Содержание

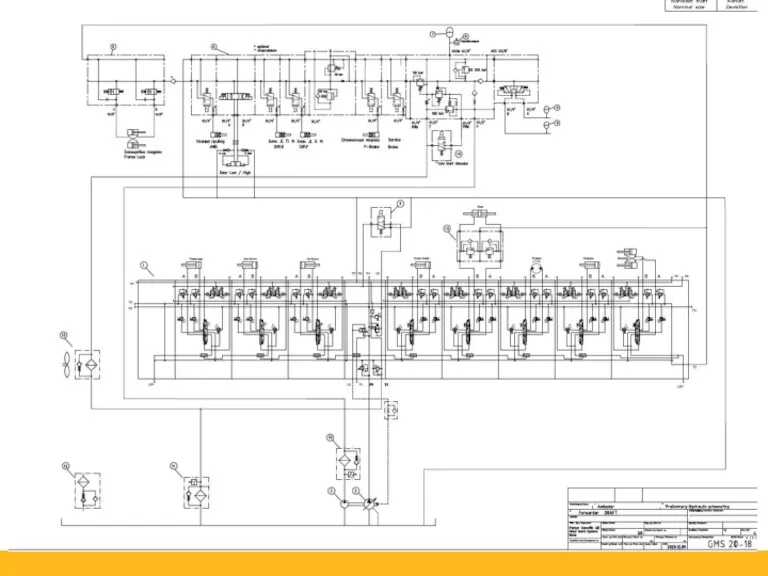

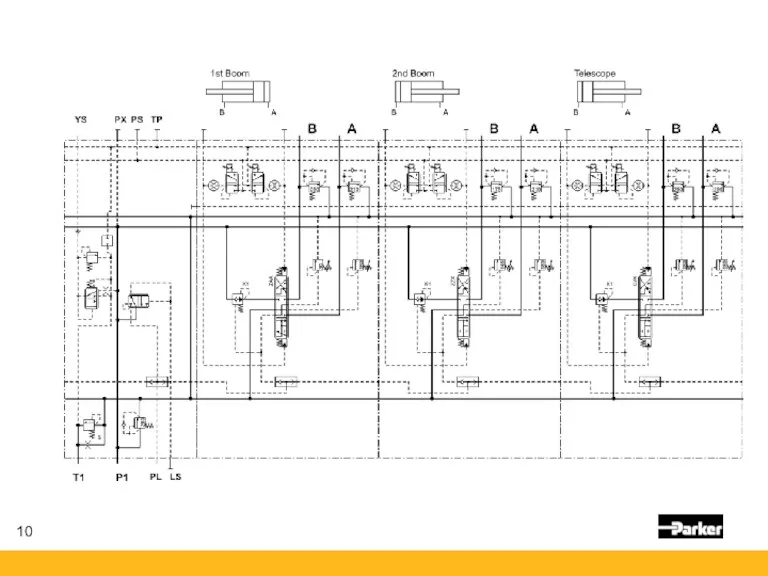

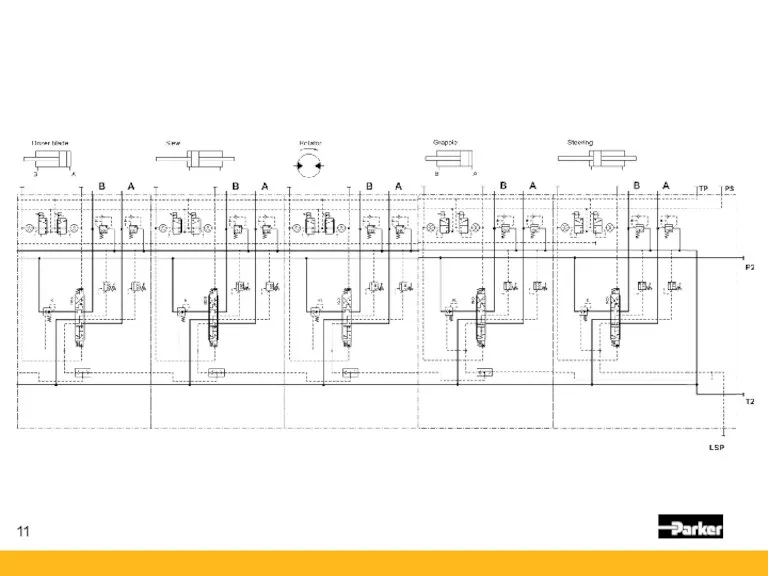

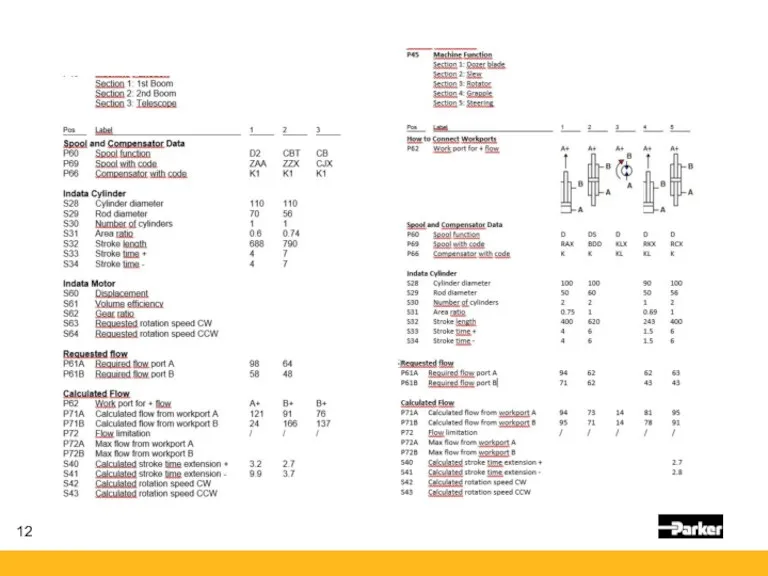

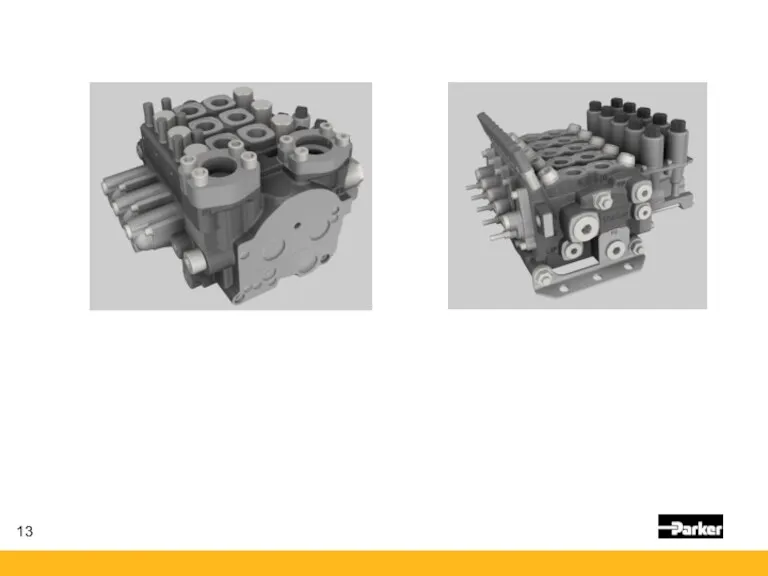

