Содержание

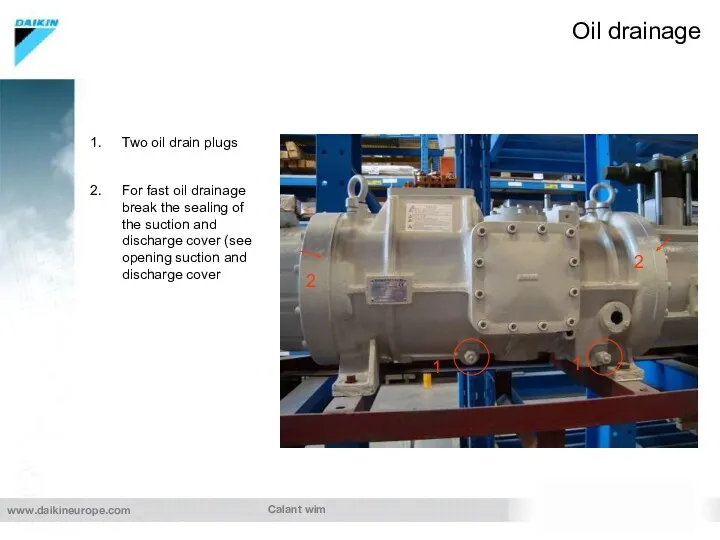

- 2. Calant wim Oil drainage Two oil drain plugs For fast oil drainage break the sealing of

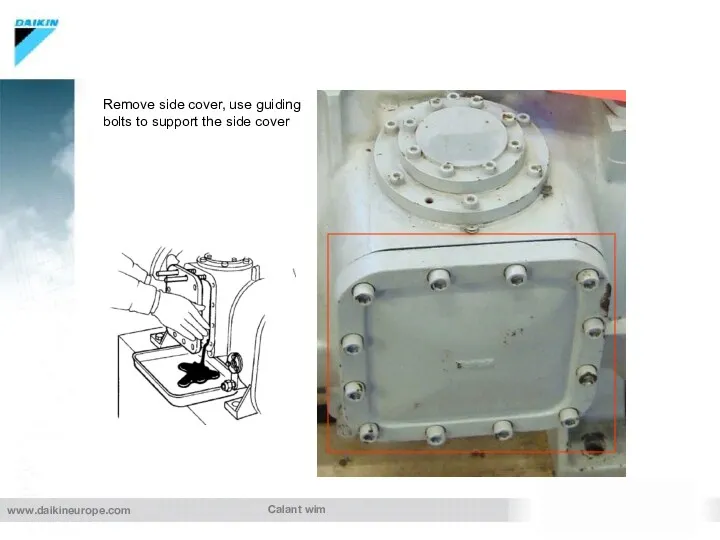

- 3. Calant wim Remove side cover, use guiding bolts to support the side cover

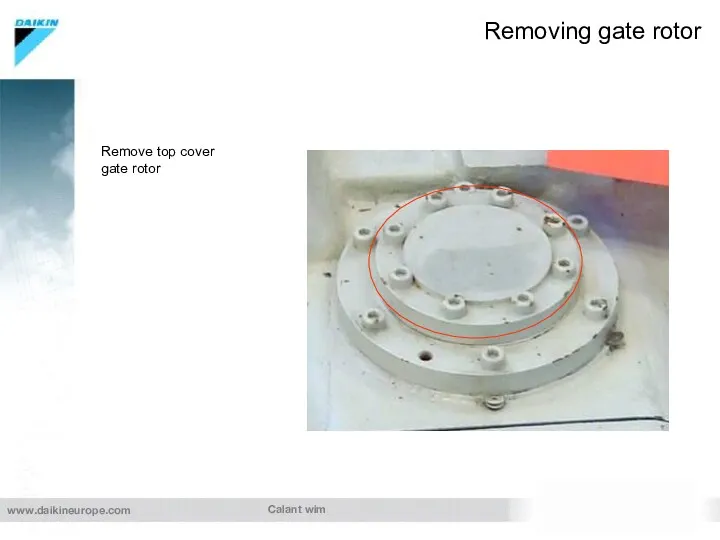

- 4. Calant wim Removing gate rotor Remove top cover gate rotor

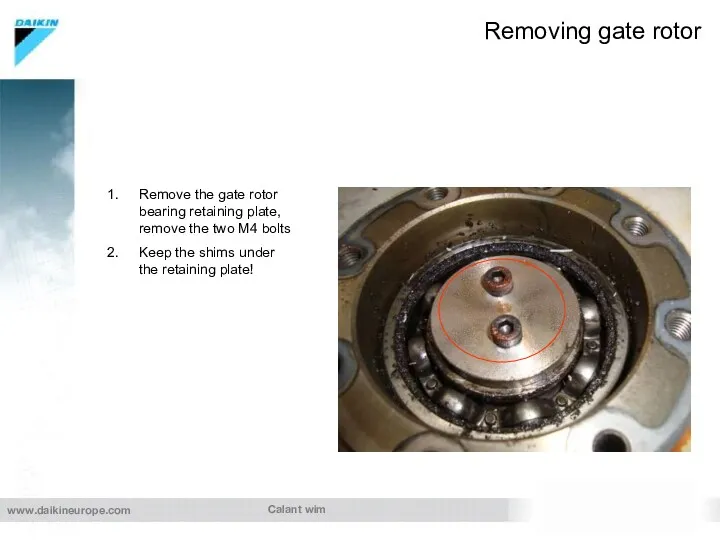

- 5. Calant wim Removing gate rotor Remove the gate rotor bearing retaining plate, remove the two M4

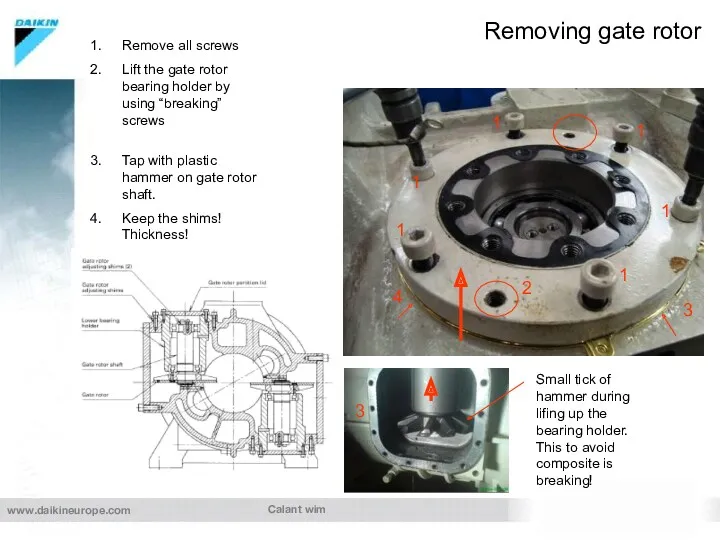

- 6. Calant wim Removing gate rotor Remove all screws Lift the gate rotor bearing holder by using

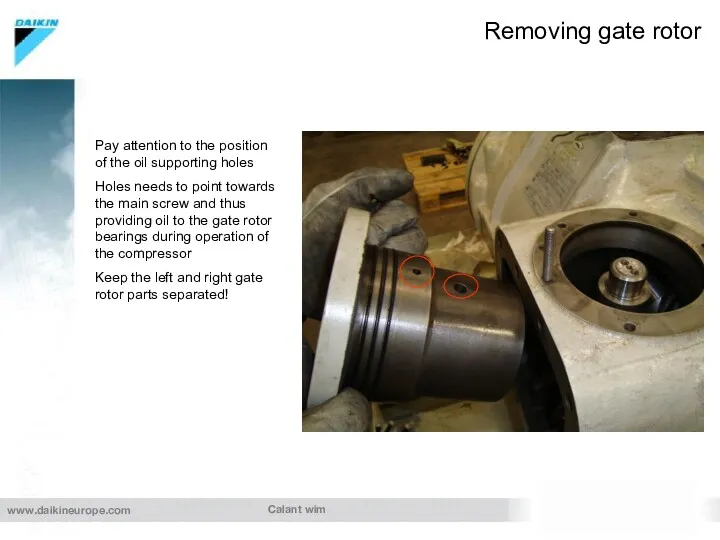

- 7. Calant wim Removing gate rotor Pay attention to the position of the oil supporting holes Holes

