Содержание

- 2. 1. Gauge panel 2. Warning lamp 3. Multi display LCD 4. Switch panel 5. Main menu

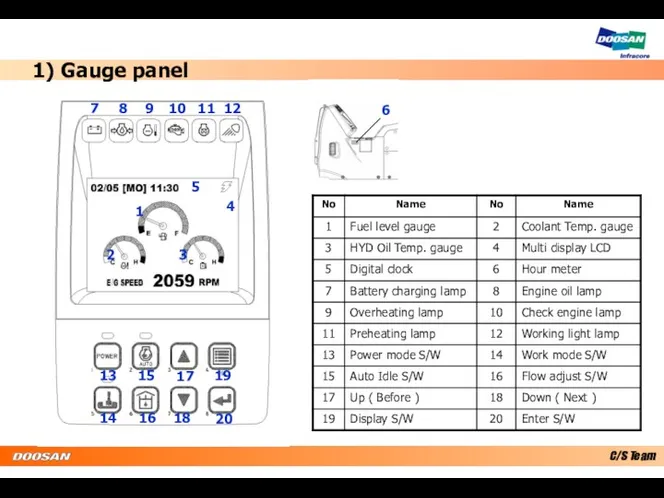

- 3. 1) Gauge panel 1 2 3 4 5 6 7 8 9 10 11 12 13

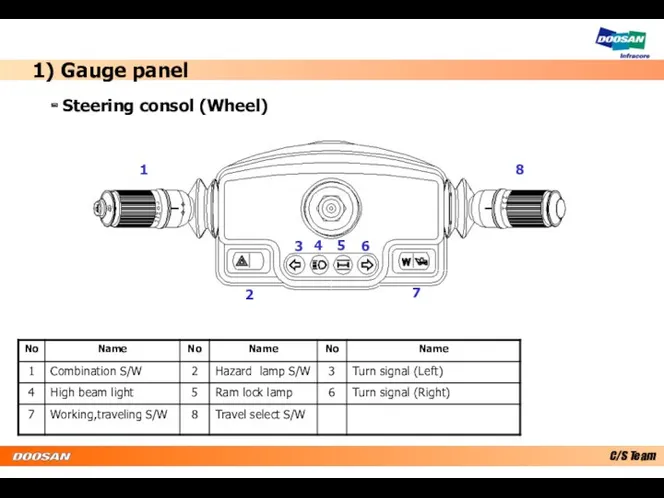

- 4. 1) Gauge panel - Steering consol (Wheel) 1 2 3 4 5 6 7 8

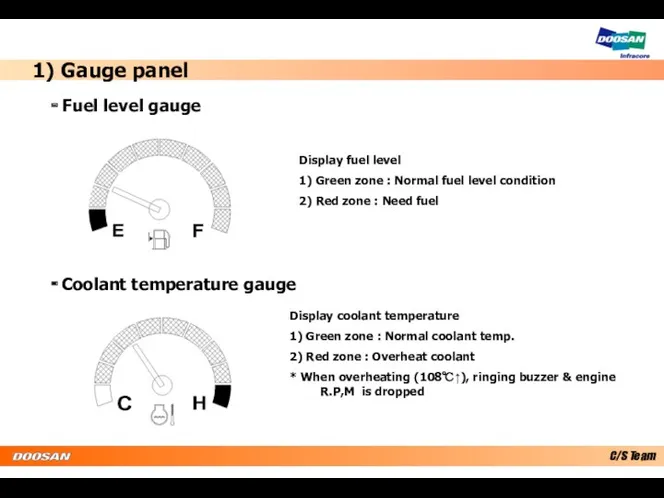

- 5. Display fuel level 1) Green zone : Normal fuel level condition 2) Red zone : Need

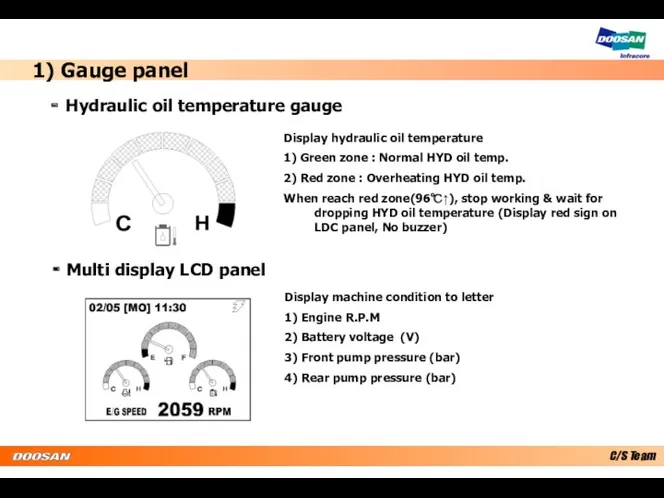

- 6. Display hydraulic oil temperature 1) Green zone : Normal HYD oil temp. 2) Red zone :

- 7. Display total working hour Blinking time is every 4 sec. - Hour meter 1) Gauge panel

