Solving ultimate pit limit problem through graph closure (L-G algorithm) and the fundamental tree algorithm презентация

Содержание

- 2. Contents 1. Introduction 2. Lerchs – Grossmann (Graph closure) 3. Fundamental Tree Algorithm 4. Assignment

- 3. Introduction Two ojectives for open pit optimization Design ultimate pit limits (Moving cone, LG, Net work

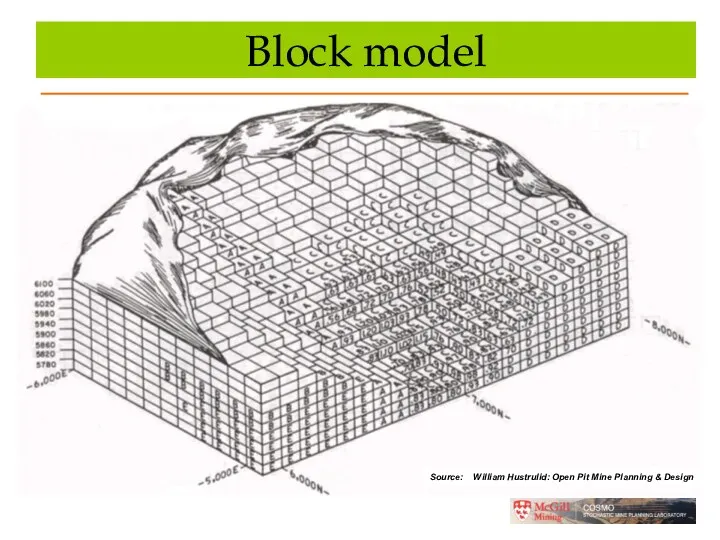

- 4. Block model gdg Source: William Hustrulid: Open Pit Mine Planning & Design

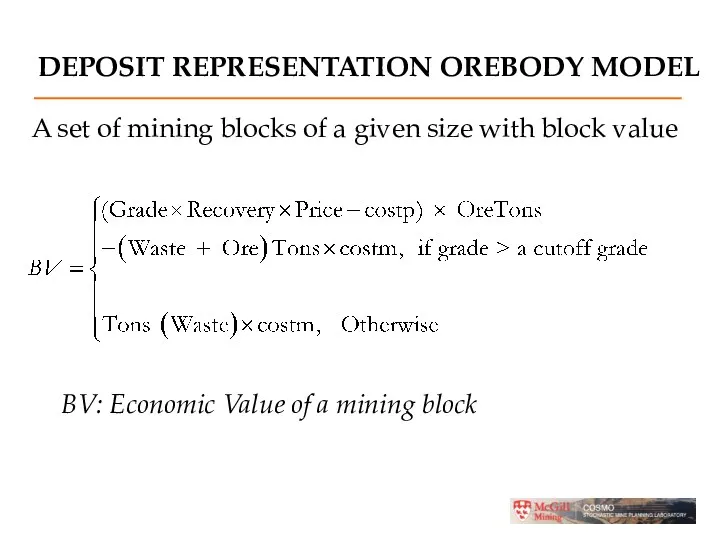

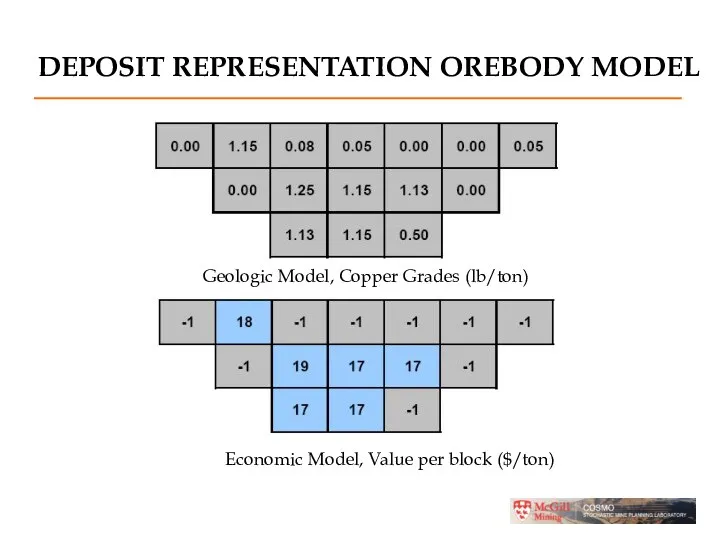

- 5. DEPOSIT REPRESENTATION OREBODY MODEL A set of mining blocks of a given size with block value

- 6. DEPOSIT REPRESENTATION OREBODY MODEL Geologic Model, Copper Grades (lb/ton) Economic Model, Value per block ($/ton)

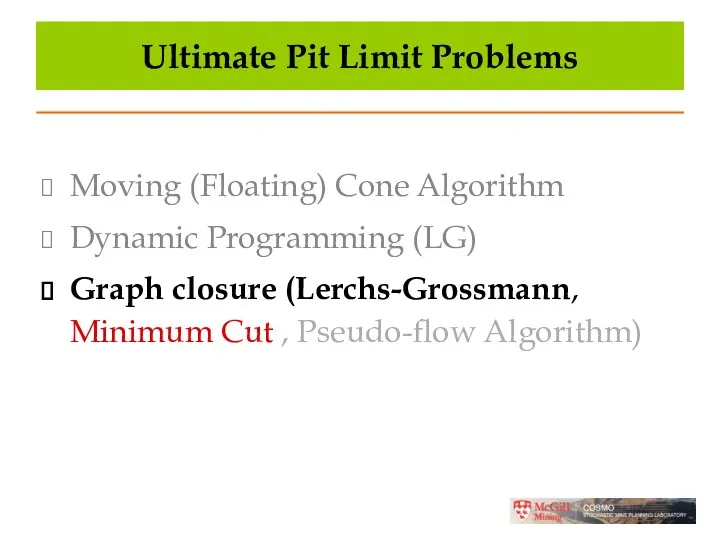

- 7. Ultimate Pit Limit Problems Moving (Floating) Cone Algorithm Dynamic Programming (LG) Graph closure (Lerchs-Grossmann, Minimum Cut

- 8. 2. Graph closure (LG) The optimal pit outline is the 3D pit outline which, if mined

- 9. Lerchs-Grossman Algorithm Mathematical search technique which works from just two sources of information: 1. Economic or

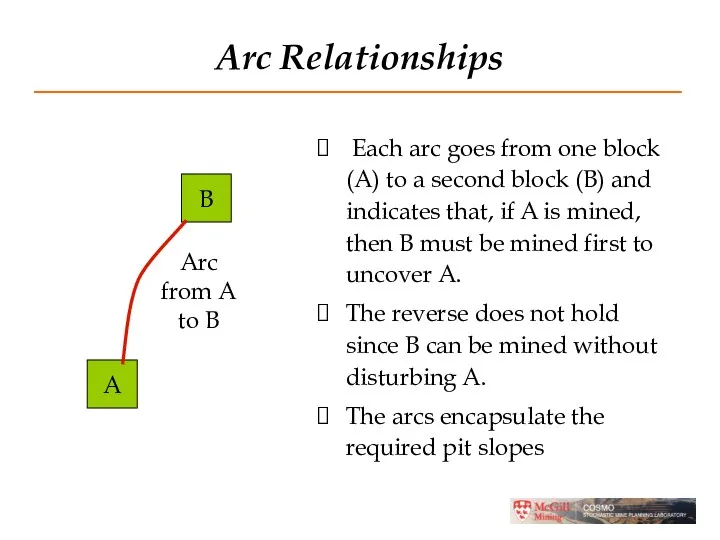

- 10. Arc Relationships Each arc goes from one block (A) to a second block (B) and indicates

