Слайд 2

History

One of key priorities of the State Industrial and Innovative Policy

in Kazakhstan is to ensure processing and production of high value-added goods, works and services that underlines the importance of the mining and metallurgy industry development.

On July 3, 2012 an official capsule and first pile ceremony was held in the Industrial Part of the Astana – New City Special Economic Zone in Astana marking the commencement of the Gold Refinery construction by Tau-Ken Altyn LLP. On 19 December 2013 the Refinery was officially placed in service in presence of the Head of State. Its design capacity is 25 tons of gold and 50 tons of silver a year.

Слайд 3

Technical Control (TC)

Technical Control is one of the most critical divisions

of the Plant since control and adjustment of processes are exercised throughout all stages from acceptance of raw materials to release of finished products.

One of the main criteria for a successful refinery is to be recognized at the international market of precious metals. With this purpose TC has the most advanced metrology equipment including measuring instruments, test tools, tolerance control and make-to-order measurement instruments ensuring highly precise and accurate weighing, measuring and testing of materials containing precious metals with the weight starting at 0.001 g.

Слайд 4

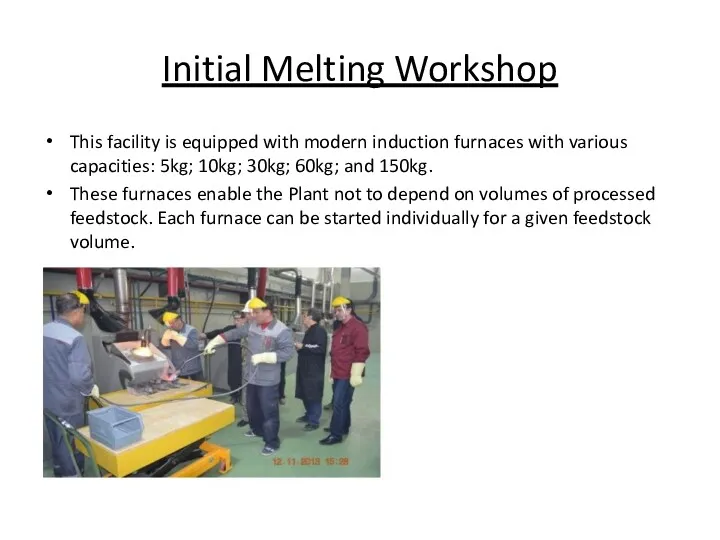

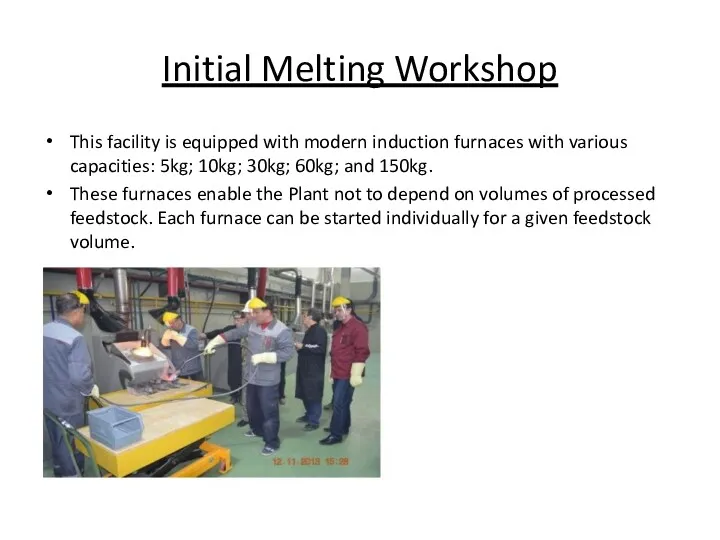

Initial Melting Workshop

This facility is equipped with modern induction furnaces with

various capacities: 5kg; 10kg; 30kg; 60kg; and 150kg.

These furnaces enable the Plant not to depend on volumes of processed feedstock. Each furnace can be started individually for a given feedstock volume.

Слайд 5

Their advantages:

Environmentally safe – each furnace has an individual aspiration system

preventing any emission of pollutants to the environment and the working area since all vapor is delivered to the filter;

Energy-saving – 10 times higher than similar analogues;

Compact size.

Workshop does:

– Initial melting of the feedstock and further correctional sampling and analyzing;

– Anode melting of silver for silver electrolysis workshop;

– Anode melting of gold for gold electrolysis workshop;

– slug treatment.

Слайд 6

Слайд 7

Silver electrolysis workshop

This facility has both main and auxiliary equipment. Electrolytic

cell is the main equipment with rectifier while the auxiliary equipment includes cementing units, filters and vacuum system for sludge pumping.