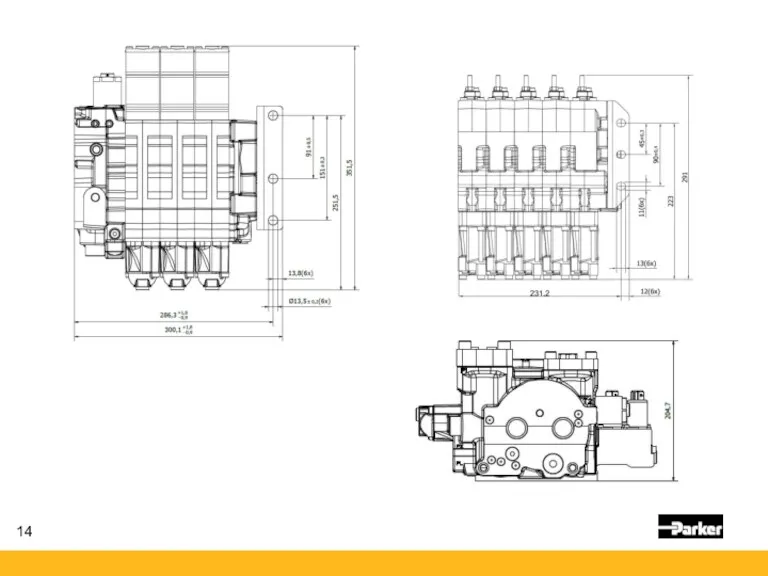

- 3. Proposed solutions main components FV-5407 combination valve K220LS-03-054508-01 : 1’st Boom, 2’nd Boom, Telescope L90LS-05-050680-02 :