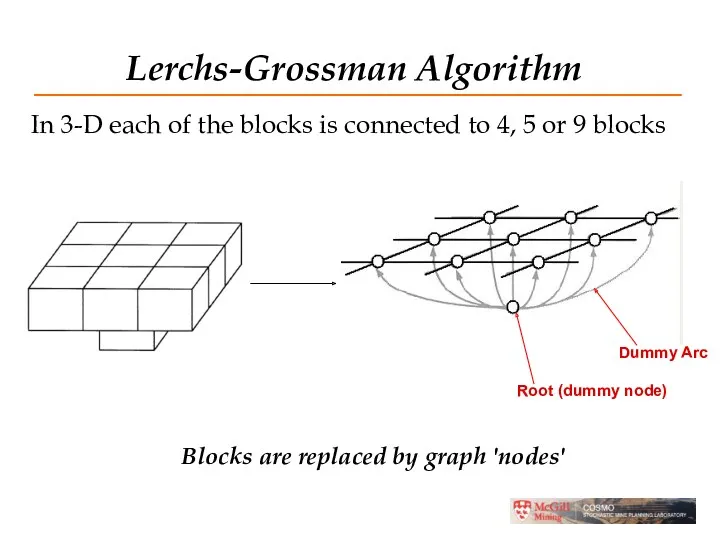

- 11. Lerchs-Grossman Algorithm In 3-D each of the blocks is connected to 4, 5 or 9 blocks

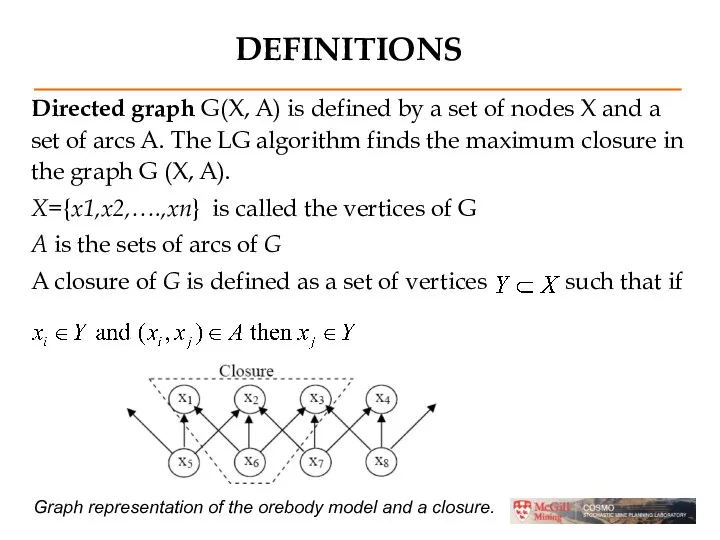

- 12. DEFINITIONS Directed graph G(X, A) is defined by a set of nodes X and a set

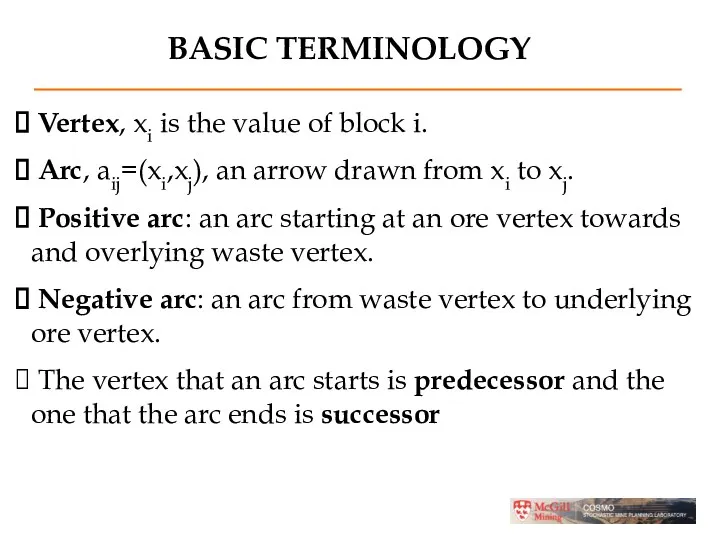

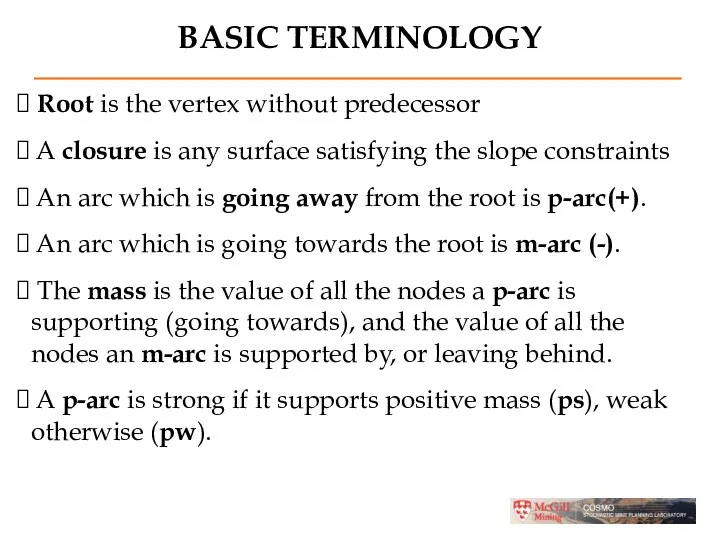

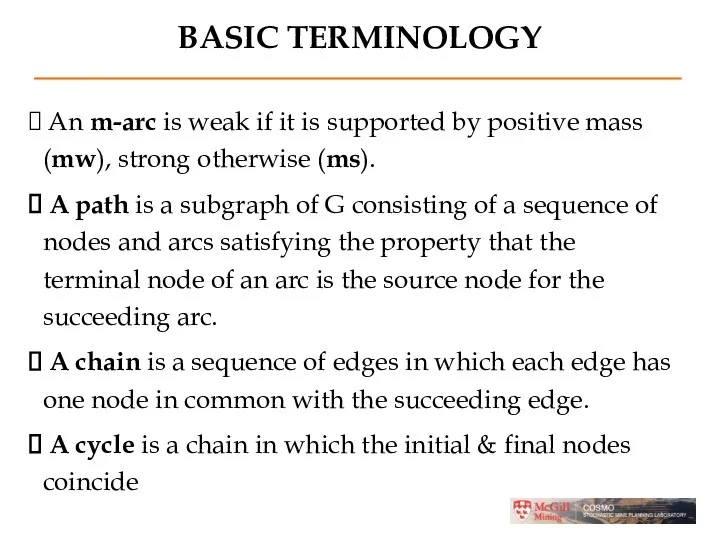

- 13. BASIC TERMINOLOGY Vertex, xi is the value of block i. Arc, aij=(xi,xj), an arrow drawn from

- 14. Root is the vertex without predecessor A closure is any surface satisfying the slope constraints An

- 15. An m-arc is weak if it is supported by positive mass (mw), strong otherwise (ms). A

