Содержание

- 2. Introduction Instructor Introduction ISM/CM 570 Course Defined Course times 09.00 - 12.00 13.00 - 17.00 No

- 3. Introduction Lunch Vouchers WC Location Fire Alarms/Exits Safety - (Glasses & Ear Defenders to be worn

- 4. Day 1 Introduction ISM Engine Overview ISM wiring diagram Overview Component Location & Identification (On Engine)

- 5. Day 2 Review of Monday CM 570 Electronic Features & Controls CD ROM Learning PC Based

- 6. Day 3 Review of Tuesday Agenda continued from Tuesday CM 570 Electronic Features & Controls Complete

- 7. Day 4 Review of Wednesday J1587/1708 & J1939 Review INLINE 1 & 2 Adaptors - Functionality

- 8. Day 5 Review of Thursday INSITE Competency Test (90% Min.Pass Mark) 1 Hour per person Use

- 9. Aim Introduce ISM Build On Existing M11 Plus Experience Review CM 570 with New Features &

- 10. Objective The ISM engine has built on the success of the M11 Plus engine and has

- 11. What Does ‘IS’ stand for? Traditionally engines operated separately from Transmissions, Brake systems etc. The Interact

- 12. ISM/CM 570 Controller ISM Evolution Strategy Original Platform - began in 1982 M11 launched in 1994

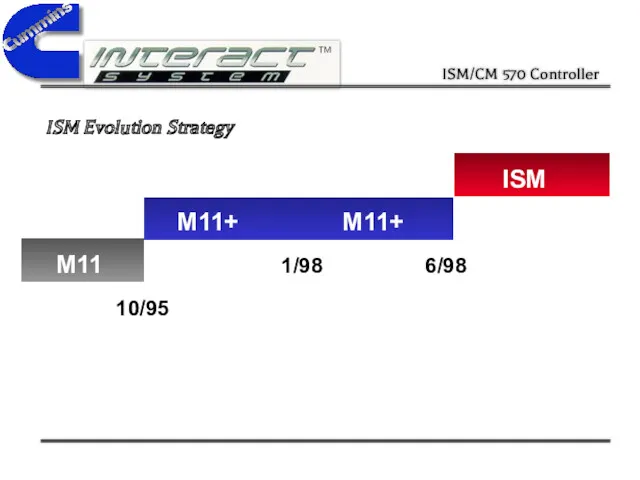

- 13. ISM Evolution Strategy 1/98 6/98 M11+ M11+ ISM M11 10/95

- 14. Evolution of the ISM Hardware improvements (internal and external) over M11 All new engine control Module

- 15. ISM at a glance Dry Weight 2114 lbs. Oil capacity 10.3 US Galls. HP Range 280

- 16. Specifications

- 17. CM 570 ECM

- 18. ECM 570 Most advanced and capable system available in the market today State-of-the art hardware platform

- 19. ECM 570 Polymoid plastic film board Motorola 68332, 32 Bit processor, 16MHz 128Kb Ram 8Kb EEPROM

- 20. ECM 570 10 x Greater capacity and processing power over Celect Plus ECM C 150 Pins

- 21. Programmable Features & Parameters An opportunity Enhance customer flexibility Improved vehicle integration

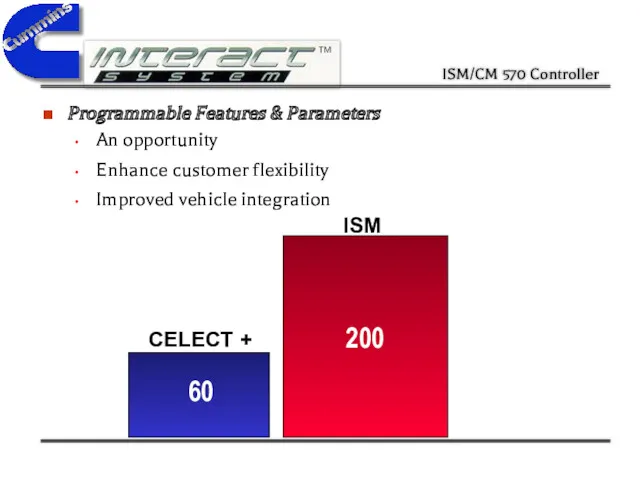

- 22. ECM 570 New Sensor Technology Software Information Systems J1939 Datalink Module Design: Thinner Lighter 150 pins