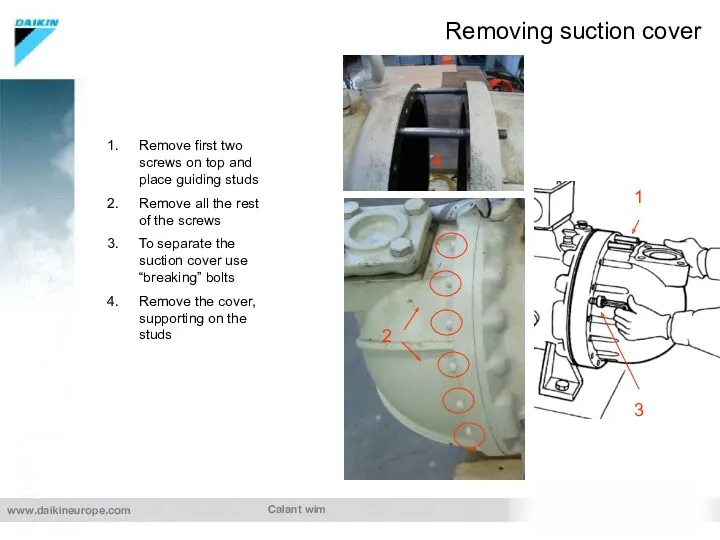

- 8. Calant wim Removing suction cover Remove first two screws on top and place guiding studs Remove

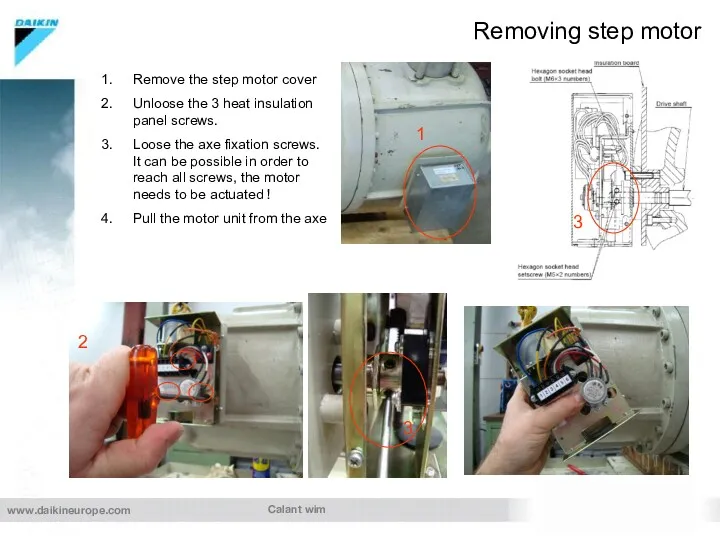

- 9. Calant wim Removing step motor Remove the step motor cover Unloose the 3 heat insulation panel

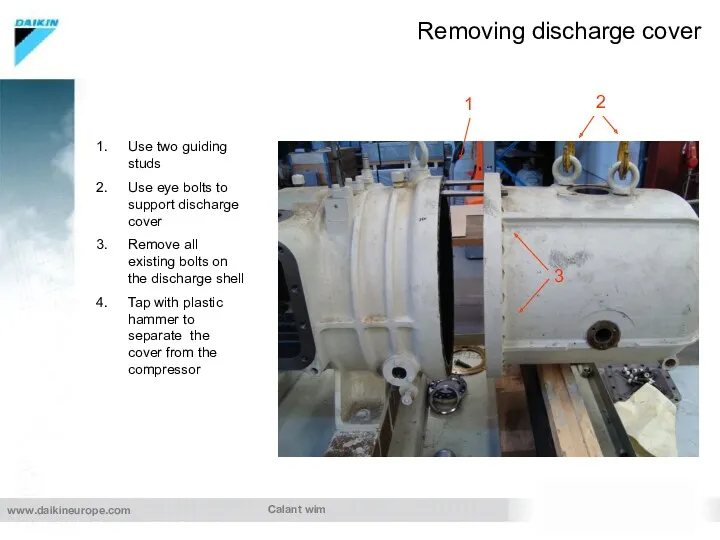

- 10. Calant wim Removing discharge cover Use two guiding studs Use eye bolts to support discharge cover

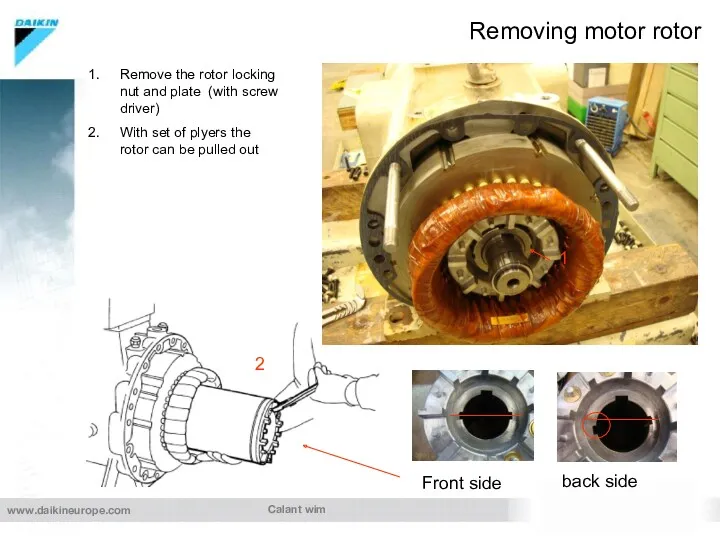

- 11. Calant wim Removing motor rotor Remove the rotor locking nut and plate (with screw driver) With

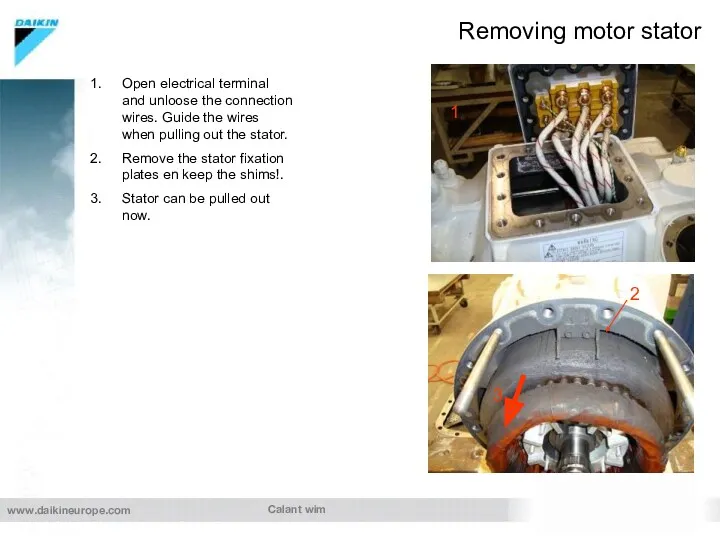

- 12. Calant wim Removing motor stator Open electrical terminal and unloose the connection wires. Guide the wires

