Содержание

- 2. Acknowledgements Prof. GuoLiang Chen; Prof. Hywel A Davies; Prof. Peter K Liaw; Prof. George Smith; Prof.

- 3. Outlines I. Background & Motivations II. Results & Discussions III. Summaries

- 4. (1) Conventional alloys I. Background & Motivations Steel, A=Fe, B=Carbon, δB Cast Iron, A=Fe, B=Carbon, δB

- 5. (2) High Entropy Alloys HEAs=A+B+C+D+E; 50% 15% AlCoCrFeNi=HEA , Zhou, APL, 2007 CoCrCuFeNi=HEA, Yeh, MMTA, 2004;

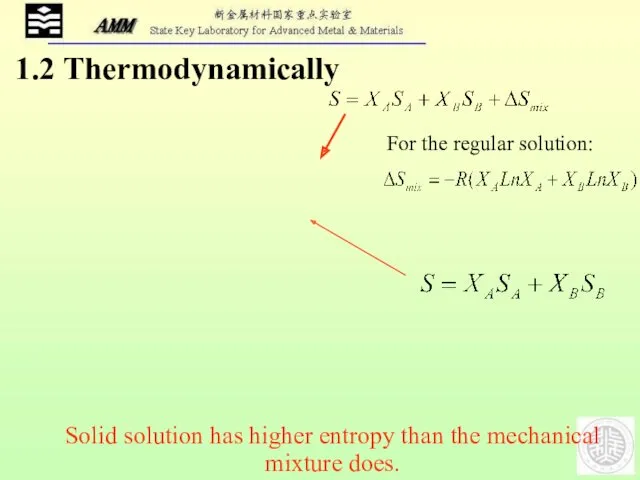

- 6. Solid solution has higher entropy than the mechanical mixture does. 1.2 Thermodynamically For the regular solution:

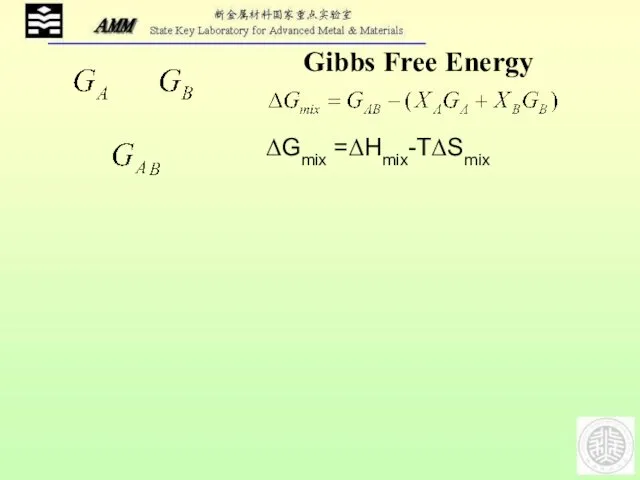

- 7. Gibbs Free Energy ΔGmix =ΔHmix-TΔSmix

- 8. 1.3 Properties and Applications High Strength; Zhou, APL, 2007; High wear resistance; Lin, Surface Coating technology,

- 9. 1 Coatings, Barriers, etc. Diffusion barriers for Cu interconnections; Tsai, APL, 2008 2 Structural Materials 3

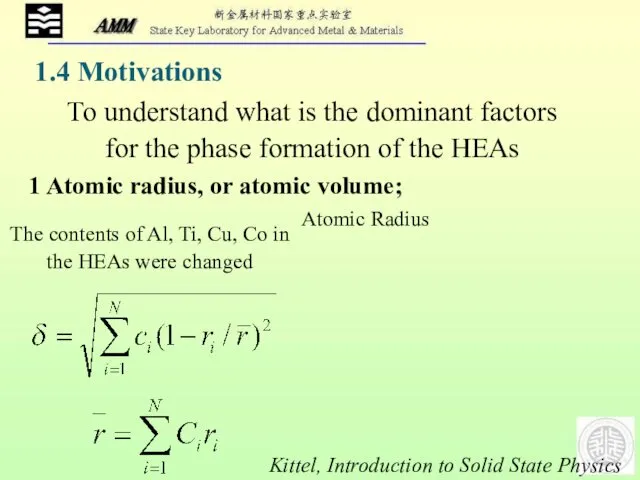

- 10. To understand what is the dominant factors for the phase formation of the HEAs 1 Atomic

