Содержание

- 2. Content Introduction Theory and principles Radiographic equipment and accessories Variables Techniques and procedures Radiographic evaluation Applications

- 3. Introduction This presentation shows information about the NDT method of radiographic inspection or radiography. Radiography uses

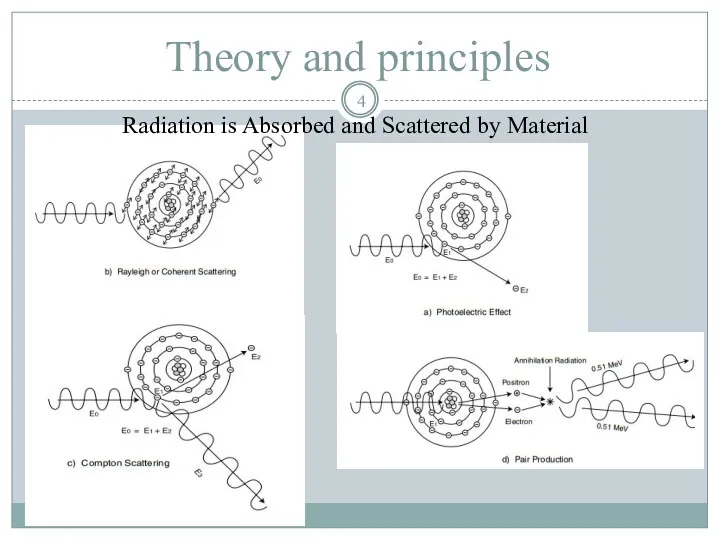

- 4. Theory and principles Radiation is Absorbed and Scattered by Material

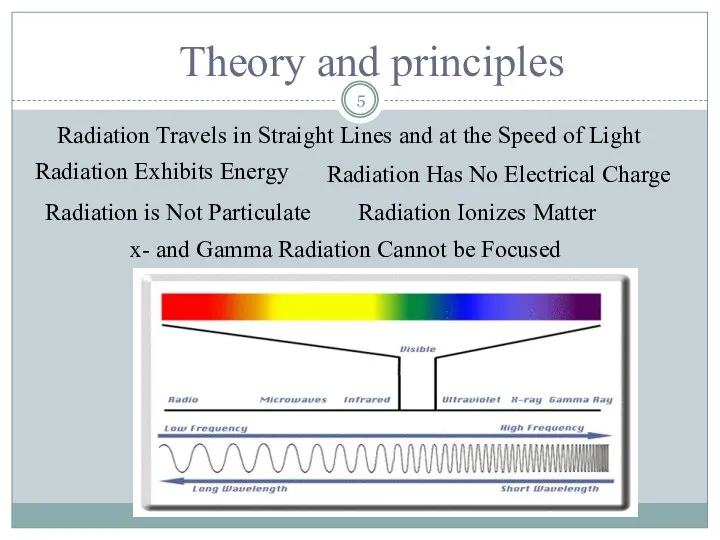

- 5. Theory and principles Radiation Travels in Straight Lines and at the Speed of Light Radiation Exhibits

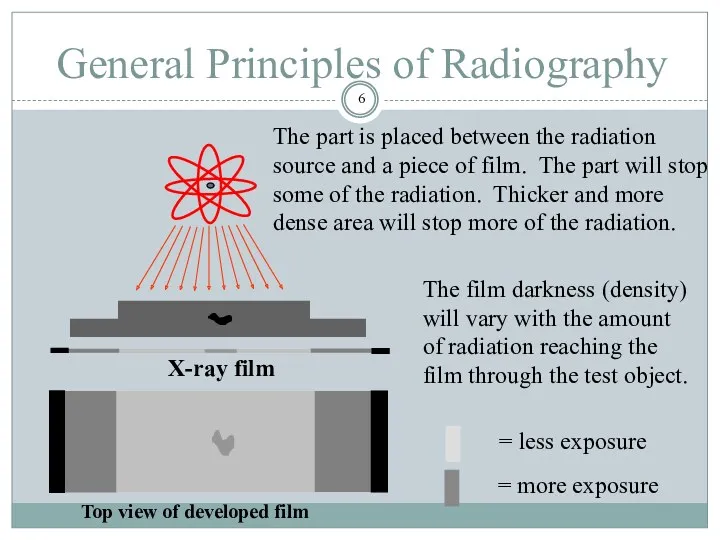

- 6. General Principles of Radiography Top view of developed film X-ray film The film darkness (density) will

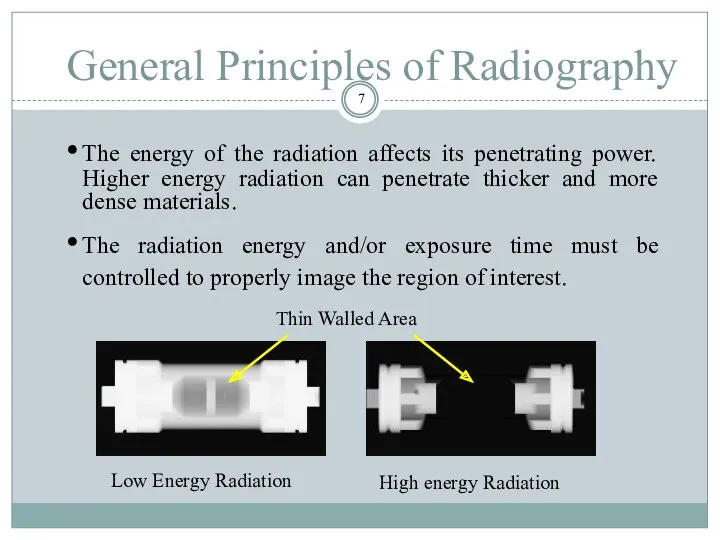

- 7. General Principles of Radiography The energy of the radiation affects its penetrating power. Higher energy radiation

- 8. Gamma Radiography Gamma rays are produced by a radioisotope. A radioisotope has an unstable nuclei that