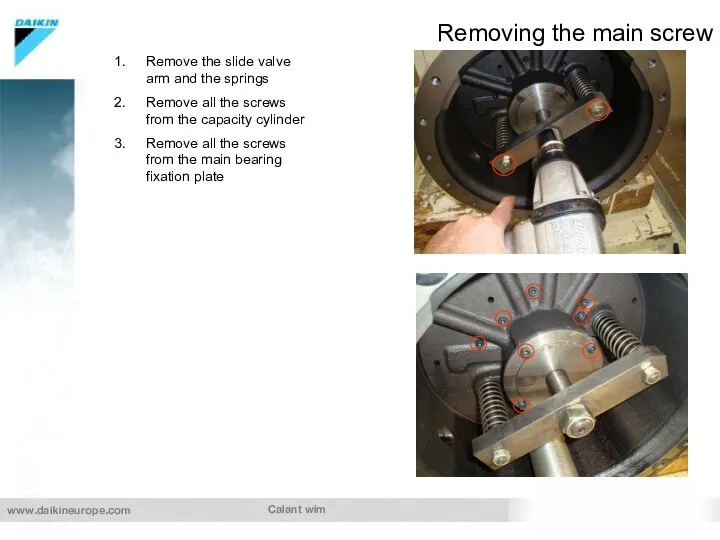

- 13. Calant wim Removing the main screw Remove the slide valve arm and the springs Remove all

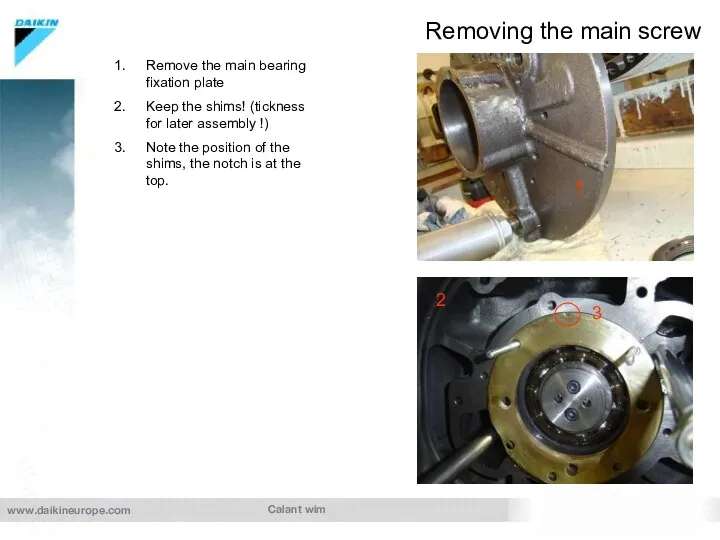

- 14. Calant wim Removing the main screw Remove the main bearing fixation plate Keep the shims! (tickness

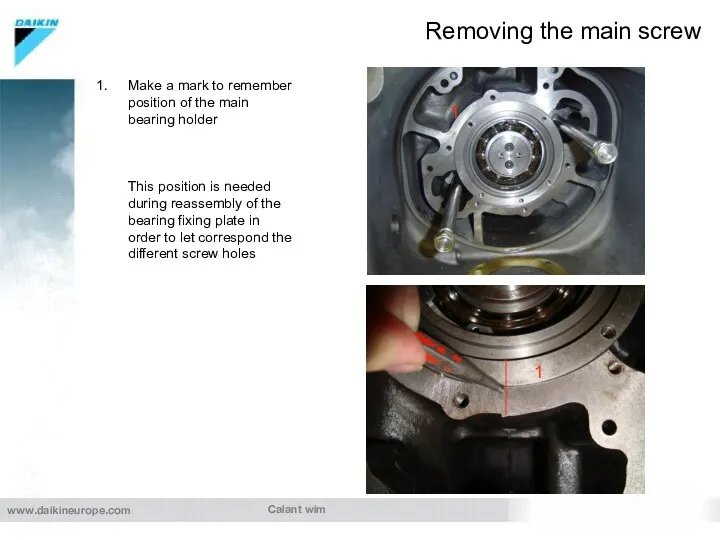

- 15. Calant wim Removing the main screw Make a mark to remember position of the main bearing

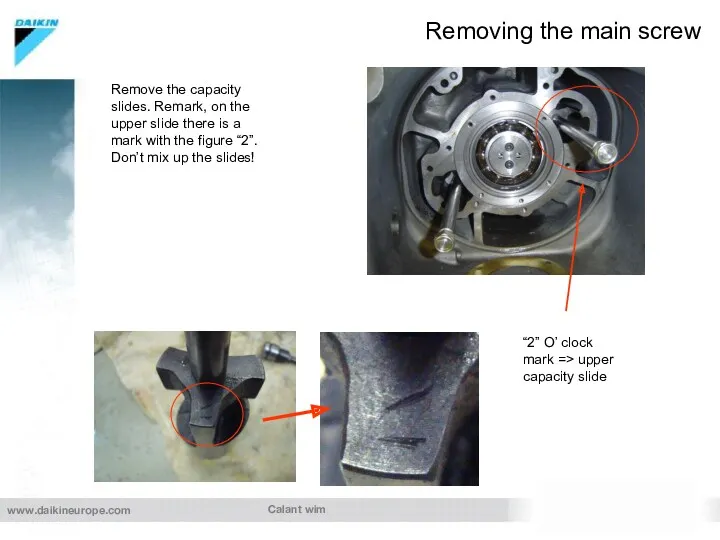

- 16. Calant wim Removing the main screw “2” O’ clock mark => upper capacity slide Remove the

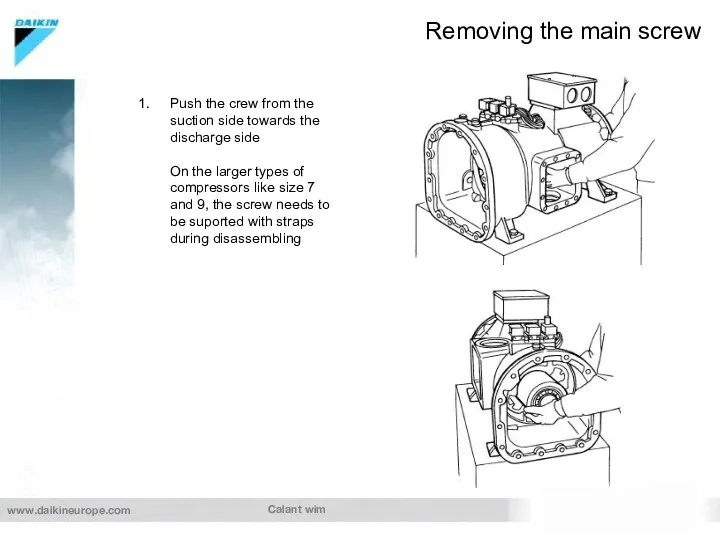

- 17. Calant wim Removing the main screw Push the crew from the suction side towards the discharge

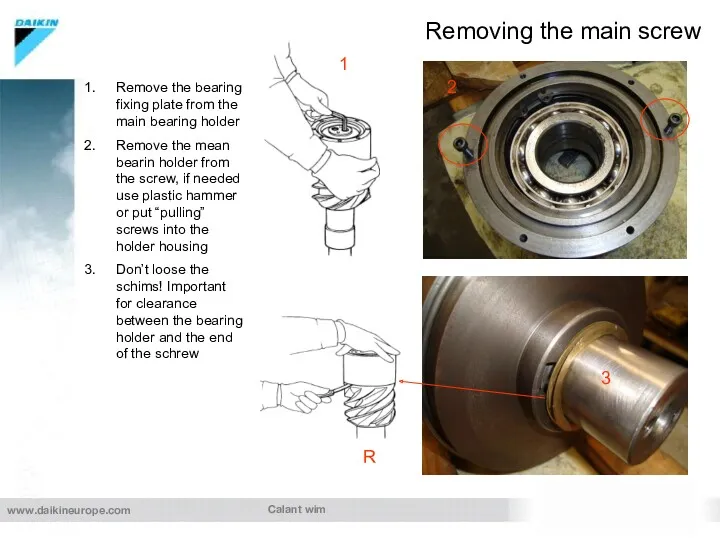

- 18. Calant wim Removing the main screw Remove the bearing fixing plate from the main bearing holder