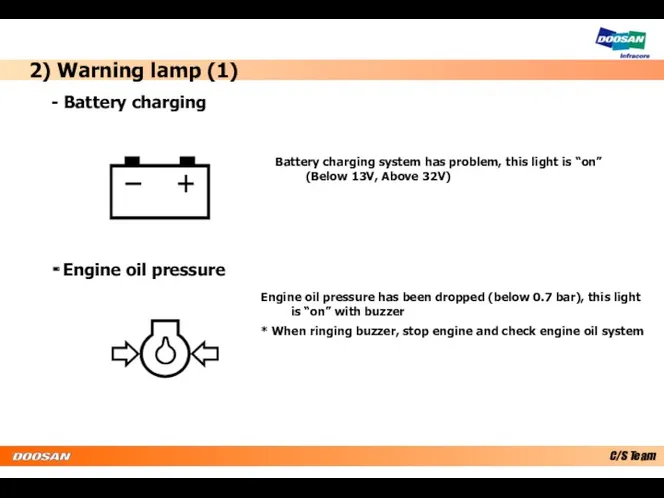

- 8. 2) Warning lamp (1) Battery charging system has problem, this light is “on” (Below 13V, Above

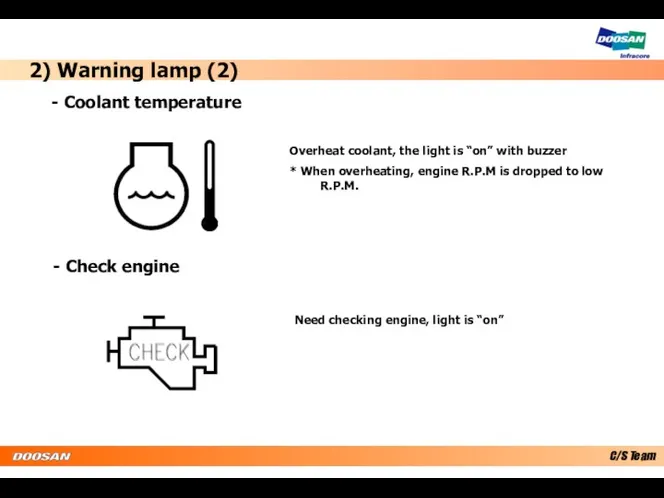

- 9. 2) Warning lamp (2) Overheat coolant, the light is “on” with buzzer * When overheating, engine

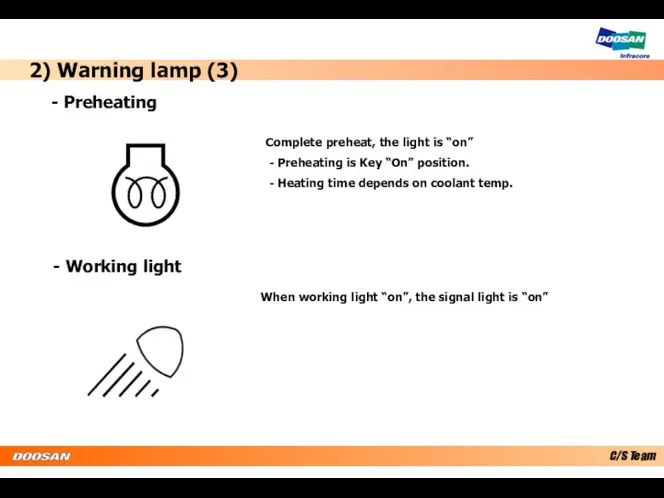

- 10. 2) Warning lamp (3) Complete preheat, the light is “on” - Preheating is Key “On” position.

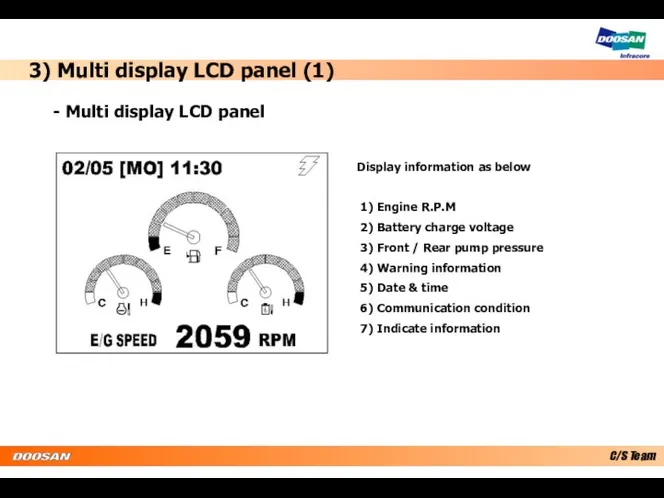

- 11. 3) Multi display LCD panel (1) Display information as below 1) Engine R.P.M 2) Battery charge

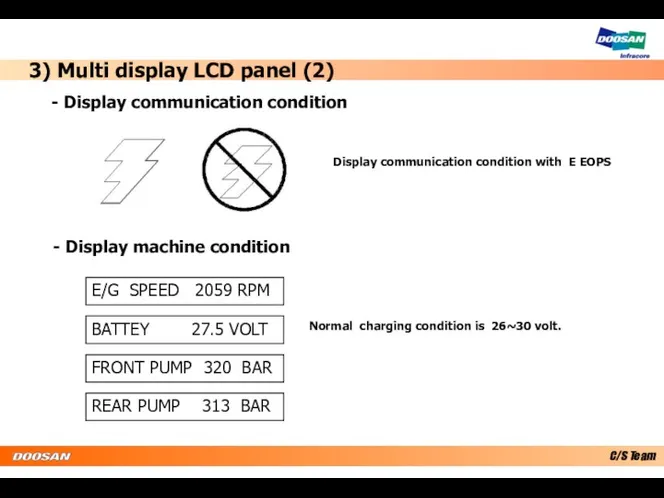

- 12. 3) Multi display LCD panel (2) Normal charging condition is 26~30 volt. - Display communication condition