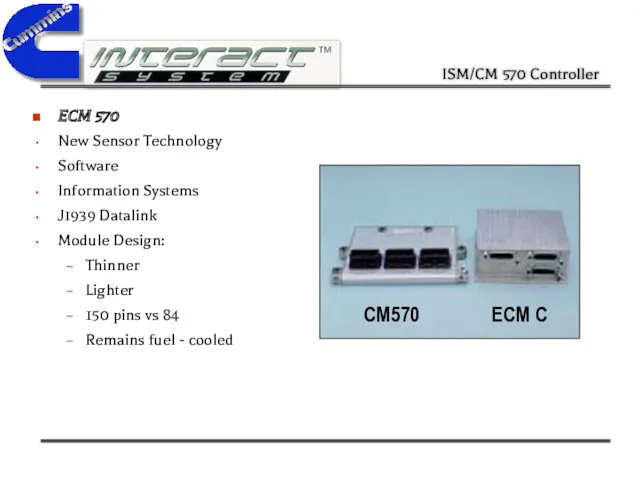

- 23. ECM High Mount Mounts over air compressor at front of engine Improved accessibility for many chassis

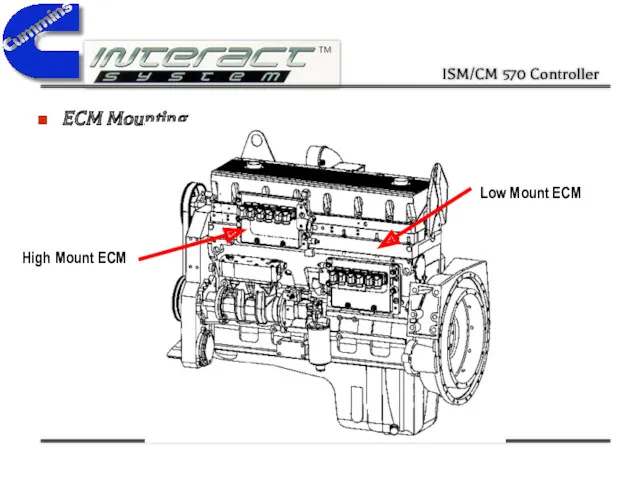

- 24. ECM Mounting Low Mount ECM High Mount ECM

- 25. ECM

- 26. SENSORS

- 27. Combination Sensor Sealed sensors eliminate water intrusion Improves reliability Combined temp and pressure for reduced number

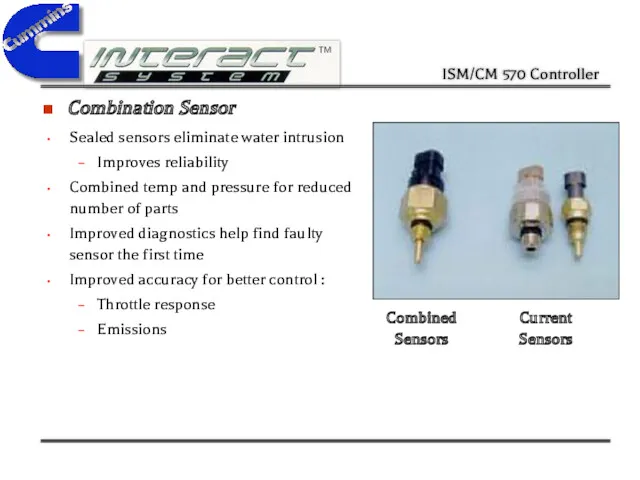

- 28. Combination Sensor Combination oil pressure/Temperature sensor introduced Relocated to accessory drive area for improved serviceability

- 29. Sensors Installed in main oil rifle Sensor input signals utilised for engine protection system Four pin

- 30. Sensors Bracket mounted Located close to rear of fuel pump Same sensor location for low and

- 31. Sensors Relocated in intake manifold Sensor input signals utilised for engine protection system Signal utilised for

- 32. Sensors Integral WIF sensor in filter body Senses water level in base of filter

