Содержание

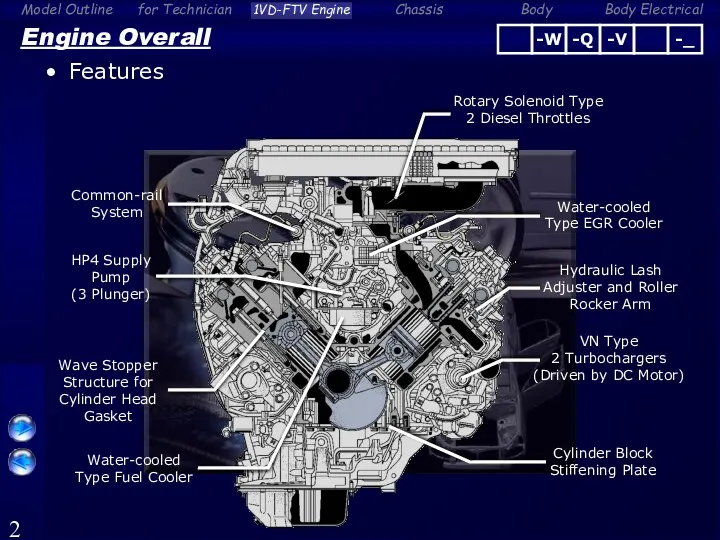

- 2. Engine Overall Features Cylinder Block Stiffening Plate Hydraulic Lash Adjuster and Roller Rocker Arm VN Type

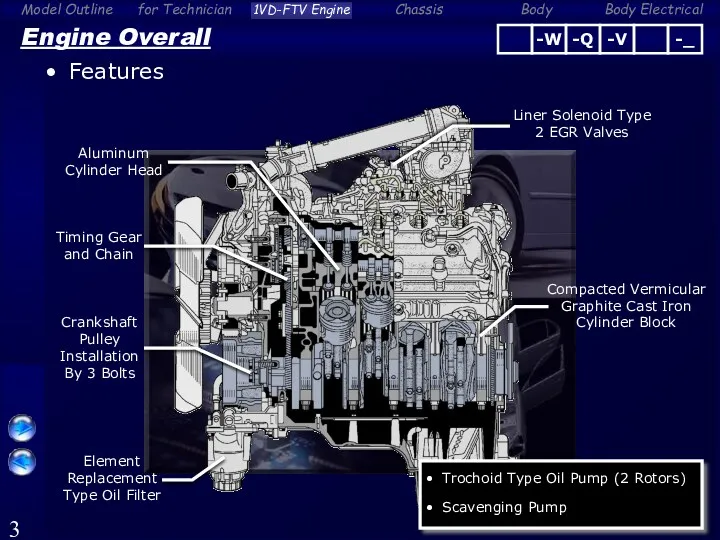

- 3. Engine Overall Features Crankshaft Pulley Installation By 3 Bolts Timing Gear and Chain Liner Solenoid Type

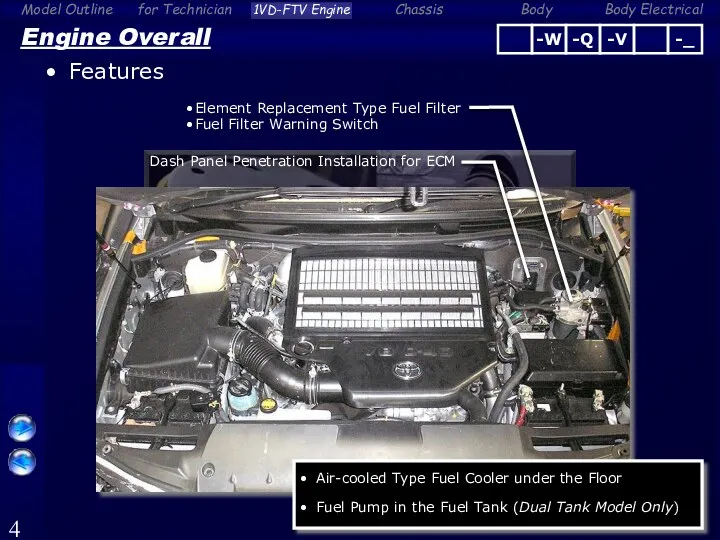

- 4. Engine Overall Features Element Replacement Type Fuel Filter Fuel Filter Warning Switch Dash Panel Penetration Installation