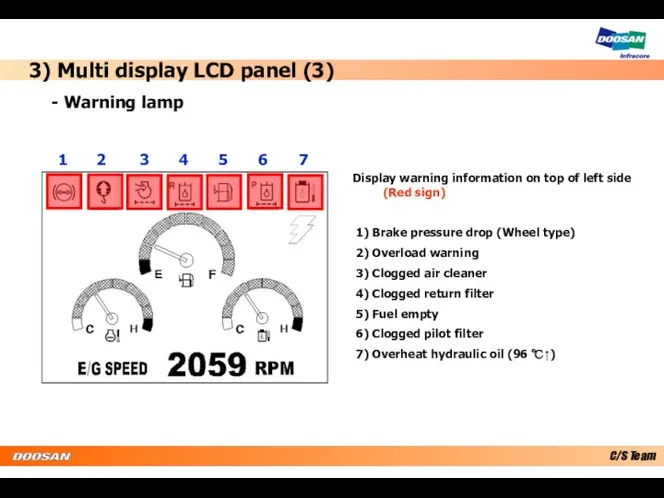

- 13. 3) Multi display LCD panel (3) - Warning lamp Display warning information on top of left

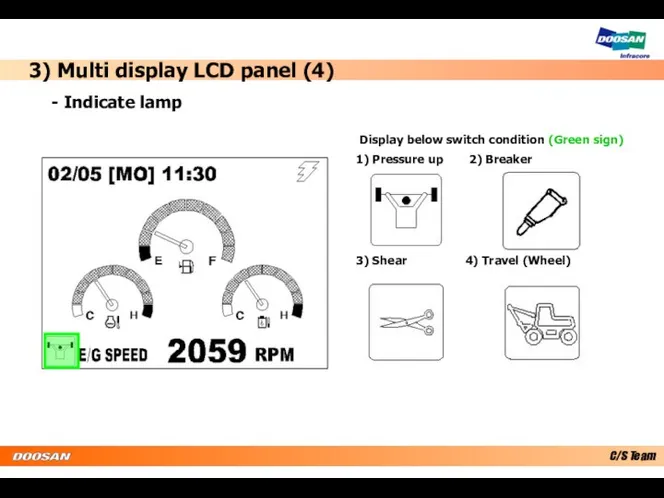

- 14. 3) Multi display LCD panel (4) - Indicate lamp Display below switch condition (Green sign) 1)

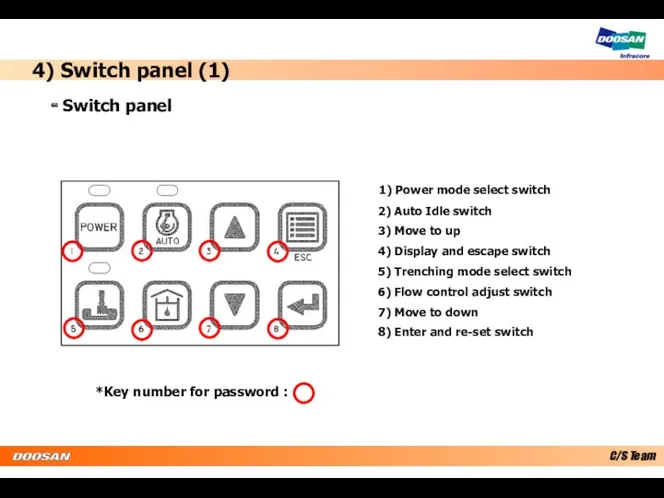

- 15. 4) Switch panel (1) - Switch panel 1) Power mode select switch 2) Auto Idle switch

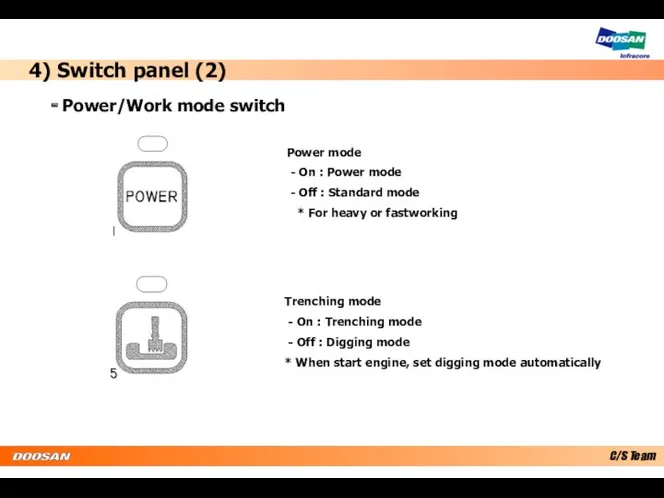

- 16. 4) Switch panel (2) - Power/Work mode switch Power mode - On : Power mode -

