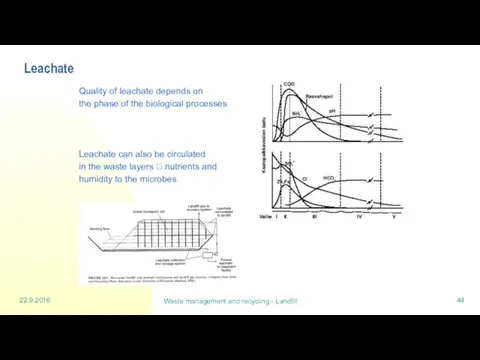

- 45. 22.9.2016 Waste management and recycling - Landfill Construction of a landfill before filling it The landfill

- 46. 22.9.2016 Waste management and recycling - Landfill Filling Filling system depends on topography Waste is placed

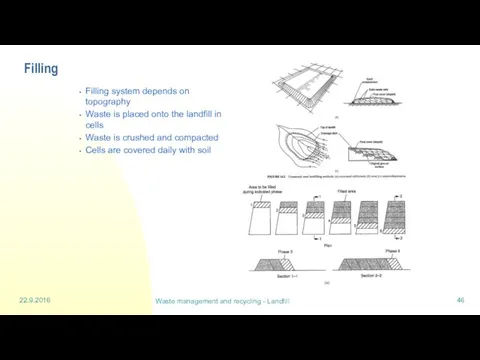

- 47. 22.9.2016 Waste management and recycling - Landfill Waste layers in a landfill a) Bottom layers are

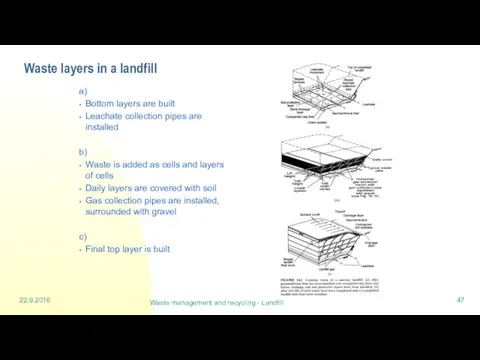

- 48. 22.9.2016 Waste management and recycling - Landfill Landfill Bottom Structure Soil quality is important Structure contains

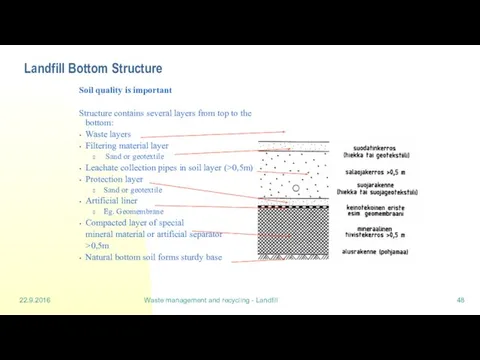

- 49. 22.9.2016 Waste management and recycling - Landfill Landfill bottom structure Waste fill Drainage Traffic layer Filter

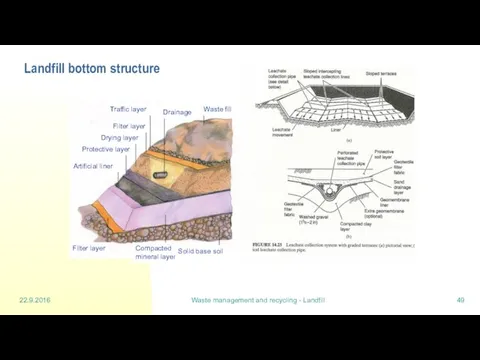

- 50. 22.9.2016 Waste management and recycling - Landfill Required bottom layers Bottom layers Base soil has to