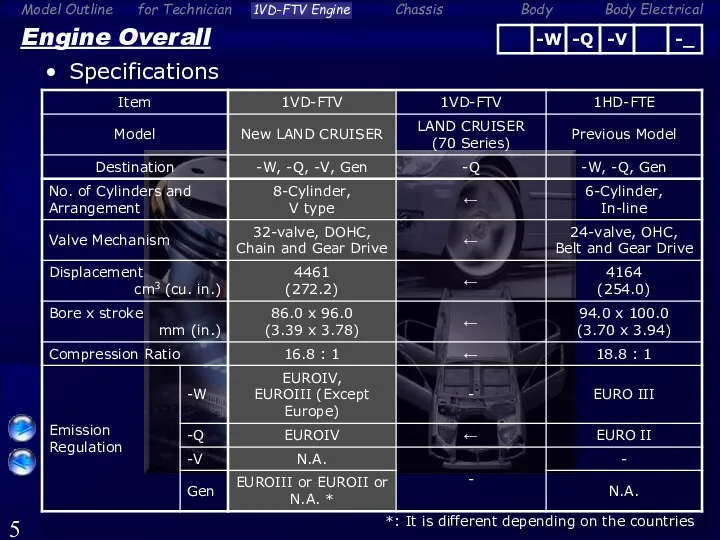

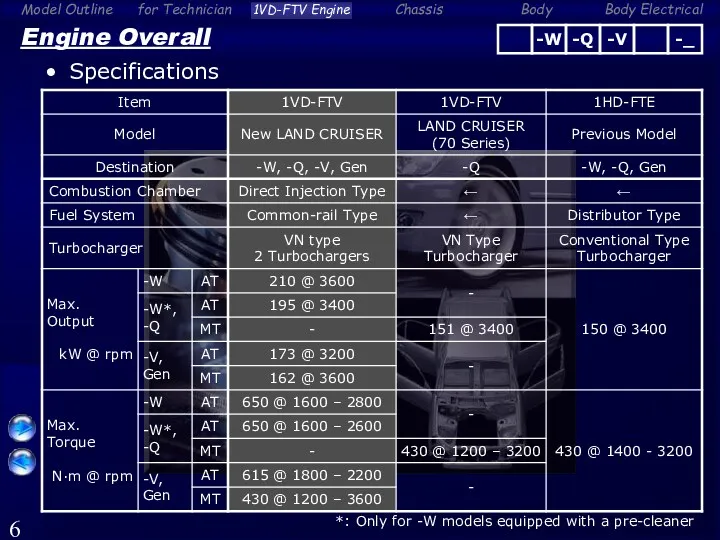

- 5. Engine Overall Specifications *: It is different depending on the countries

- 6. Engine Overall Specifications *: Only for -W models equipped with a pre-cleaner

- 7. Reference (Engine Overall) Major Difference From LAND CRUISER (VDJ70)

- 8. Engine Proper Cylinder Block High strength compacted vermicular graphite cast iron is used for weight reduction

- 9. Engine Proper Cylinder Head Gasket Wave stopper structure is used around the cylinder bore to improve

- 10. Engine Proper Crankshaft and Flywheel Balance weight is appropriately provided to reduce vibration Oil Pump Drive

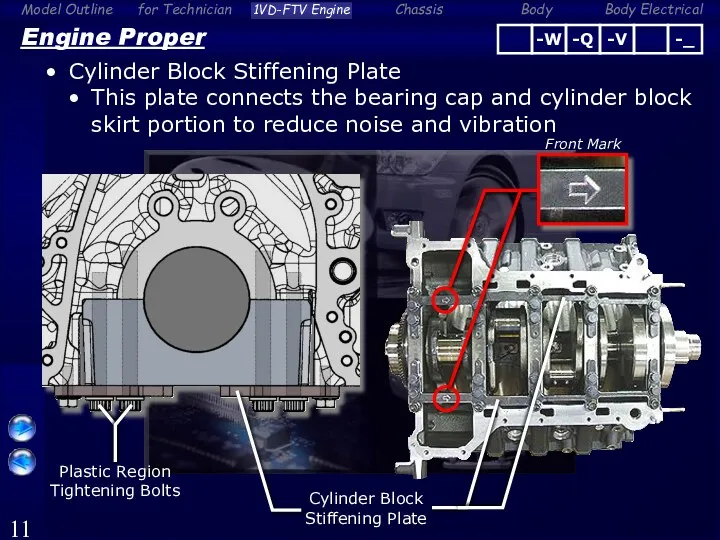

- 11. Engine Proper Cylinder Block Stiffening Plate This plate connects the bearing cap and cylinder block skirt

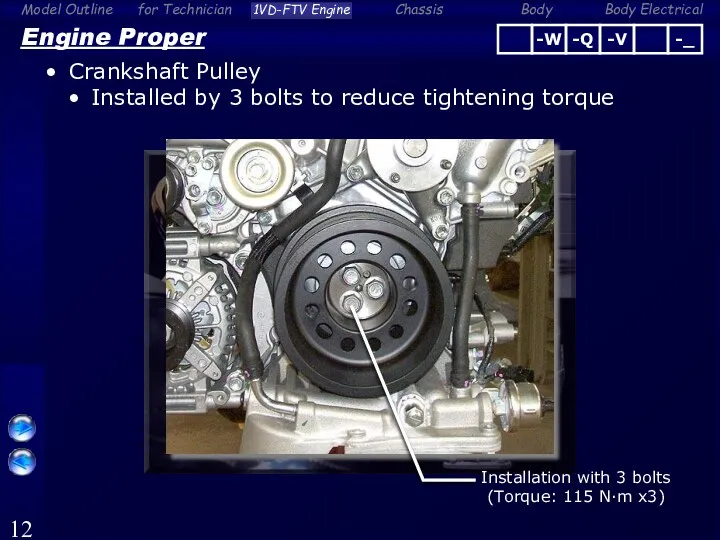

- 12. Engine Proper Crankshaft Pulley Installed by 3 bolts to reduce tightening torque Installation with 3 bolts