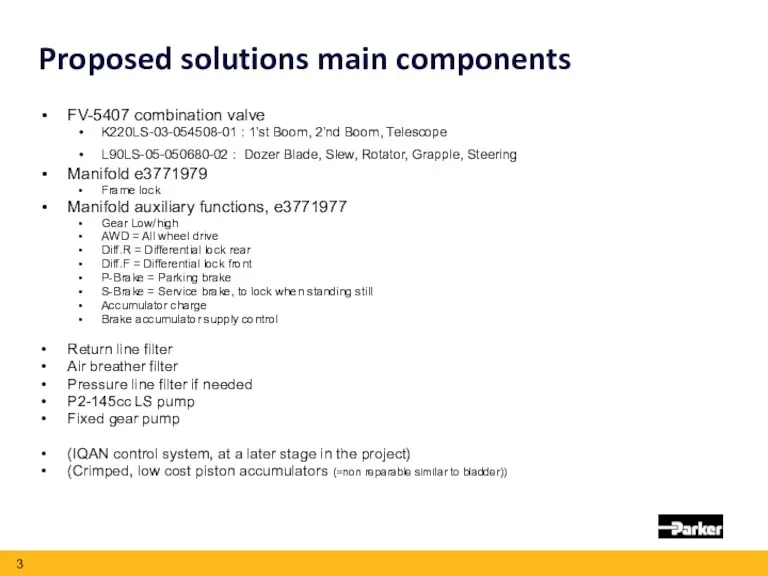

- 4. Mid Inlet - Copy Spool, Tank Counter Pressure

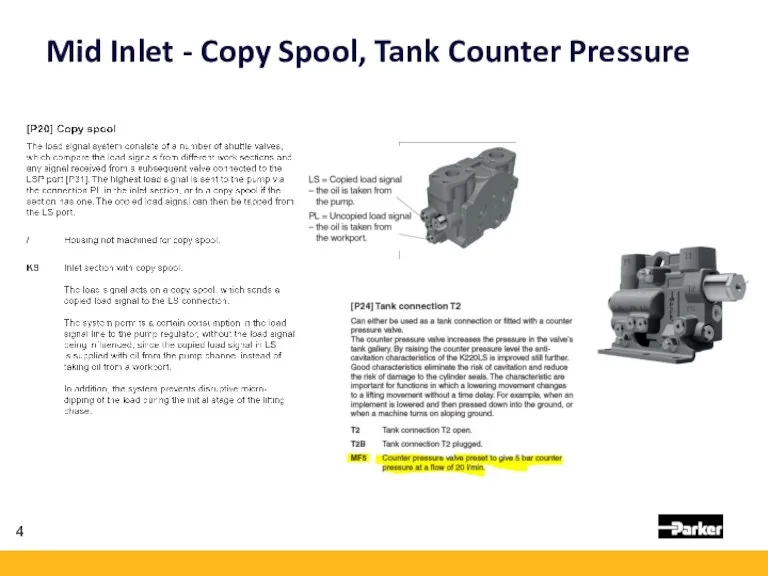

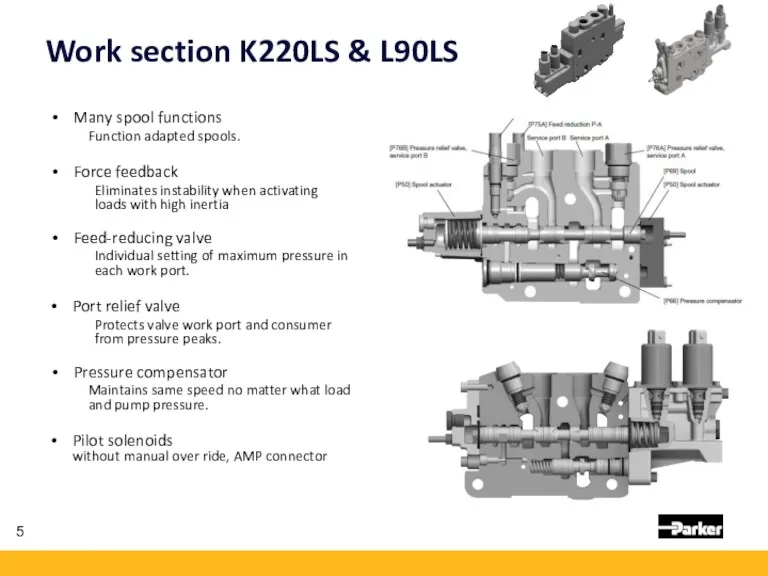

- 5. Work section K220LS & L90LS Many spool functions Function adapted spools. Force feedback Eliminates instability when