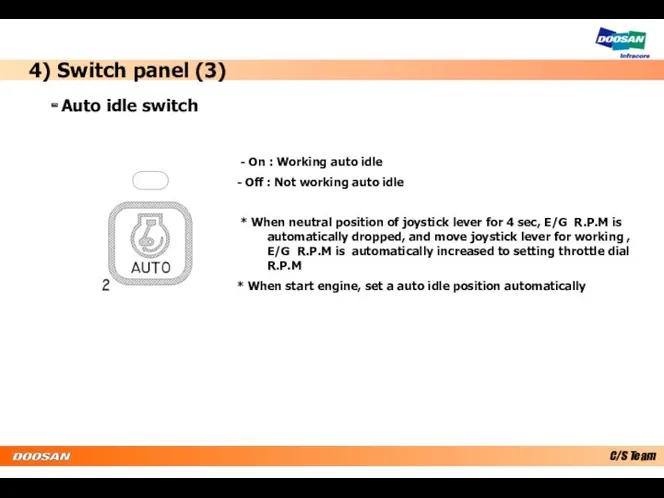

- 17. - Auto idle switch - On : Working auto idle - Off : Not working auto

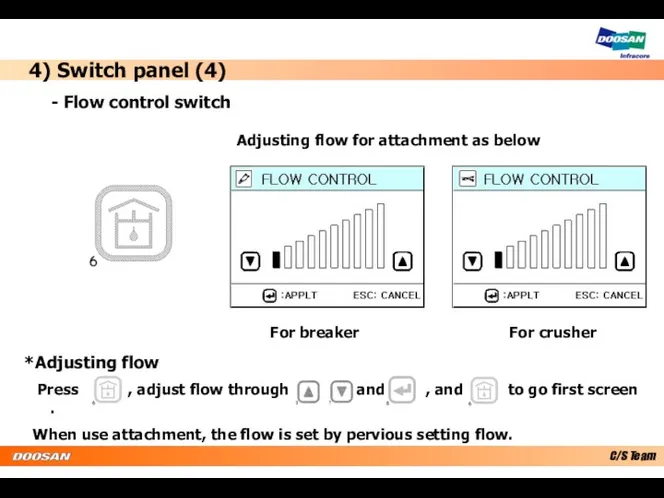

- 18. - Flow control switch Adjusting flow for attachment as below For breaker For crusher 4) Switch

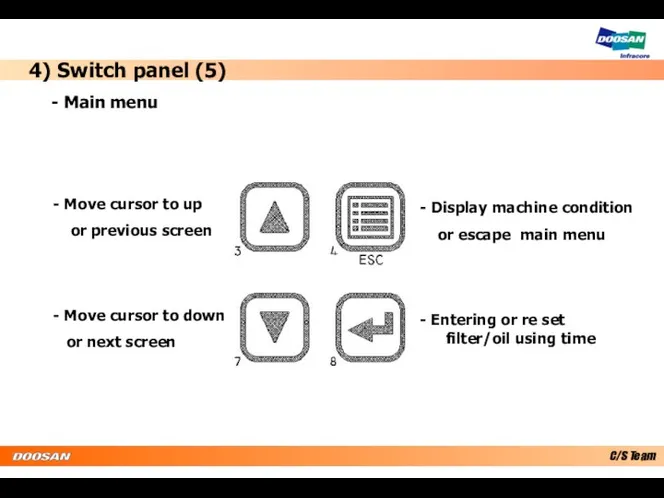

- 19. - Main menu - Move cursor to up or previous screen - Move cursor to down

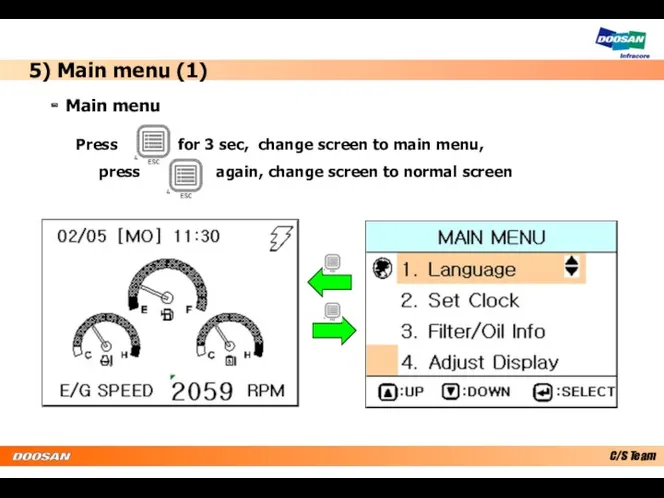

- 20. 5) Main menu (1) - Main menu Press for 3 sec, change screen to main menu,

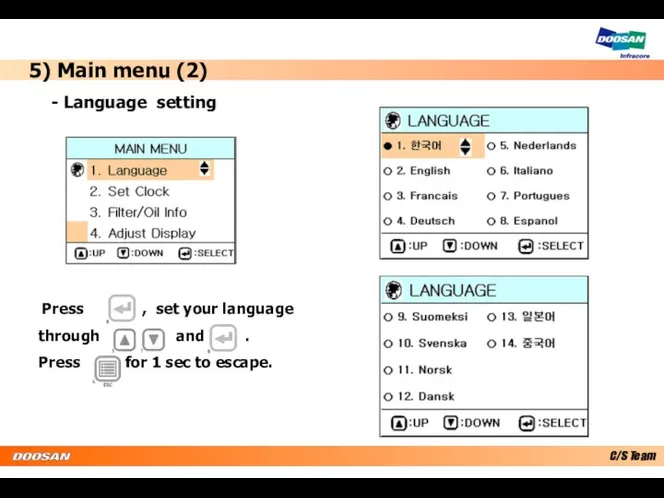

- 21. 5) Main menu (2) - Language setting Press , set your language through and . Press

- 22. 5) Main menu (3) - Clock setting Press , set your local time through and .

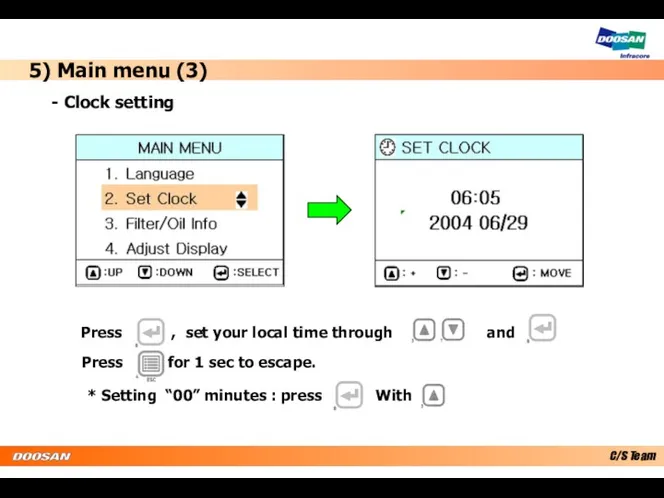

- 23. 5) Main menu (4) - Filter & oil information Press , check used time through .