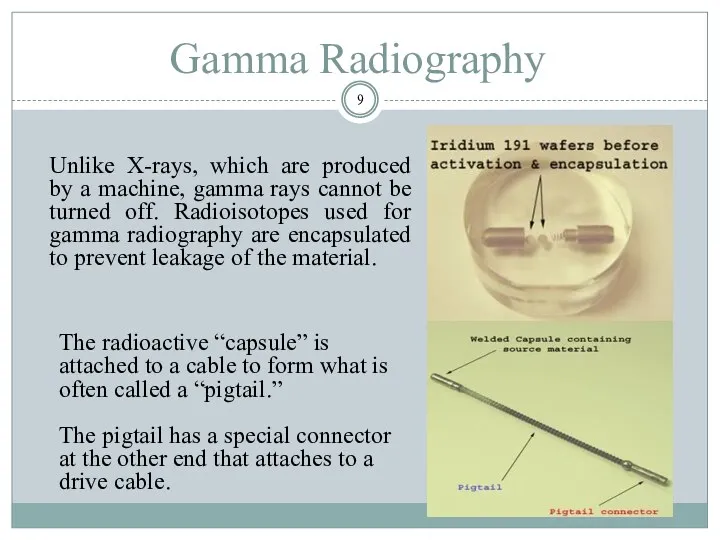

- 9. Gamma Radiography Unlike X-rays, which are produced by a machine, gamma rays cannot be turned off.

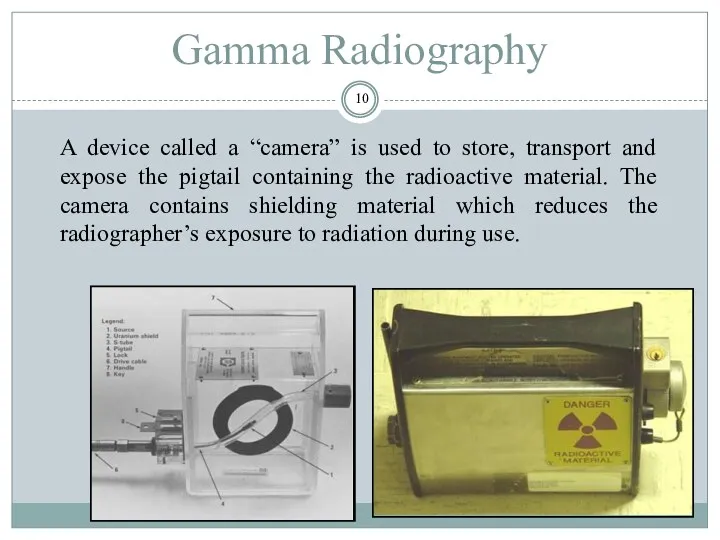

- 10. Gamma Radiography A device called a “camera” is used to store, transport and expose the pigtail

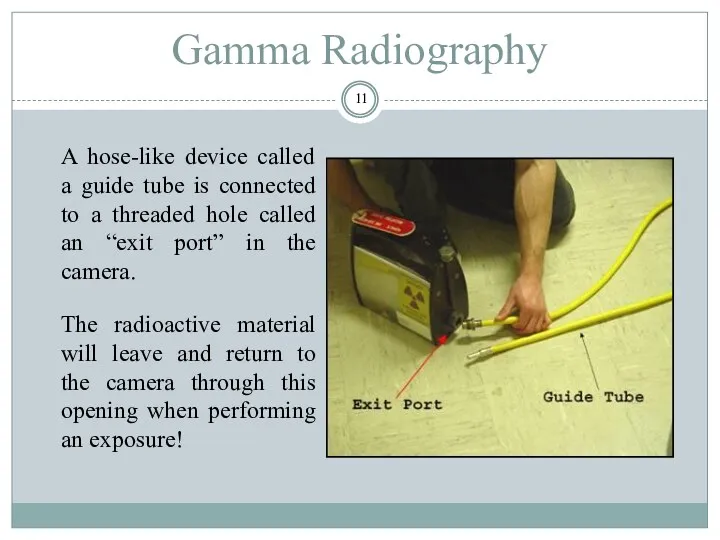

- 11. Gamma Radiography A hose-like device called a guide tube is connected to a threaded hole called

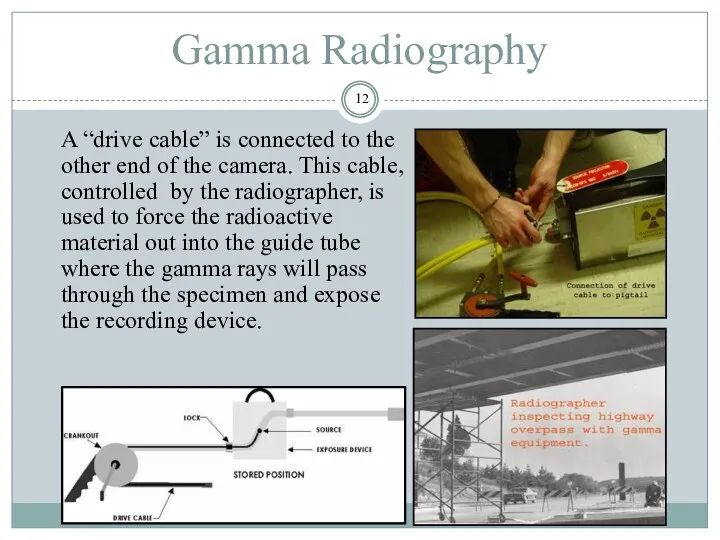

- 12. Gamma Radiography A “drive cable” is connected to the other end of the camera. This cable,