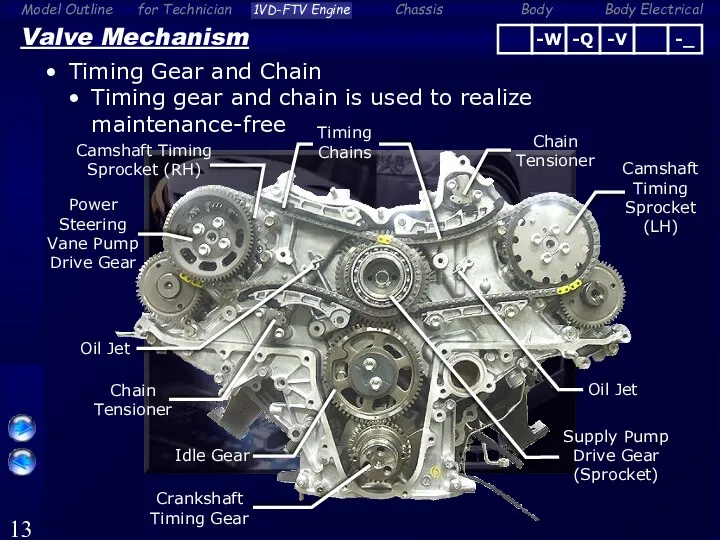

- 13. Valve Mechanism Timing Gear and Chain Timing gear and chain is used to realize maintenance-free Crankshaft

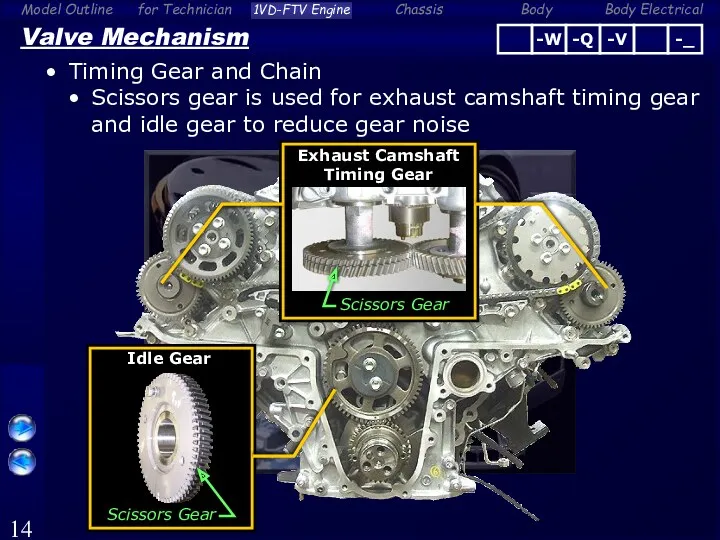

- 14. Valve Mechanism Timing Gear and Chain Scissors gear is used for exhaust camshaft timing gear and

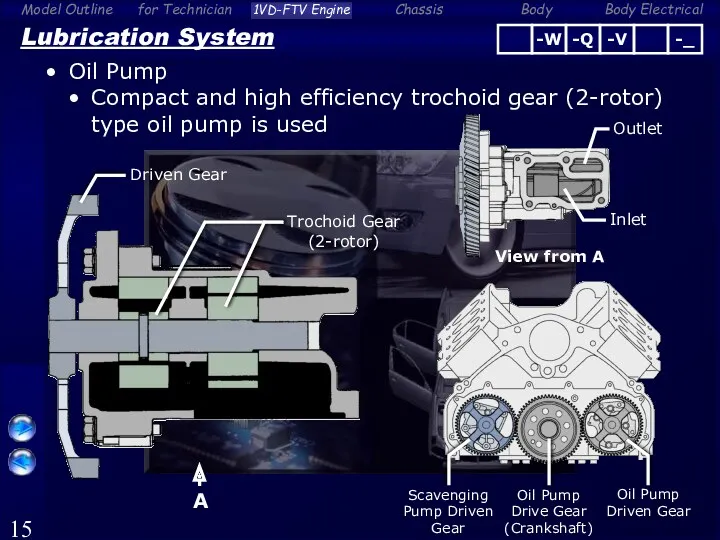

- 15. Lubrication System Oil Pump Compact and high efficiency trochoid gear (2-rotor) type oil pump is used

- 16. Lubrication System Oil Filter Element replacement type oil filter is used Oil Filter Cap (Resin) Oil

- 17. Lubrication System Scavenging Pump This system is used to prevents oil from retaining in the turbocharger

- 18. Lubrication System Scavenging Pump Scavenging pump sucks the engine oil in the catch tank and discharge

- 19. Lubrication System Scavenging Pump Parts Location Turbocharger (LH (Bank2)) Scavenging Pump Oil Catch Tank Ventilation Tube

- 20. Lubrication System Scavenging Pump Scavenging pump is driven by crankshaft Driven Gear A View from A