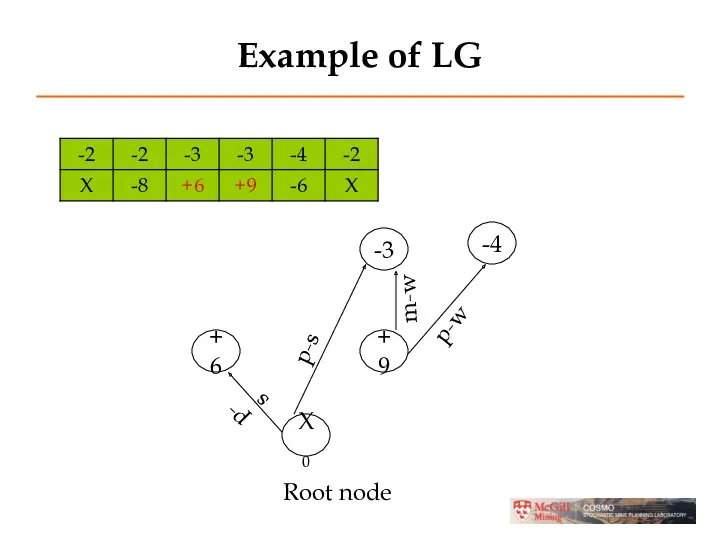

- 16. Example of LG -3 -4 +6 +9 X0 p-s m-w p-w p-s Root node

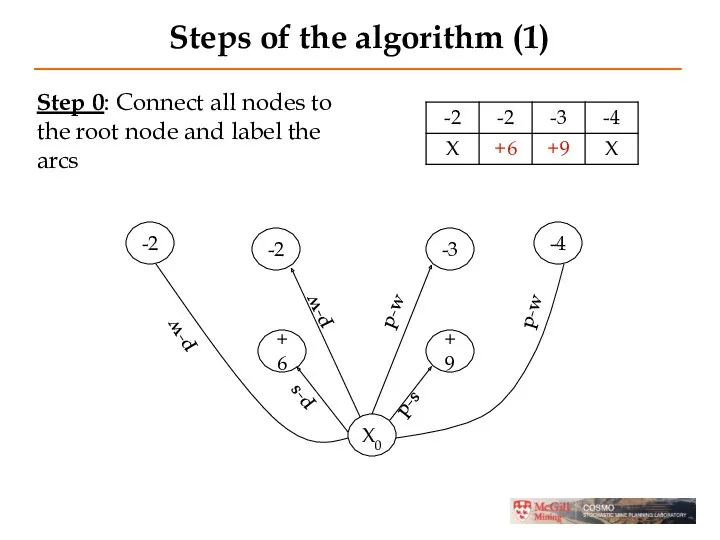

- 17. Steps of the algorithm (1) -2 -2 -3 -4 +6 +9 X0 Step 0: Connect all

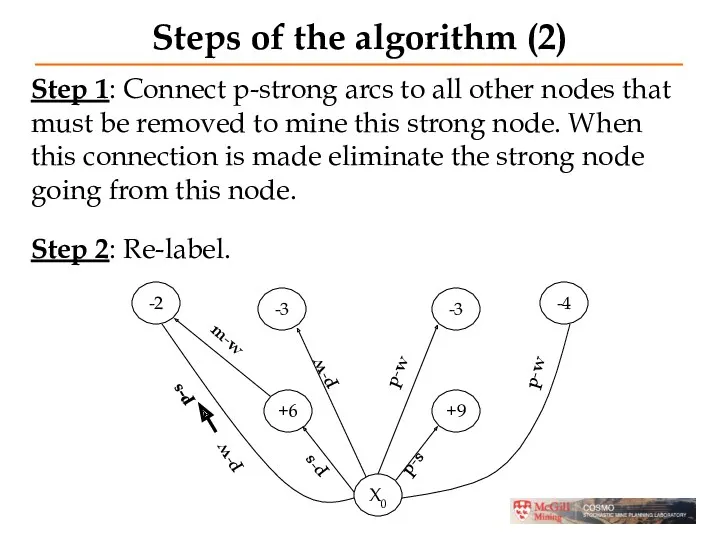

- 18. Steps of the algorithm (2) -2 -3 -3 -4 +6 +9 X0 Step 1: Connect p-strong

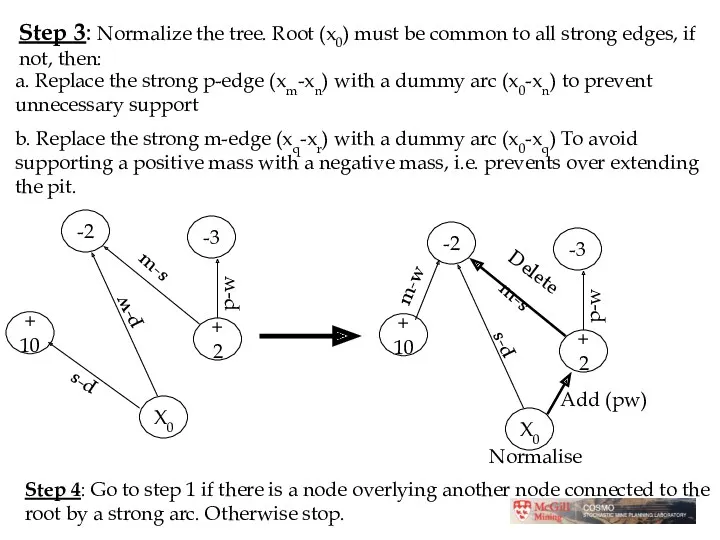

- 19. Step 3: Normalize the tree. Root (x0) must be common to all strong edges, if not,

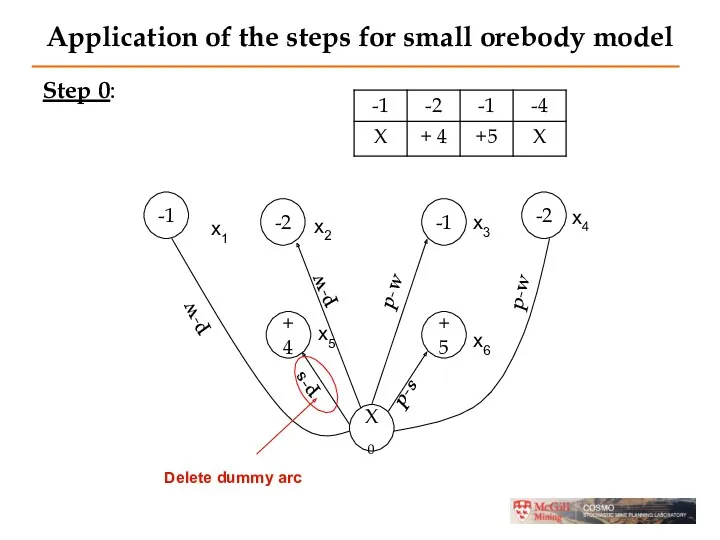

- 20. Application of the steps for small orebody model Step 0:

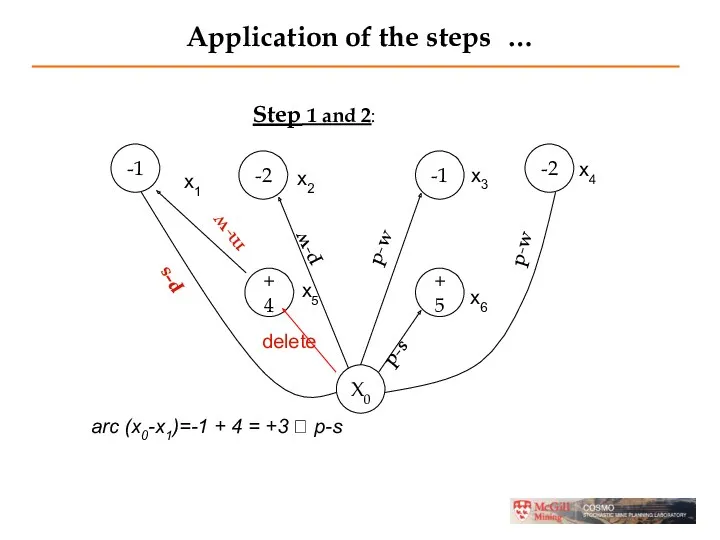

- 21. Application of the steps … Step 1 and 2:

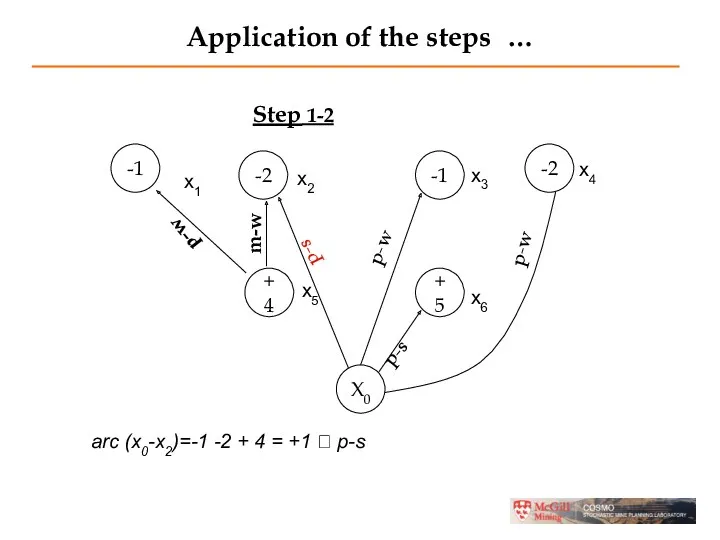

- 22. Application of the steps … Step 1-2 -1 -2 -1 -2 +4 +5 X0 p-w p-w

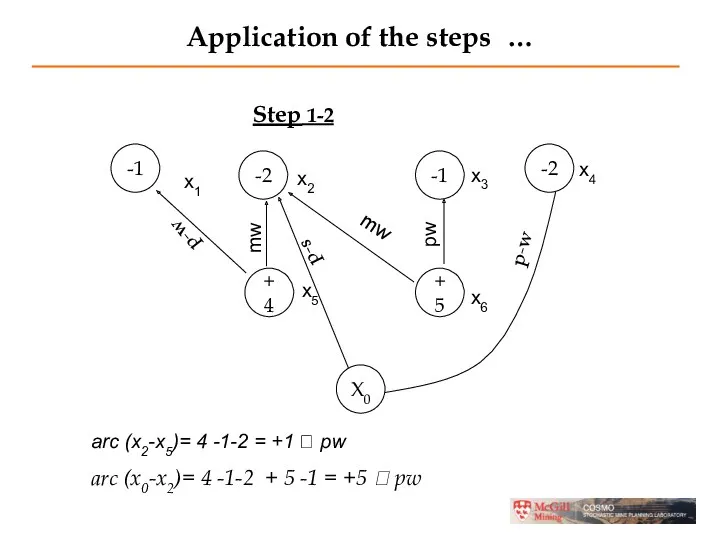

- 23. Application of the steps … Step 1-2 -1 -2 -1 -2 +4 +5 X0 mw p-w

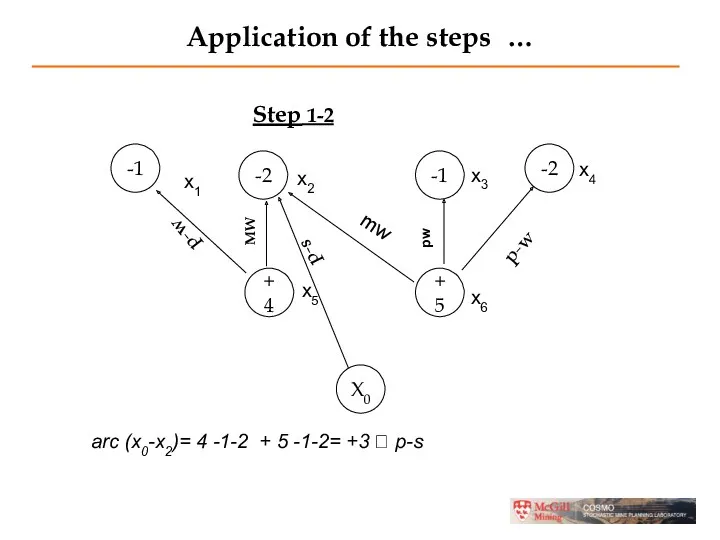

- 24. Application of the steps … Step 1-2 arc (x0-x2)= 4 -1-2 + 5 -1-2= +3 ?

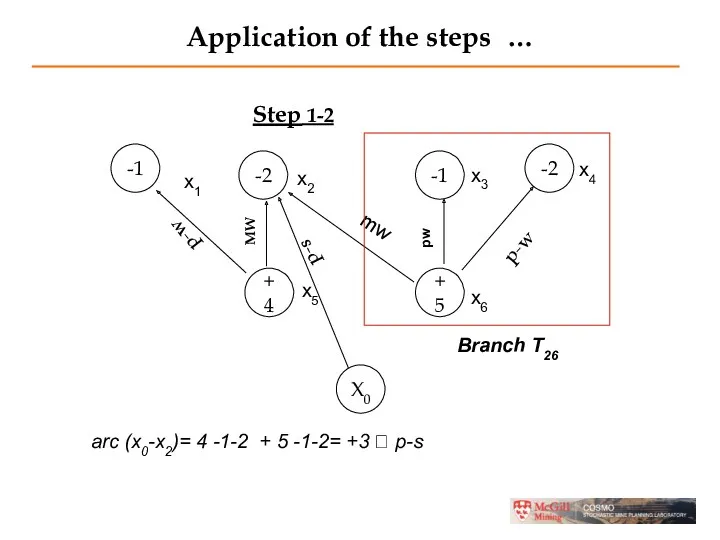

- 25. Application of the steps … Step 1-2 -1 -2 -1 -2 +4 +5 X0 mw p-w

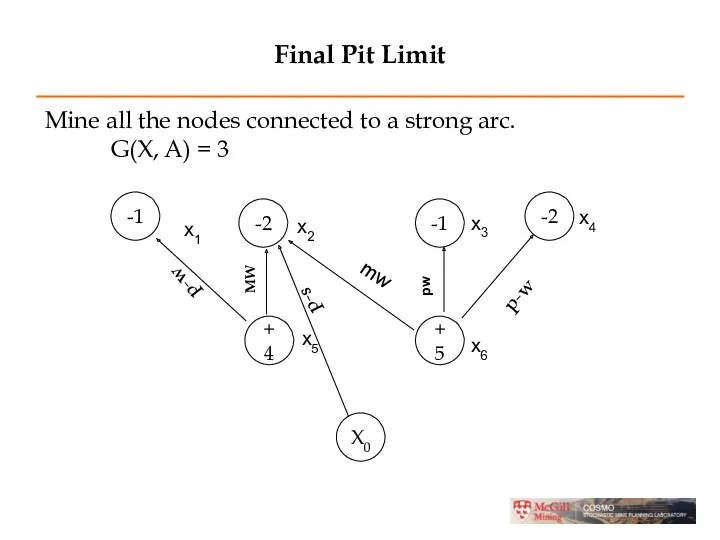

- 26. Final Pit Limit Mine all the nodes connected to a strong arc. G(X, A) = 3

- 27. Optimal Pit The L-G algorithm will flag each block as being inside or outside the optimal

- 28. Varying Slope Angles It is possible to have different slope angles in different areas of the

- 29. 3. Fundamental Tree Algorithm Long-term production scheduling consists of determining an optimal sequence of extracting the

- 30. The Approach To simplify the MIP we would like to decrease the number of blocks in

- 31. The Approach A Fundamental Tree is defined as a combination of blocks such that: The blocks

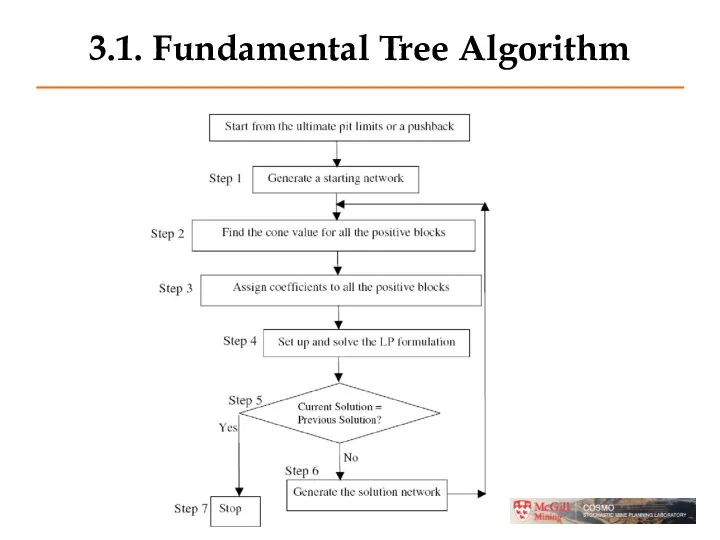

- 32. 3.1. Fundamental Tree Algorithm

- 33. Step 1 - Generate a Starting Network Given a our pushback block model represent blocks by