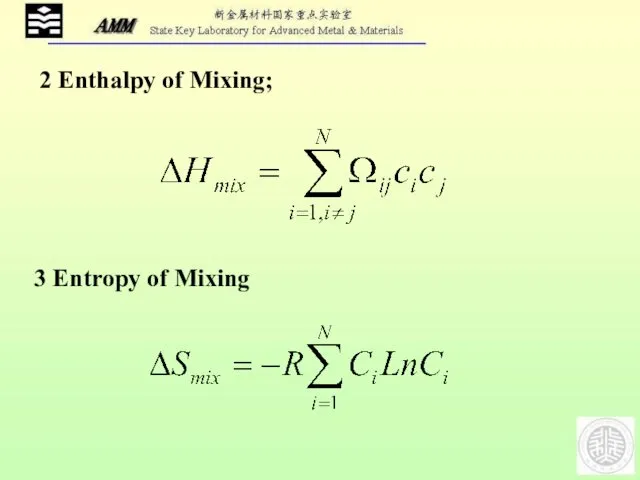

- 11. 2 Enthalpy of Mixing; 3 Entropy of Mixing

- 12. 4 Cooling Rate 5 Tensile and compressive properties Critical cooling rate? Like the BMG? Tensile elongation=0?

- 13. CoCrFeNiCu1-yAly FCC BCC, High APE to Lower APE, with larger atoms Al 2.1. Alloying with different

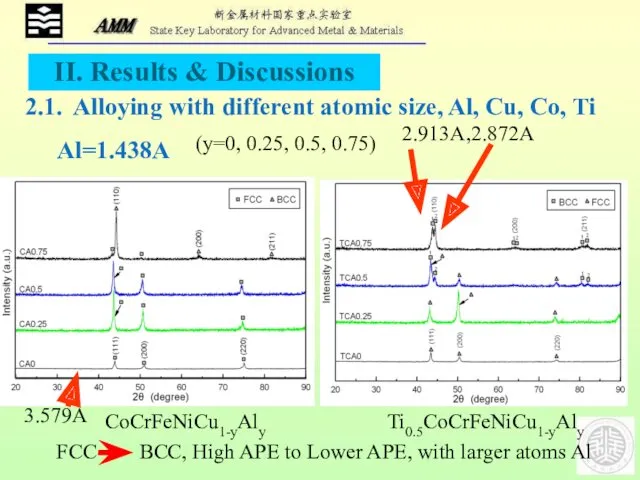

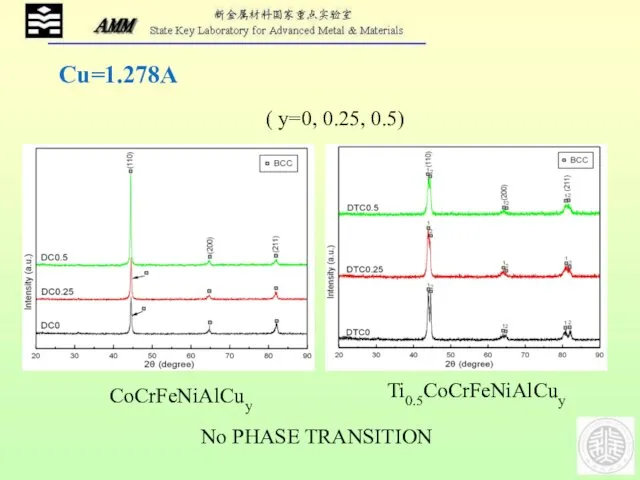

- 14. Cu=1.278A CoCrFeNiAlCuy ( y=0, 0.25, 0.5) Ti0.5CoCrFeNiAlCuy No PHASE TRANSITION

- 15. Co=1.251A The smaller BCC transit to FCC firstly after adding Co Biger BCC1phase:2.913A; Smaller BCC2phase:2.872A

