Содержание

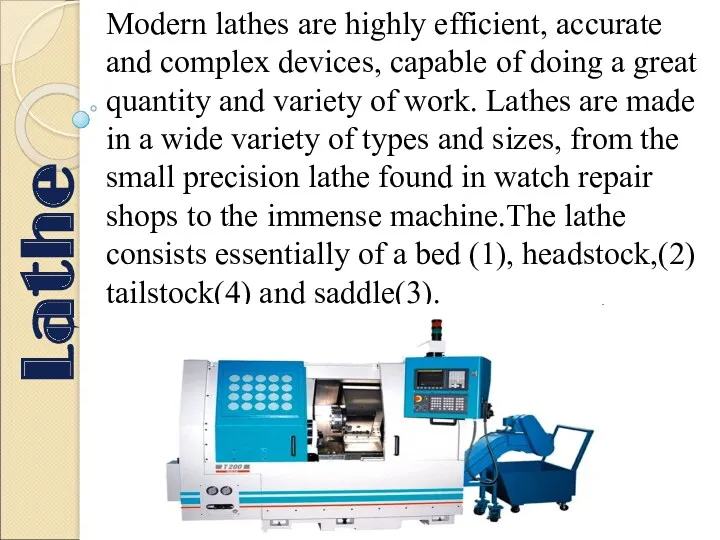

- 2. Modern lathes are highly efficient, accurate and complex devices, capable of doing a great quantity and

- 3. 1.bed 2. head- stock 3.saddle 4.tailstock

- 4. The bed – The main casting of the lathe is called the bed, and usually consists

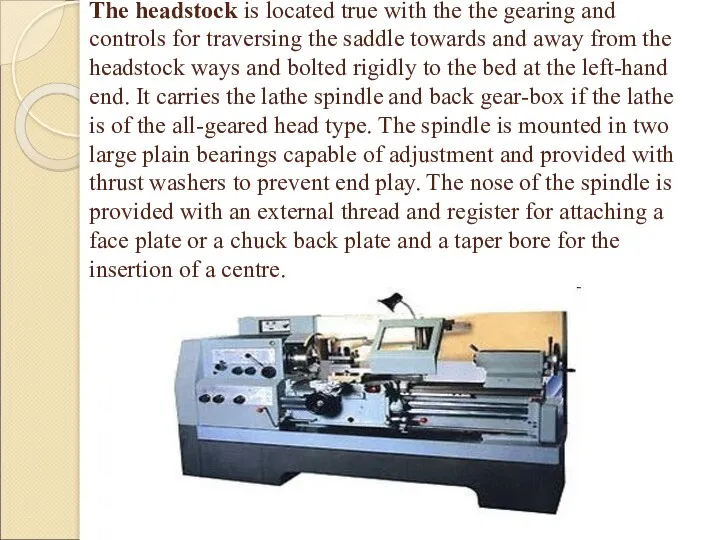

- 5. The headstock is located true with the the gearing and controls for traversing the saddle towards

- 6. The saddle consists of a casting designed to carry the tool post slide or slides, and

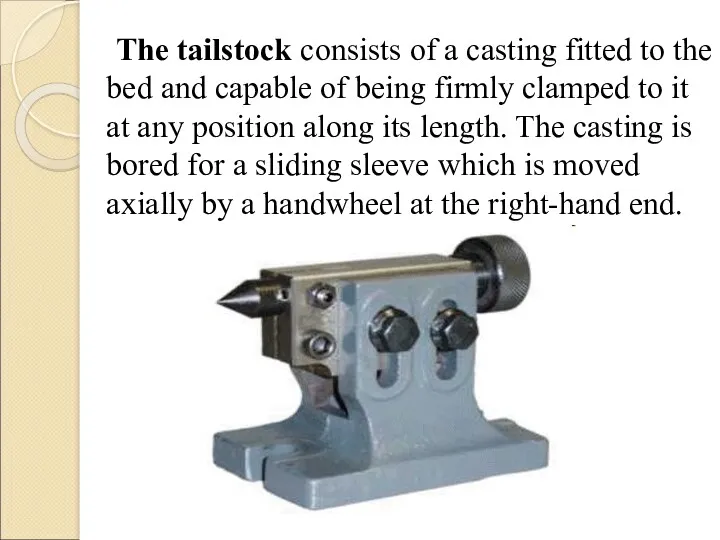

- 7. The tailstock consists of a casting fitted to the bed and capable of being firmly clamped

