Содержание

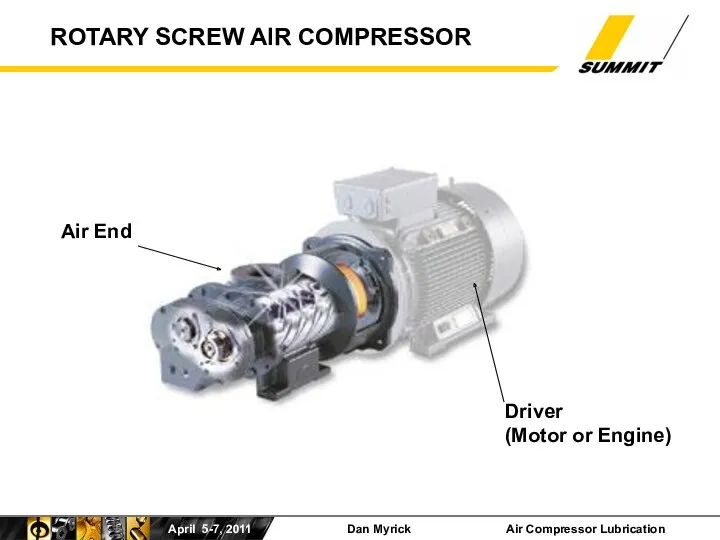

- 2. ROTARY SCREW AIR COMPRESSOR Air End Driver (Motor or Engine)

- 3. ROTARY SCREW COMPRESSOR AIR END

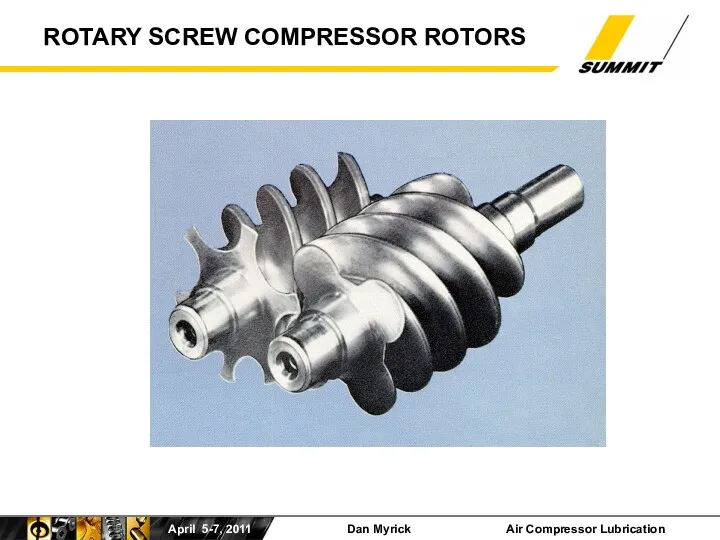

- 4. ROTARY SCREW COMPRESSOR ROTORS

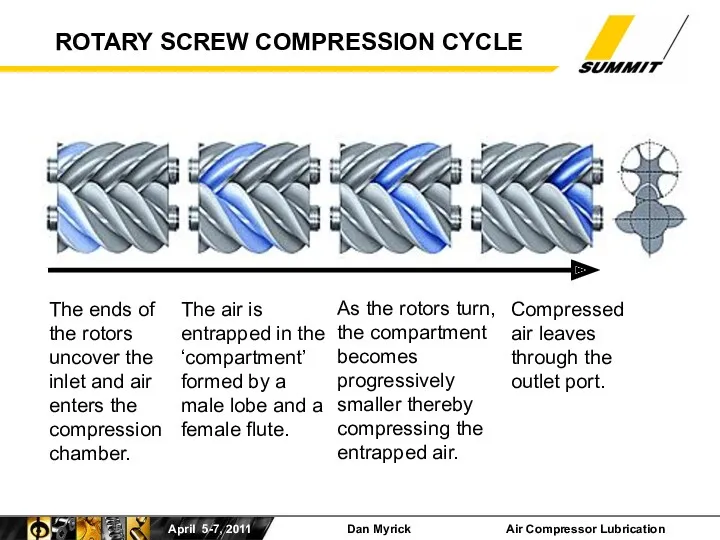

- 5. The ends of the rotors uncover the inlet and air enters the compression chamber. The air