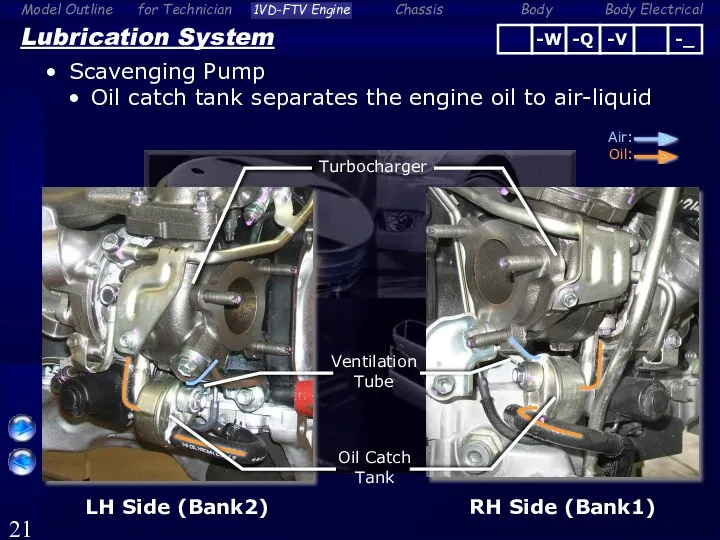

- 21. Lubrication System Scavenging Pump Oil catch tank separates the engine oil to air-liquid Oil Catch Tank

- 22. Reference (Lubrication System) Scavenging Pump Oil flow from oil catch tank to scavenging pump To Scavenging

- 23. Intake and Exhaust System Variable Nozzle Vane Type Turbocharger VN (Variable Nozzle-vane) type 2 turbochargers VN

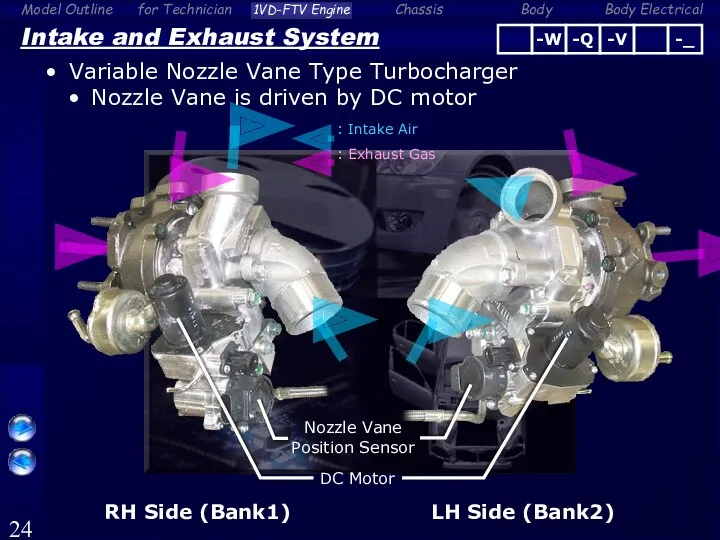

- 24. Intake and Exhaust System Variable Nozzle Vane Type Turbocharger Nozzle Vane is driven by DC motor

- 25. Intake and Exhaust System Variable Nozzle Vane Type Turbocharger Construction (RH Side (Bank1)) DC Motor Linkage

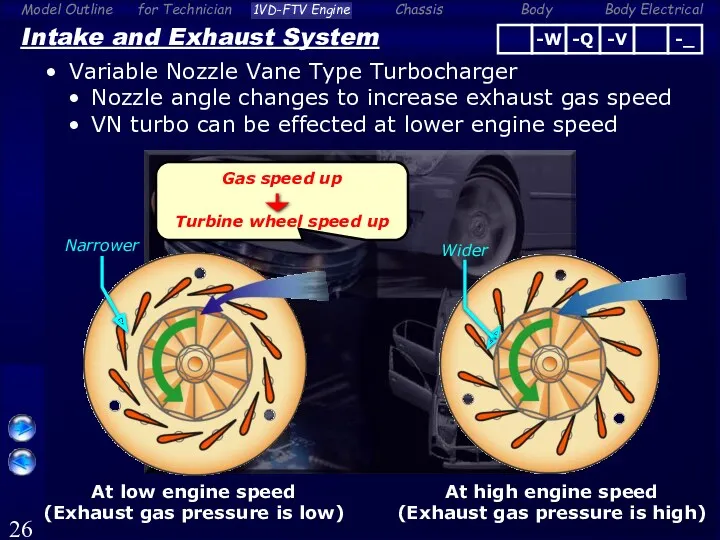

- 26. Intake and Exhaust System Variable Nozzle Vane Type Turbocharger Nozzle angle changes to increase exhaust gas

- 27. ECM Intake and Exhaust System Variable Nozzle Vane Type Turbocharger Control Nozzle Vane Position Turbo Motor

- 28. ECM Turbo Motor Driver [for Bank1 (RH)] EFI Relay +B GND M+ M- VNTI VNTO VN