Basic products of the silver electrolysis shop include cathode silver CpA-1 with 99.99% purity and other products of the electrolytic process.

The electrolytic cell is made of polypropylene, a dielectric and chemically resistant material.

The Cell is fitted with stainless steel cathodes and stainless steel frames for anodes with filter bags to collect anode sludge generated from the electrolytic refining of silver.

Слайд 8

Gold Electrolytic Workshop

Electrolytic refining of gold provides for a highly pure

product . This facility is designed to produce cathode gold meeting quality standards.

The workshop is based on electrolytic units each consisting of separate and independently operated cells. The equipment material is polypropylene ensuring a longer service life due to its resistance to acids and various environmental factors. A distinctive feature of this equipment is its absolute environmental safety thanks to aspiration systems in each element of the equipment. All evaporation resulted from the electrolytic process is trapped by aspiration system towers that automatically neutralize it using caustic soda ensuring 99% treatment. Only after that the clean air is released. A separate rectifier for each electrolytic unit, enabling to operate a required number of electrolytic cells depending on the composition and amount of the feedstock.

Слайд 9

Gold and Silver Granulation Furnaces

Static induction melting furnace for production of

granules from alloys of precious metals in the graphite crucible equipped with the automatic temperature regulator. The temperature is controlled automatically by the temperature regulator built in the microprocessor. The furnace control is exercised from the microprocessor-based control panel.

Advantages:

Lesser melting duration thanks to the new technology applied;

Compact size;

No electromagnetic impact;

Low noise.

Слайд 10

FLAMELESS TUNNEL FURNACE for production of standard gold and silver bars and

weighed bars

Слайд 11

Tunnel furnace is an innovation patented by IECO, an Italian company.

Advantages:

Environmentally

safe;

Energy saving;

No extra treatment required;

No loss;

Safe operation;

Fully automated.

It should be noted that all equipment is manufactured in accordance with EU technical standards and adapted to Kazakhstan standards.

Слайд 12

Management of bulls for reproductive and economic success

Management of bulls for reproductive and economic success Экономика. Внешние эффекты

Экономика. Внешние эффекты Отношения собственности и их роль в экономике

Отношения собственности и их роль в экономике Рыночная экономика

Рыночная экономика Соціальні цілі економіки. (Лекція 2)

Соціальні цілі економіки. (Лекція 2) Сущность этики бизнеса

Сущность этики бизнеса Социально-экономическая организация

Социально-экономическая организация Стратегия социально-экономического развития РФ

Стратегия социально-экономического развития РФ Анализ и оценка инновационной составляющей человеческого капитала Краснодарского края

Анализ и оценка инновационной составляющей человеческого капитала Краснодарского края Измерение миграции: международная практика и рекомендации для РФ

Измерение миграции: международная практика и рекомендации для РФ Финансовая система в Республике Казахстан

Финансовая система в Республике Казахстан Экономика и её основные участники

Экономика и её основные участники Проблема монополизации рынков в России

Проблема монополизации рынков в России О реализации мер по обеспечению доступа негосударственных организаций к предоставлению услуг в социальной сфере

О реализации мер по обеспечению доступа негосударственных организаций к предоставлению услуг в социальной сфере Интераактивная игра. Семейный бюджет

Интераактивная игра. Семейный бюджет Производство: затраты, выручка, прибыль

Производство: затраты, выручка, прибыль Економіка праці та соціальнотрудові відносини. Оплата праці. (Лекція 6)

Економіка праці та соціальнотрудові відносини. Оплата праці. (Лекція 6) Предпринимательство и его роль в экономике

Предпринимательство и его роль в экономике Основные понятия и категории анализа данных. (Лекция 1)

Основные понятия и категории анализа данных. (Лекция 1) Дүниежүзілік сауда ұйымы

Дүниежүзілік сауда ұйымы Заработная плата, как экономическая категория

Заработная плата, как экономическая категория Классическая рыночная модель

Классическая рыночная модель Ломоносовские идеи и геополитика

Ломоносовские идеи и геополитика Цифровая трансформация национальной экономики Беларуси

Цифровая трансформация национальной экономики Беларуси Формирование новой модели мирового экономического развития

Формирование новой модели мирового экономического развития Реализация государственной молодежной политики в Пермском Крае

Реализация государственной молодежной политики в Пермском Крае Производство. Понятие. Основные элементы. Типы производств. Эффективность производства. Издержки производства

Производство. Понятие. Основные элементы. Типы производств. Эффективность производства. Издержки производства Об участии Республики Башкортостан в реализации национальных проектов

Об участии Республики Башкортостан в реализации национальных проектов