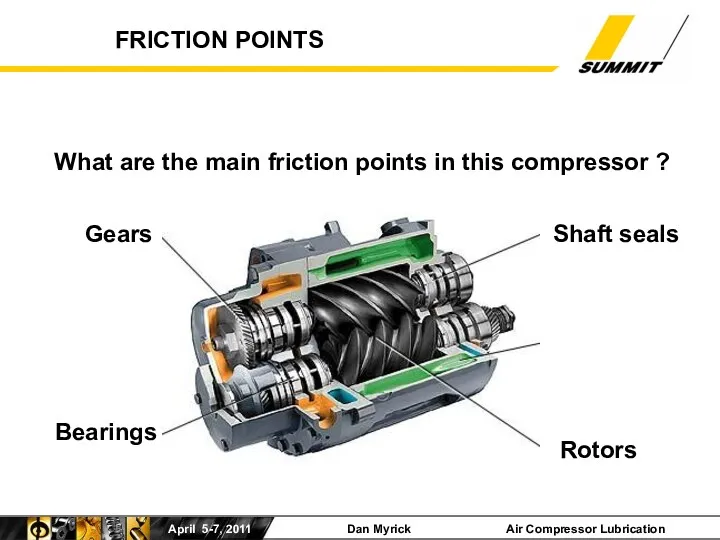

- 6. Gears Bearings Shaft seals Rotors What are the main friction points in this compressor ? FRICTION

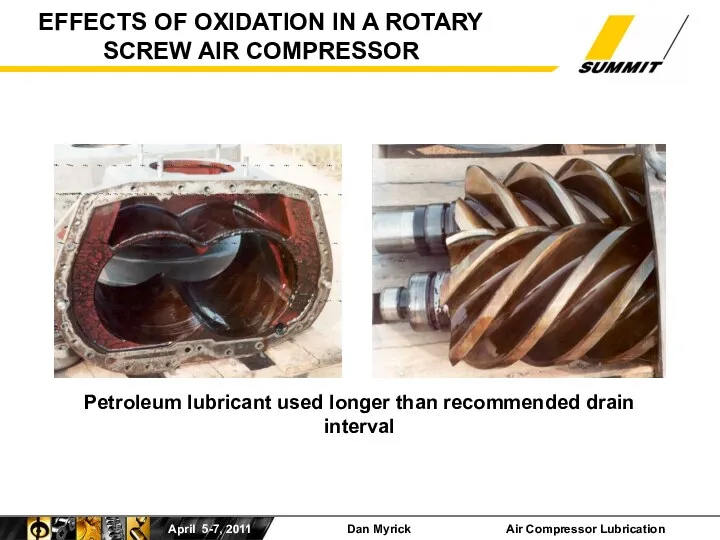

- 8. EFFECTS OF OXIDATION IN A ROTARY SCREW AIR COMPRESSOR Petroleum lubricant used longer than recommended drain

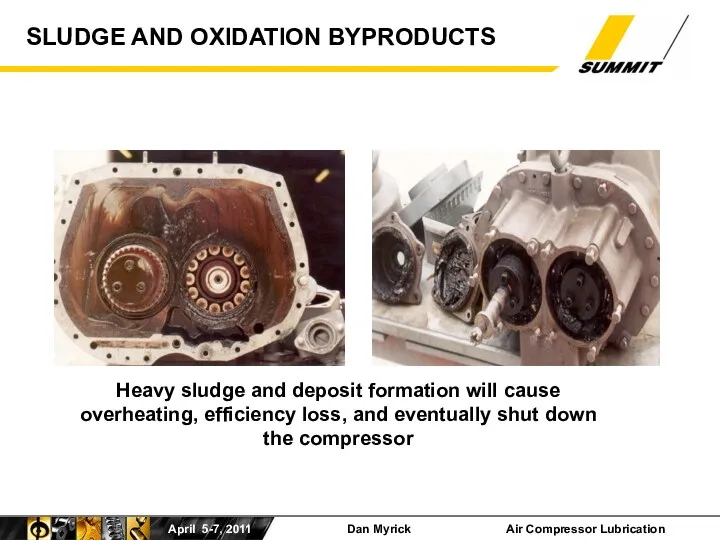

- 9. SLUDGE AND OXIDATION BYPRODUCTS Heavy sludge and deposit formation will cause overheating, efficiency loss, and eventually

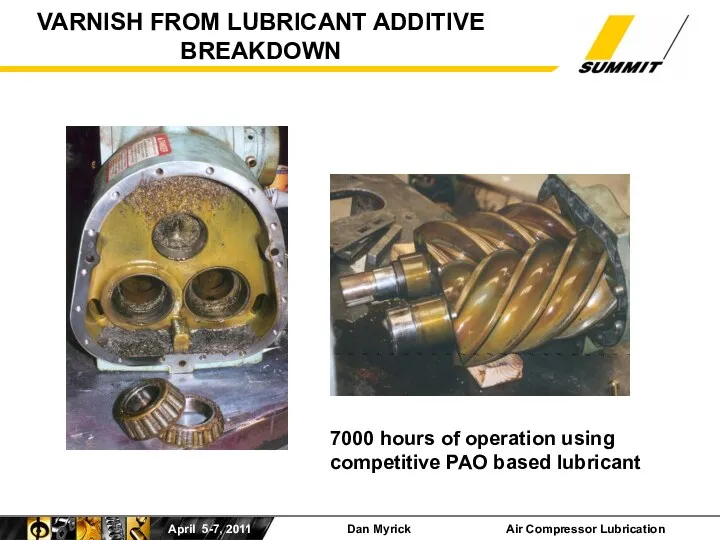

- 10. VARNISH FROM LUBRICANT ADDITIVE BREAKDOWN 7000 hours of operation using competitive PAO based lubricant