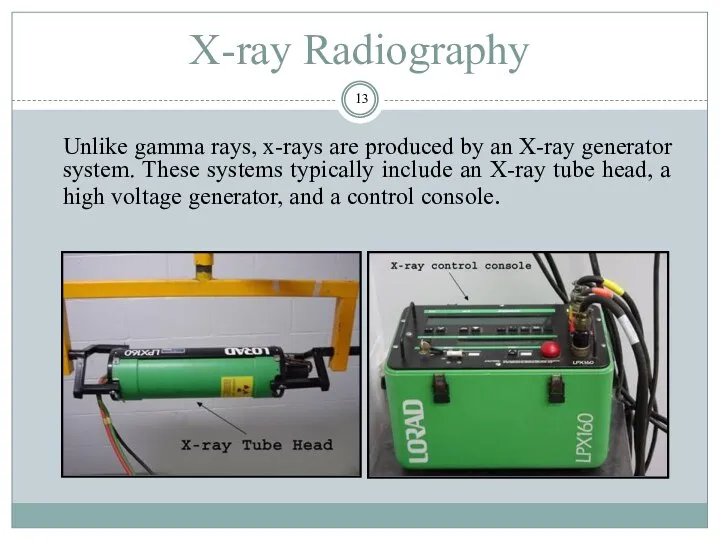

- 13. X-ray Radiography Unlike gamma rays, x-rays are produced by an X-ray generator system. These systems typically

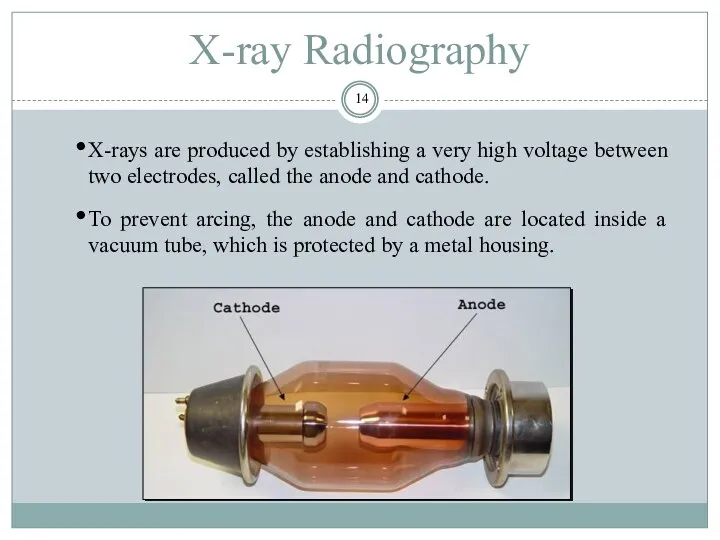

- 14. X-ray Radiography X-rays are produced by establishing a very high voltage between two electrodes, called the

- 15. Variables of radiography Of all the nondestructive testing methods, radiography certainly has the most variables. These

- 16. Variables of radiography In order to control these variables so that the benefits can be maximized

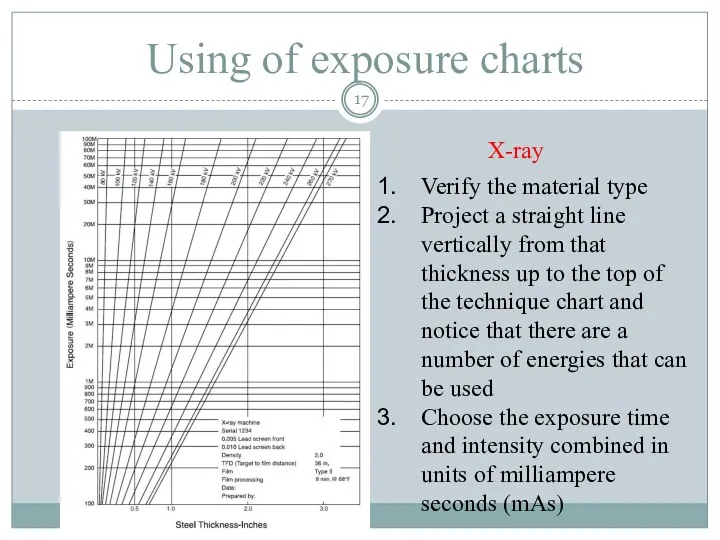

- 17. Using of exposure charts Verify the material type Project a straight line vertically from that thickness

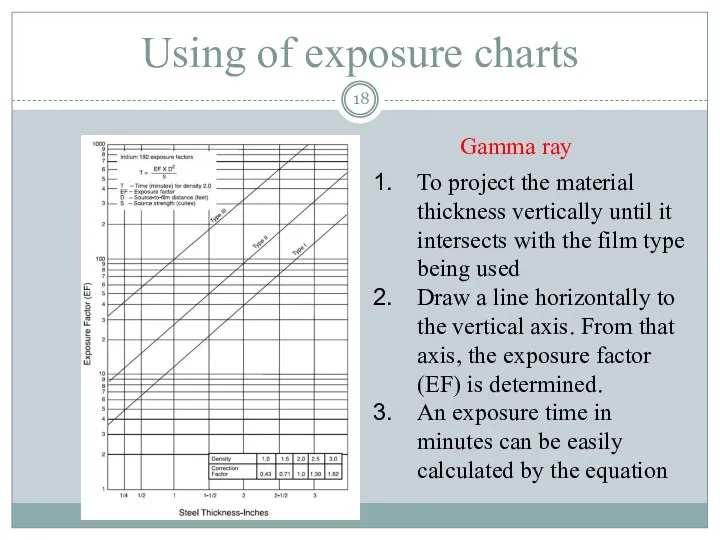

- 18. Using of exposure charts To project the material thickness vertically until it intersects with the film

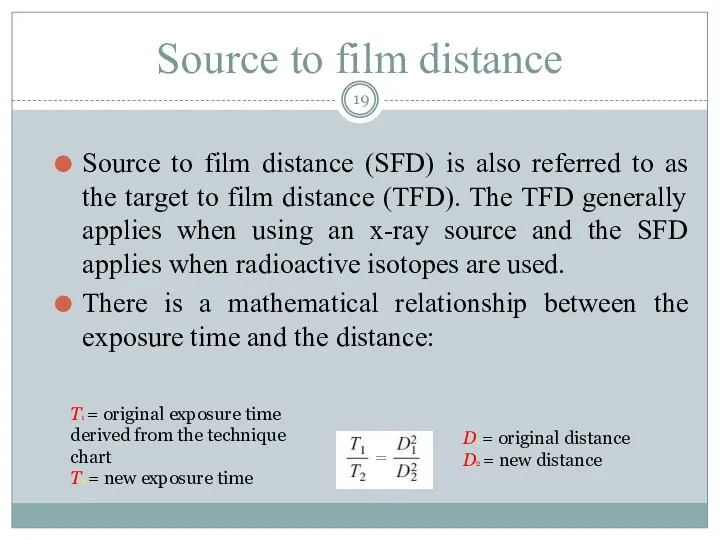

- 19. Source to film distance Source to film distance (SFD) is also referred to as the target