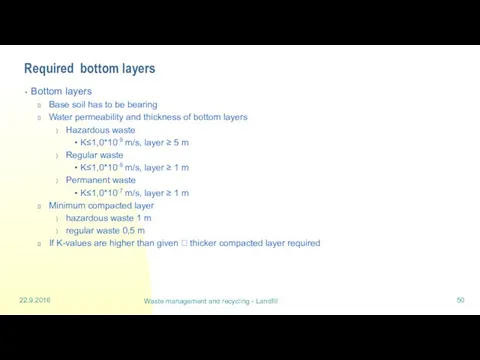

- 51. 22.9.2016 Waste management and recycling - Landfill An example of bottom liners and leachate tubes

- 52. Lecture 5: Composting (part 1)

- 53. 29.9.2016 Waste management and recycling - Composting Definitions Composting = aerobic biological decomposition of the biodegradable

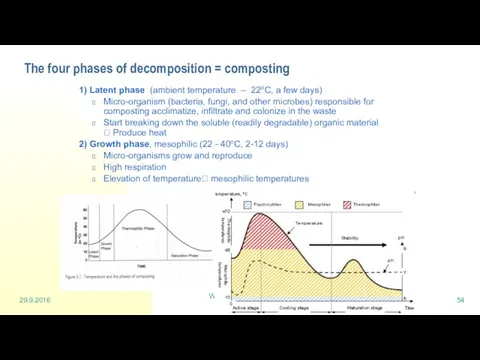

- 54. 29.9.2016 Waste management and recycling - Composting The four phases of decomposition = composting 1) Latent

- 55. 29.9.2016 Waste management and recycling - Composting The five phases of decomposition = composting 3) Thermophilic

- 56. 29.9.2016 Waste management and recycling - Composting Factors affecting the decomposition in the compost Temperature Depends

- 57. 29.9.2016 Waste management and recycling - Composting Factors affecting the decomposition in the compost Particle size

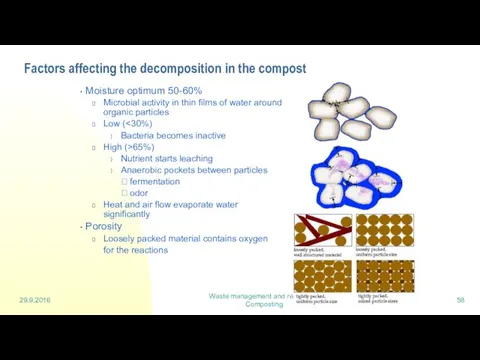

- 58. 29.9.2016 Waste management and recycling - Composting Factors affecting the decomposition in the compost Moisture optimum

- 59. 29.9.2016 Waste management and recycling - Composting Factors affecting the decomposition in the compost Composition of

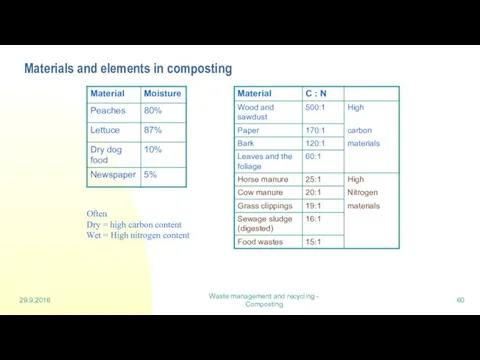

- 60. 29.9.2016 Waste management and recycling - Composting Materials and elements in composting Often Dry = high

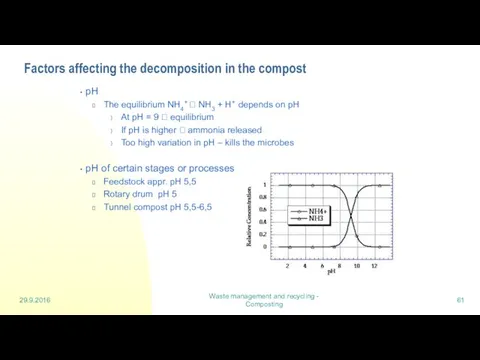

- 61. 29.9.2016 Waste management and recycling - Composting Factors affecting the decomposition in the compost pH The