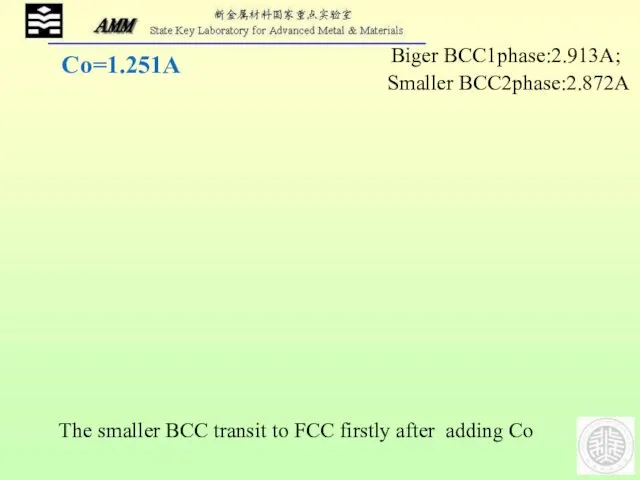

- 16. [Al1Co1Cr1Fe1Ni1]Tix alloys BCC+Ti BCC+BCC Ti=1.448A

- 17. After adding Ti, Laves phase forms

- 18. Zhou, APL, 2008 The transition is mainly lattice distortion induced and APE related

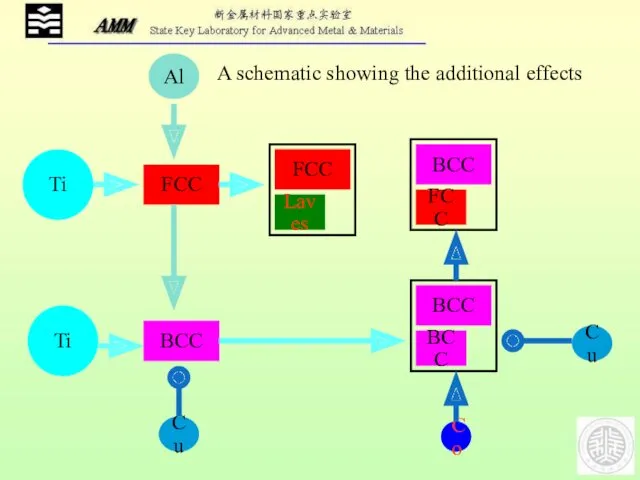

- 19. A schematic showing the additional effects

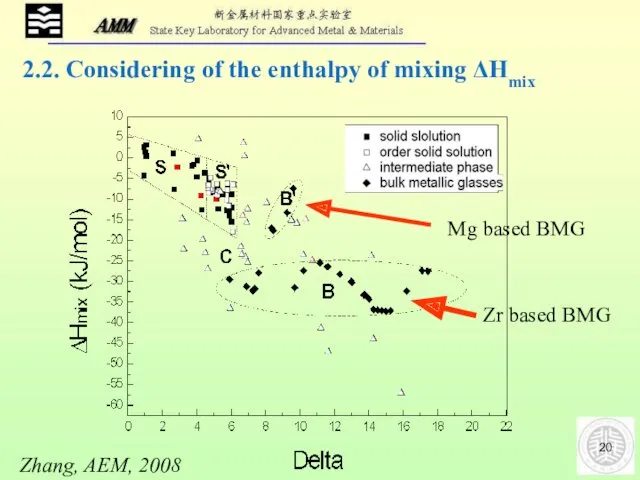

- 20. Zhang, AEM, 2008 2.2. Considering of the enthalpy of mixing ΔHmix Mg based BMG Zr based

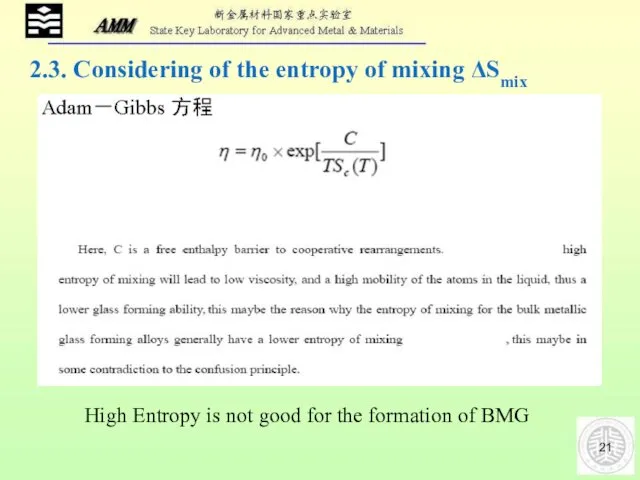

- 21. 2.3. Considering of the entropy of mixing ΔSmix High Entropy is not good for the formation