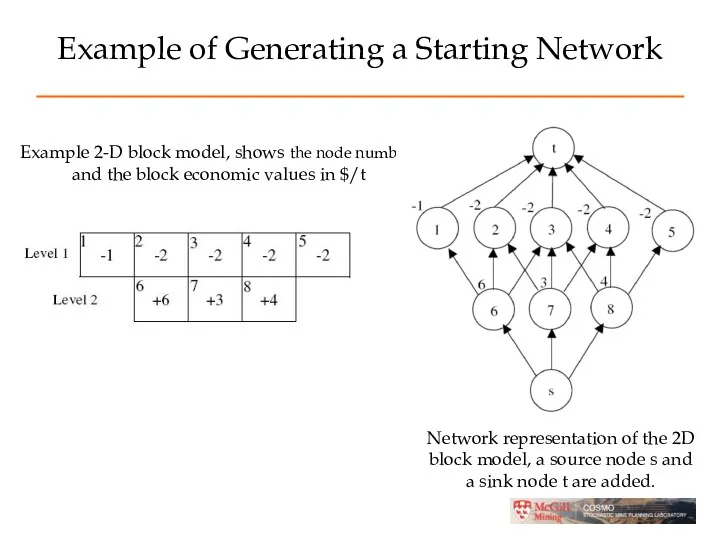

- 34. Example of Generating a Starting Network Example 2-D block model, shows the node numbers and the

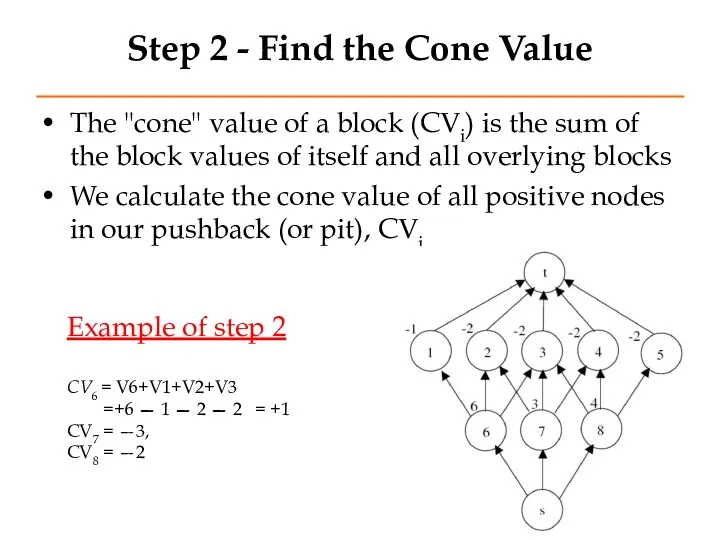

- 35. Step 2 - Find the Cone Value The "cone" value of a block (CVi) is the

- 36. Step 3 – Assign cofficients to the Positive Nodes Each positive node will be assigned a

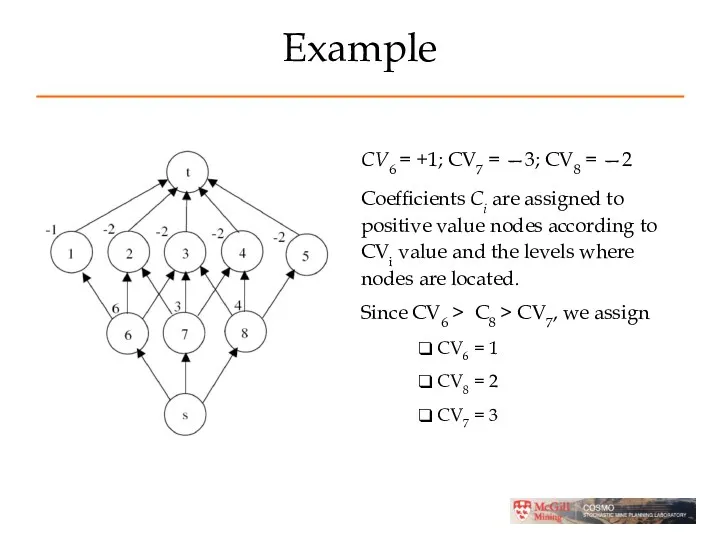

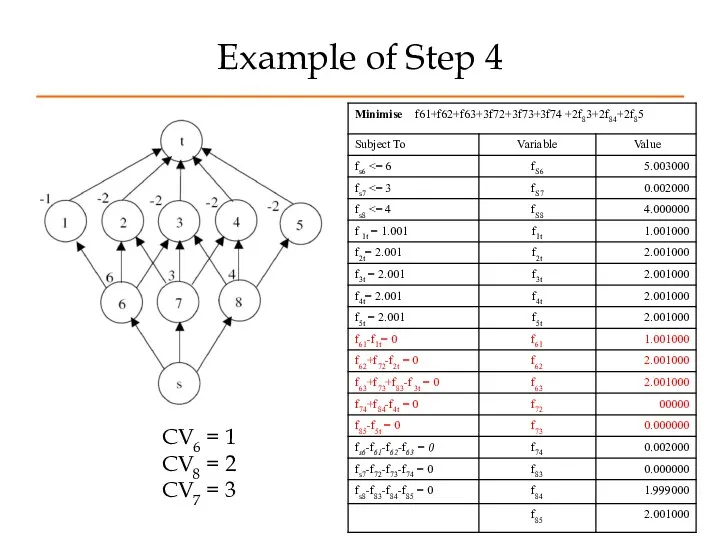

- 37. Example CV6 = +1; CV7 = —3; CV8 = —2 Coefficients Ci are assigned to positive

- 38. Step 4 - Set up the LP Set up a Linear Program to find the first

- 39. Step 5 - Check if we are done If the number of Fundamental Trees found is

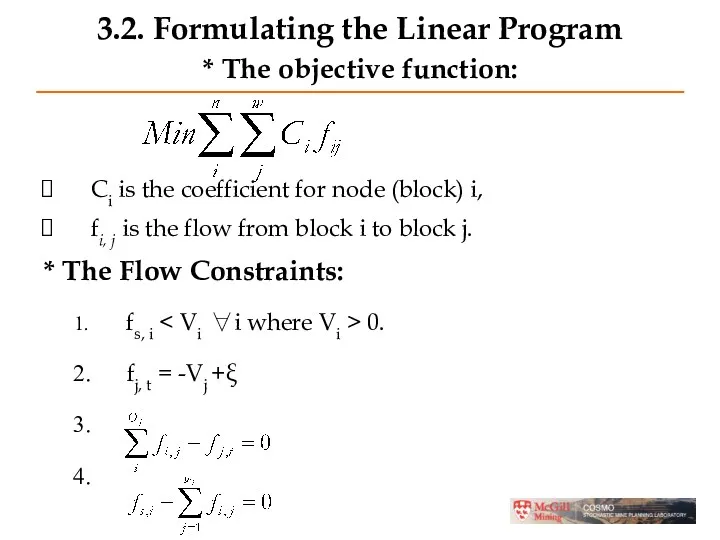

- 40. 3.2. Formulating the Linear Program * The objective function: Ci is the coefficient for node (block)