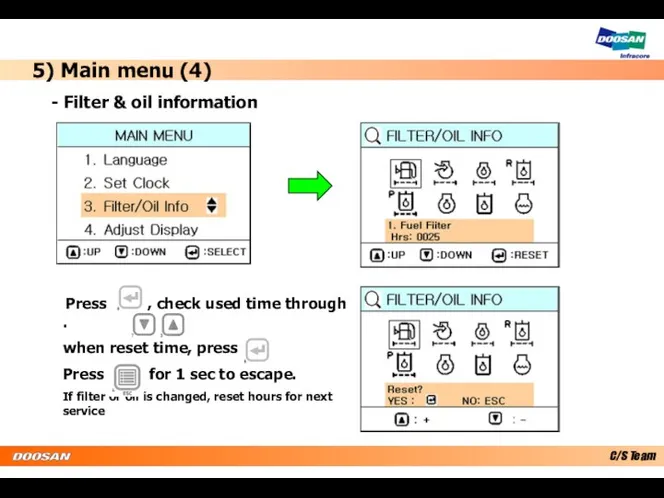

- 24. Press , set LCD bright through . Press for 1 sec to escape. 5) Main menu

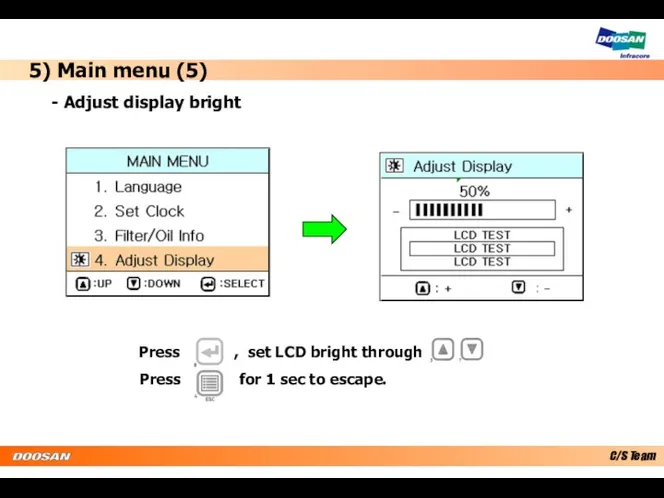

- 25. 5) Main menu (6) - Setting password Key in four-figure number password within 10 minutes, First

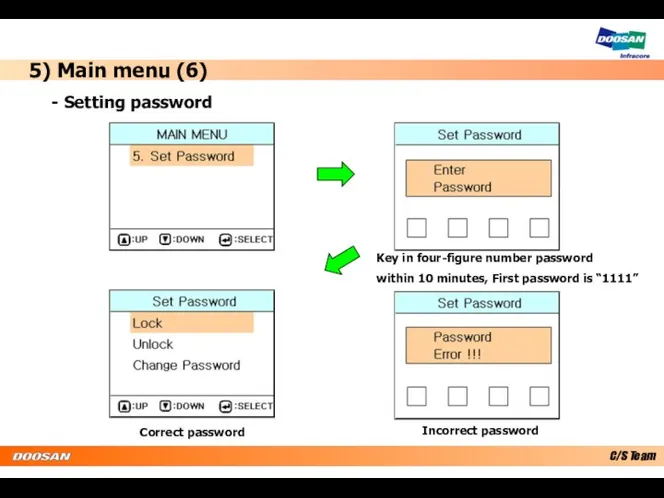

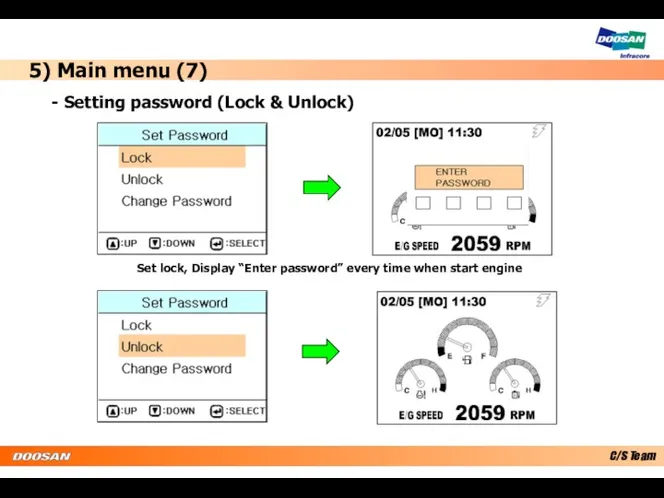

- 26. 5) Main menu (7) - Setting password (Lock & Unlock) Set lock, Display “Enter password” every

- 27. 5) Main menu (8) - Setting password (Change password) Key in same password two times Incorrect