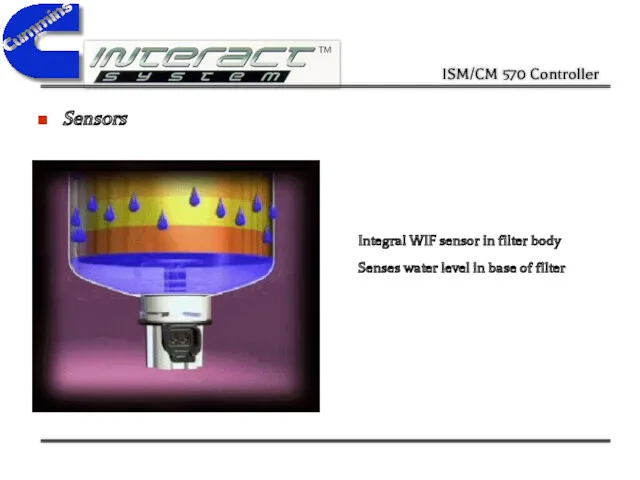

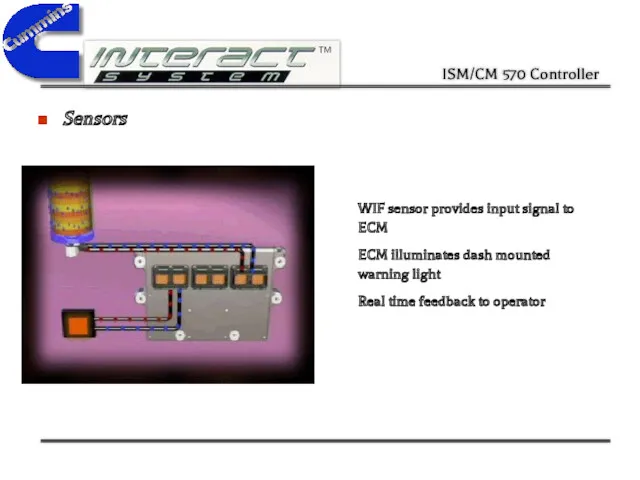

- 33. Sensors WIF sensor provides input signal to ECM ECM illuminates dash mounted warning light Real time

- 34. Oil System

- 35. Industry-Leading Cummins next generation filtration technology ISM Signature 600 Longer life Stratapore media capable of extended

- 36. What does it do?? Generates flow through the highly efficient/restrictive bypass media. How does it do

- 37. Lubricating Oil Filter Combined full flow and bypass filter Extension of oil and filter change intervals