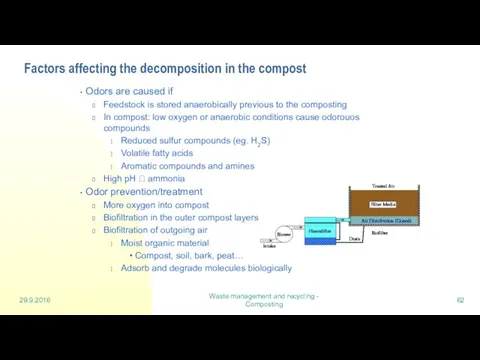

- 62. 29.9.2016 Waste management and recycling - Composting Factors affecting the decomposition in the compost Odors are

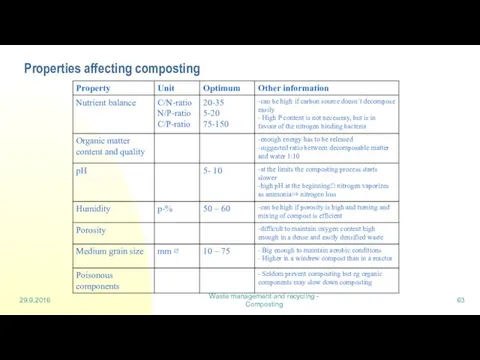

- 63. 29.9.2016 Waste management and recycling - Composting Properties affecting composting Taulukko 3.1 Jätteen ominaisuuksien optimiarvoja. (Lilja

- 64. Lecture 6: Digestion

- 65. 6.10.2016 Waste management and recycling - Digestion Basics of digestion Treatment for biological waste that cannot

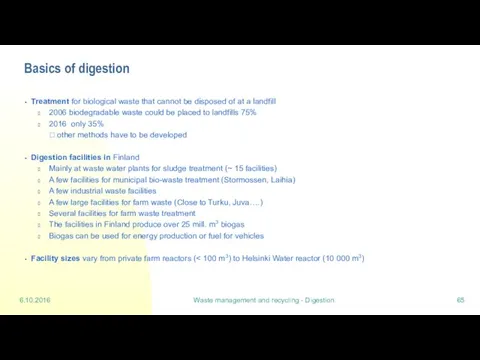

- 66. 6.10.2016 Waste management and recycling - Digestion Classification of anaerobic processes Wet process: total dry solids

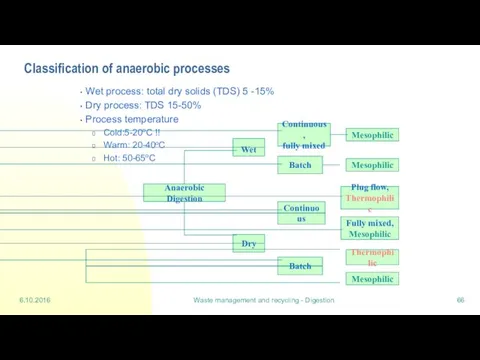

- 67. 6.10.2016 Waste management and recycling - Digestion Digestion process Biological reactions in the digestion are similar

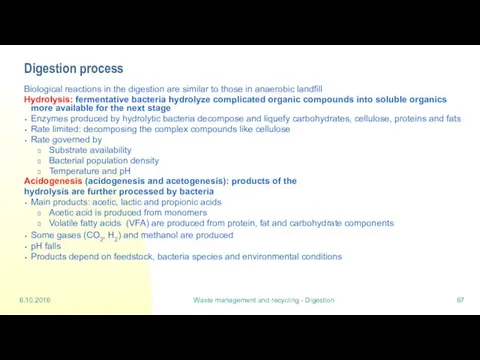

- 68. 6.10.2016 Waste management and recycling - Digestion Digestion process Methanogenesis: methane - forming bacteria produces methane