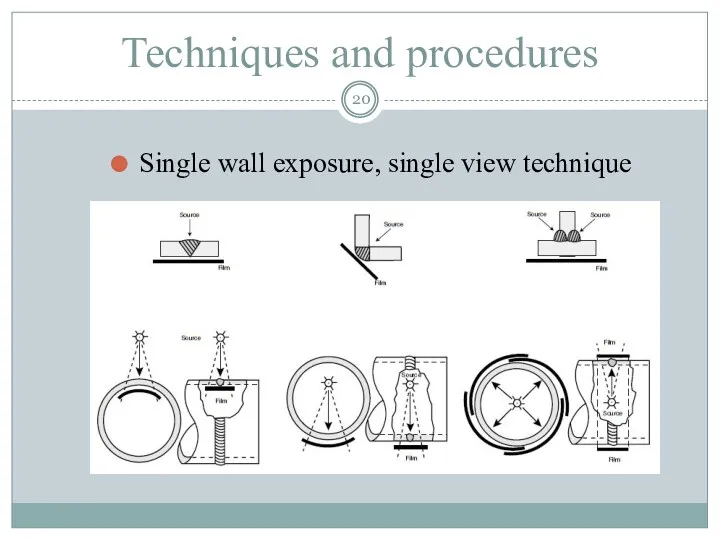

- 20. Techniques and procedures Single wall exposure, single view technique

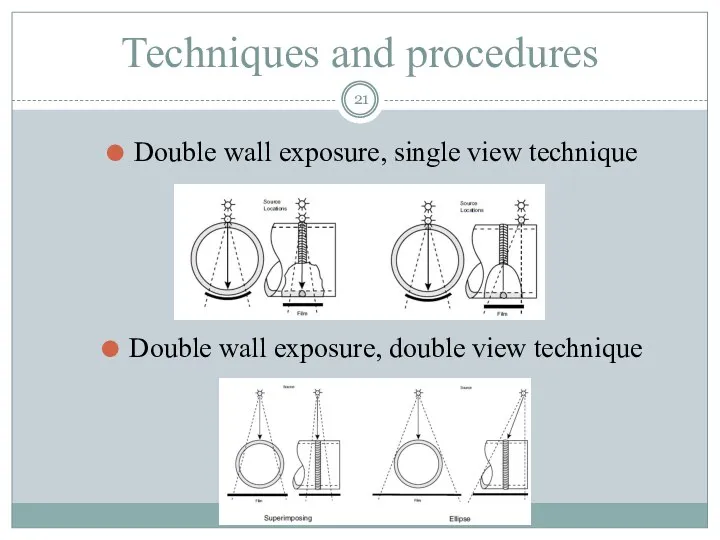

- 21. Techniques and procedures Double wall exposure, single view technique Double wall exposure, double view technique

- 22. Procedure Understand the codes, specifications, and customer requirements thoroughly Develop a technique based on the thickness

- 23. Radiographic Film Class I is described as extra-fine grain, low speed, with very high contrast capabilities.

- 24. Film processing Developing Developers are alkaline solutions that change the latent or chemically stored image in

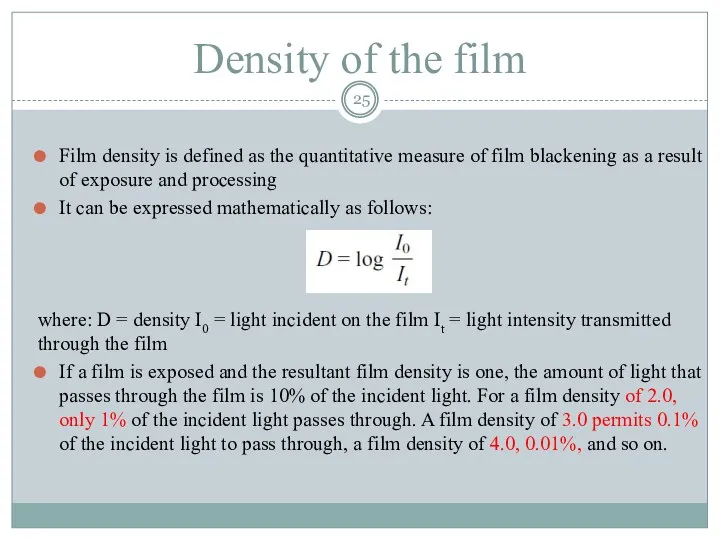

- 25. Density of the film Film density is defined as the quantitative measure of film blackening as

- 26. Radiographic evaluation Interpretation of radiographs requires hours of reviewing and understanding the different types of images.