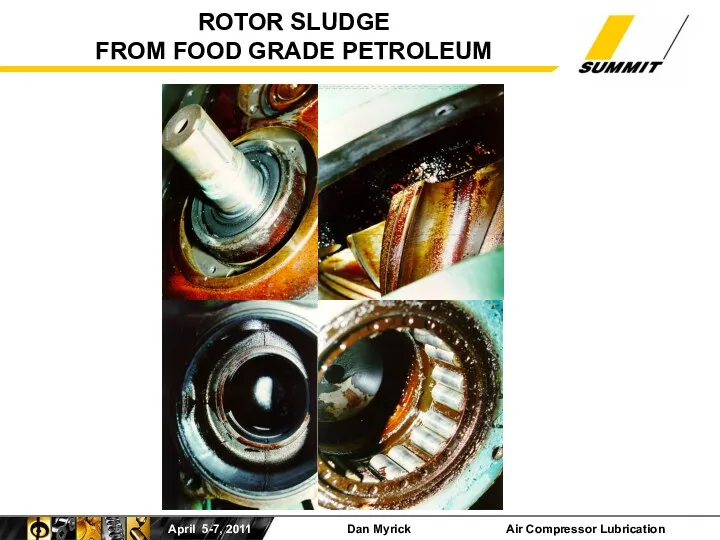

- 11. ROTOR SLUDGE FROM FOOD GRADE PETROLEUM

- 12. SEPARATOR PLUGGING An improperly formulated synthetic compressor lubricant was the cause of this plugged separator

- 13. DEPOSIT FREE OPERATION Sullair compressor after 10,000 hours using Summit SH-32

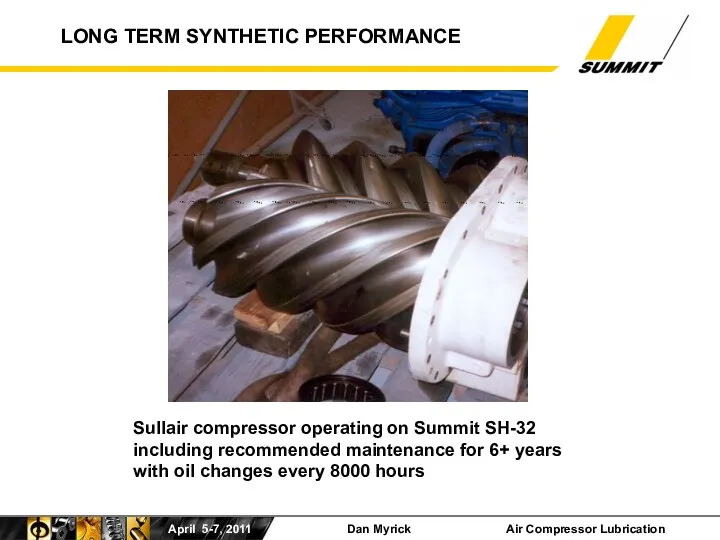

- 14. LONG TERM SYNTHETIC PERFORMANCE Sullair compressor operating on Summit SH-32 including recommended maintenance for 6+ years

- 15. 1. Extended oil service life of 8000+ hours 2. Reduced formation of sludge, varnish and carbonaceous

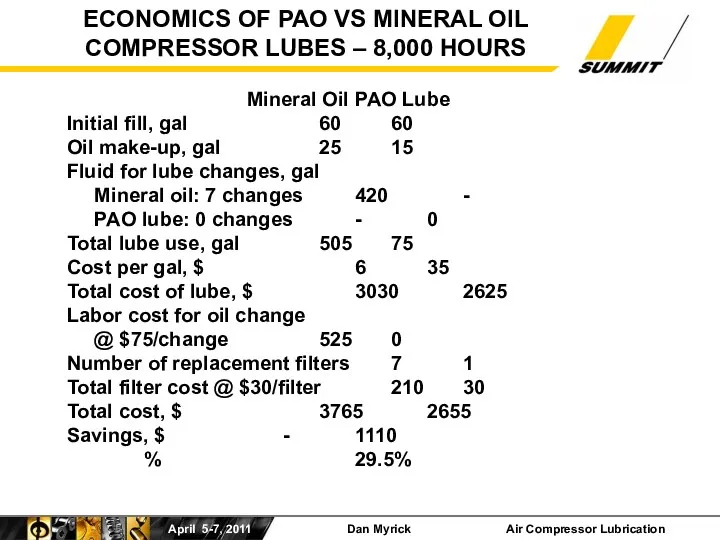

- 16. ECONOMICS OF PAO VS MINERAL OIL COMPRESSOR LUBES – 8,000 HOURS Mineral Oil PAO Lube Initial