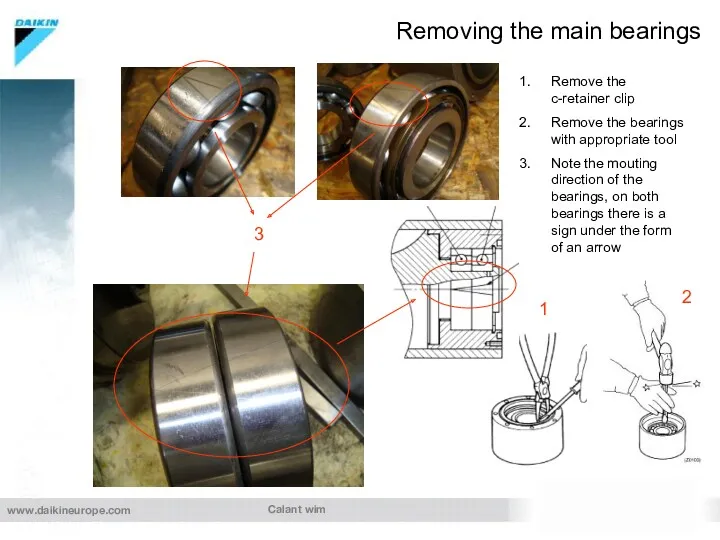

- 19. Calant wim Removing the main bearings Remove the c-retainer clip Remove the bearings with appropriate tool

- 20. Calant Wim Overhaul Daikin screw compressor important issues during assembling of the Daikin G/F type compressor

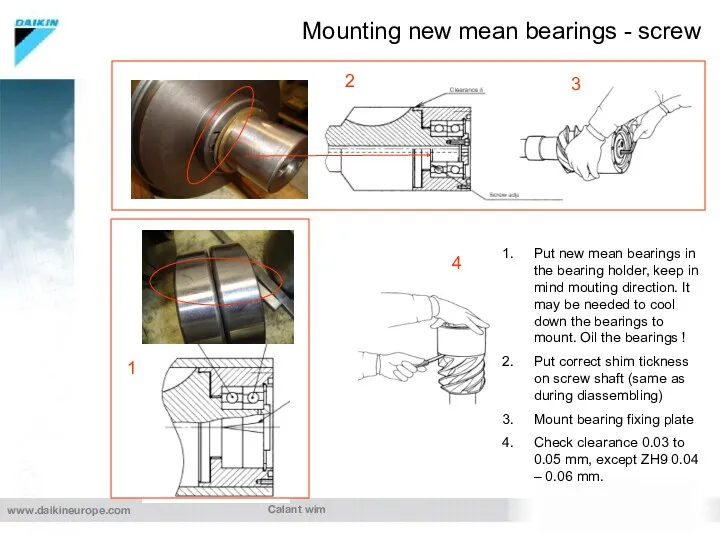

- 21. Calant wim Put new mean bearings in the bearing holder, keep in mind mouting direction. It

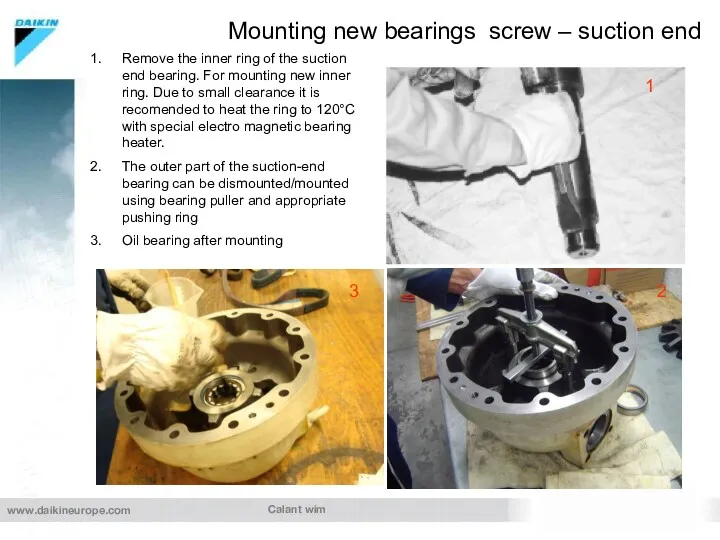

- 22. Calant wim Mounting new bearings screw – suction end Remove the inner ring of the suction

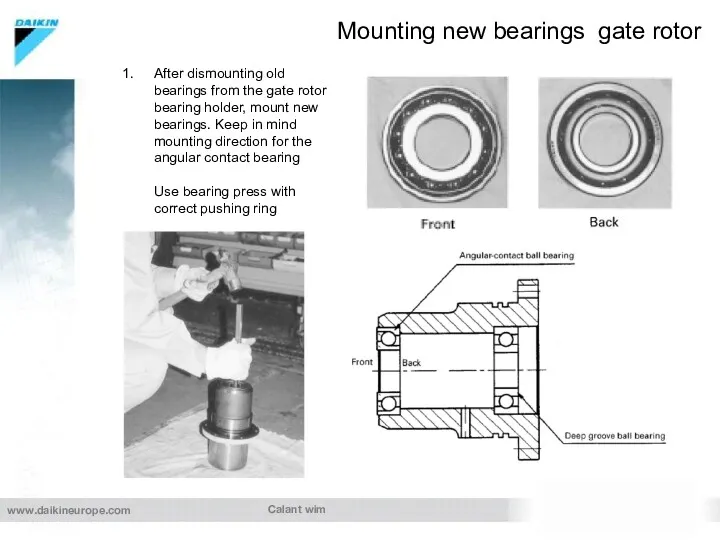

- 23. Calant wim Mounting new bearings gate rotor After dismounting old bearings from the gate rotor bearing

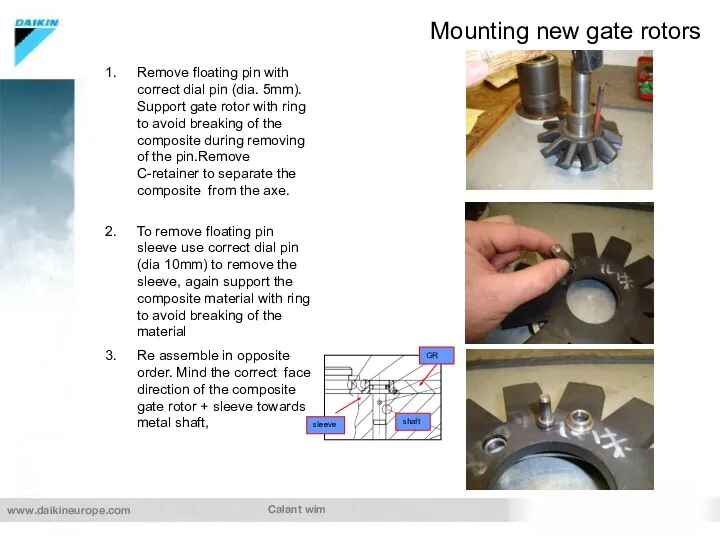

- 24. Calant wim Mounting new gate rotors Remove floating pin with correct dial pin (dia. 5mm). Support