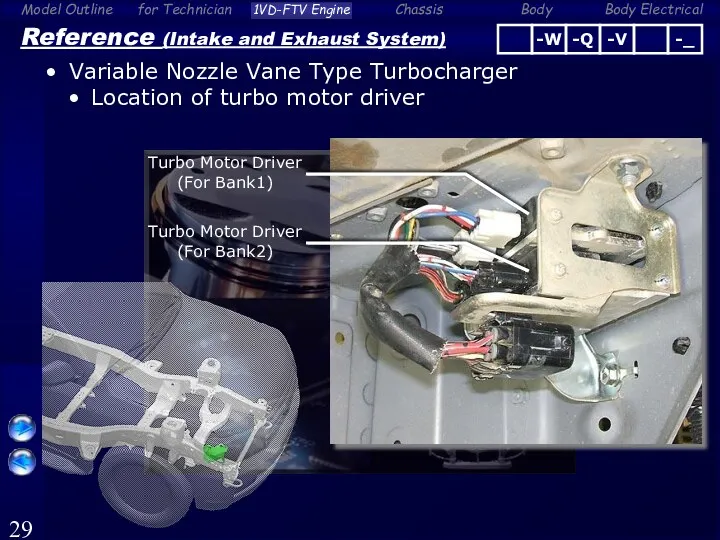

- 29. Reference (Intake and Exhaust System) Variable Nozzle Vane Type Turbocharger Location of turbo motor driver Turbo

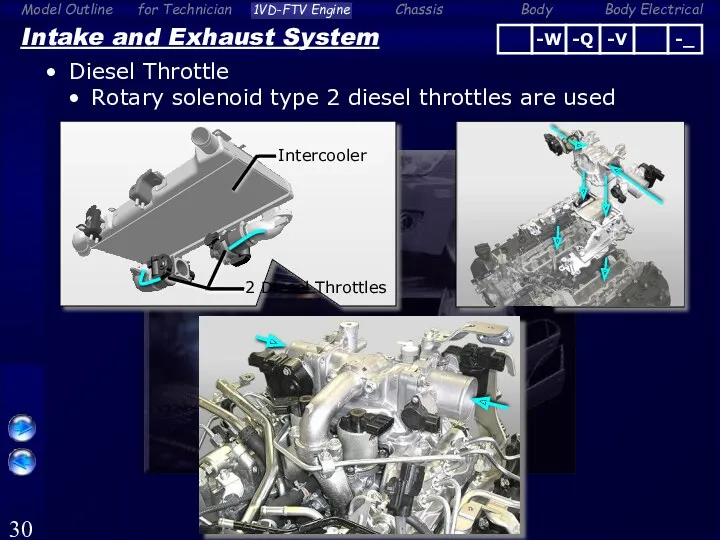

- 30. Intake and Exhaust System Diesel Throttle Rotary solenoid type 2 diesel throttles are used 2 Diesel

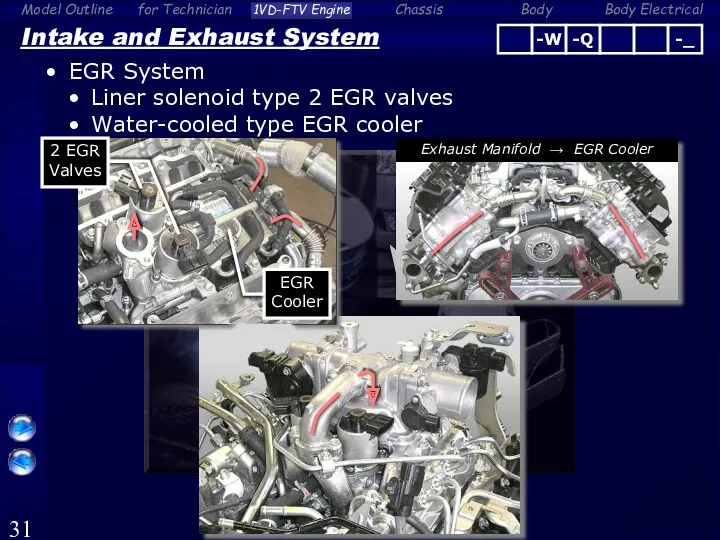

- 31. Intake and Exhaust System EGR System Liner solenoid type 2 EGR valves Water-cooled type EGR cooler

- 32. Fuel System Components and Features 3 Plunger Type HP4 Supply Pump Element Replacement Type Fuel Filter

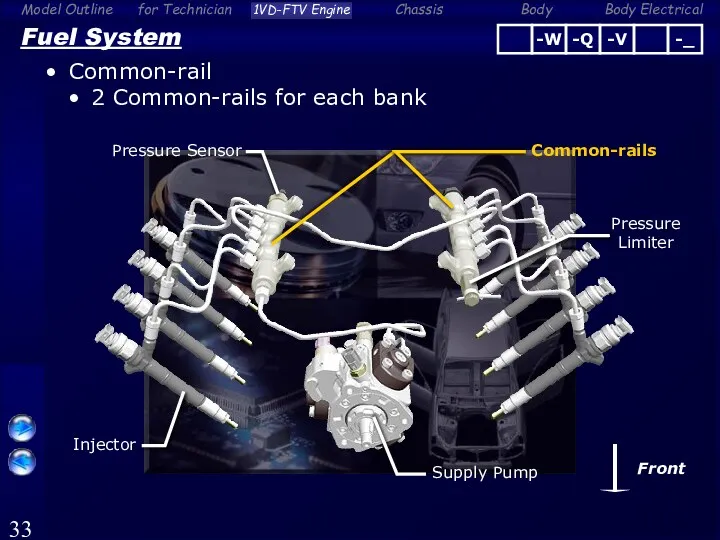

- 33. Fuel System Common-rail 2 Common-rails for each bank Common-rails Pressure Sensor Pressure Limiter Supply Pump Front