- 41. Example of Step 4

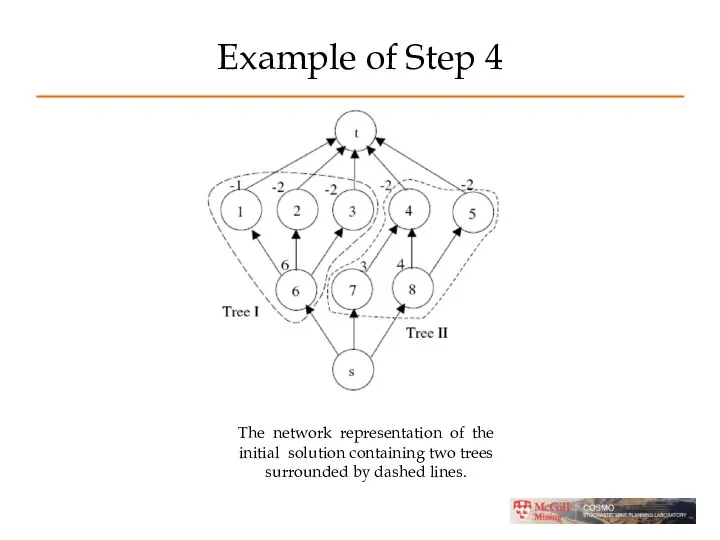

- 42. Example of Step 4 The network representation of the initial solution containing two trees surrounded by

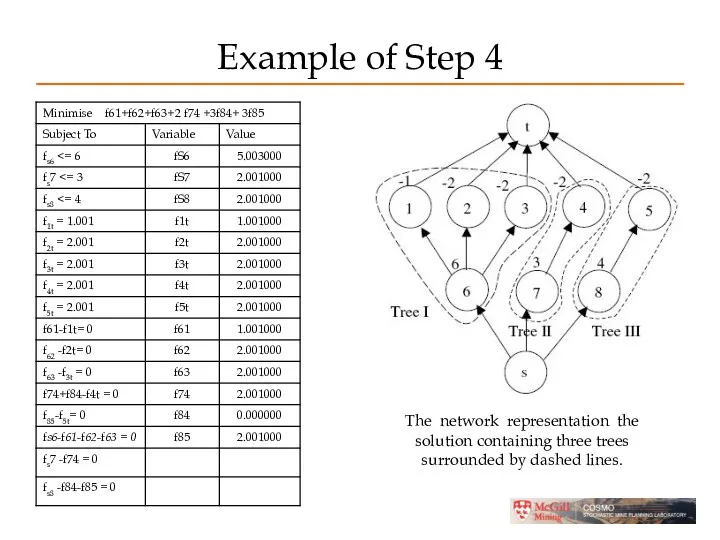

- 43. Example of Step 4 The network representation the solution containing three trees surrounded by dashed lines.

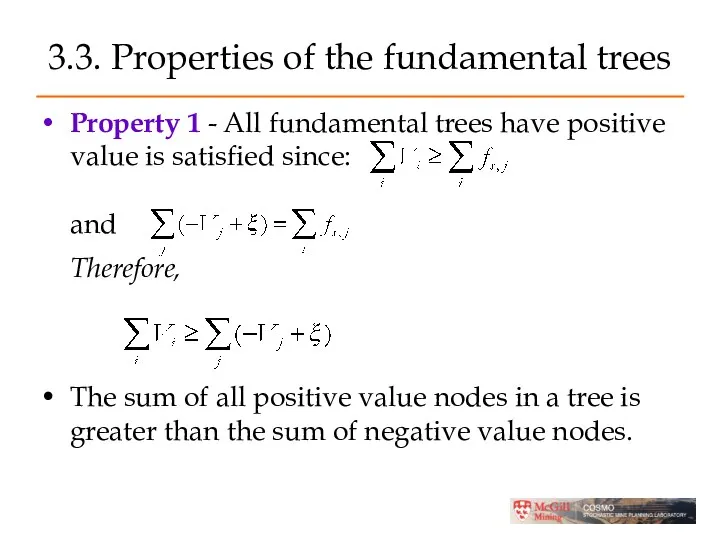

- 44. 3.3. Properties of the fundamental trees Property 1 - All fundamental trees have positive value is

- 45. Property 2 of the fundamental trees All fundamental trees obey the slope constraints if they are

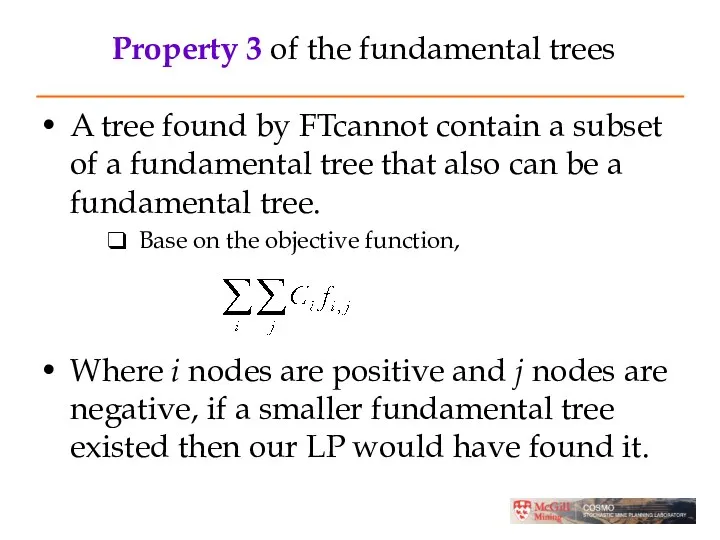

- 46. Property 3 of the fundamental trees A tree found by FTcannot contain a subset of a

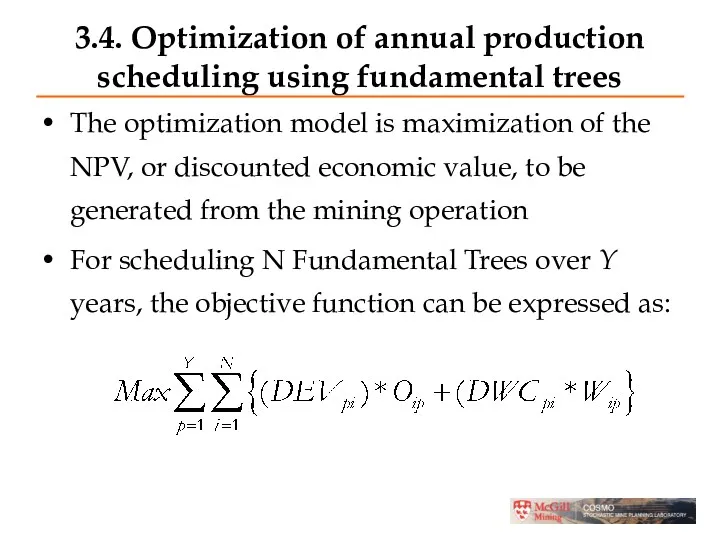

- 47. 3.4. Optimization of annual production scheduling using fundamental trees The optimization model is maximization of the

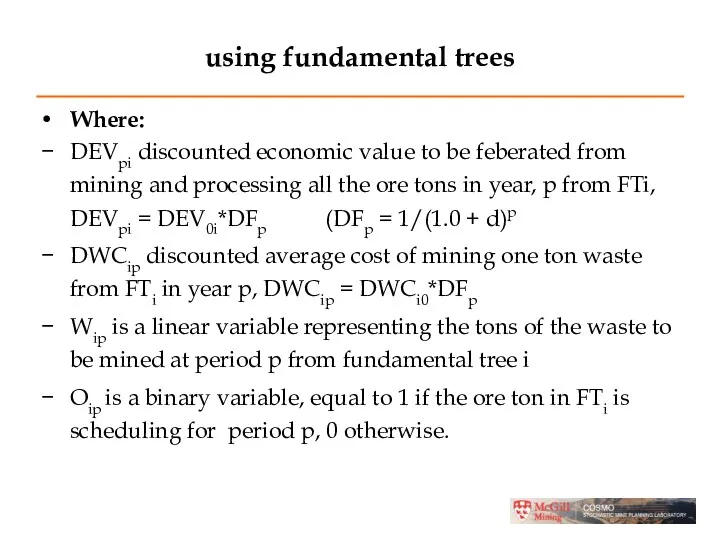

- 48. using fundamental trees Where: DEVpi discounted economic value to be feberated from mining and processing all