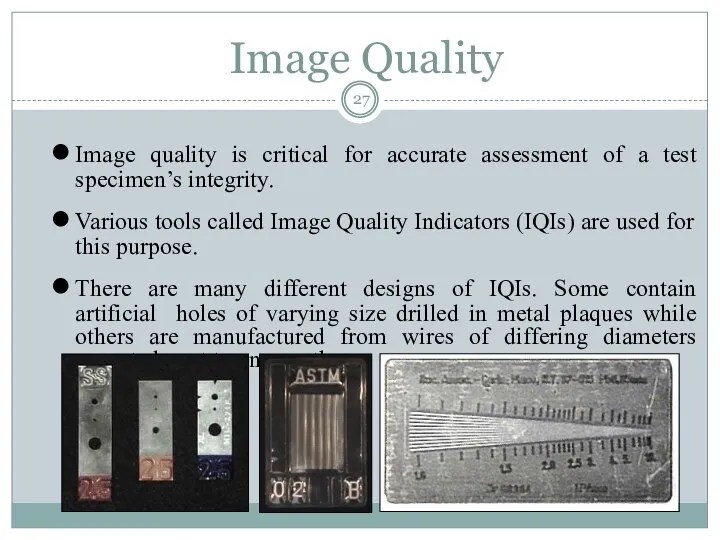

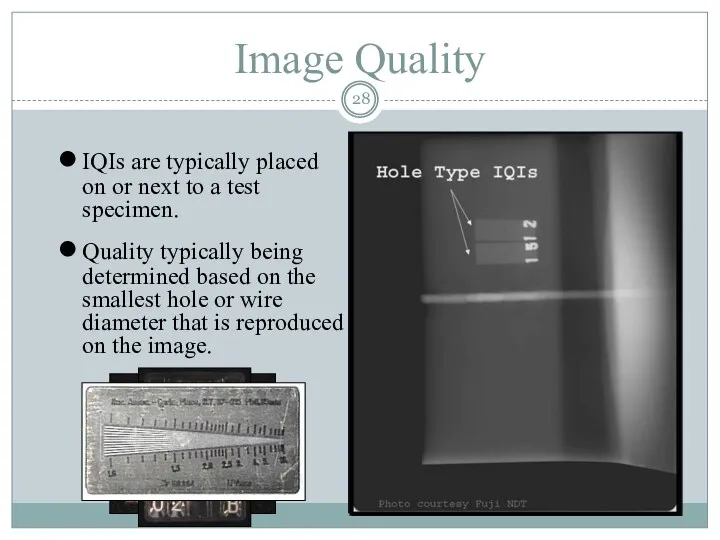

- 27. Image Quality Image quality is critical for accurate assessment of a test specimen’s integrity. Various tools

- 28. Image Quality IQIs are typically placed on or next to a test specimen. Quality typically being

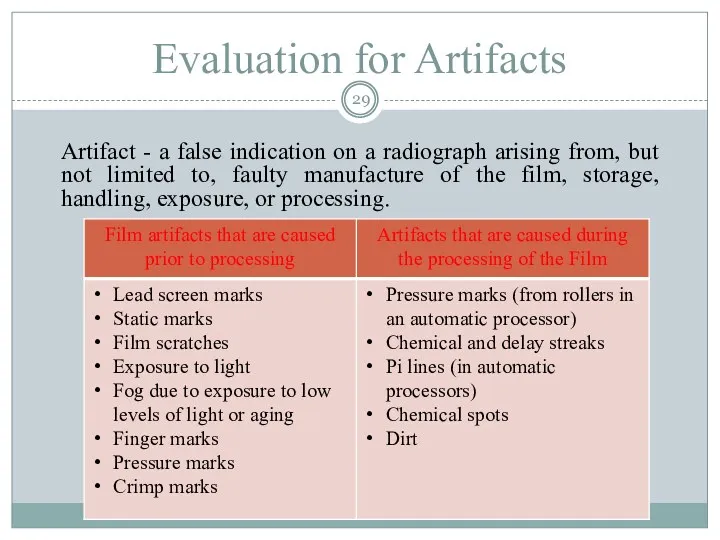

- 29. Evaluation for Artifacts Artifact - a false indication on a radiograph arising from, but not limited

- 30. Evaluation for Discontinuities Discontinuity conditions that are normally found in welds include those in the following

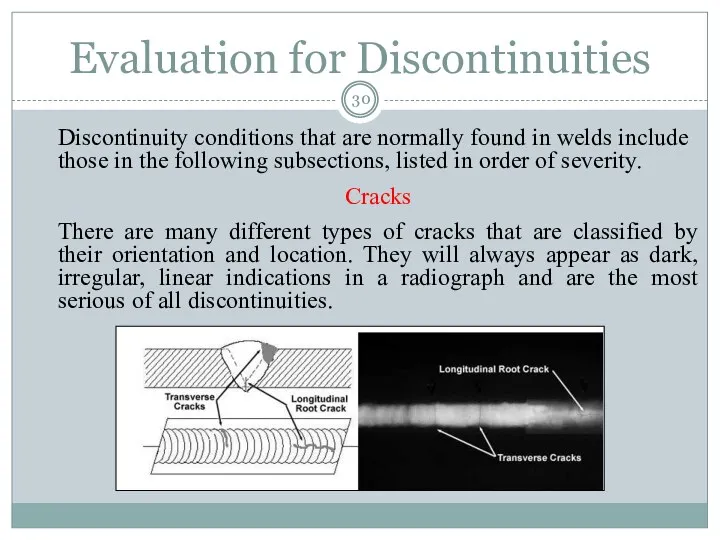

- 31. Evaluation for Discontinuities Lack of Fusion This serious discontinuity results from an absence of metallurgical fusion,

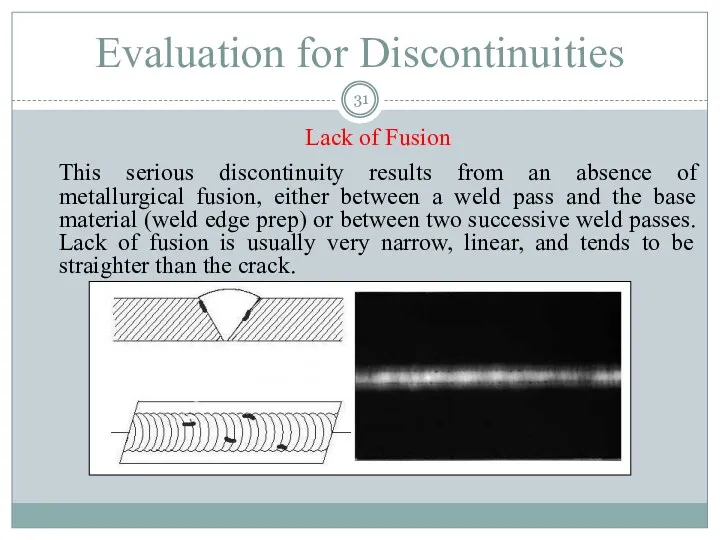

- 32. Incomplete Penetration This discontinuity is an absence of weld metal or an area of “nonfusion” in