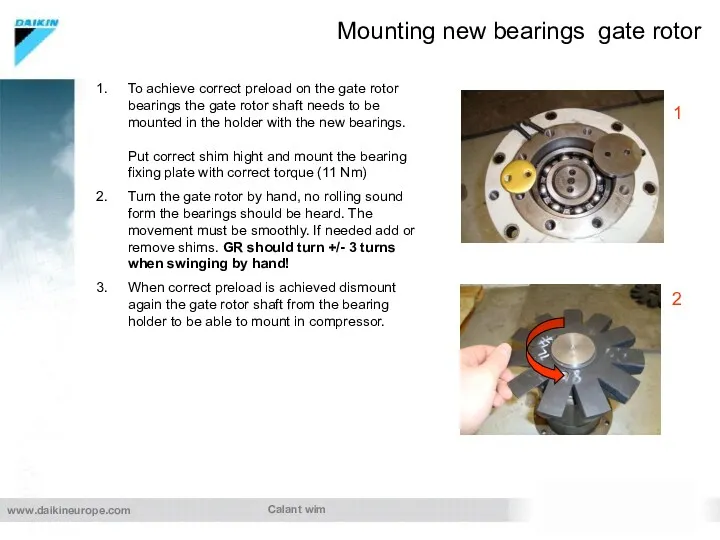

- 25. Calant wim Mounting new bearings gate rotor To achieve correct preload on the gate rotor bearings

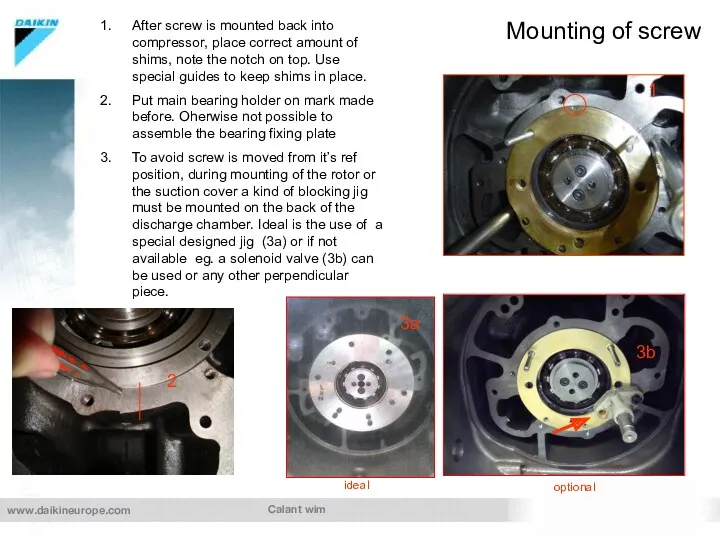

- 26. Calant wim Mounting of screw After screw is mounted back into compressor, place correct amount of

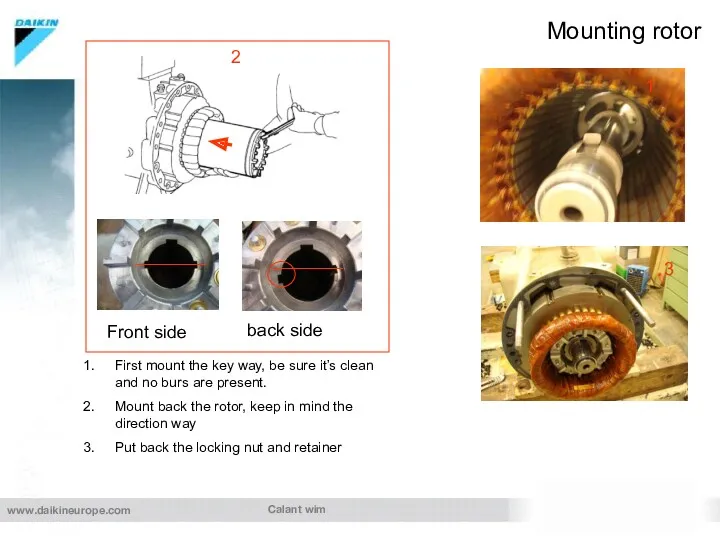

- 27. Calant wim Mounting rotor Front side back side First mount the key way, be sure it’s

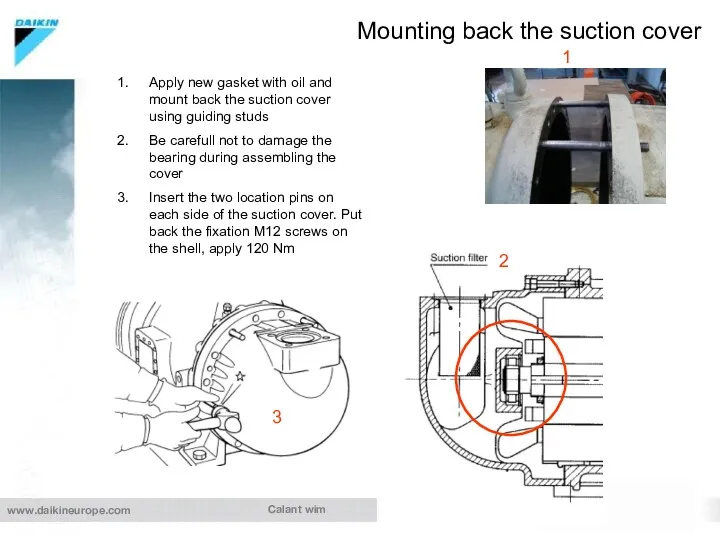

- 28. Calant wim Mounting back the suction cover 1 Apply new gasket with oil and mount back

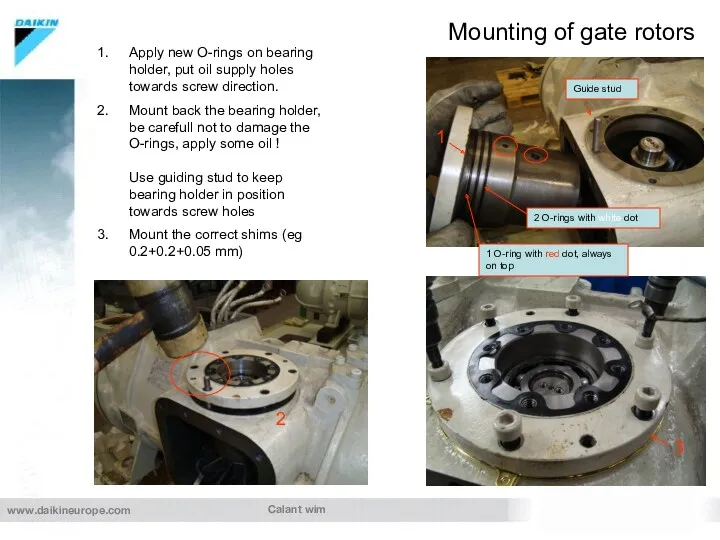

- 29. Calant wim Mounting of gate rotors Apply new O-rings on bearing holder, put oil supply holes

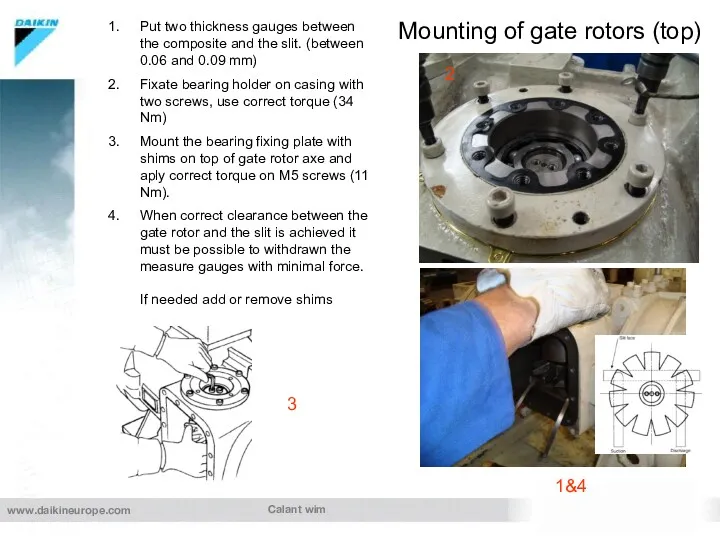

- 30. Calant wim Mounting of gate rotors (top) Put two thickness gauges between the composite and the