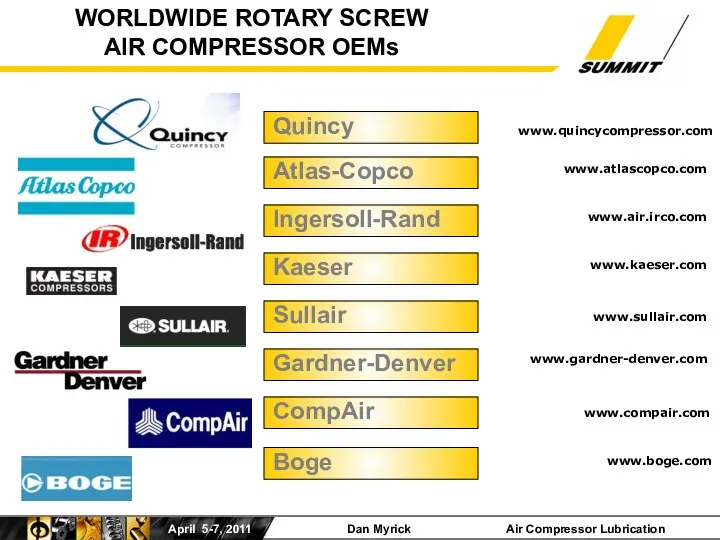

- 17. www.atlascopco.com www.air.irco.com www.kaeser.com www.sullair.com www.gardner-denver.com www.compair.com www.boge.com WORLDWIDE ROTARY SCREW AIR COMPRESSOR OEMs www.quincycompressor.com

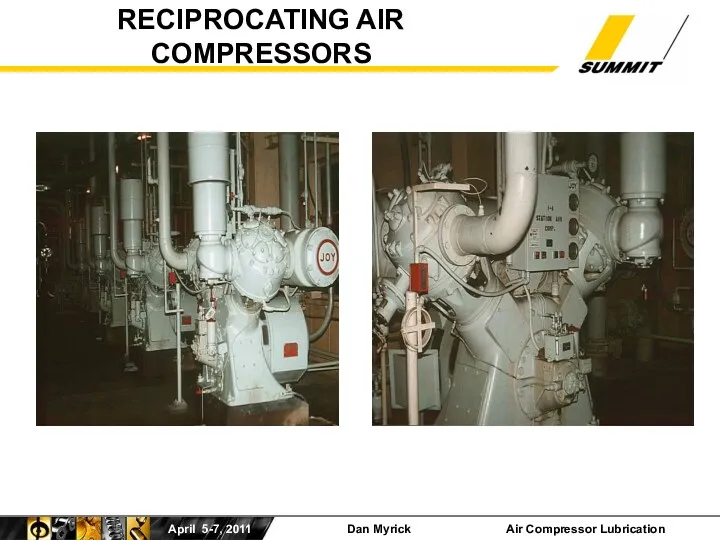

- 18. RECIPROCATING AIR COMPRESSORS

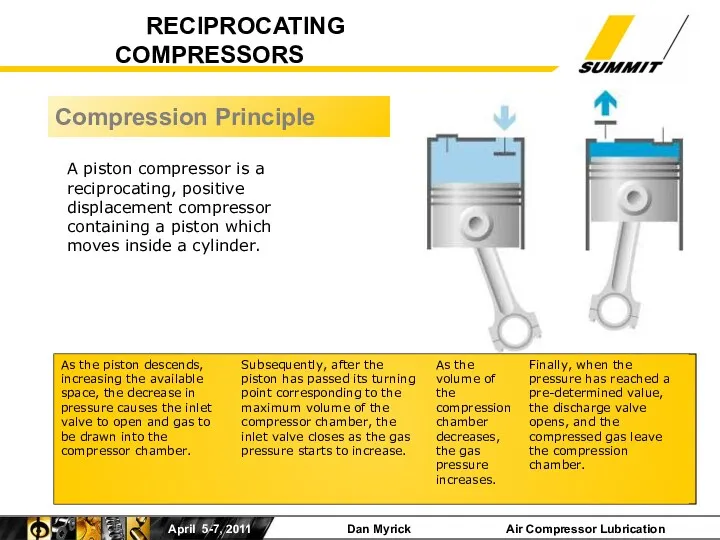

- 19. A piston compressor is a reciprocating, positive displacement compressor containing a piston which moves inside a

- 20. RECIPROCATING COMPRESSOR TYPES Single Acting Double Acting Multi-Stage Different Lubrication Methods

