Technology in brief

3D printing, also known as “Additive Manufacturing”, turns digital

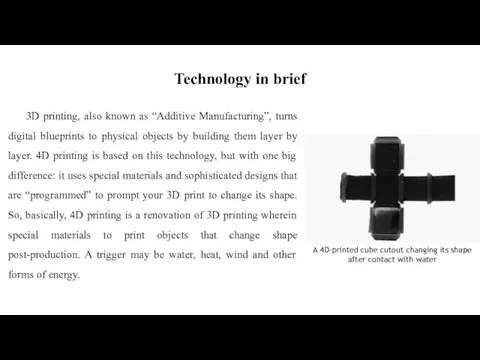

blueprints to physical objects by building them layer by layer. 4D printing is based on this technology, but with one big difference: it uses special materials and sophisticated designs that are “programmed” to prompt your 3D print to change its shape. So, basically, 4D printing is a renovation of 3D printing wherein special materials to print objects that change shape post-production. A trigger may be water, heat, wind and other forms of energy.

A 4D-printed cube cutout changing its shape after contact with water

Реализация представлений. (Лекция 8)

Реализация представлений. (Лекция 8) Безопасность детей в Интернете

Безопасность детей в Интернете Единая корпоративная автоматизированная система управления инфраструктурой (ЕК АСУИ)

Единая корпоративная автоматизированная система управления инфраструктурой (ЕК АСУИ) Microsoft Office. Основные компоненты

Microsoft Office. Основные компоненты Canvas

Canvas Общая характеристика и классификация технических средств информатизации

Общая характеристика и классификация технических средств информатизации Разработка программной платформы для создания и проведения квест-мероприятий

Разработка программной платформы для создания и проведения квест-мероприятий Презентация Рабочий стол и панель задач

Презентация Рабочий стол и панель задач Конспект интернет-урока по теме Healthy food, в 6 классе

Конспект интернет-урока по теме Healthy food, в 6 классе Разработка игры QUICK

Разработка игры QUICK Презентация Компьютерные сети 10 класс

Презентация Компьютерные сети 10 класс Two-Level Logic Minimization Algorithms. Lecture 3

Two-Level Logic Minimization Algorithms. Lecture 3 Урок-подорож у безпечний інтернет

Урок-подорож у безпечний інтернет Решение простых задач с помощью Excel

Решение простых задач с помощью Excel Решение задач на компьютере. Алгоритмизация и программирование

Решение задач на компьютере. Алгоритмизация и программирование Основные устройства персонального компьютера

Основные устройства персонального компьютера Базы данных. Основные понятия и общие представления

Базы данных. Основные понятия и общие представления The Britich Press

The Britich Press Геоинформационные системы

Геоинформационные системы Юные мыслители

Юные мыслители Информационные технологии на уроке

Информационные технологии на уроке Игровые движки. Различия в движках 2D и 3D

Игровые движки. Различия в движках 2D и 3D Структура программы

Структура программы Як захистити себе від атак хакерів

Як захистити себе від атак хакерів Интерфейс электронных таблиц. Данные в ячейках таблицы. Основные режимы работы

Интерфейс электронных таблиц. Данные в ячейках таблицы. Основные режимы работы 20181122_virusov_beregis

20181122_virusov_beregis Компьютерная революция и информационное общество

Компьютерная революция и информационное общество Форматы графических файлов

Форматы графических файлов