- 6. Crane valve – K220LS / L90LS 1st Boom Single acting spool on to save energy and

- 7. L90LS Dozer Blade Consider using a load holding valve. L90LS D-spool, work port relief 230 bar,

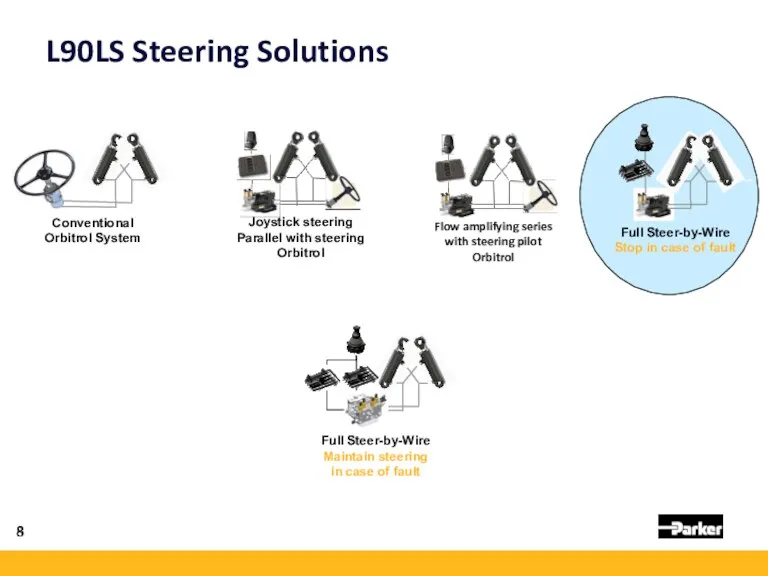

- 8. L90LS Steering Solutions Flow amplifying series with steering pilot Orbitrol Joystick steering Parallel with steering Orbitrol

- 9. Steering A standard L90 work section in this proposal. Consider using additional equipment to fullfil high

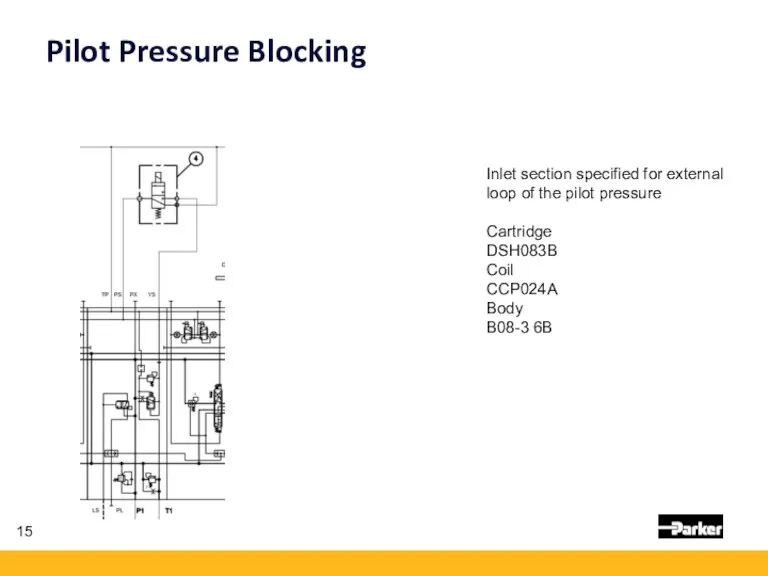

- 15. Pilot Pressure Blocking Inlet section specified for external loop of the pilot pressure Cartridge DSH083B Coil