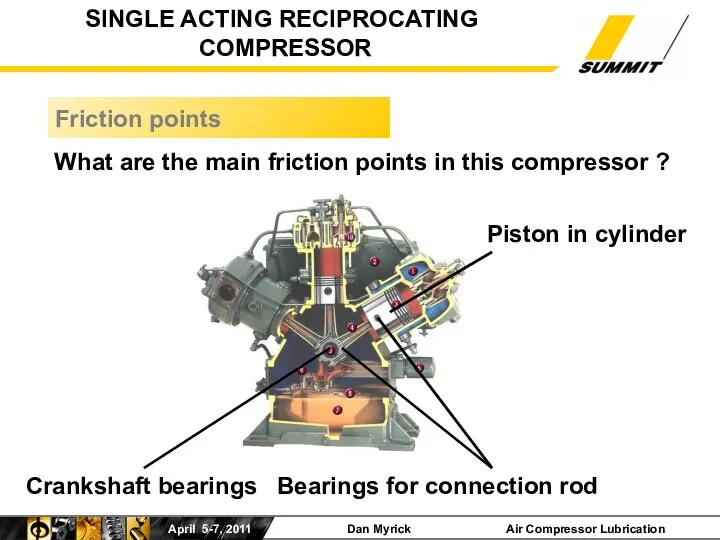

- 21. What are the main friction points in this compressor ? Friction points SINGLE ACTING RECIPROCATING COMPRESSOR

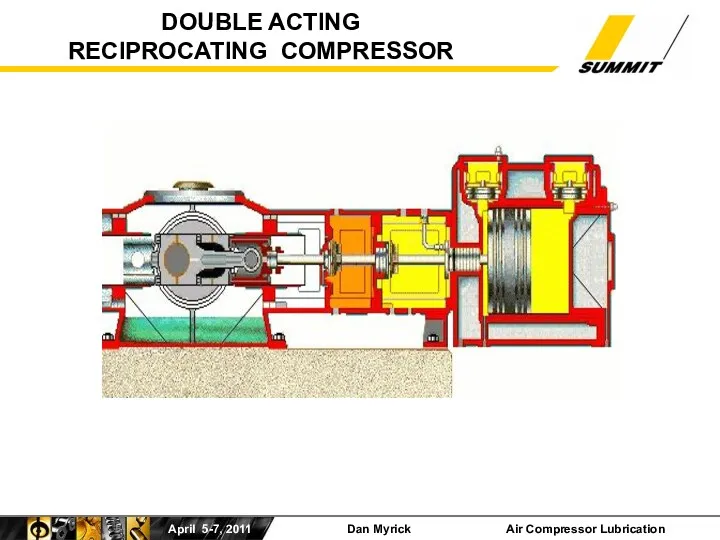

- 22. DOUBLE ACTING RECIPROCATING COMPRESSOR

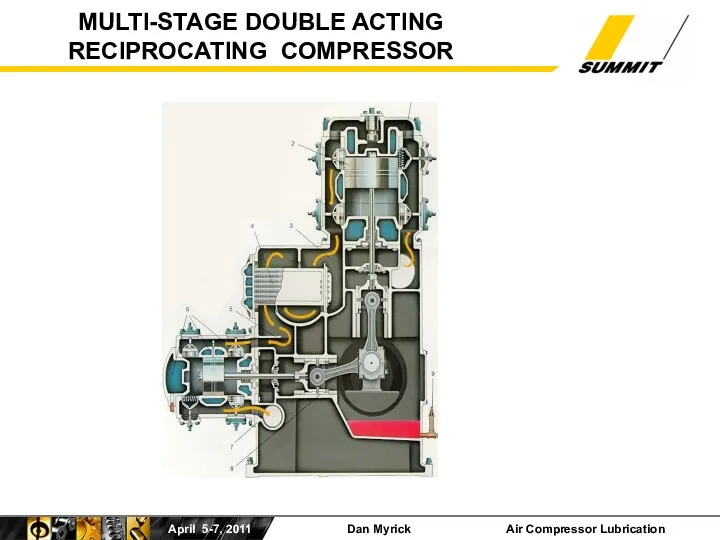

- 23. MULTI-STAGE DOUBLE ACTING RECIPROCATING COMPRESSOR

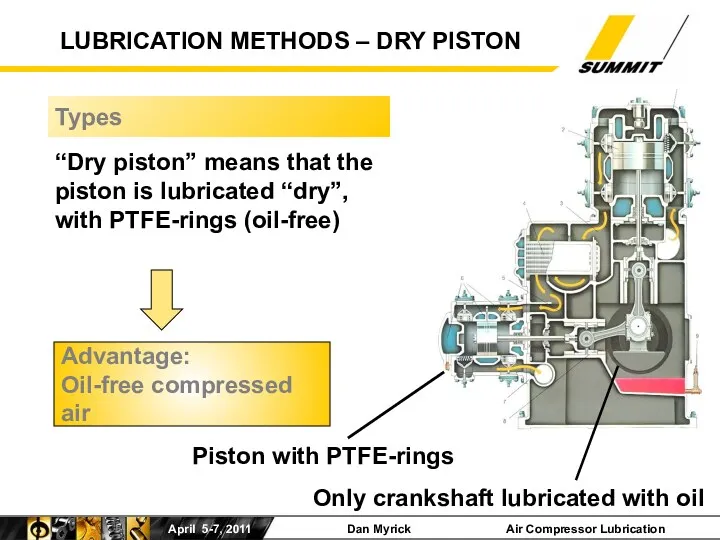

- 24. “Dry piston” means that the piston is lubricated “dry”, with PTFE-rings (oil-free) Types LUBRICATION METHODS –