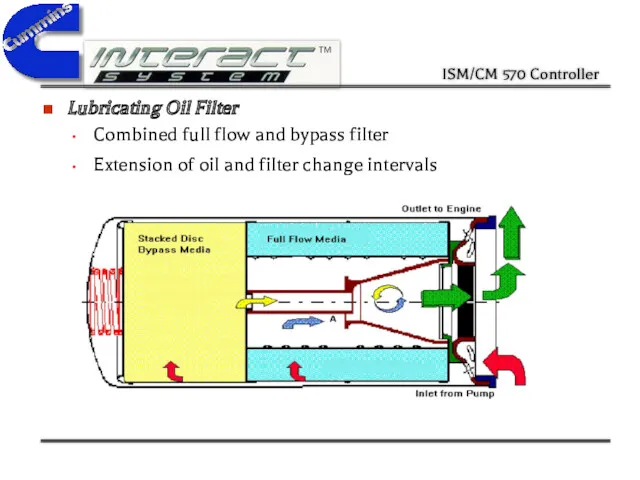

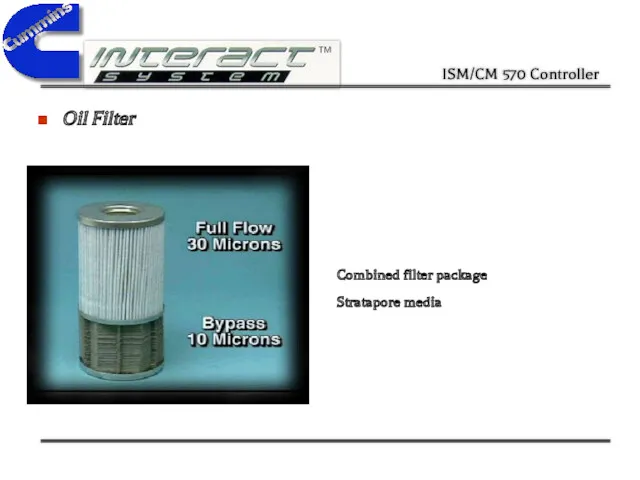

- 38. Lubricating Oil Filter - Media

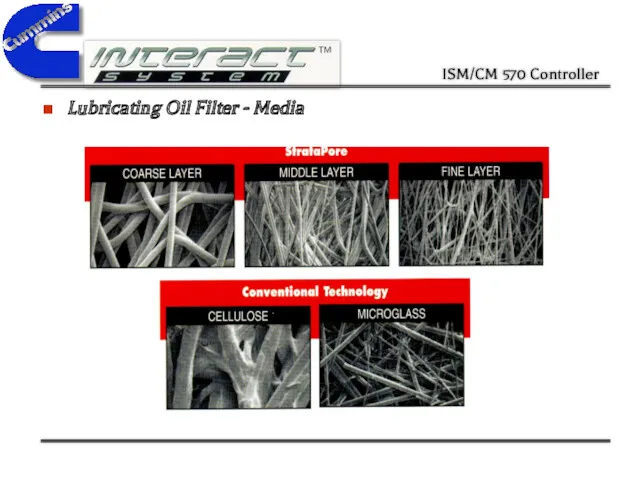

- 39. Oil Filter Stratapore media Multi layer design Maximum dirt holding capacity High efficiency Less restriction to

- 40. Oil Filter Combined filter package Stratapore media

- 41. Oil Filter By pass return circuit eliminated Increased by- pass flow compared to LF 3000 More

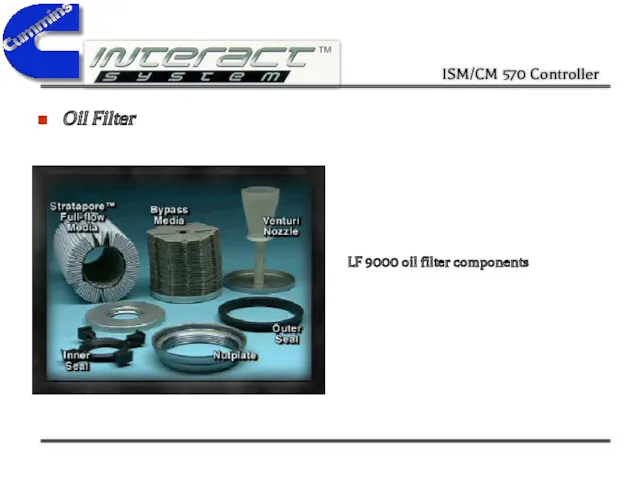

- 42. Oil Filter LF 9000 oil filter components

- 43. Oil Filter LF 9000 series filters Two inches longer than M11 filter Not interchangeable with LF

- 44. Fuel System

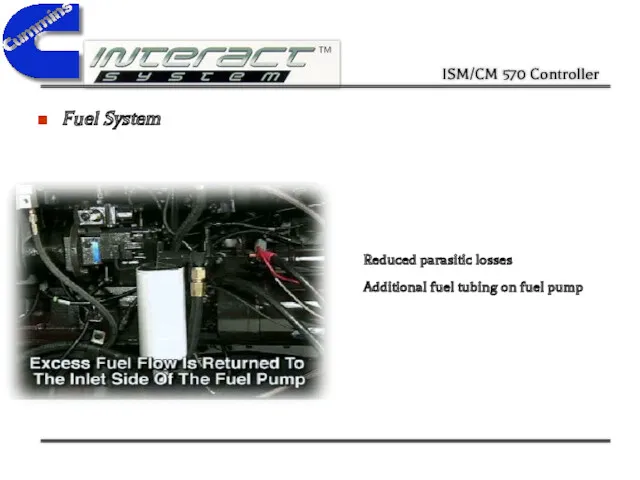

- 45. Fuel System Regulated fuel pressure Positive displacement Relatively constant pressure to injectors from low idle to

- 46. Fuel System Reduced parasitic losses Additional fuel tubing on fuel pump

- 47. Fuel System Re designed to for increased fuel flow Larger spray holes compared to M11 Plus

- 48. Fuel System Fleetguard FS 1003 filter Stratapore filter media Specific design for component protection 98.7% efficient

- 49. Fuel System Internal Suction tube Central Location Fuel Drawn from lower Level Quicker engine starts Prevents