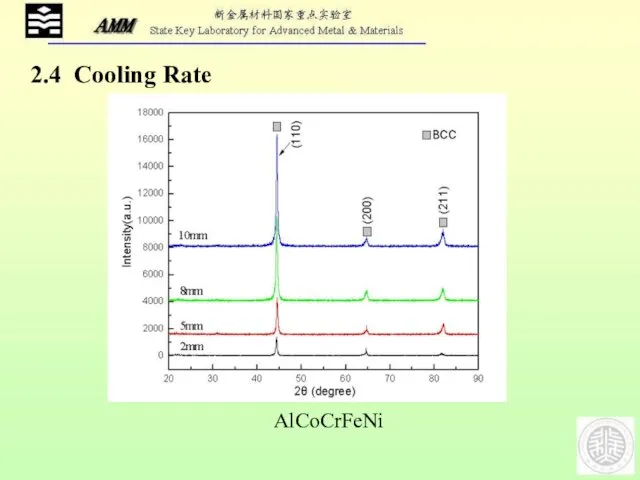

- 22. 2.4 Cooling Rate AlCoCrFeNi

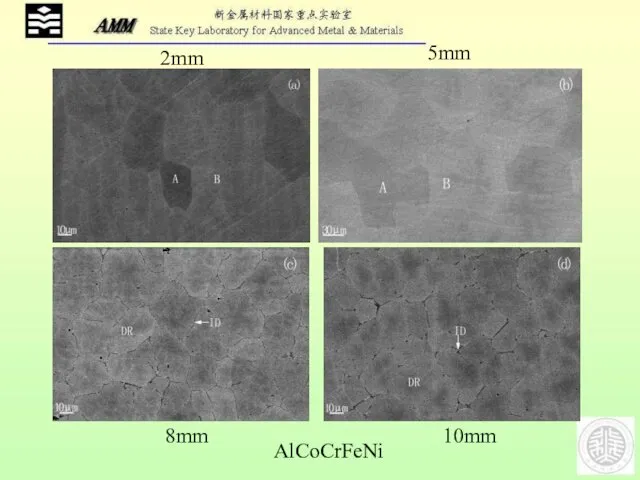

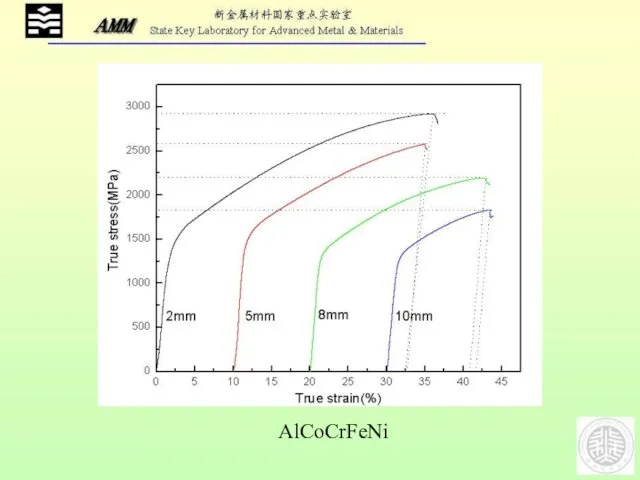

- 23. AlCoCrFeNi 2mm 5mm 8mm 10mm

- 24. AlCoCrFeNi

- 25. 2.5 Tensile and Compressive properties XRD pattern for the CoCrCuFeNiAl0.5 alloy.