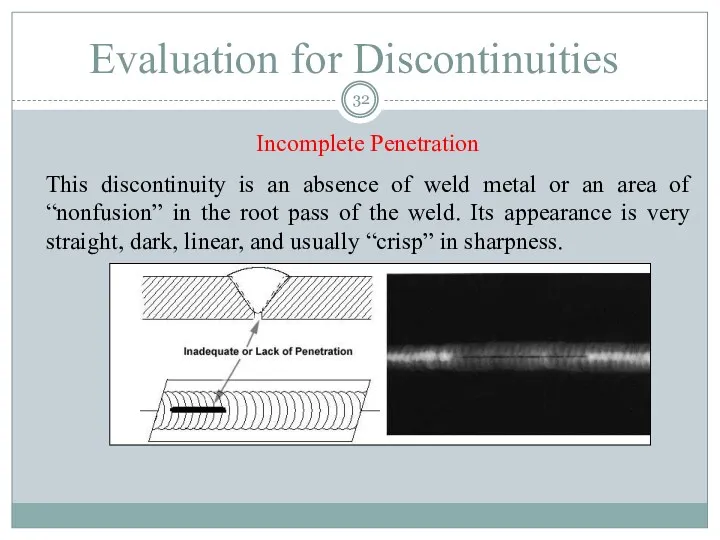

- 33. Inclusions (Dense and Less Dense) Inclusions are basically materials that have been entrapped in the weld

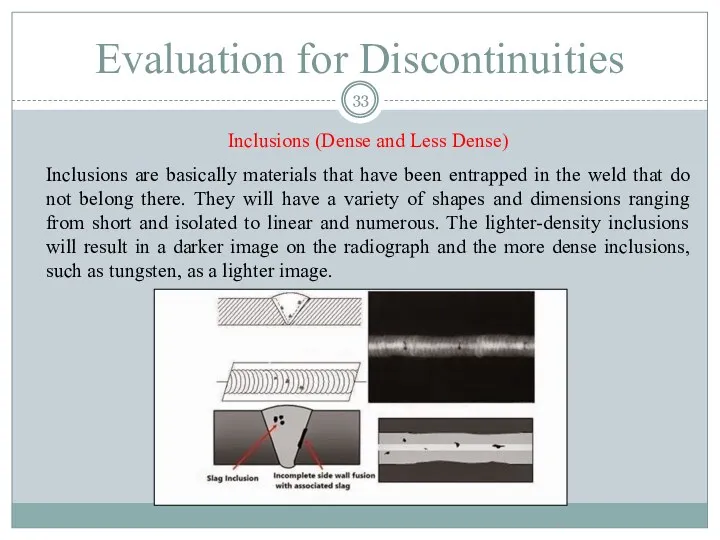

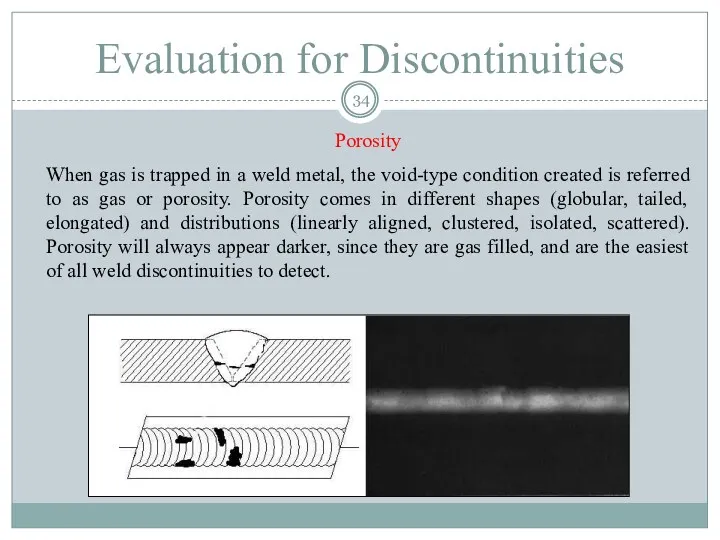

- 34. Porosity When gas is trapped in a weld metal, the void-type condition created is referred to

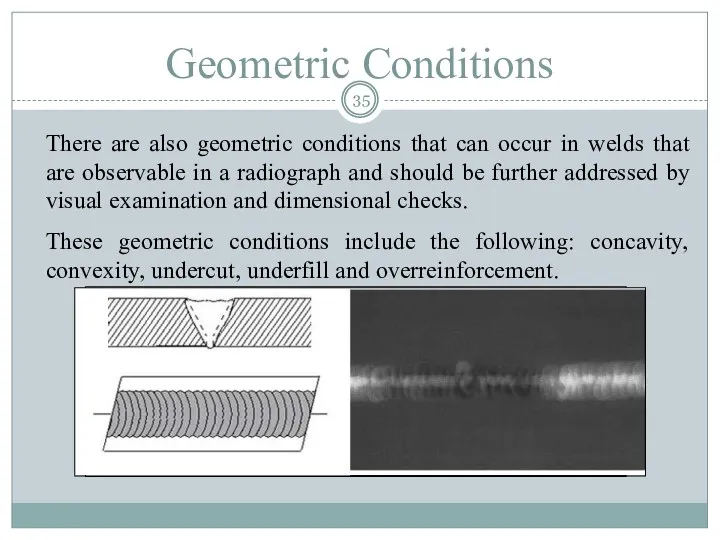

- 35. There are also geometric conditions that can occur in welds that are observable in a radiograph