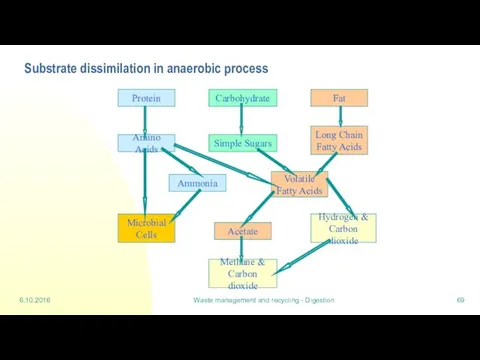

- 69. 6.10.2016 Waste management and recycling - Digestion Substrate dissimilation in anaerobic process Protein Carbohydrate Fat Long

- 70. 6.10.2016 Waste management and recycling - Digestion Gas formation in anaerobic processes See anaerobic processes in

- 71. Lecture 7: Waste incineration (part 2)

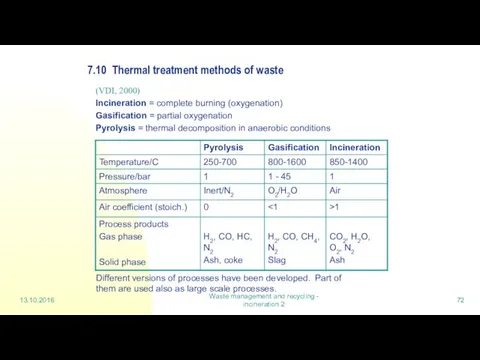

- 72. 13.10.2016 Waste management and recycling - incineration 2 7.10 Thermal treatment methods of waste (VDI, 2000)

- 73. 13.10.2016 Waste management and recycling - incineration 2 7.10.2 Municipal waste incineration plants – basic structure

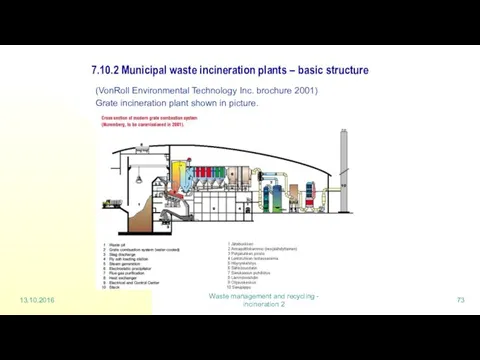

- 74. 13.10.2016 Waste management and recycling - incineration 2 Grate firing Grate firing basics Fuel in suitable

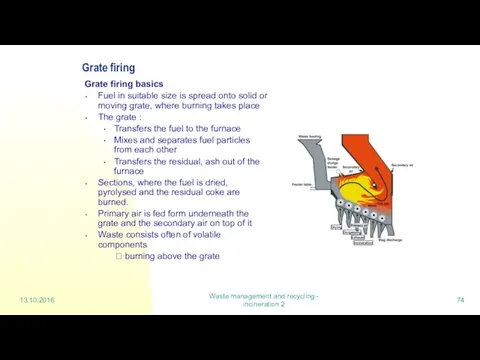

- 75. 13.10.2016 Waste management and recycling - incineration 2 Grate firing (cont) Different air flows in grate

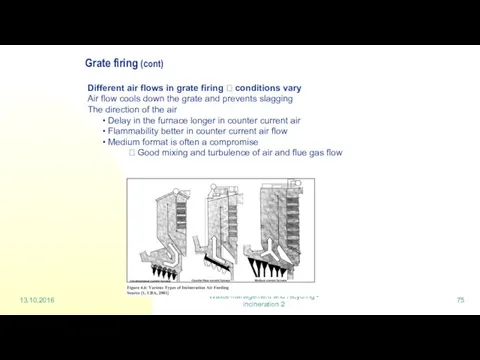

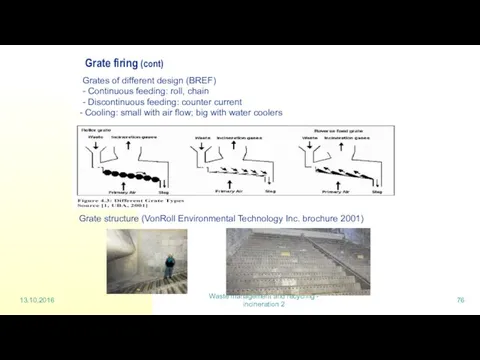

- 76. 13.10.2016 Waste management and recycling - incineration 2 Grate firing (cont) Grate structure (VonRoll Environmental Technology