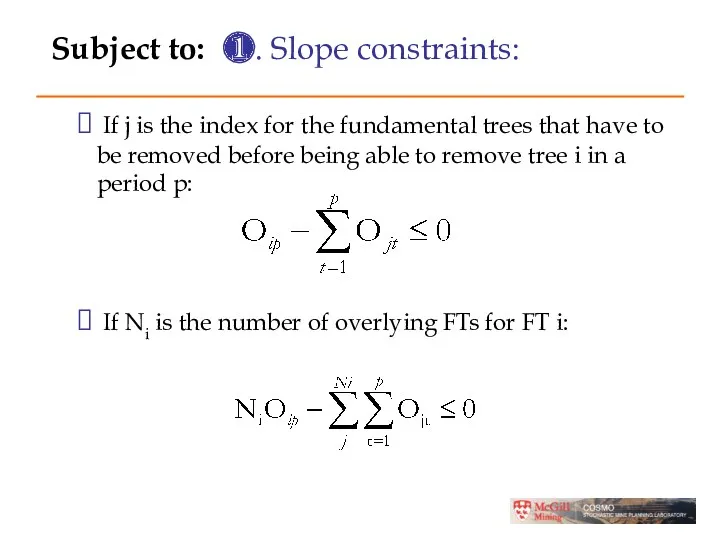

- 49. Subject to: ❶. Slope constraints: If j is the index for the fundamental trees that have

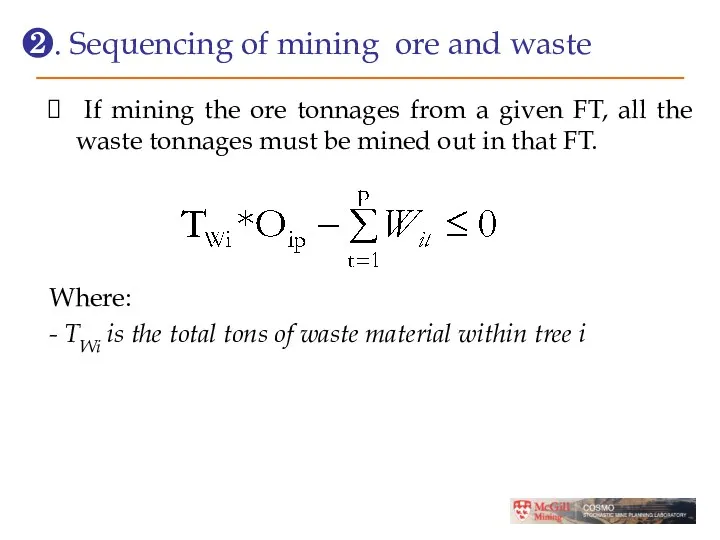

- 50. ❷. Sequencing of mining ore and waste If mining the ore tonnages from a given FT,

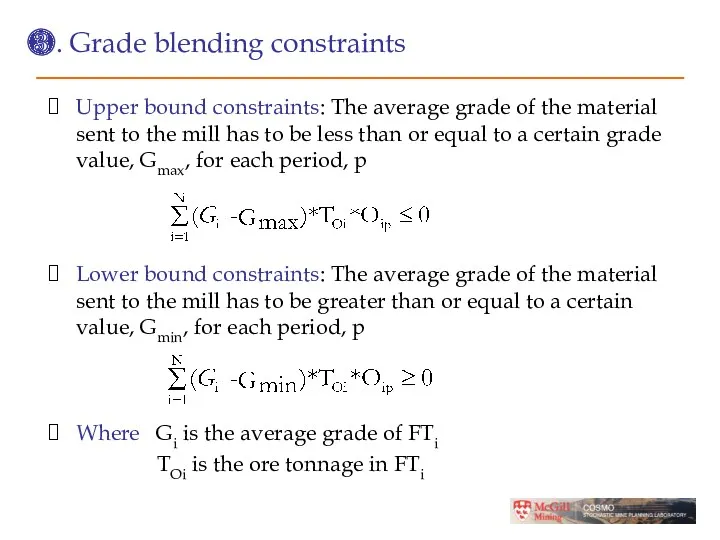

- 51. ❸. Grade blending constraints Upper bound constraints: The average grade of the material sent to the

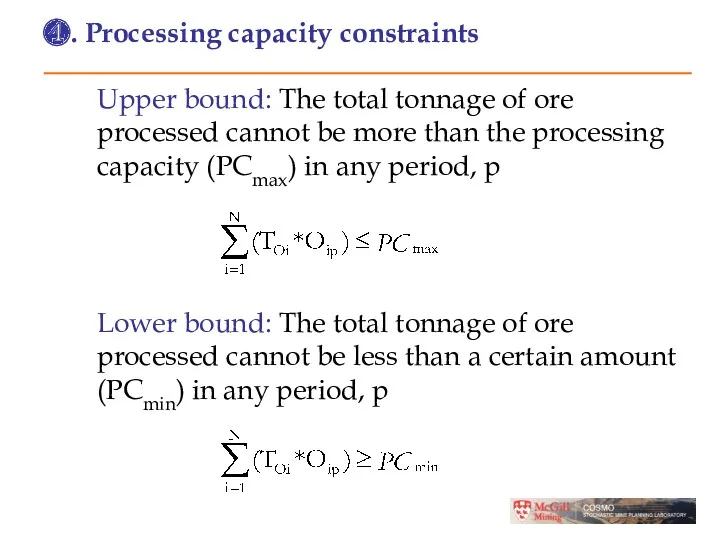

- 52. ❹. Processing capacity constraints Upper bound: The total tonnage of ore processed cannot be more than

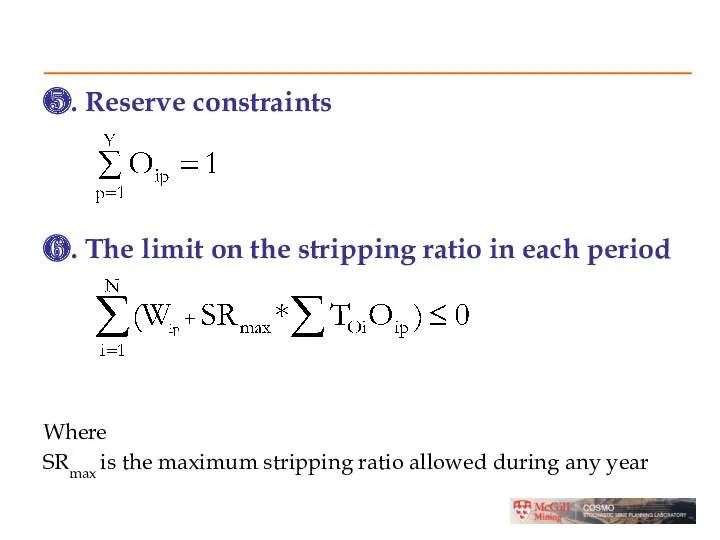

- 53. ❻. The limit on the stripping ratio in each period Where SRmax is the maximum stripping