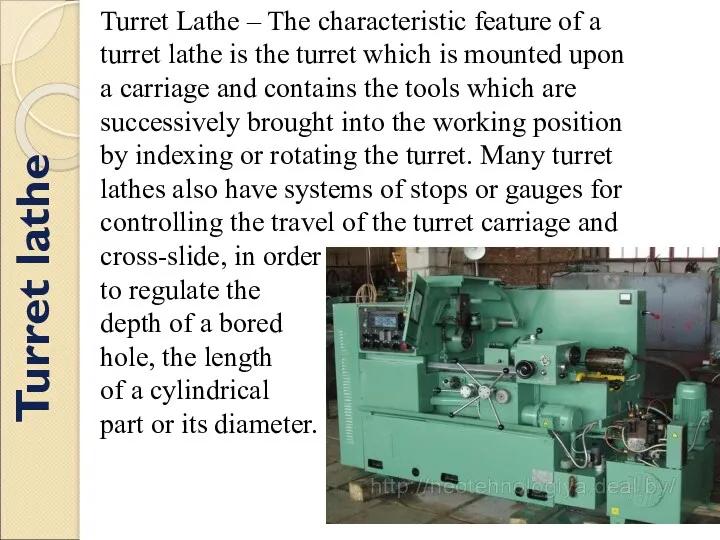

- 8. Turret Lathe – The characteristic feature of a turret lathe is the turret which is mounted

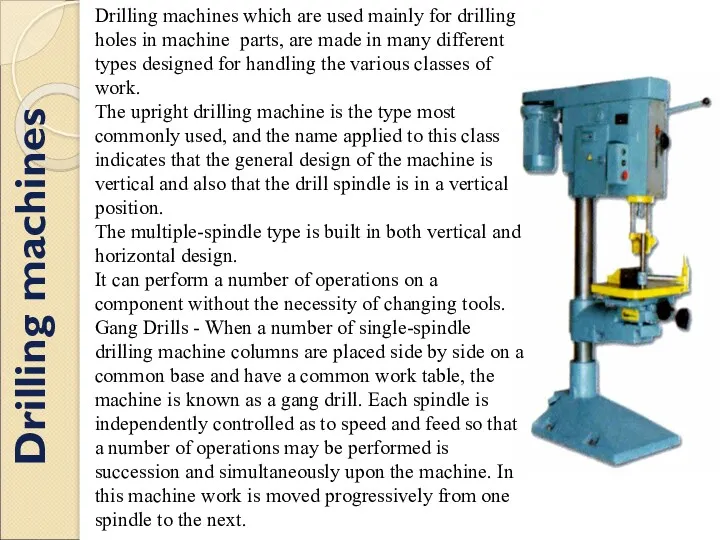

- 9. Drilling machines Drilling machines which are used mainly for drilling holes in machine parts, are made

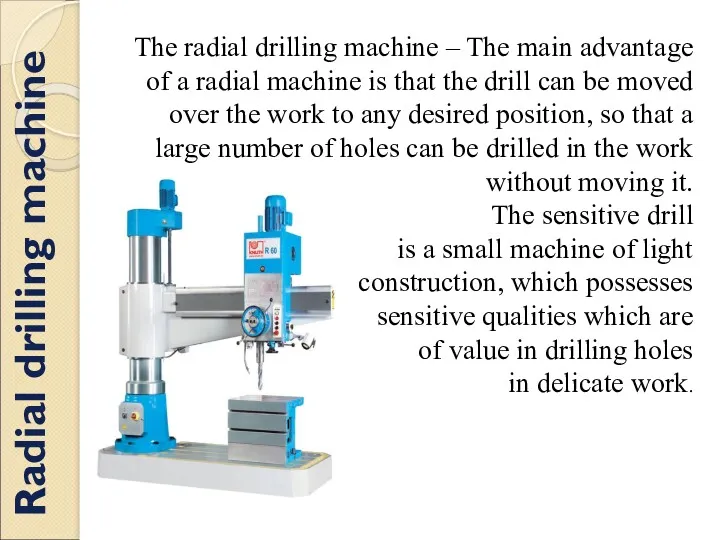

- 10. The radial drilling machine – The main advantage of a radial machine is that the drill