- 77. 13.10.2016 Waste management and recycling - incineration 2 Grate firing (cont) The grate removes the slag

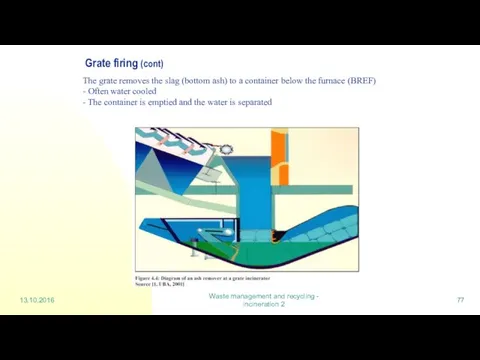

- 78. 13.10.2016 Waste management and recycling - incineration 2 Fluidised bed incineration Fluidised bed incineration has been

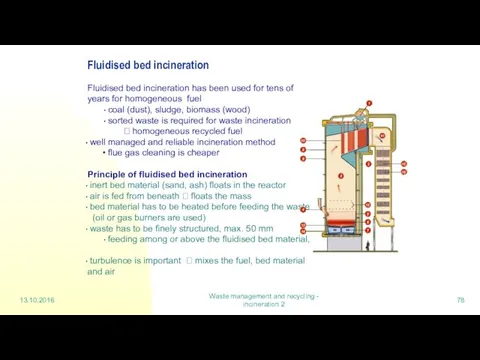

- 79. 13.10.2016 Waste management and recycling - incineration 2 Fluidised bed incineration (cont) The purpose for using

- 80. 13.10.2016 Waste management and recycling - incineration 2 Fluidised bed incineration (cont) Fluidised bed reactors are

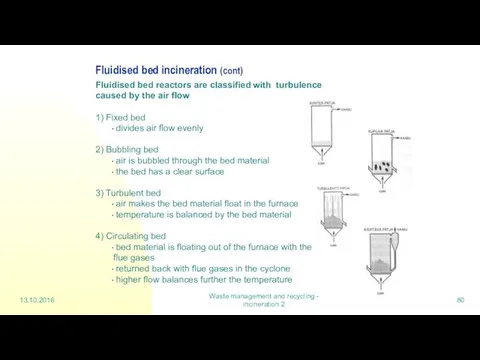

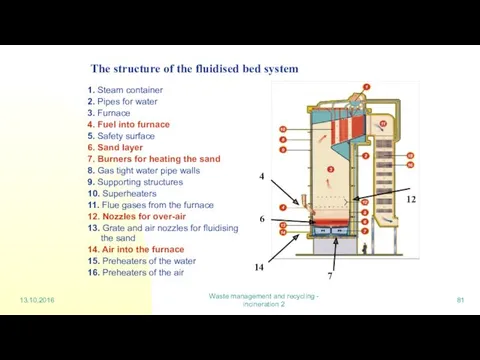

- 81. 13.10.2016 Waste management and recycling - incineration 2 The structure of the fluidised bed system 1.

- 82. 13.10.2016 Waste management and recycling - incineration 2 Fluidised bed techniques Common The bed material has

- 83. 13.10.2016 Waste management and recycling - incineration 2 Fluidised bed techniques (cont) Small emissions Moderate temperature:

- 84. 13.10.2016 Waste management and recycling - incineration 2 7.10.3 Pyrolysis and gasification Optional methods for waste

- 85. 13.10.2016 Waste management and recycling - incineration 2 Pyrolysis and gasification (cont) Smouldering Gas formation from

- 86. 13.10.2016 Waste management and recycling - incineration 2 Gasification Several processes suitable for municipal waste, dried