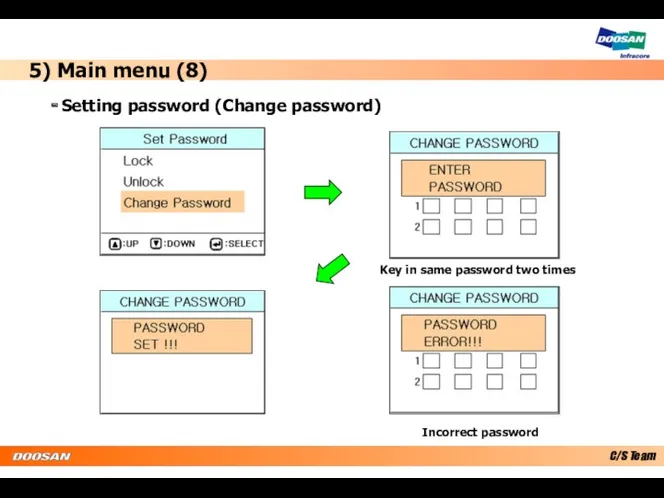

- 28. Press and for 3 sec, change screen to special menu, press again, change screen to normal

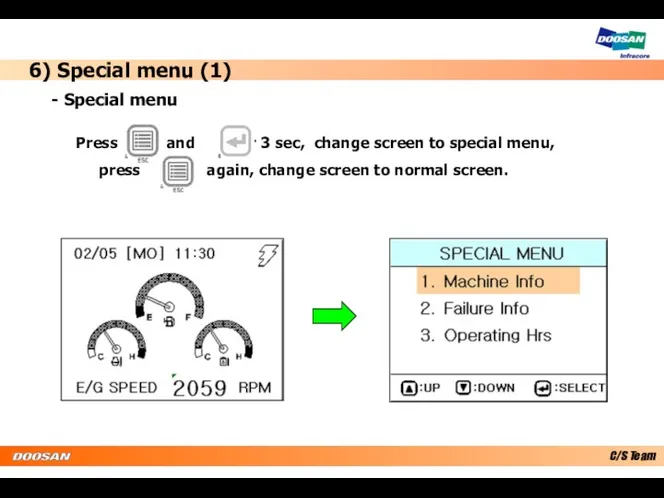

- 29. 6) Special menu (2) - Machine Information I) Analog Input State Analog Input State is Input

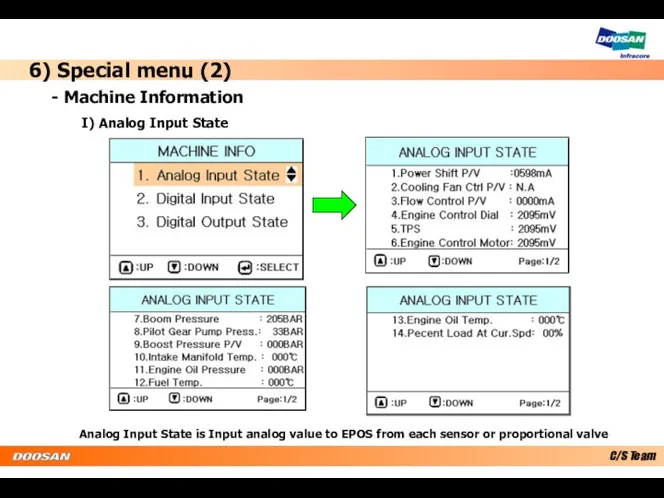

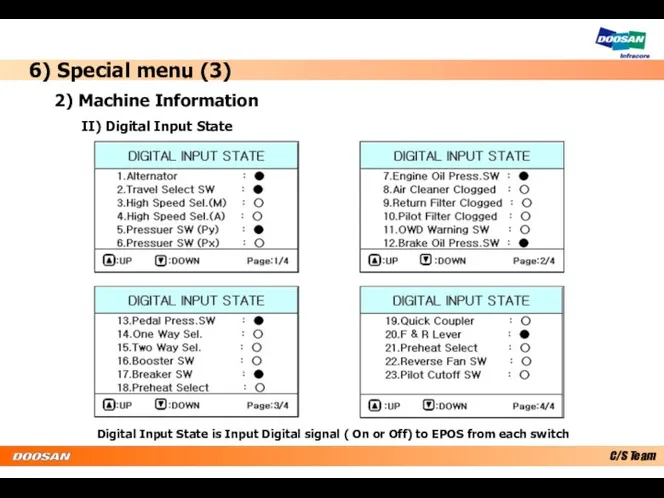

- 30. 6) Special menu (3) 2) Machine Information II) Digital Input State Digital Input State is Input

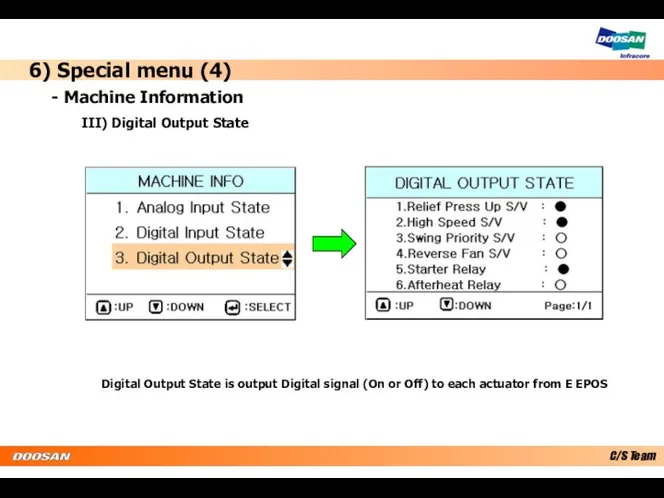

- 31. 6) Special menu (4) - Machine Information III) Digital Output State Digital Output State is output