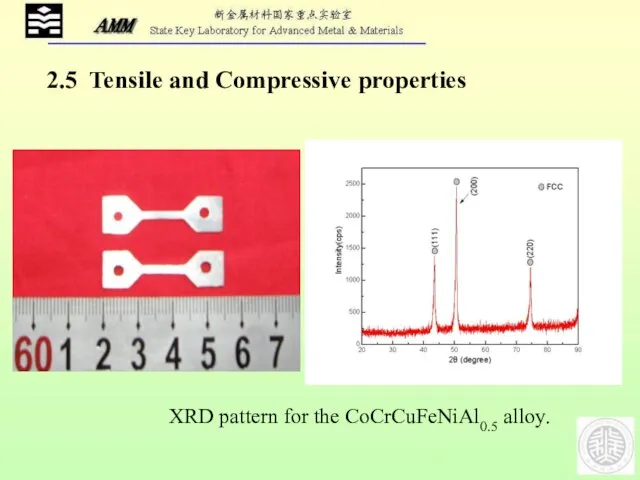

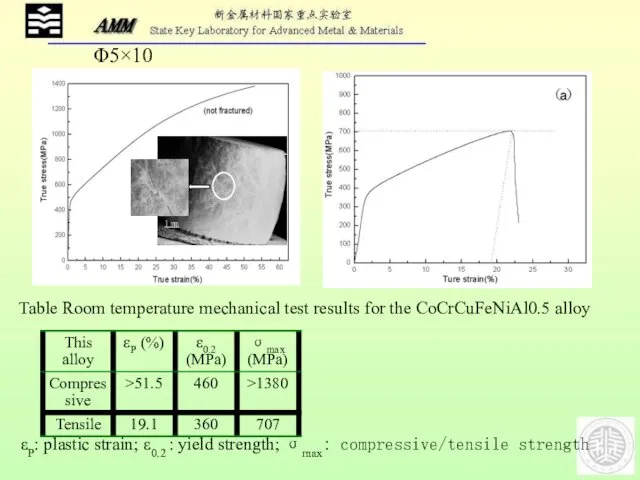

- 26. Table Room temperature mechanical test results for the CoCrCuFeNiAl0.5 alloy εP: plastic strain; ε0.2 : yield

- 27. III. Summaries 1 Atomic size mismatch is the dominant factor for the phase formation of the

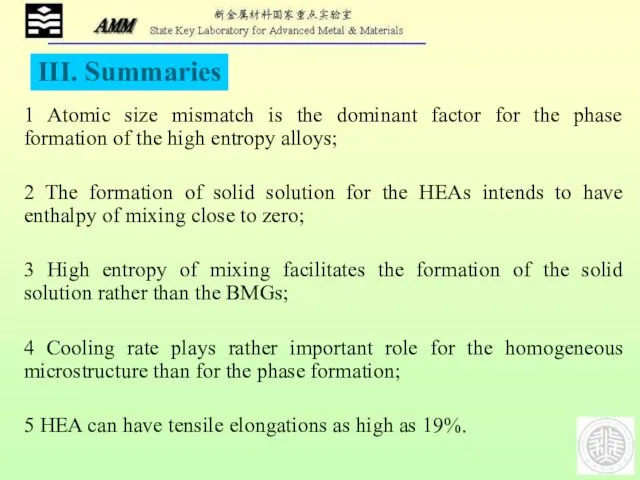

- 29. Скачать презентацию

![[Al1Co1Cr1Fe1Ni1]Tix alloys BCC+Ti BCC+BCC Ti=1.448A](/_ipx/f_webp&q_80&fit_contain&s_1440x1080/imagesDir/jpg/17753/slide-15.jpg)

Системы электростартерного пуска

Системы электростартерного пуска Водород - топливо будущего

Водород - топливо будущего Последовательное соединение проводников

Последовательное соединение проводников Коробка передач на ВАЗ-2106

Коробка передач на ВАЗ-2106 Последние достижения в области нанотехнологий

Последние достижения в области нанотехнологий Детали и механизмы машин. Паровая машина

Детали и механизмы машин. Паровая машина Мирный атом. АЭС

Мирный атом. АЭС Охота за полярными сияниями

Охота за полярными сияниями Организация рабочего места слесаря. Тема 1.2

Организация рабочего места слесаря. Тема 1.2 Механические характеристики материалов

Механические характеристики материалов Приборы для измерения давления

Приборы для измерения давления Презентация к уроку Гамма - излучение.

Презентация к уроку Гамма - излучение. Механика твердого тела. Тема 4

Механика твердого тела. Тема 4 Smart технологиялар. Smart қызметтерді пайдалану

Smart технологиялар. Smart қызметтерді пайдалану Воздухораспределитель 292 - 001 пассажирский

Воздухораспределитель 292 - 001 пассажирский Механическая энергия. Кинетическая и потенциальная энергия. Закон сохранения энергии

Механическая энергия. Кинетическая и потенциальная энергия. Закон сохранения энергии Классификация переездов. Устройство и оборудование переездов

Классификация переездов. Устройство и оборудование переездов Радиоволны. Диапазон