- 87. 13.10.2016 Waste management and recycling - incineration 2 Gasification (cont) Example of gasification of wet waste;

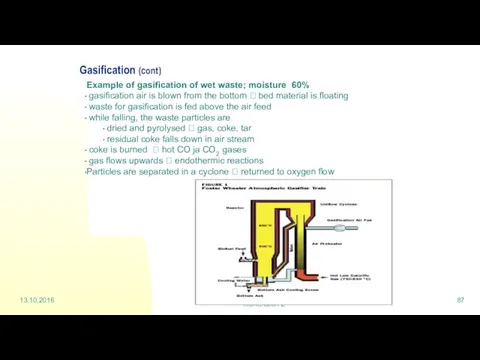

- 88. 13.10.2016 Waste management and recycling - incineration 2 Gasification (cont Pressurised gasification (BREF, 2003) Coal-waste mixture

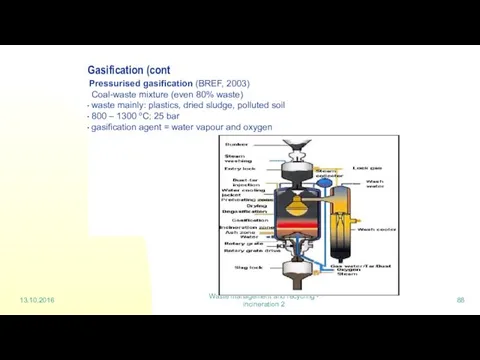

- 89. 13.10.2016 Waste management and recycling - incineration 2 Gasification Figures (cont) Concurrent gasifier (BREF, 2003) German

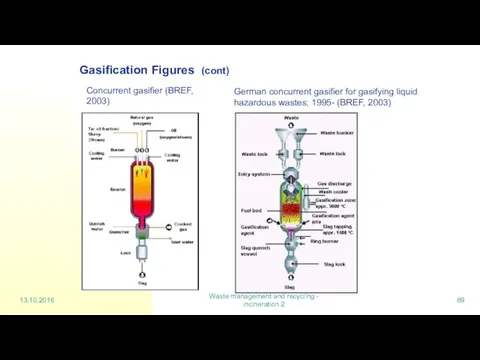

- 90. 13.10.2016 Waste management and recycling - incineration 2 Gasification (cont) Benefits gasification enables also low quality,

- 91. 13.10.2016 Waste management and recycling - incineration 2 Gasification (cont) Negative features new processes ? uncertainty

- 92. Lecture 8: Hazardous waste

- 93. 20.10.2016 Waste management and recycling - Hazardous waste Is the list definite? If a material is

- 94. Types of hazardous waste Solid wastes Liquid wastes Chemicals Industrial wastes Well known; in environmental permits

- 95. Treatment, main aspects Sorted and labelled waste Waste to energy Thermal treatment Physico-chemical treatment Biological treatment

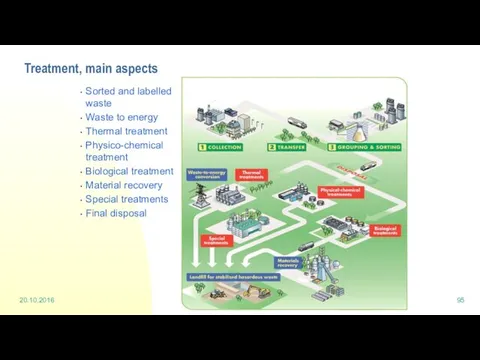

- 96. 1 High temperature incineration Process units at Ekokem The core unit is a 12-metre rotary kiln