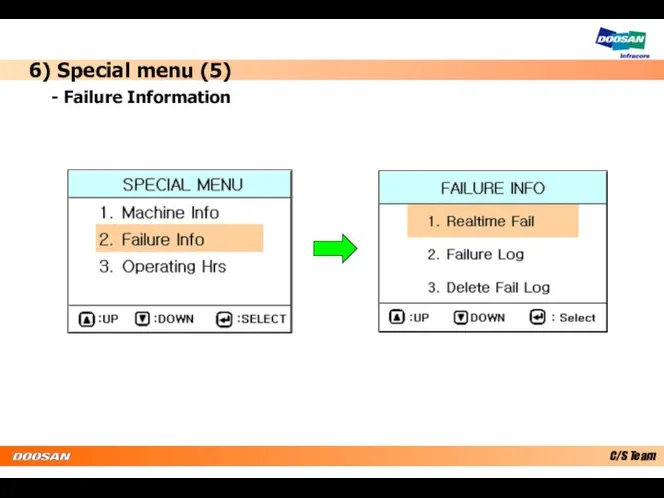

- 32. 6) Special menu (5) - Failure Information

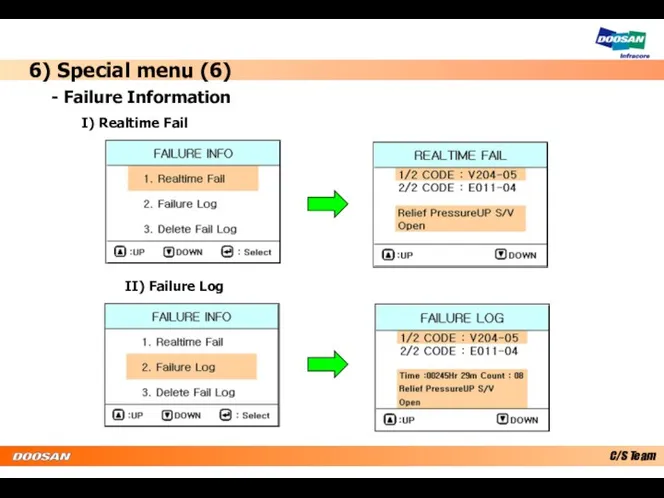

- 33. 6) Special menu (6) - Failure Information I) Realtime Fail II) Failure Log

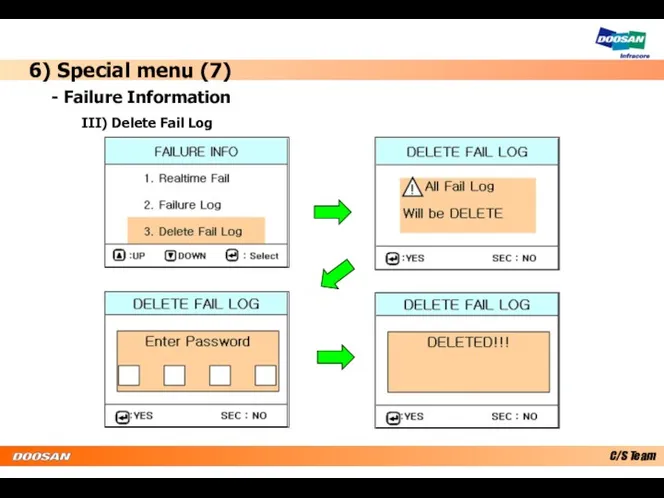

- 34. 6) Special menu (7) - Failure Information III) Delete Fail Log

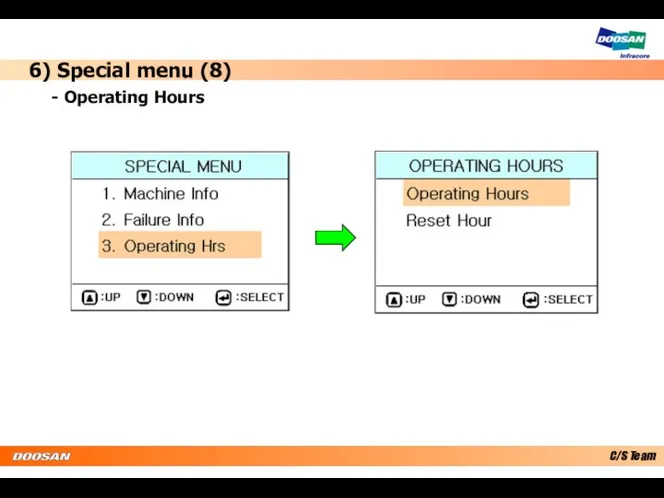

- 35. 6) Special menu (8) - Operating Hours

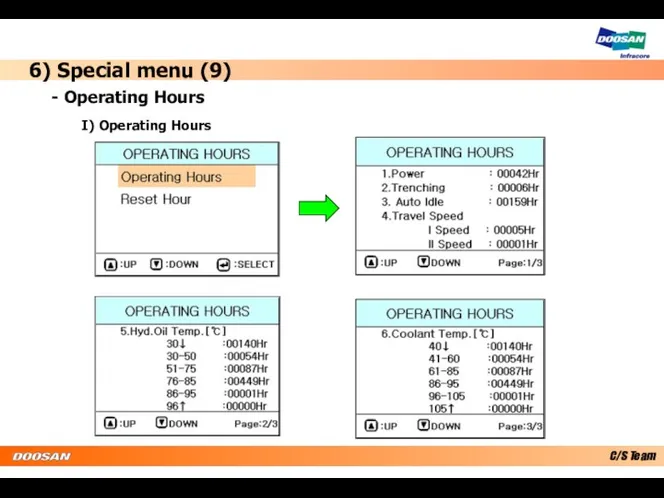

- 36. 6) Special menu (9) - Operating Hours I) Operating Hours

- 38. Скачать презентацию

Линейные антенные решетки

Линейные антенные решетки Энергия электрического поля. Тема 6

Энергия электрического поля. Тема 6 Элементы гемодинамики

Элементы гемодинамики Метрология. Допуски и посадки шпоночных и шлицевых соединений