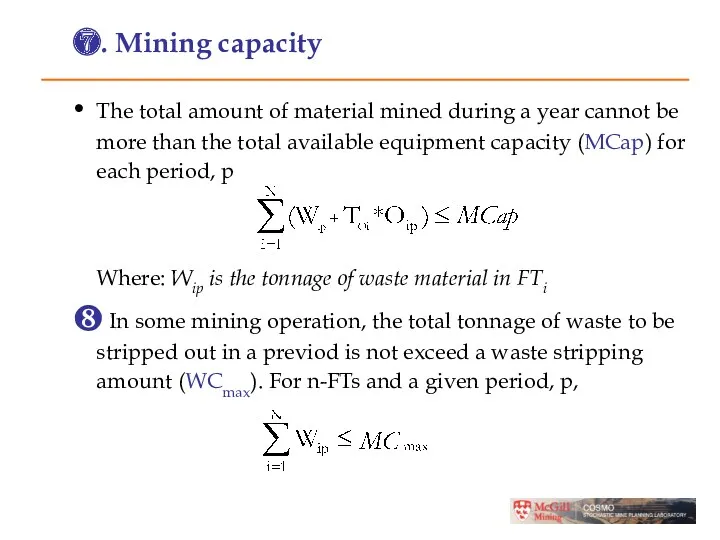

- 54. ❼. Mining capacity The total amount of material mined during a year cannot be more than

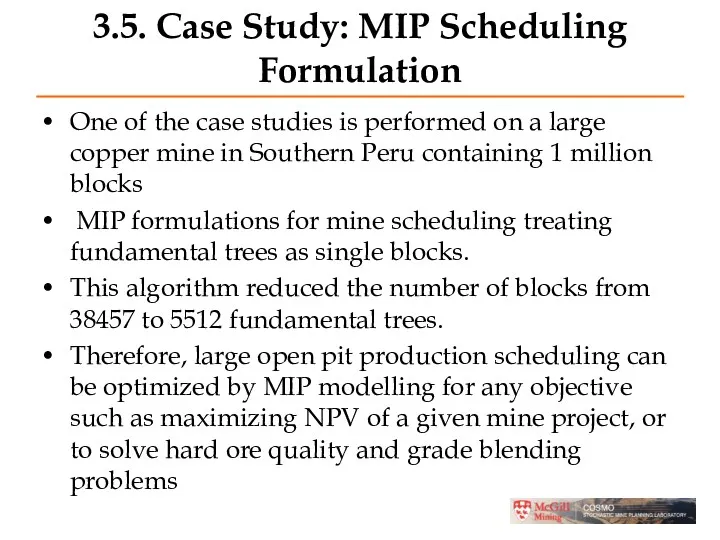

- 55. 3.5. Case Study: MIP Scheduling Formulation One of the case studies is performed on a large

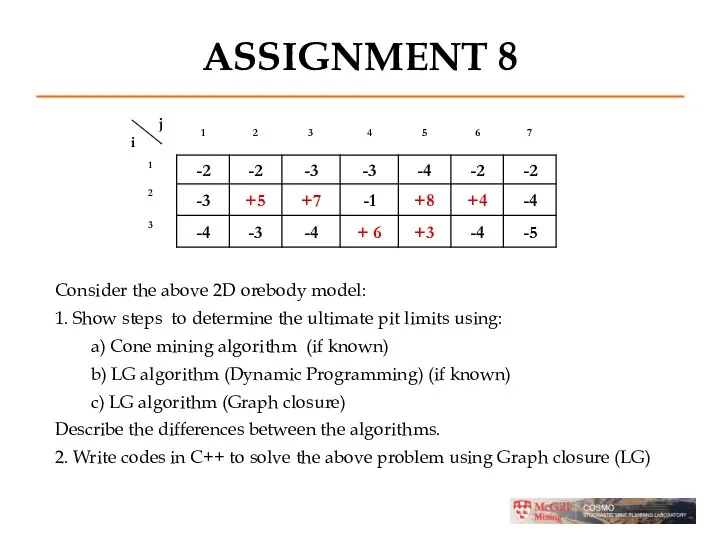

- 56. ASSIGNMENT 8 Consider the above 2D orebody model: 1. Show steps to determine the ultimate pit

- 58. Скачать презентацию

Разработка логической игры Пазлы на платформе UNITY

Разработка логической игры Пазлы на платформе UNITY Introduction to computer systems. Architecture of computer systems. Lecture2

Introduction to computer systems. Architecture of computer systems. Lecture2 Брейн ринг по информатике

Брейн ринг по информатике Готовимся к ЕГЭ. Задание №12. IP-адрес

Готовимся к ЕГЭ. Задание №12. IP-адрес Презентация по информатике Умники и умницы

Презентация по информатике Умники и умницы Модели надежности

Модели надежности Электронный учебник по информатике

Электронный учебник по информатике Виды современных компьютеров (от мощных компьютерных систем, до мини-компьютеров)

Виды современных компьютеров (от мощных компьютерных систем, до мини-компьютеров) Информатика и история развития информационных технологий

Информатика и история развития информационных технологий Логические значения. Ветвление (Delphi)

Логические значения. Ветвление (Delphi) Модели информационных процессов

Модели информационных процессов WEB-дизайн. Эргономика WEB-сайта

WEB-дизайн. Эргономика WEB-сайта HTML: Базові, основні та складні елементи. Лекция 25

HTML: Базові, основні та складні елементи. Лекция 25 Интернет-технологии. Интернет-маркетинг

Интернет-технологии. Интернет-маркетинг Интеллектуальные методы в экономике и бизнесе

Интеллектуальные методы в экономике и бизнесе Навигатор дополнительного образования

Навигатор дополнительного образования Web index report. Аудитория интернет-проектов. Результаты исследования: Март 2016

Web index report. Аудитория интернет-проектов. Результаты исследования: Март 2016 Компьютерные атаки

Компьютерные атаки История связи. Простейшие средства связи

История связи. Простейшие средства связи Информационные технологии

Информационные технологии Алгоритм и его формальное исполнение

Алгоритм и его формальное исполнение Спам. Возникновение, распространение, способы защиты

Спам. Возникновение, распространение, способы защиты Цифровые технологии при съемках фильма Аватар

Цифровые технологии при съемках фильма Аватар Урок Группы клавиш. Основная позиция пальцев на клавиатуре 5 класс

Урок Группы клавиш. Основная позиция пальцев на клавиатуре 5 класс Создание мобильной версии сайта

Создание мобильной версии сайта Объекты и их имена. Признаки объектов. (Урок 1)

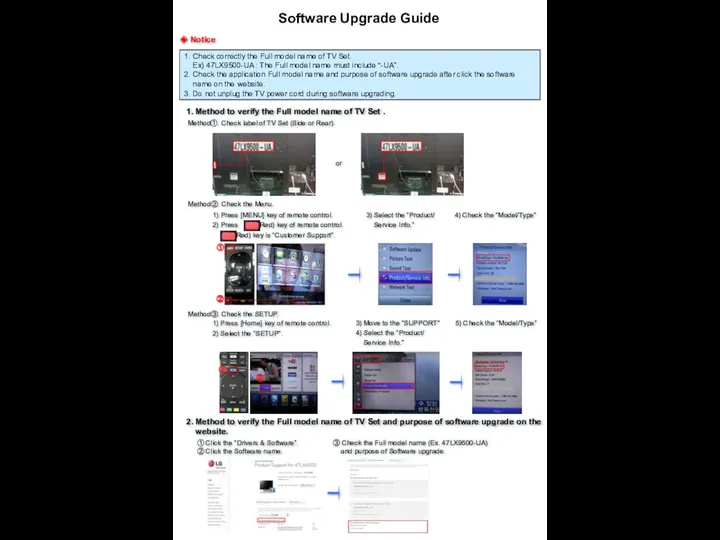

Объекты и их имена. Признаки объектов. (Урок 1) Software upgrade guide

Software upgrade guide Внесение данных в информационную систему Мониторинг оказания паллиативной медицинской помощи взрослому населению и детям

Внесение данных в информационную систему Мониторинг оказания паллиативной медицинской помощи взрослому населению и детям