- 34. Fuel System Supply Pump (HP4) 3 plunger type supply pump is used to correspond to the

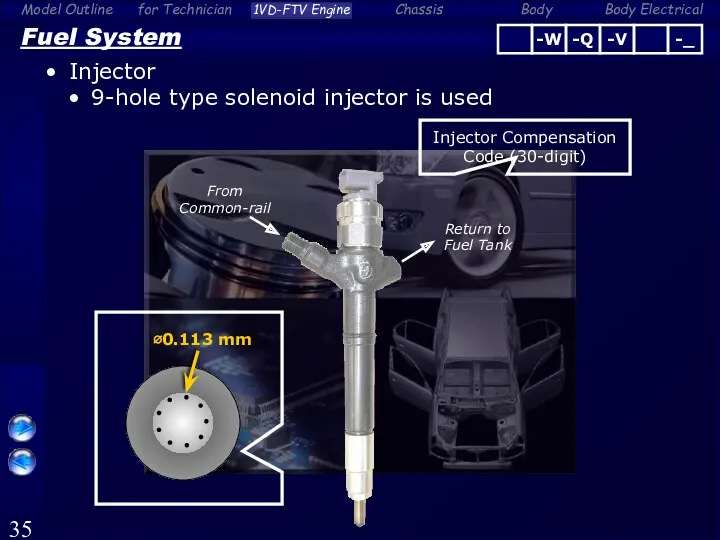

- 35. Fuel System Injector 9-hole type solenoid injector is used From Common-rail Return to Fuel Tank ∅0.113

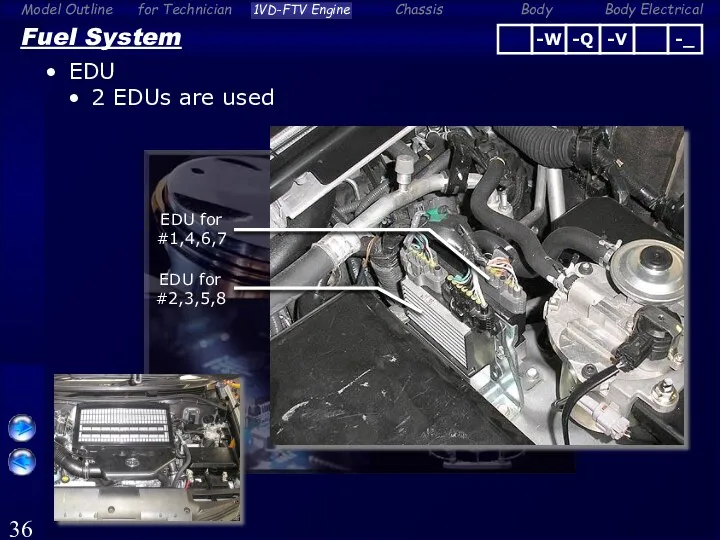

- 36. Fuel System EDU 2 EDUs are used EDU for #1,4,6,7 EDU for #2,3,5,8

- 37. Fuel System Fuel Filter Element replacement type fuel filter is used Fuel Filter From Fuel Tank

- 38. Fuel System Fuel Filter Main Components Filter Element Fuel Sedimenter Level Warning Switch Bolt x3 Fuel

- 39. Fuel System Fuel Filter When the fuel filter clogging is detected by fuel filter warning switch,

- 40. Fuel System Fuel Filter Fuel filter warning switch is turned OFF when the filter outlet pressure

- 41. Analog Type Combination Meter Fuel System Fuel Filter (Analog Type Combination Meter Only) Warning light condition

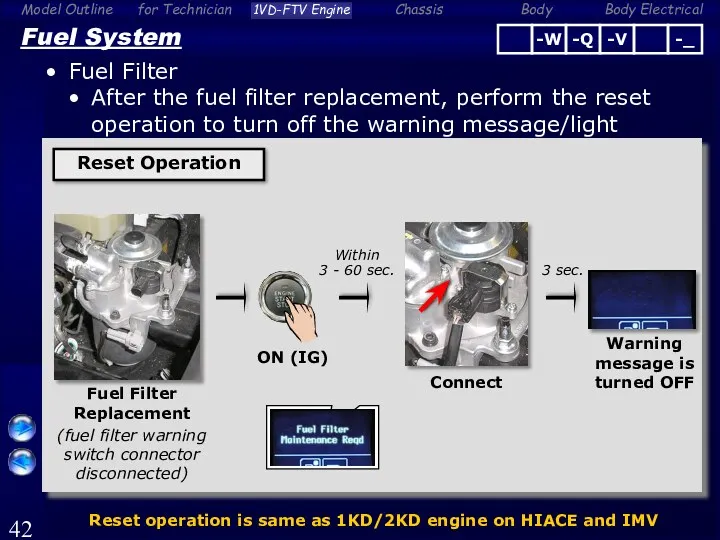

- 42. Fuel System Fuel Filter After the fuel filter replacement, perform the reset operation to turn off