- 50. Drive Belt

- 51. Auto Tensioning Belt Option One belt drives both fan and alternator Increased power capacity Reduced maintenance

- 52. Auto Tensioning Belt Option

- 53. Drive Belt

- 54. Internal/External Components

- 55. Camshaft - Full Time Double Pulse Redesigned injector cam lobe combined with the increased processing power

- 56. Piston Crown Re designed piston bowl Matches injector design features High quality forged steel crown Resists

- 57. Oil Control Ring Redesigned piston ring pack Improved oil control New expander Lower tension Narrow rails

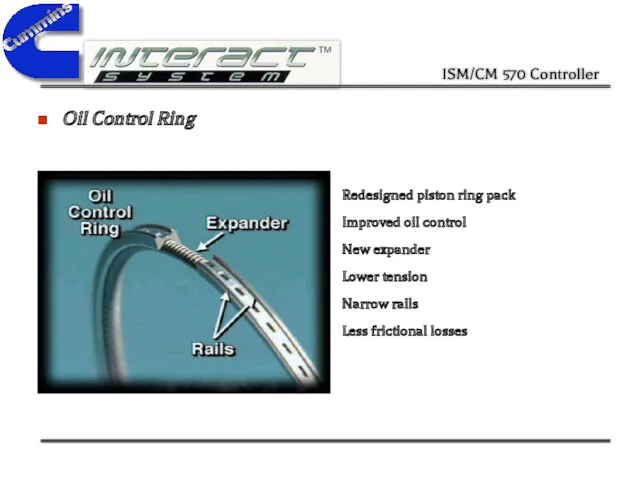

- 58. Valve Rocker Levers Cast steel construction Right hand and left hand levers Integral replaceable bushing

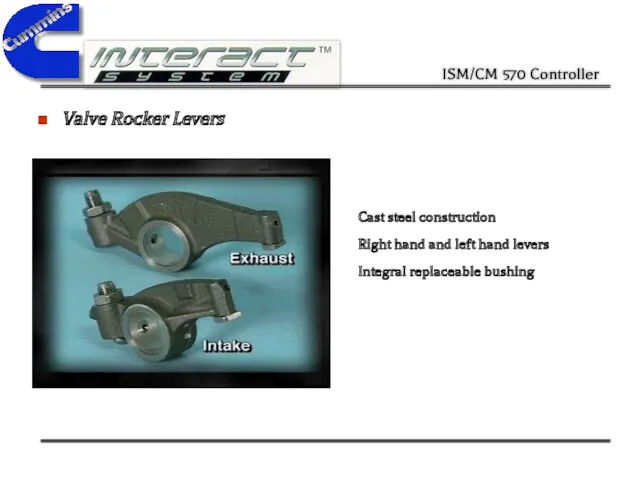

- 59. Valve Rocker Levers Integral nose pad in both levers Increased durability Open oil drilling Lubrication to

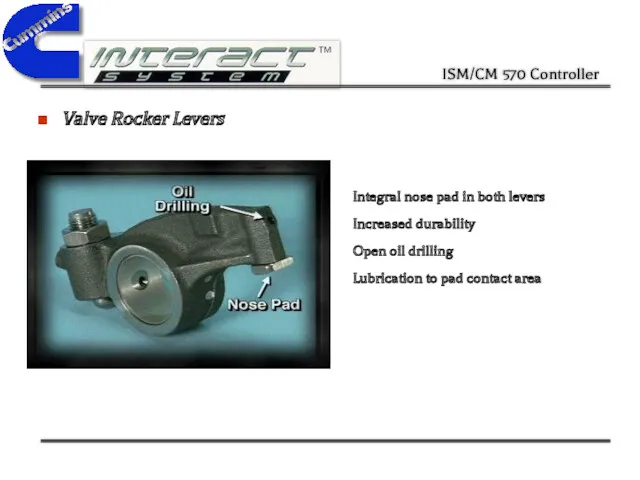

- 60. Injector Rocker Lever High quality forged steel construction Maximum strength and reliability Incorporates replaceable bushing Drilled

- 61. Oil Capacitors Integral with block casting Slows return oil flow back to pan Same oil capacity