Метрология. Допуски и посадки шпоночных и шлицевых соединений Динамика механической системы

Динамика механической системы тепловые явления в юрте

тепловые явления в юрте Силовий трансформатор ЧС-4

Силовий трансформатор ЧС-4 Особливості будови систем та механізмів автомобіля ГАЗ-66

Особливості будови систем та механізмів автомобіля ГАЗ-66 Введение. Общие сведения о машинах и механизмах

Введение. Общие сведения о машинах и механизмах Зубчатые передачи

Зубчатые передачи Теоретическая механика. Статика абсолютно твердого тела

Теоретическая механика. Статика абсолютно твердого тела Diesel and petrol power

Diesel and petrol power Буксирное устройство судна и его техническая эксплуатация

Буксирное устройство судна и его техническая эксплуатация Пневмотранспорт, виды и применение. Достоинства и недостатки. Тема 14

Пневмотранспорт, виды и применение. Достоинства и недостатки. Тема 14 Методическая разработка для урока по теме Поперечность световых волн.

Методическая разработка для урока по теме Поперечность световых волн. Разборка и сборка тормозных колодок автобуса ЛИАЗ-5256

Разборка и сборка тормозных колодок автобуса ЛИАЗ-5256 Блок - разновидность простого механизма

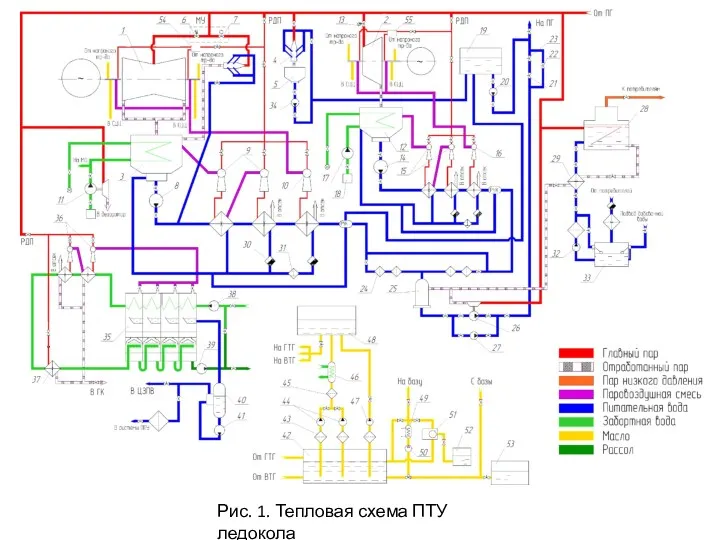

Блок - разновидность простого механизма Системы ПТУ 2

Системы ПТУ 2 Гидродинамика. Поток жидкости и его основные понятия

Гидродинамика. Поток жидкости и его основные понятия Электрические цепи при гармоническом воздействии в установившемся режиме

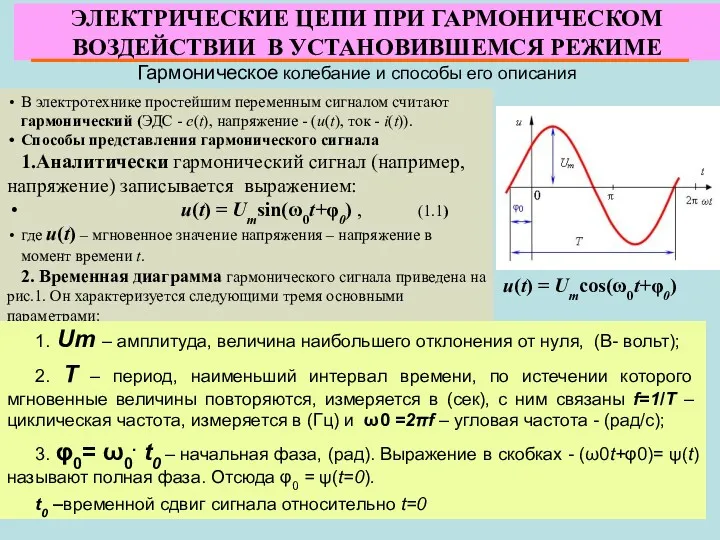

Электрические цепи при гармоническом воздействии в установившемся режиме Уравнение Менделеева - Клапейрона

Уравнение Менделеева - Клапейрона Урок по физике в 7классе на тему Плотность вещества. Решение задач

Урок по физике в 7классе на тему Плотность вещества. Решение задач Tiristor GTO

Tiristor GTO Электротехника. Резонанс в электрических цепях. (Лекция 9)

Электротехника. Резонанс в электрических цепях. (Лекция 9) Измерение параметров инфракрасного и терагерцового излучения ч.2 Схемы измерения параметров

Измерение параметров инфракрасного и терагерцового излучения ч.2 Схемы измерения параметров Спектры. Виды спектров

Спектры. Виды спектров Инструментальные методы анализа

Инструментальные методы анализа Реализация проблемного метода обучения на уроках физики с помощью интерактивных компьютерных моделей

Реализация проблемного метода обучения на уроках физики с помощью интерактивных компьютерных моделей