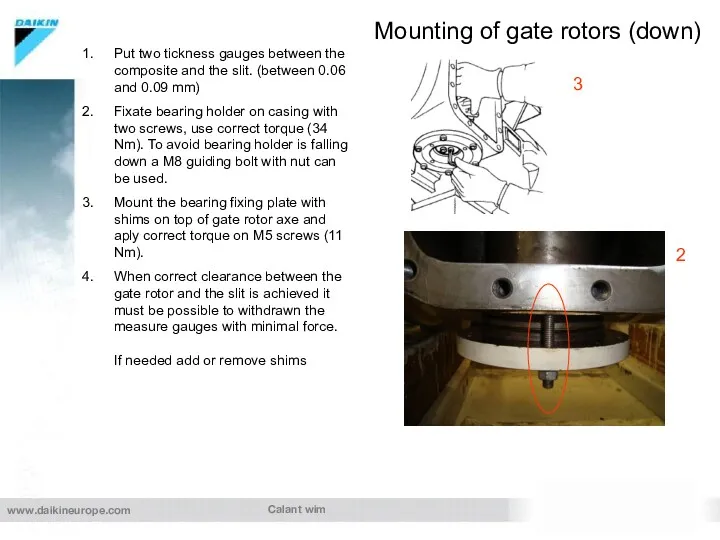

- 31. Calant wim Mounting of gate rotors (down) Put two tickness gauges between the composite and the

- 32. Calant wim Checking idle run screw After both gate rotors are mounted, an idle run of

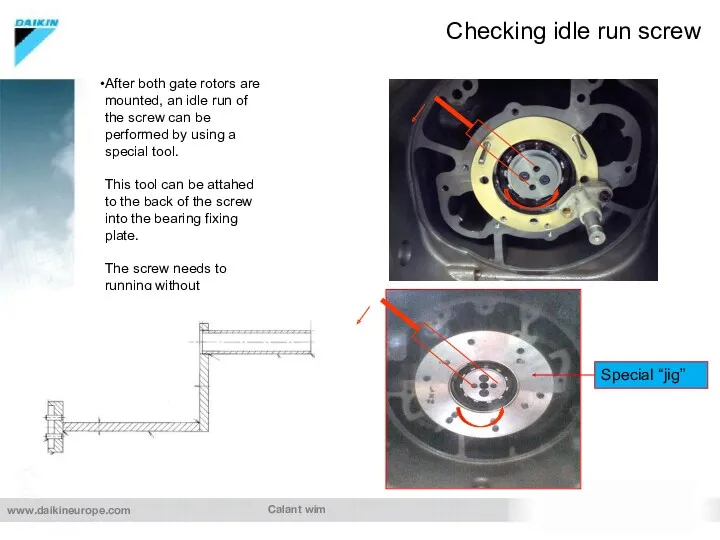

- 33. Calant wim Final assembly of mean bearing fixing plate Finally the capacity valves and the main

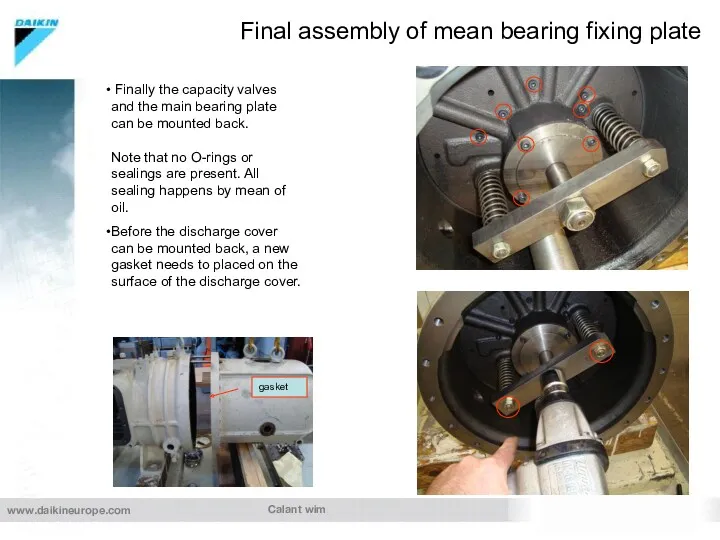

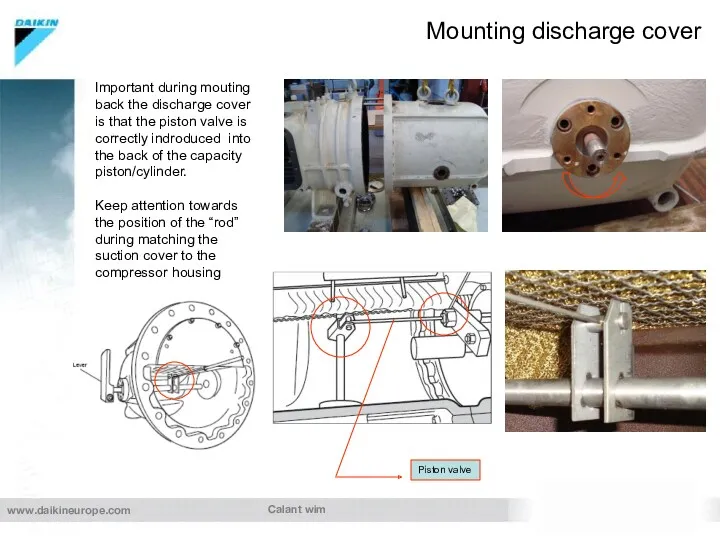

- 34. Calant wim Mounting discharge cover Important during mouting back the discharge cover is that the piston

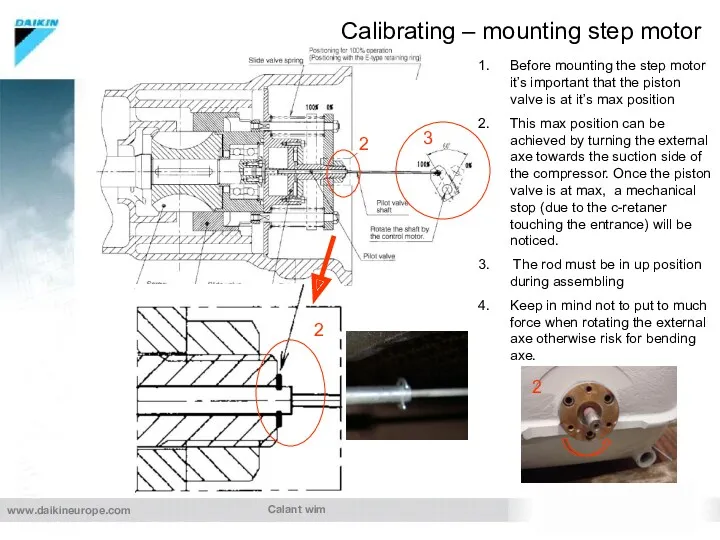

- 35. Calant wim Calibrating – mounting step motor Before mounting the step motor it’s important that the