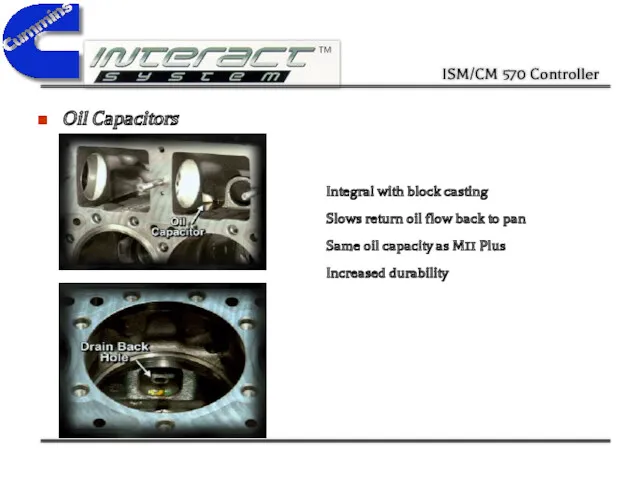

- 62. Oil Capacitor Oil Stored below Camshaft Oil stored in valley below camshaft Lowers oil pan level

- 63. Turbocharger Located on top of air intake manifold Available with new HX 55 Holset turbo Fitted

- 64. Turbocharger Four orifice flow device Two solenoid valves ECM controlled Controls signal to wastegate canister

- 65. Air Compressor Air compressor ‘Smart Governor’ Improved fuel efficiency ECM monitors vehicle air system pressure ECM

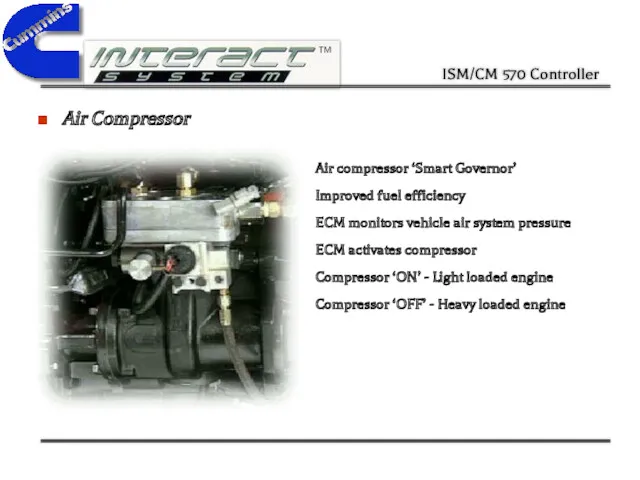

- 66. Vibration Damper Upgraded vibration damper Up to 440 hp at rated speed Reduced torsional vibrations Increased

- 67. Thermostat Improved seal Better sealing between thermostat and seal face

- 68. Valve Cover New internal breather system developed for the ISM Eliminate oil carryover Breather tube routes

- 70. Скачать презентацию

Фотоэффект. Уравнение Эйнштейна для фотоэффекта. Фотоны. Давление света. Эффект Комптона

Фотоэффект. Уравнение Эйнштейна для фотоэффекта. Фотоны. Давление света. Эффект Комптона Ядерные реакции

Ядерные реакции Солнечная установка для получения электрической энергии и горячей воды

Солнечная установка для получения электрической энергии и горячей воды Требования к видимости на дорогах. Торможение автомобиля

Требования к видимости на дорогах. Торможение автомобиля Технологиялық жабдықтарды майлау. Жағармайды таңдау

Технологиялық жабдықтарды майлау. Жағармайды таңдау Электрич ток в проводниках ТОР 21-1

Электрич ток в проводниках ТОР 21-1 Тема:Влажность воздуха. Для подготовки учащихся 11 классов при сдаче ЕГЭ

Тема:Влажность воздуха. Для подготовки учащихся 11 классов при сдаче ЕГЭ Air Compressor Lubrication

Air Compressor Lubrication Тепловые явления.