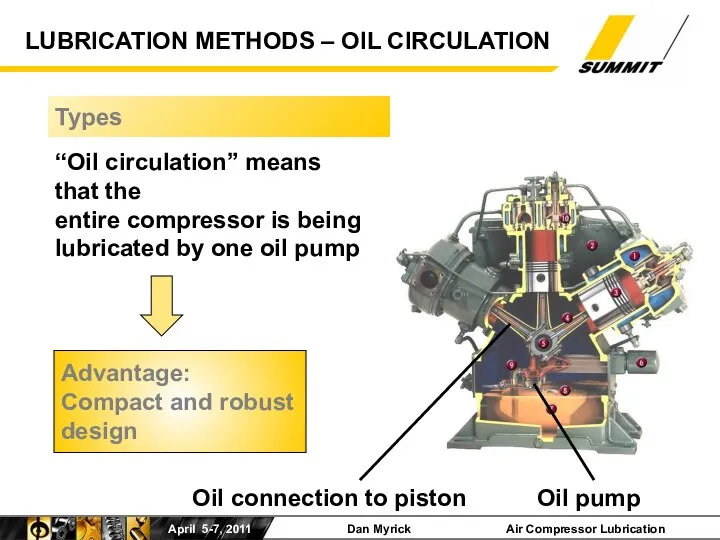

- 25. “Oil circulation” means that the entire compressor is being lubricated by one oil pump Types LUBRICATION

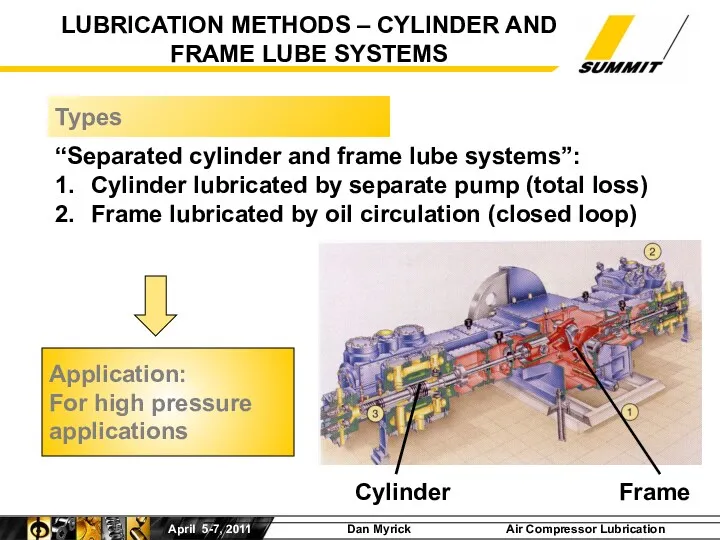

- 26. “Separated cylinder and frame lube systems”: 1. Cylinder lubricated by separate pump (total loss) 2. Frame

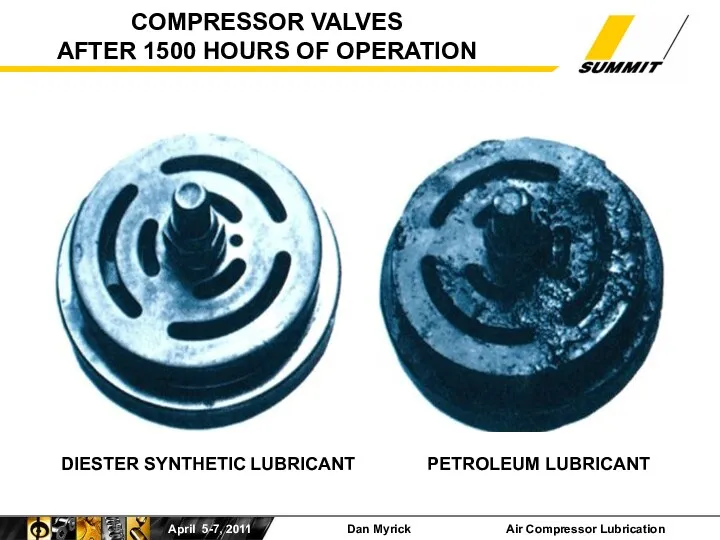

- 27. COMPRESSOR VALVES AFTER 1500 HOURS OF OPERATION PETROLEUM LUBRICANT DIESTER SYNTHETIC LUBRICANT

- 28. HYDROGEN COMPRESSOR VALVE USING PETROLEUM LUBRICANT

- 29. VALVE PROBLEMS? WE DON’T HAVE ANY VALVE PROBLEMS!