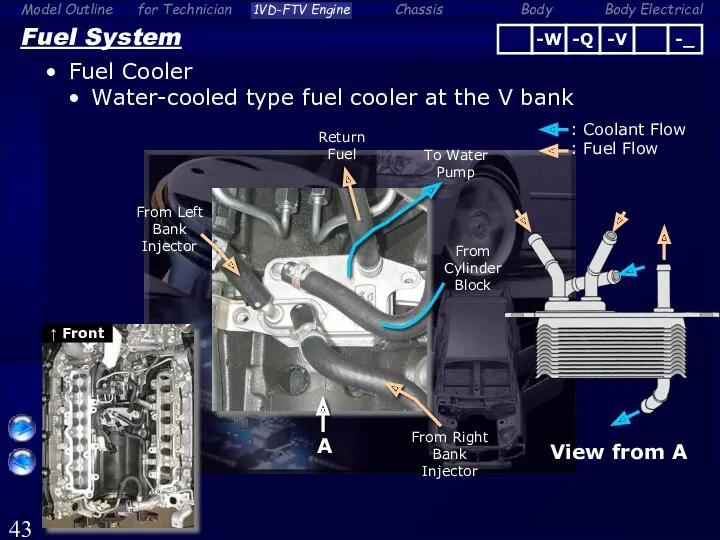

- 43. Fuel System Fuel Cooler Water-cooled type fuel cooler at the V bank From Cylinder Block From

- 44. Fuel System Fuel Cooler Air-cooled type fuel cooler under the floor To Fuel Tank From Engine

- 45. Fuel Tank (Main) [93-liter] Fuel Tank (Sub) [45-liter] Fuel System Fuel Pump (Dual Fuel Tank Model

- 46. Fuel System Fuel Pump (Dual Fuel Tank Model Only) Location Fuel Tank (Main) [93-liter] Fuel Tank

- 47. Fuel System Fuel Pump (Dual Fuel Tank Model Only) ECM controls a fuel pump in accordance

- 48. Fuel System Fuel Pump (Dual Fuel Tank Model Only) When the malfunction is detected in the

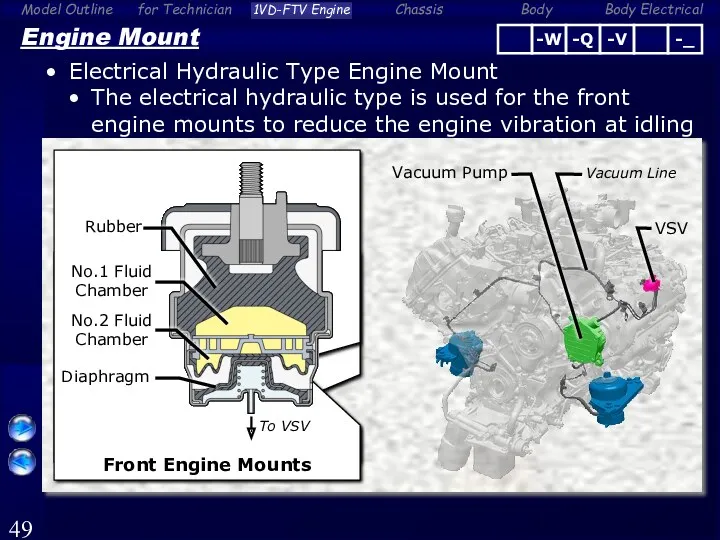

- 49. Engine Mount Electrical Hydraulic Type Engine Mount The electrical hydraulic type is used for the front

- 50. Engine Mount Electrical Hydraulic Type Engine Mount System Diagram Electrical Hydraulic type Engine Mounts Vehicle Speed

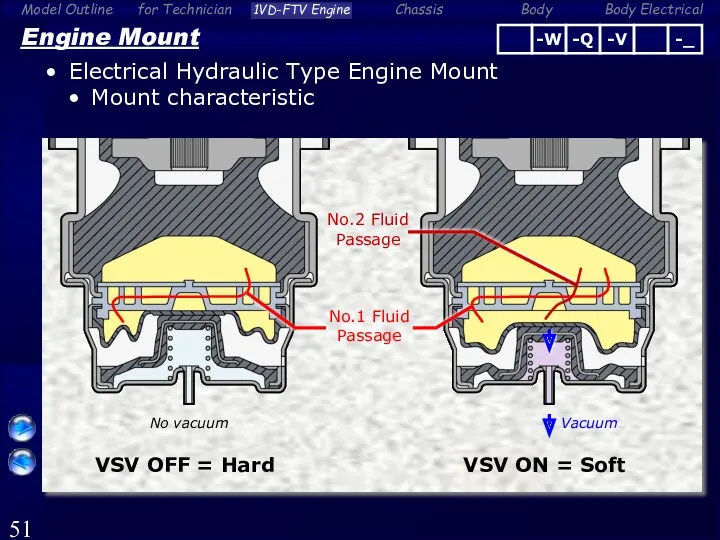

- 51. Engine Mount Electrical Hydraulic Type Engine Mount Mount characteristic VSV ON = Soft VSV OFF =

- 52. VSV OFF (Hard) Engine Mount Electrical Hydraulic Type Engine Mount When the engine is idling and

- 54. Скачать презентацию

![ECM Turbo Motor Driver [for Bank1 (RH)] EFI Relay +B](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/353980/slide-27.jpg)