Тепловые явления. внеклассное мероприятие Как сберечь воду и уменьшить ее загрязнение для учащихся 6-7 классов

внеклассное мероприятие Как сберечь воду и уменьшить ее загрязнение для учащихся 6-7 классов Прямолінійний рівномірний рух

Прямолінійний рівномірний рух Есептеу әдістемесі мен механикалық құралжабдықтарды таңдау

Есептеу әдістемесі мен механикалық құралжабдықтарды таңдау Давление в жидкости и газе. Решение задач

Давление в жидкости и газе. Решение задач Измерение физической величины (Лекция № 6)

Измерение физической величины (Лекция № 6) Движение с постоянным ускорением

Движение с постоянным ускорением Масс-спектрометрия с индуктивно связанной плазмой (ИСП-МС)

Масс-спектрометрия с индуктивно связанной плазмой (ИСП-МС) М.В. Ломоносов в области физики и астрономии

М.В. Ломоносов в области физики и астрономии Внеклассное мероприятие по физике для 10 - 11 классов Звездный час.

Внеклассное мероприятие по физике для 10 - 11 классов Звездный час. Физика колебаний и волн

Физика колебаний и волн Конденсаторы. Электрическая емкость

Конденсаторы. Электрическая емкость Металлорежущие станки и станочные комплексы. Общие сведения и механизмы станков. (Темы 1 и 2)

Металлорежущие станки и станочные комплексы. Общие сведения и механизмы станков. (Темы 1 и 2) КРД, engine indicating, тахометры

КРД, engine indicating, тахометры Топливные форсунки автомобиля

Топливные форсунки автомобиля Решение задач. Магнитное поле и проводник с током

Решение задач. Магнитное поле и проводник с током Презентация по физике для 8 класса - своя игра по теме Электричество

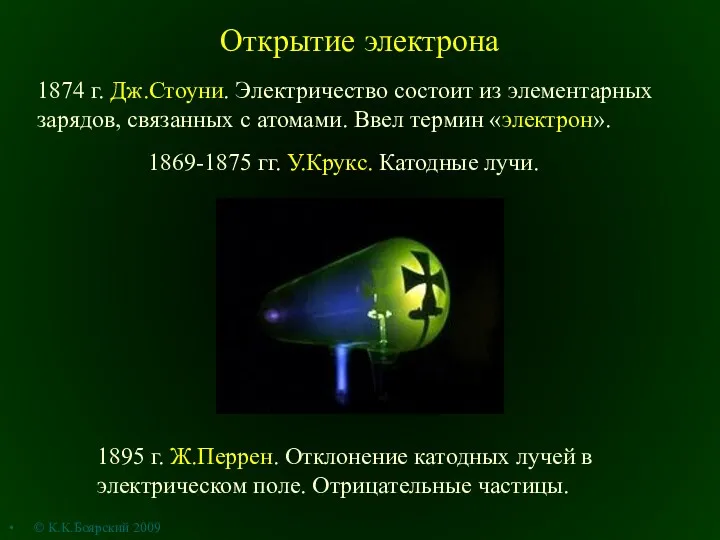

Презентация по физике для 8 класса - своя игра по теме Электричество Открытие электрона

Открытие электрона Работа и мощность электрического тока

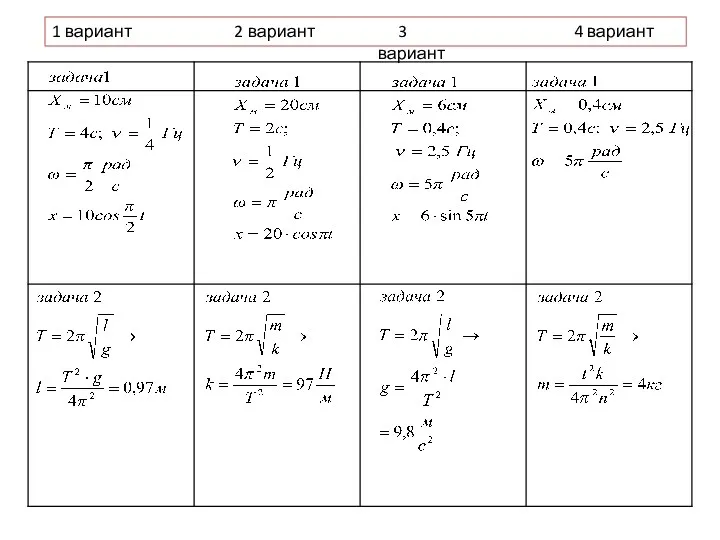

Работа и мощность электрического тока Урок физики в 11 классе Определение ускорения свободного падения лабораторная работа

Урок физики в 11 классе Определение ускорения свободного падения лабораторная работа