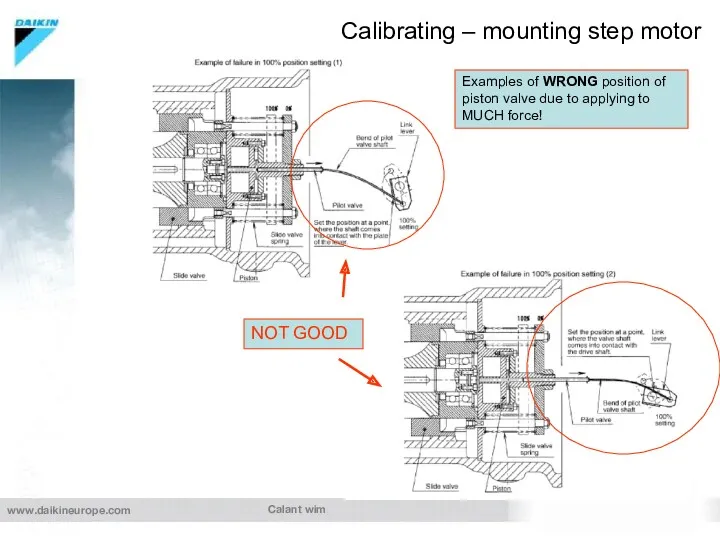

- 36. Calant wim Calibrating – mounting step motor Examples of WRONG position of piston valve due to

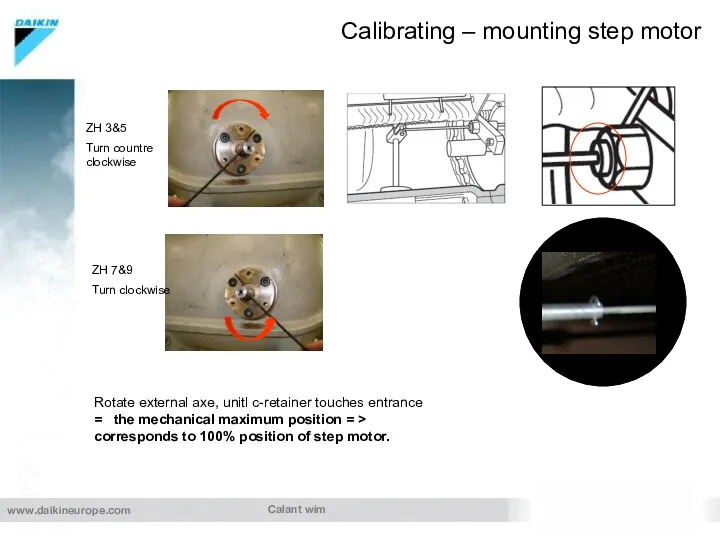

- 37. Calant wim Calibrating – mounting step motor Rotate external axe, unitl c-retainer touches entrance = the

- 38. Calant wim Calibrating – mounting step motor ZH.. 3& 5 types ZH.. 7&9 types VM30APTE VM30APZTE

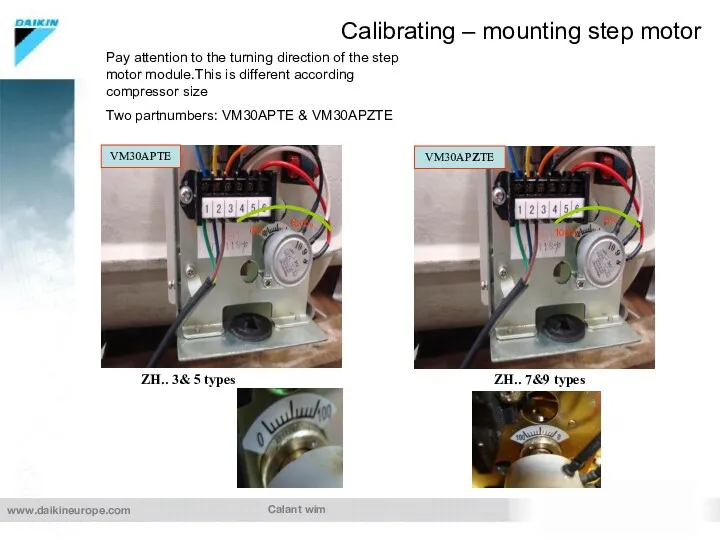

- 39. Calant wim Calibrating – mounting step motor Before stepmotor is mounted on external axe the stepmotor

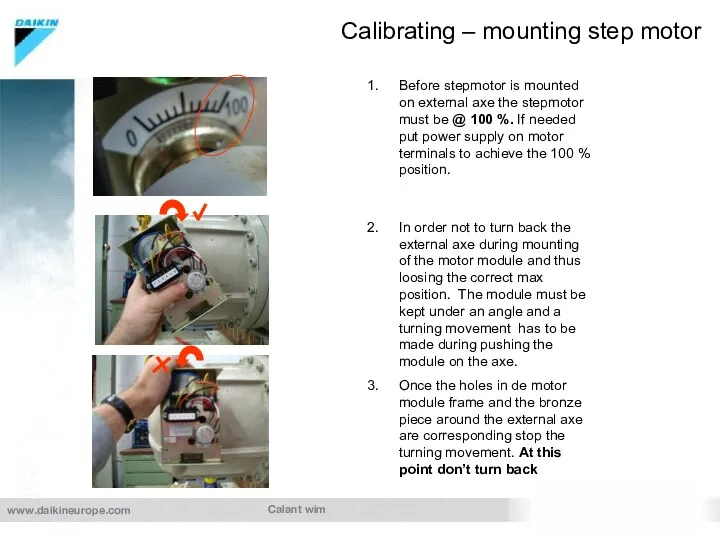

- 40. Calant wim Calibrating – mounting step motor Once the motormodule is at its position, fasten the

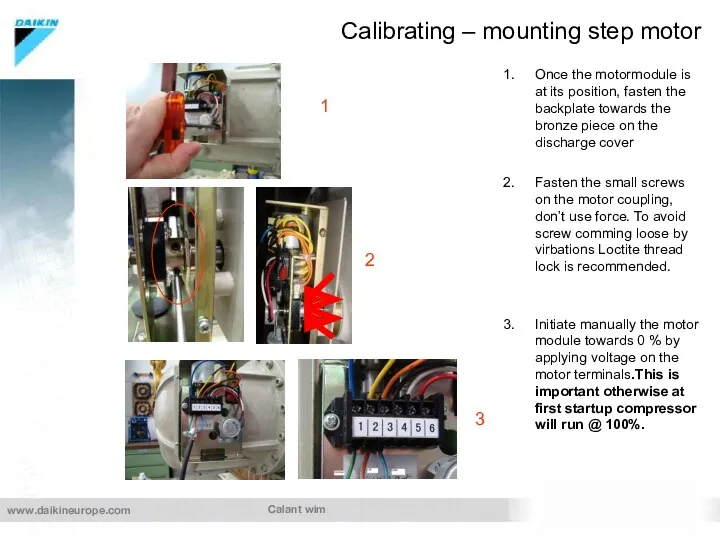

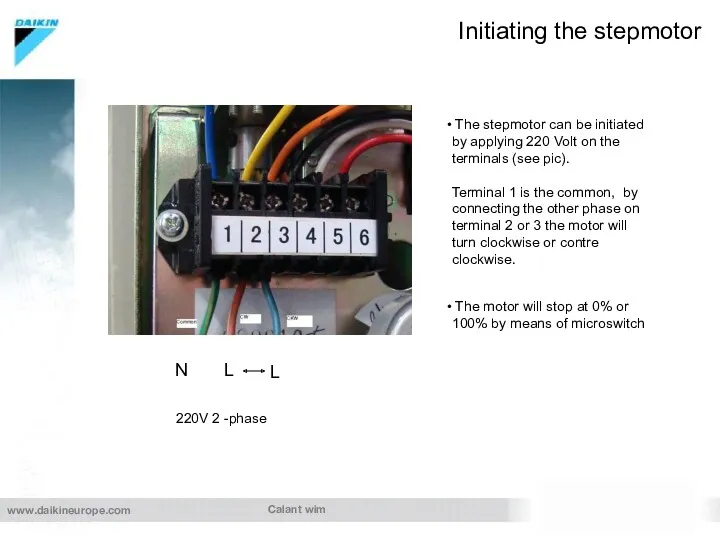

- 41. Calant wim Initiating the stepmotor 220V 2 -phase N L L The stepmotor can be initiated

- 43. Скачать презентацию

Задачи на машины постоянного тока. Лекция 1

Задачи на машины постоянного тока. Лекция 1 Игра по физике Тайна черных ящиков для учащихся 10-11 классов

Игра по физике Тайна черных ящиков для учащихся 10-11 классов История развития физики. Физика и техника

История развития физики. Физика и техника Познавательная викторина

Познавательная викторина Будова атома. Склад атомних ядер. Протонне та нуклонне число

Будова атома. Склад атомних ядер. Протонне та нуклонне число Урок Оптические приборы, физика11 класс

Урок Оптические приборы, физика11 класс БЛОКИ. «ЗОЛОТОЕ ПРАВИЛО МЕХАНИКИ»

БЛОКИ. «ЗОЛОТОЕ ПРАВИЛО МЕХАНИКИ» Общественному смотр знаний в 9классе по разделу Механика.