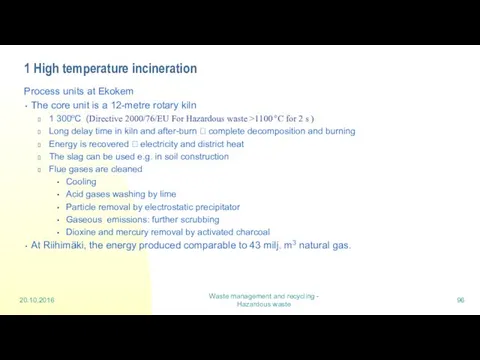

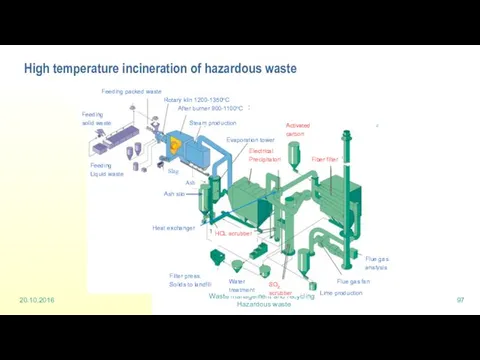

- 97. High temperature incineration of hazardous waste 20.10.2016 Waste management and recycling - Hazardous waste Water treatment

- 98. 4 Physico- chemical processes Inorganic wastes, such as acids, bases and heavy metal containing liquids are

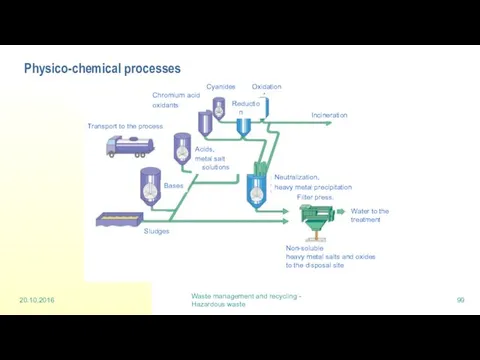

- 99. Physico-chemical processes 20.10.2016 Waste management and recycling - Hazardous waste Non-soluble heavy metal salts and oxides

- 100. Lecture 9: Life cycle assessment

- 101. Waste management and recycling - LCA 10 Life Cycle Assessment = LCA Various names Life cycle

- 102. Waste management and recycling - LCA Life Cycle Assessment = LCA Main idea – think of

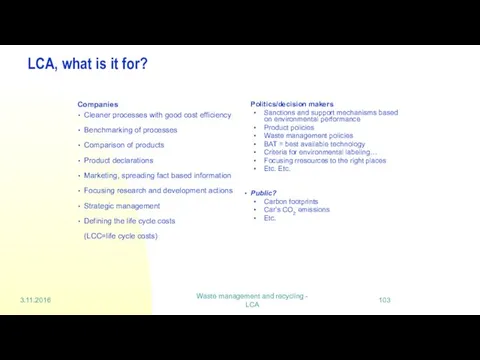

- 103. Waste management and recycling - LCA LCA, what is it for? Companies Cleaner processes with good

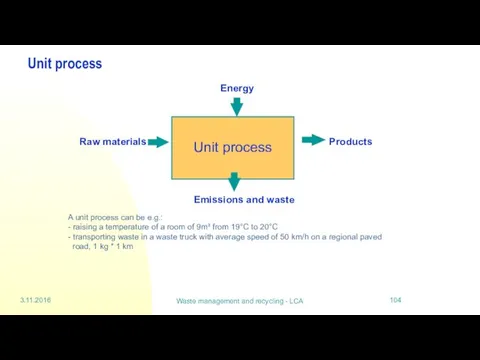

- 104. Waste management and recycling - LCA Unit process A unit process can be e.g.: - raising

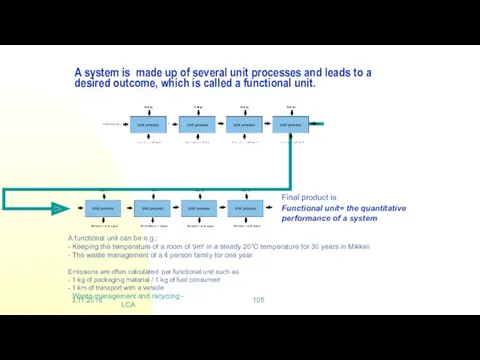

- 105. Waste management and recycling - LCA A system is made up of several unit processes and