- 30. BENEFITS OF USING SYNTHETICS IN RECIPROCATING AIR COMPRESSORS Reduced carbon deposits on compressor valves resulting in

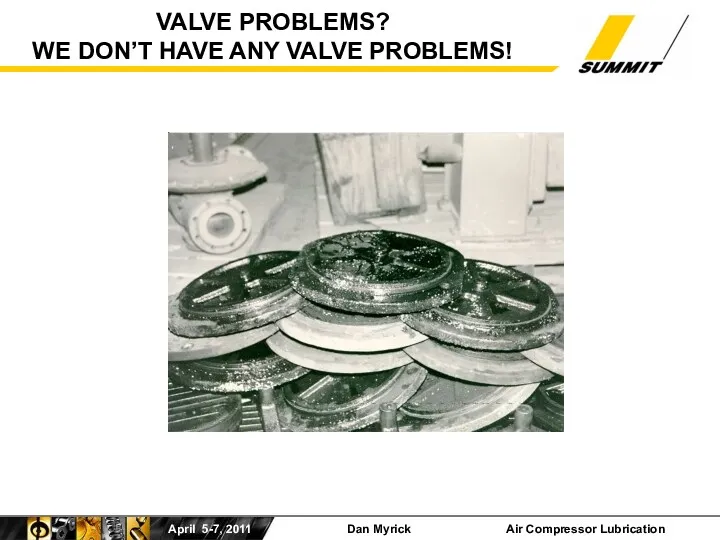

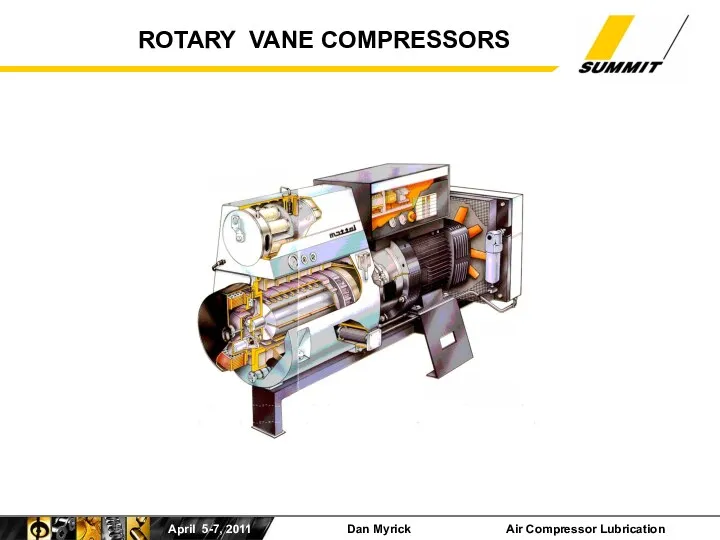

- 31. ROTARY VANE COMPRESSORS

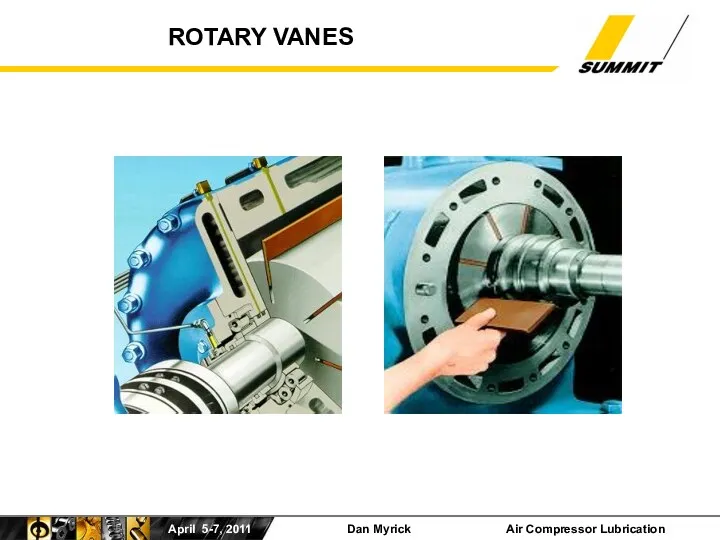

- 33. ROTARY VANES

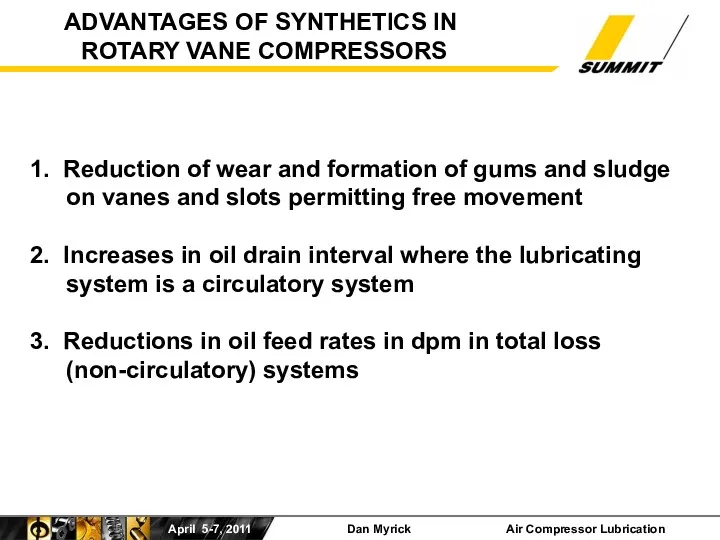

- 34. 1. Reduction of wear and formation of gums and sludge on vanes and slots permitting free

- 35. CENTRIFUGAL COMPRESSORS

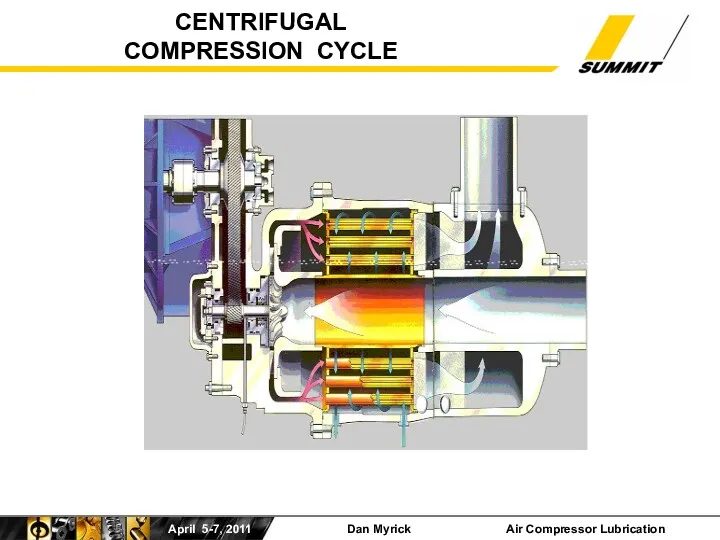

- 36. CENTRIFUGAL COMPRESSION CYCLE

- 37. MULTI-STAGE CENTRIFUGAL COMPRESSORS

- 38. CENTRIFUGAL COMPRESSOR PARTS

- 39. BENEFITS OF SYNTHETIC LUBRICANTS IN CENTRIFUGAL COMPRESSORS Energy efficiency Bearing life The lubricant does not contact

- 41. Скачать презентацию

Термодинамика. Теплота

Термодинамика. Теплота Диффузия примесей. Практическое занятие №7

Диффузия примесей. Практическое занятие №7 Барометрическая формула. (Лекция 6)

Барометрическая формула. (Лекция 6) Рекомендации по выбору посадок

Рекомендации по выбору посадок Образование гидридов

Образование гидридов Скорость испарения воды. Опыты

Скорость испарения воды. Опыты Прямолинейные колебания точки

Прямолинейные колебания точки Процессы переноса: диффузия, теплопроводность и вязкость

Процессы переноса: диффузия, теплопроводность и вязкость Механическая работа. 7 класс

Механическая работа. 7 класс Электрическое напряжение. Единицы напряжения. Вольтметр. Измерение напряжения