Общественному смотр знаний в 9классе по разделу Механика. Разработка внеклассного мероприятия Физический КВН (8 класс)

Разработка внеклассного мероприятия Физический КВН (8 класс) Адсорбция изотермалары

Адсорбция изотермалары ФОРМИРОВАНИЕ ИНФОРМАЦИОННОЙ КОМПЕТЕНЦИИ УЧАЩИХСЯ ПРИ ИЗУЧЕНИИ ТЕМЫ ЭЛЕМЕНТЫ КВАНТОВОЙ ФИЗИКИ9 КЛАСС

ФОРМИРОВАНИЕ ИНФОРМАЦИОННОЙ КОМПЕТЕНЦИИ УЧАЩИХСЯ ПРИ ИЗУЧЕНИИ ТЕМЫ ЭЛЕМЕНТЫ КВАНТОВОЙ ФИЗИКИ9 КЛАСС Радиоактивность, модели атомов

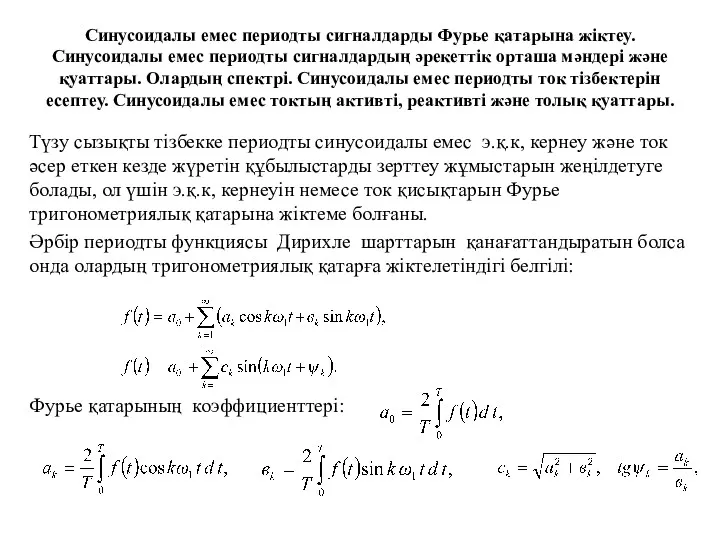

Радиоактивность, модели атомов Синусоидалы емес периодты сигналдарды Фурье қатарына жіктеу. Синусоидалы емес периодты сигналдардың әрекеттік орташа мәндері

Синусоидалы емес периодты сигналдарды Фурье қатарына жіктеу. Синусоидалы емес периодты сигналдардың әрекеттік орташа мәндері Система живлення двигуна УТД-20С1 повітрям

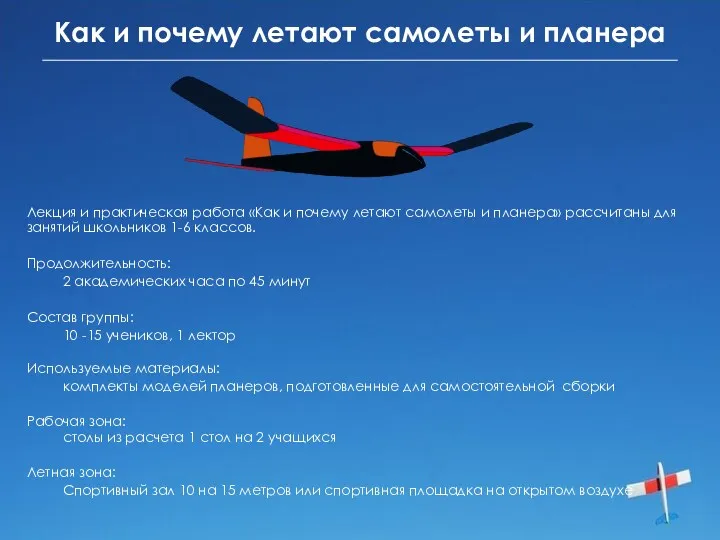

Система живлення двигуна УТД-20С1 повітрям Как и почему летают самолеты и планера

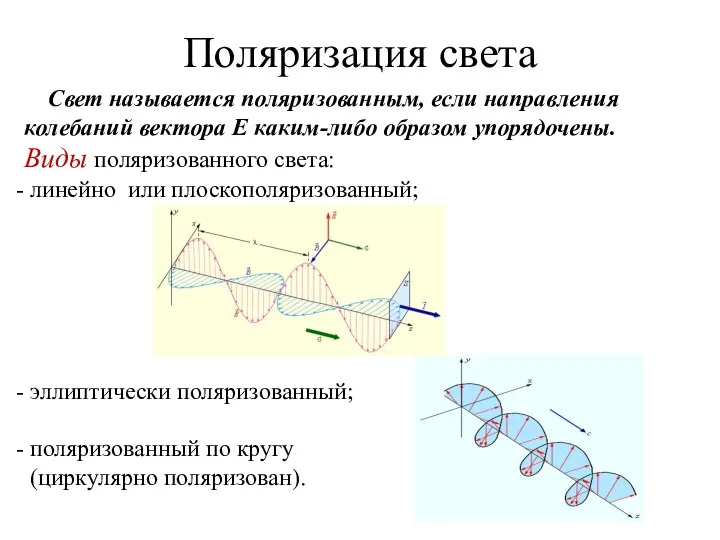

Как и почему летают самолеты и планера Поляризация света

Поляризация света Ядерная физика. (Урок-обобщение). 9 класс

Ядерная физика. (Урок-обобщение). 9 класс Электрические цепи

Электрические цепи Принцип действия тепловых двигателей

Принцип действия тепловых двигателей Физика и техника

Физика и техника Качественные задачи по физике

Качественные задачи по физике Повышение качества образования по предмету физика через систему использования интегрированных уроков в условиях модернизации образовательной системы РФ

Повышение качества образования по предмету физика через систему использования интегрированных уроков в условиях модернизации образовательной системы РФ Рентгеновские аппараты. Цифровые рентгенодиагностические комплексы. (Лекция 10)

Рентгеновские аппараты. Цифровые рентгенодиагностические комплексы. (Лекция 10) Первый закон термодинамики

Первый закон термодинамики Сила упругости

Сила упругости Основы триботехники. Лекция 1

Основы триботехники. Лекция 1 Лекция 8.2. Диэлектрические материалы. Классификация

Лекция 8.2. Диэлектрические материалы. Классификация Анализ технико-экономической эффективности КПГУ на базе паротурбинной установки ПТ-135/165-130/15

Анализ технико-экономической эффективности КПГУ на базе паротурбинной установки ПТ-135/165-130/15