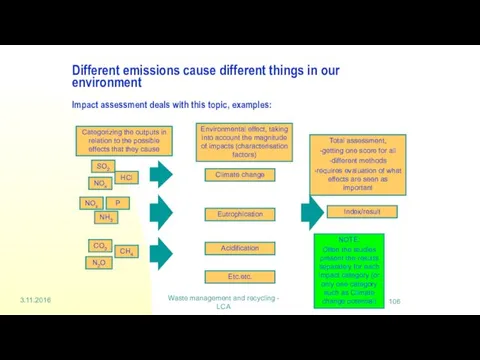

- 106. Waste management and recycling - LCA Different emissions cause different things in our environment Impact assessment

- 107. Waste management and recycling - LCA Impact assessment methods - Midpoint Methods are either Midpoint or

- 108. Waste management and recycling - LCA Impact assessment methods - Midpoint cont. Midpoint-oriented methods place indicators

- 110. Скачать презентацию

Гигиеническая характеристика основных методов очистки сточных вод

Гигиеническая характеристика основных методов очистки сточных вод Отчет о проведении краевой экологической акции Зеленая волна

Отчет о проведении краевой экологической акции Зеленая волна Охрана природы

Охрана природы How to save the Earth

How to save the Earth Вторая жизнь ненужных вещей

Вторая жизнь ненужных вещей Инженерная защита окружающей среды

Инженерная защита окружающей среды Мониторинг окружающей среды

Мониторинг окружающей среды Высокотоксичные соединения в атмосфере

Высокотоксичные соединения в атмосфере Мікологія та альгологія. Тема 4. Група відділів псевдогрибів

Мікологія та альгологія. Тема 4. Група відділів псевдогрибів Урок Без потерь. Фудшеринг и культура рационального потребления

Урок Без потерь. Фудшеринг и культура рационального потребления City Life and Country Life

City Life and Country Life Раздельный сбор мусора

Раздельный сбор мусора Современное состояние и рациональное использование почвенных ресурсов Белоруссии (лекция 3)

Современное состояние и рациональное использование почвенных ресурсов Белоруссии (лекция 3) Загрязнение Мирового океана

Загрязнение Мирового океана Влияние электричества и электростанций на окружающую среду

Влияние электричества и электростанций на окружающую среду Valsts, civilā un vides aizsardzība. Katastrofas, to iedalījums un veidi. Terorisms, cīņa ar terorismu

Valsts, civilā un vides aizsardzība. Katastrofas, to iedalījums un veidi. Terorisms, cīņa ar terorismu Экологические проблемы

Экологические проблемы 02.2022 Биология 11 класс

02.2022 Биология 11 класс ҚР зкологиялық дағдарыс және экологиялық апатты аймақтары

ҚР зкологиялық дағдарыс және экологиялық апатты аймақтары Қоршаған ортаның биологиялық ластануы және оның адам денсаулығына әсері

Қоршаған ортаның биологиялық ластануы және оның адам денсаулығына әсері Загрязнение Мирового океана

Загрязнение Мирового океана Лишайники, как индикатор загрязнения городской среды

Лишайники, как индикатор загрязнения городской среды Зеленая планета

Зеленая планета Правовые основы природопользования. Лекция 13

Правовые основы природопользования. Лекция 13 Альтернативное зелёное топливо

Альтернативное зелёное топливо Екологічні проблеми та їх розв’язування

Екологічні проблеми та їх розв’язування Ластану және қалдықтарды кәдеге жарату. Қолданыстан шыққан материалдарды қайта өңдеу мүмкіндіктері

Ластану және қалдықтарды кәдеге жарату. Қолданыстан шыққан материалдарды қайта өңдеу мүмкіндіктері Экологические основы безопасности жизнедеятельности человека в среде обитания. 10 класс

Экологические основы безопасности жизнедеятельности человека в среде обитания. 10 класс