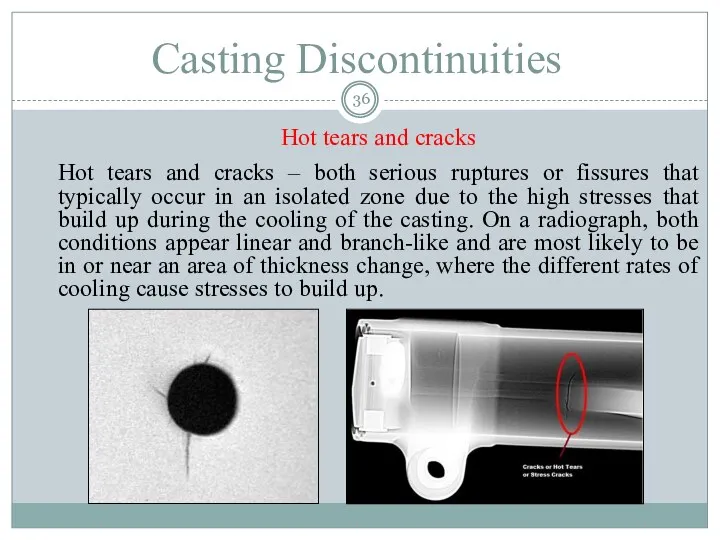

- 36. Casting Discontinuities Hot tears and cracks Hot tears and cracks – both serious ruptures or fissures

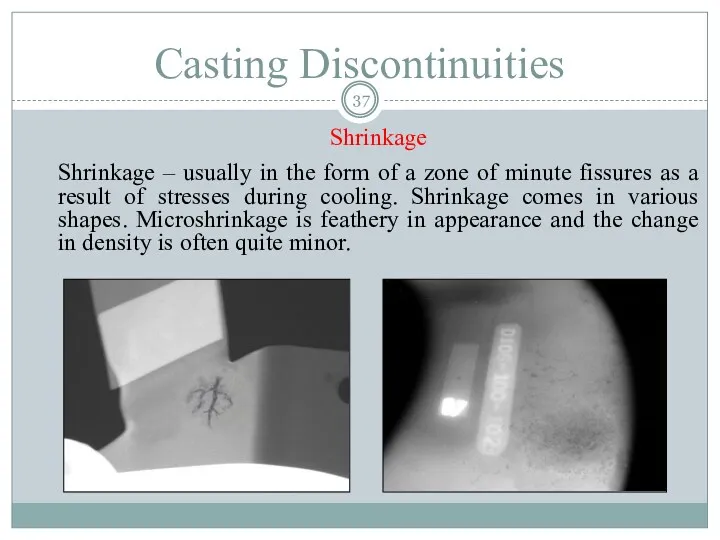

- 37. Casting Discontinuities Shrinkage Shrinkage – usually in the form of a zone of minute fissures as

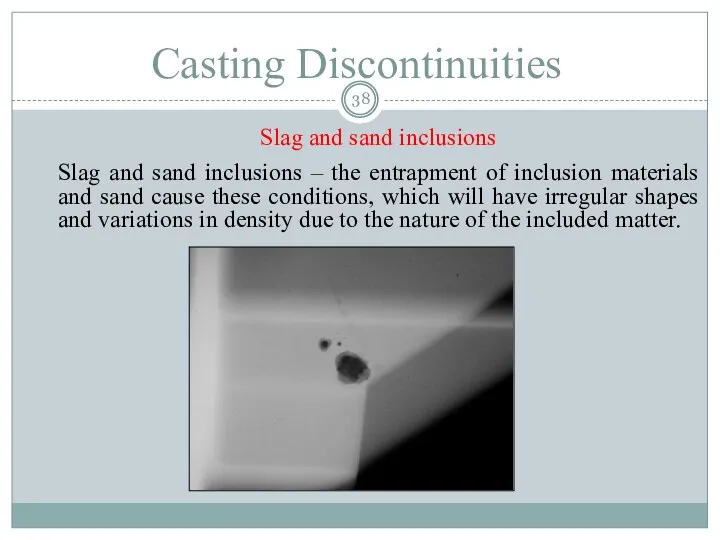

- 38. Casting Discontinuities Slag and sand inclusions Slag and sand inclusions – the entrapment of inclusion materials

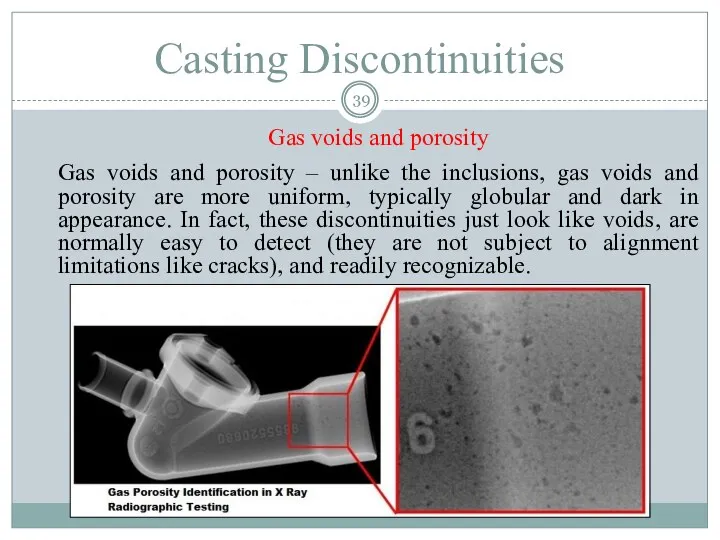

- 39. Casting Discontinuities Gas voids and porosity Gas voids and porosity – unlike the inclusions, gas voids

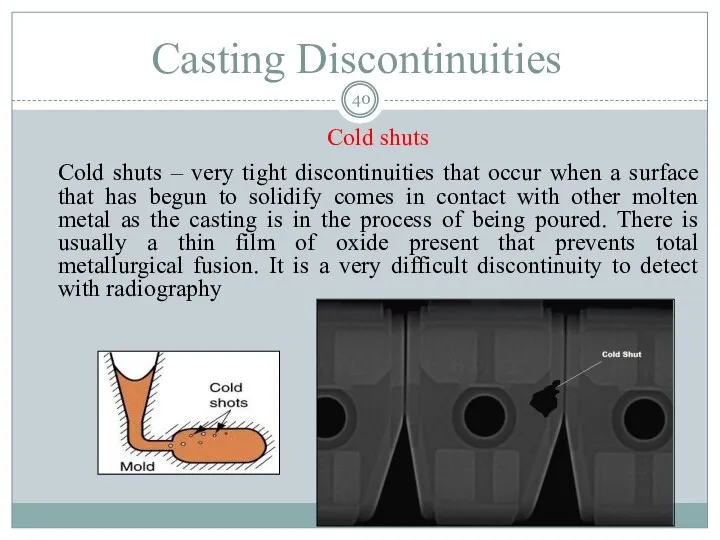

- 40. Casting Discontinuities Cold shuts Cold shuts – very tight discontinuities that occur when a surface that