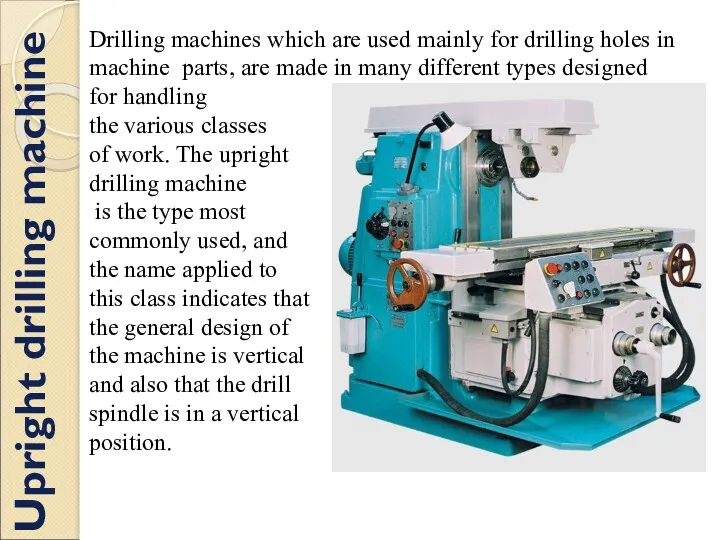

- 11. Drilling machines which are used mainly for drilling holes in machine parts, are made in many

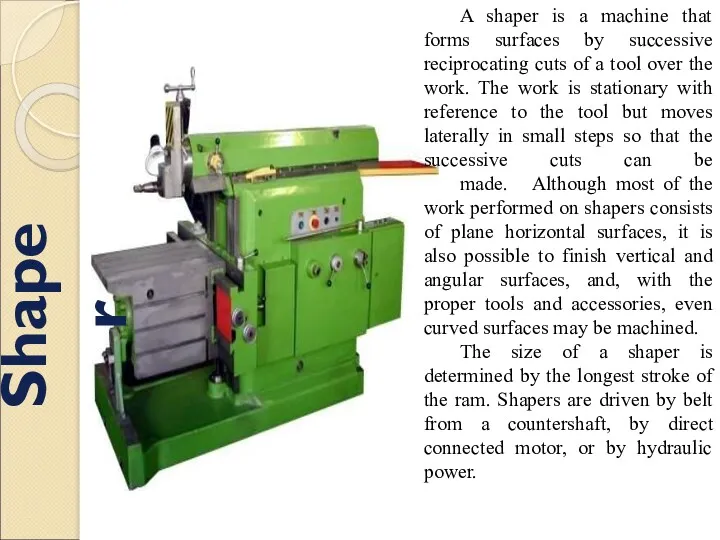

- 12. A shaper is a machine that forms surfaces by successive reciprocating cuts of a tool over