Электрическое напряжение. Единицы напряжения. Вольтметр. Измерение напряжения Электромонтер по ремонту электрооборудования

Электромонтер по ремонту электрооборудования Метрология, стандартизация и сертификация

Метрология, стандартизация и сертификация Билеты. Кислородного баллона

Билеты. Кислородного баллона Источники света

Источники света А.С. Попов, изобретатель радио

А.С. Попов, изобретатель радио Интегрированный урок по физике и информатике 6 класс

Интегрированный урок по физике и информатике 6 класс Атмосферное давление 7

Атмосферное давление 7 Энергия. Потенциальная и кинетическая энергия тел

Энергия. Потенциальная и кинетическая энергия тел Ультразвук

Ультразвук Двигатели самолетов с вертикальным взлетом и посадкой. Тяговооруженность

Двигатели самолетов с вертикальным взлетом и посадкой. Тяговооруженность Исследовательский проект Машина Голдберга Как включить свет?

Исследовательский проект Машина Голдберга Как включить свет? Решение задач по теме Закон сохранения импульса

Решение задач по теме Закон сохранения импульса Реактивний двигун

Реактивний двигун Проектировочный расчет закрытой зубчатой передачи

Проектировочный расчет закрытой зубчатой передачи Quick Quiz

Quick Quiz Презентация Законы Ньютона

Презентация Законы Ньютона Применение первого закона термодинамики к различным процессам

Применение первого закона термодинамики к различным процессам Системно-деятельностный подход в обучении физики как основа ФГОС

Системно-деятельностный подход в обучении физики как основа ФГОС