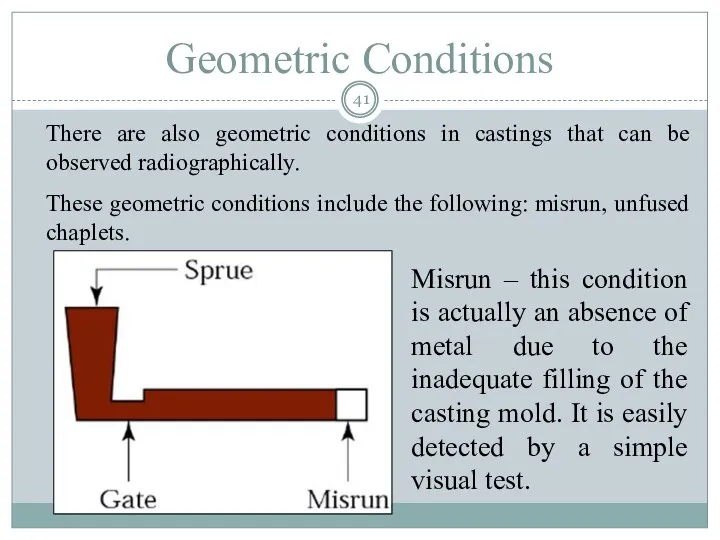

- 41. There are also geometric conditions in castings that can be observed radiographically. These geometric conditions include

- 42. Applications Although the majority of applications in radiographic testing appear to involve welds and castings, it

- 43. Advantages of Radiography Provides an extremely accurate and permanent record Is very versatile and can be

- 44. Limitations 1. There are safety hazards with the use of radiation devices 2. RT has thickness

- 46. Скачать презентацию

Тепловой насос. Принцип его действия

Тепловой насос. Принцип его действия Міцність при змінних навантаженнях. (Лекція 4)

Міцність при змінних навантаженнях. (Лекція 4) Презентация Механическое движение

Презентация Механическое движение Laws of Thermodynamics

Laws of Thermodynamics Щелевые антенны. (Лекция 11)

Щелевые антенны. (Лекция 11) Дополнительный материал по физике для 7 класса - 1 и 2 часть

Дополнительный материал по физике для 7 класса - 1 и 2 часть Основи термодинаміки. Підготовка до контрольної роботи

Основи термодинаміки. Підготовка до контрольної роботи Проводник в электроститческом поле. Электроемксоть. Энергия

Проводник в электроститческом поле. Электроемксоть. Энергия Скорость света

Скорость света Электрический ток в газах

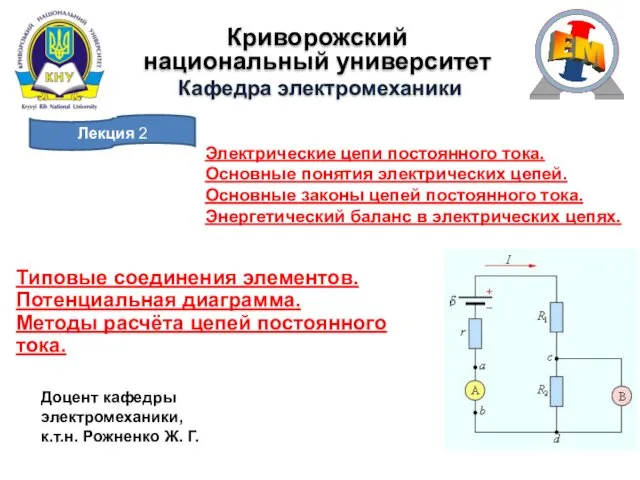

Электрический ток в газах Электрические цепи постоянного тока

Электрические цепи постоянного тока Закон Ома

Закон Ома Оптика. Поляризация света (лекция 25)

Оптика. Поляризация света (лекция 25) Закон Кулона. Электрическое поле. Напряженность электрического поля. Принцип суперпозиции полей. Силовые линии электрического

Закон Кулона. Электрическое поле. Напряженность электрического поля. Принцип суперпозиции полей. Силовые линии электрического Путь к звездам

Путь к звездам Электрический ток в газах. Газовый разряд. 10 класс

Электрический ток в газах. Газовый разряд. 10 класс Сопла и диффузоры. Истечение жидкостей, паров и газов

Сопла и диффузоры. Истечение жидкостей, паров и газов Кинематика, обобщение темы

Кинематика, обобщение темы Влияние звука на живые организмы

Влияние звука на живые организмы Конспект урока по физике в 8 классе по теме Линзы. Оптичесая сила линзы

Конспект урока по физике в 8 классе по теме Линзы. Оптичесая сила линзы Свободное паление тел. Движение с постоянным ускорением свободного падения

Свободное паление тел. Движение с постоянным ускорением свободного падения Магнит өрісі

Магнит өрісі Электрическая лампа

Электрическая лампа Презентация по физике Механические колебания

Презентация по физике Механические колебания Дифракция света. Дифракция Френеля и Фраунгофера

Дифракция света. Дифракция Френеля и Фраунгофера Дисперсия. Дифракция. Интерференция. Физический диктант

Дисперсия. Дифракция. Интерференция. Физический диктант Почему радуга разноцветная

Почему радуга разноцветная Электронное управление трансмиссией автомобиля. Система активного распределения крутящего момента. Урок 190

Электронное управление трансмиссией автомобиля. Система активного распределения крутящего момента. Урок 190