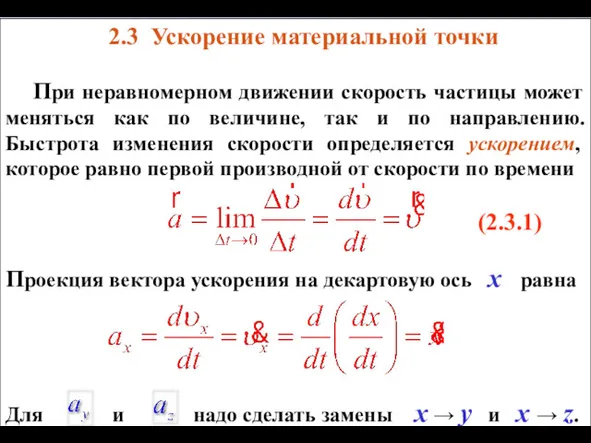

Радиоволны. Диапазон Ускорение материальной точки

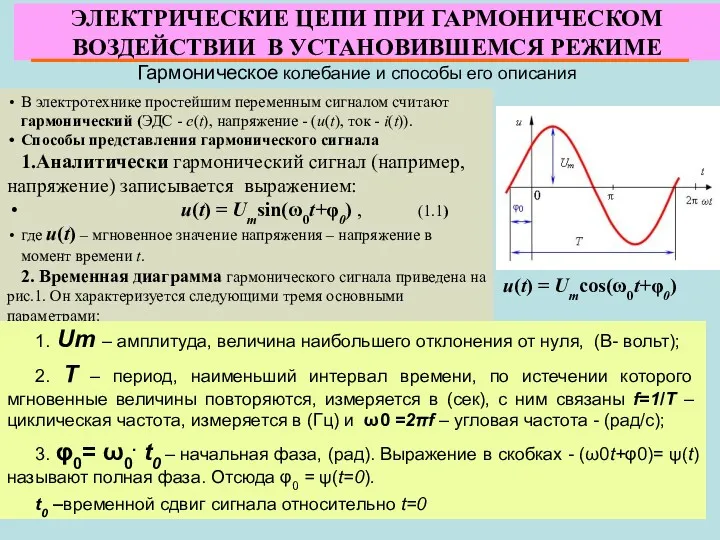

Ускорение материальной точки Электрические цепи при гармоническом воздействии в установившемся режиме

Электрические цепи при гармоническом воздействии в установившемся режиме Спектры. Виды спектров

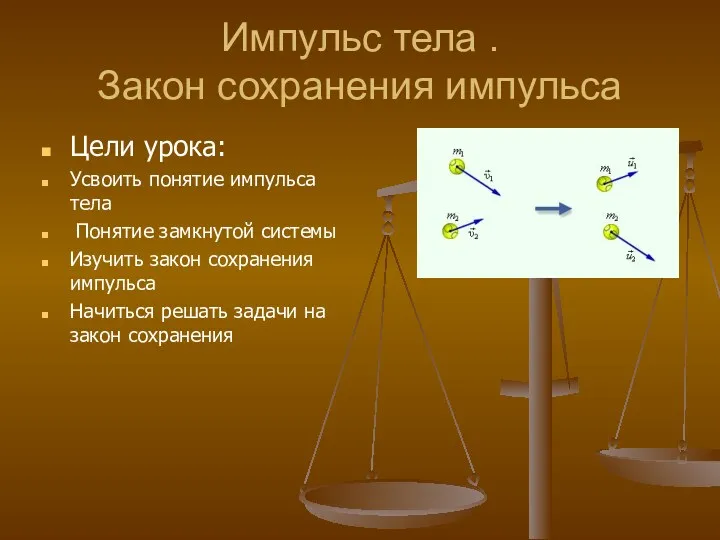

Спектры. Виды спектров Импульс тела. Закон сохранения импульса

Импульс тела. Закон сохранения импульса Презентация урока Теплота сгорания топлива. Удельная теплота сгорания 8 класс.

Презентация урока Теплота сгорания топлива. Удельная теплота сгорания 8 класс. Интегральные датчики. Датчики давления, влажности, Холла

Интегральные датчики. Датчики давления, влажности, Холла Лабораторная работа №4 Изучение капиллярных явлений, обусловленных поверхностным натяжением жидкости 10 класс.

Лабораторная работа №4 Изучение капиллярных явлений, обусловленных поверхностным натяжением жидкости 10 класс. Взаимодействие тел. Масса тела.

Взаимодействие тел. Масса тела. Физика. Что изучает физика. Физические явления, наблюдения, опыты. Механика

Физика. Что изучает физика. Физические явления, наблюдения, опыты. Механика Полупроводниковые материалы. Лекция 4

Полупроводниковые материалы. Лекция 4