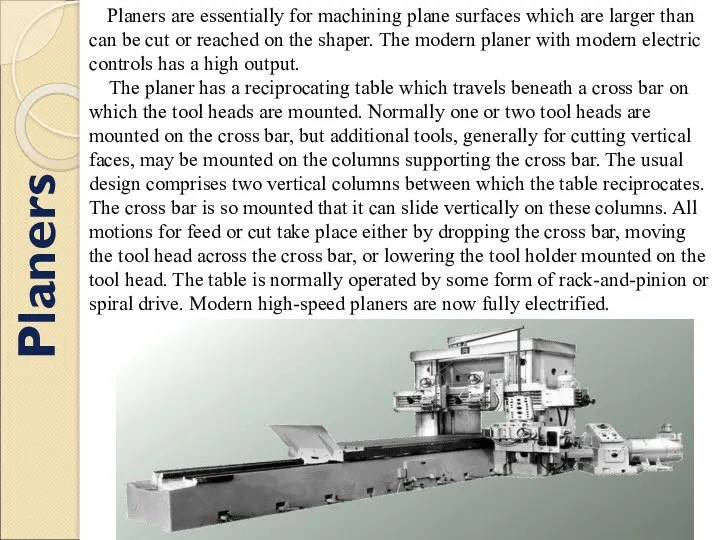

- 13. Planers Planers are essentially for machining plane surfaces which are larger than can be cut or

- 15. Скачать презентацию

Заломлення світла

Заломлення світла Ходова частина БТР-80

Ходова частина БТР-80 Прогнозирование отбраковки авиационных пар трения

Прогнозирование отбраковки авиационных пар трения Физические основы архитектурной светотехники

Физические основы архитектурной светотехники Тепловые явления. Температура. Урок физики. 8 класс

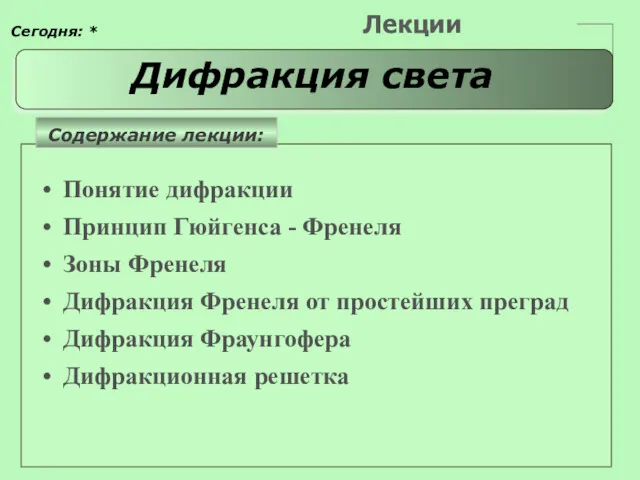

Тепловые явления. Температура. Урок физики. 8 класс Дифракция света

Дифракция света Статическое электричество

Статическое электричество Что называют волнами?

Что называют волнами? Кинематические характеристики движения точки

Кинематические характеристики движения точки Презентация по теме Разделы механики для 10 класса

Презентация по теме Разделы механики для 10 класса Оружие ведущее к победе

Оружие ведущее к победе Применение интерференции в технике

Применение интерференции в технике Экологические проблемы работы АЭС

Экологические проблемы работы АЭС Роль испарения и конденсации в природе, в жизни человека и животных

Роль испарения и конденсации в природе, в жизни человека и животных Презентация к уроку Исследование капиллярных свойств столовых салфеток. Урок-контрольная закупка.

Презентация к уроку Исследование капиллярных свойств столовых салфеток. Урок-контрольная закупка. История связи. Виды телеграфной связи и основные этапы ее развития

История связи. Виды телеграфной связи и основные этапы ее развития Ремонтный процесс Standox Nissan KAB Ultimate Metal Silver. Тренинговая информация

Ремонтный процесс Standox Nissan KAB Ultimate Metal Silver. Тренинговая информация Кинематика тела. Лекция 7

Кинематика тела. Лекция 7 Качество электрической энергии

Качество электрической энергии Биологические мембраны. Биоэлектрогенез

Биологические мембраны. Биоэлектрогенез Презентация Материальная точка. Система отсчёта

Презентация Материальная точка. Система отсчёта Электрические тали

Электрические тали Динамика. Классическая механика. Законы Ньютона

Динамика. Классическая механика. Законы Ньютона Звуковые волны

Звуковые волны Переменный ток

Переменный ток Технологический процесс ремонта КПП М16А автомобиля Suzuki Liana

Технологический процесс ремонта КПП М16А автомобиля Suzuki Liana Электрические цепи постоянного тока. Лекция 1

Электрические цепи постоянного тока. Лекция 1 Устройство механической коробки передач

Устройство механической коробки передач