![Fuel Tank (Main) [93-liter] Fuel Tank (Sub) [45-liter] Fuel System](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/353980/slide-44.jpg)

Транспортирующие машины. (Лекция № 5)

Транспортирующие машины. (Лекция № 5) Построение эпюр внутренних сил, напряжений и деформаций растяжения-сжатия

Построение эпюр внутренних сил, напряжений и деформаций растяжения-сжатия Смесеобразование в бензиновых двигателях

Смесеобразование в бензиновых двигателях Молекулярная физика. Термодинамика

Молекулярная физика. Термодинамика Geschichte der Eisenbahn

Geschichte der Eisenbahn Урок Преломление света – 8 класс

Урок Преломление света – 8 класс Классификация резисторов и их обозначения на схемах. (8 класс)

Классификация резисторов и их обозначения на схемах. (8 класс) Элементы оптоэлектроники. Приборы с зарядовой связью. Светодиоды. (Лекция 14.2)

Элементы оптоэлектроники. Приборы с зарядовой связью. Светодиоды. (Лекция 14.2) Метрология. Посадки подшипников качения

Метрология. Посадки подшипников качения Тормозная система Lada Priora

Тормозная система Lada Priora Инерция. Галилео Галилей

Инерция. Галилео Галилей Экспериментальное крыло самолета ВАe 125

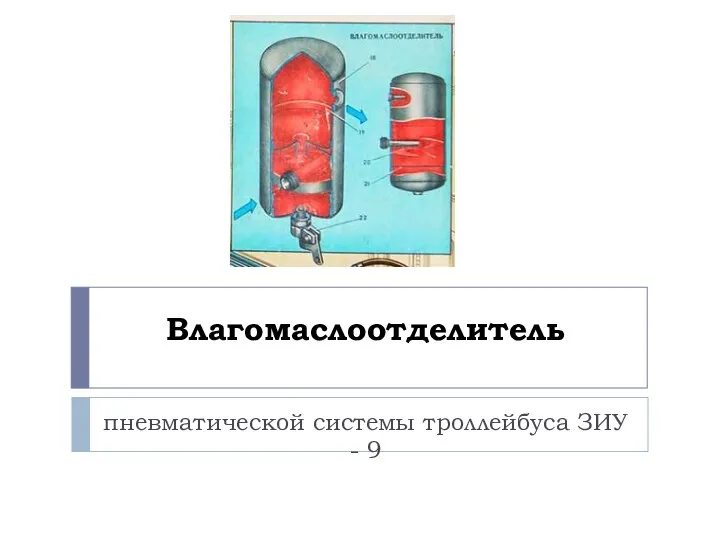

Экспериментальное крыло самолета ВАe 125 Влагомаслоотделитель пневматической системы троллейбуса ЗИУ - 9

Влагомаслоотделитель пневматической системы троллейбуса ЗИУ - 9 Електричний струм у газах

Електричний струм у газах Кристаллические и аморфные тела

Кристаллические и аморфные тела Искусственные алмазы

Искусственные алмазы Инфракрасные средства обнаружения

Инфракрасные средства обнаружения Мощность и работа электрического тока

Мощность и работа электрического тока Основы теории передачи теплоты. Основные понятия и определения, механизмы переноса тепла. Теплопроводность

Основы теории передачи теплоты. Основные понятия и определения, механизмы переноса тепла. Теплопроводность Люминесцентный анализ

Люминесцентный анализ Турбина. Назначение турбин

Турбина. Назначение турбин Сложное сопротивление

Сложное сопротивление Топливный насос высокого давления. Форсунки

Топливный насос высокого давления. Форсунки Электризация тел

Электризация тел Ядерные реакции. Ядерная энергия

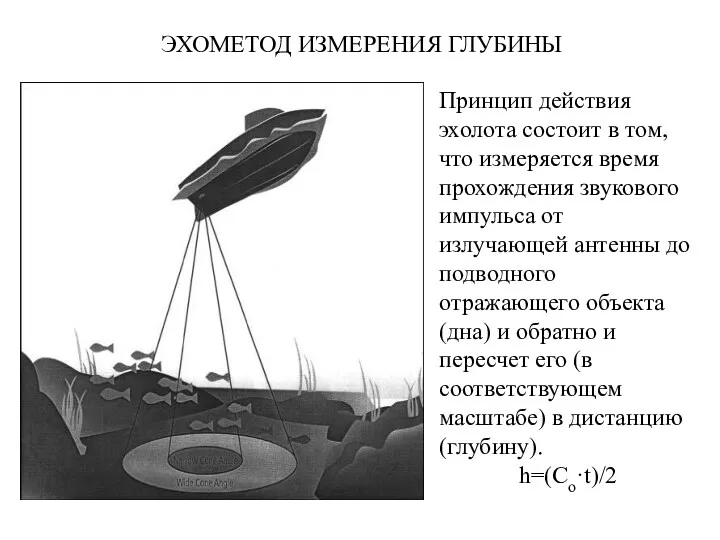

Ядерные реакции. Ядерная энергия Эхометод измерения глубины

Эхометод измерения глубины Автомобили с управляемыми системами подрессоривания

Автомобили с управляемыми системами подрессоривания