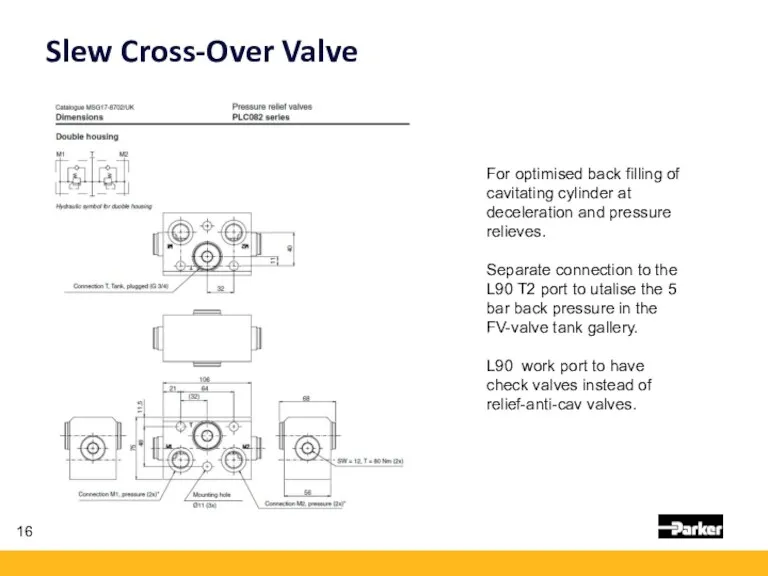

- 16. Slew Cross-Over Valve For optimised back filling of cavitating cylinder at deceleration and pressure relieves. Separate

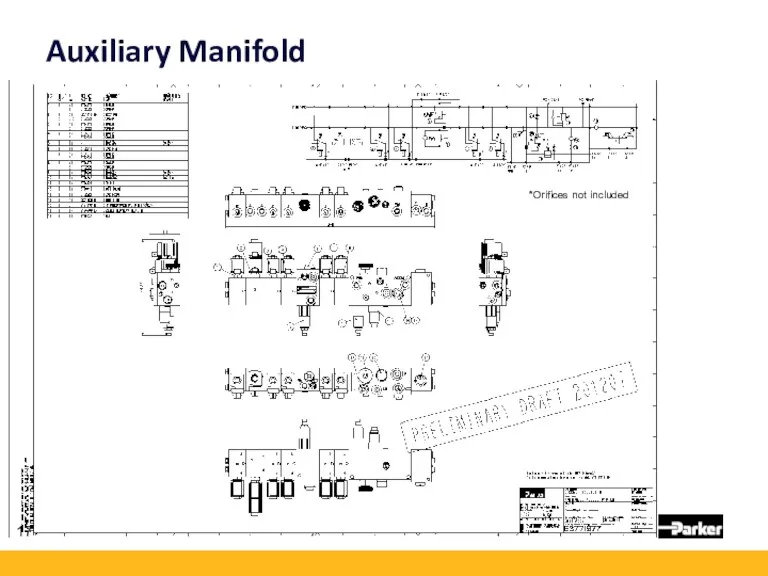

- 17. Auxiliary Manifold *Orifices not included

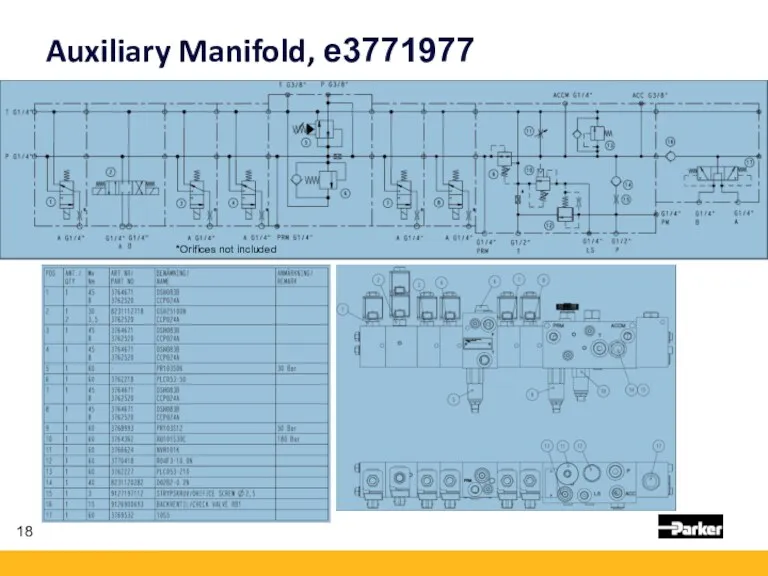

- 18. Auxiliary Manifold, e3771977 *Orifices not included

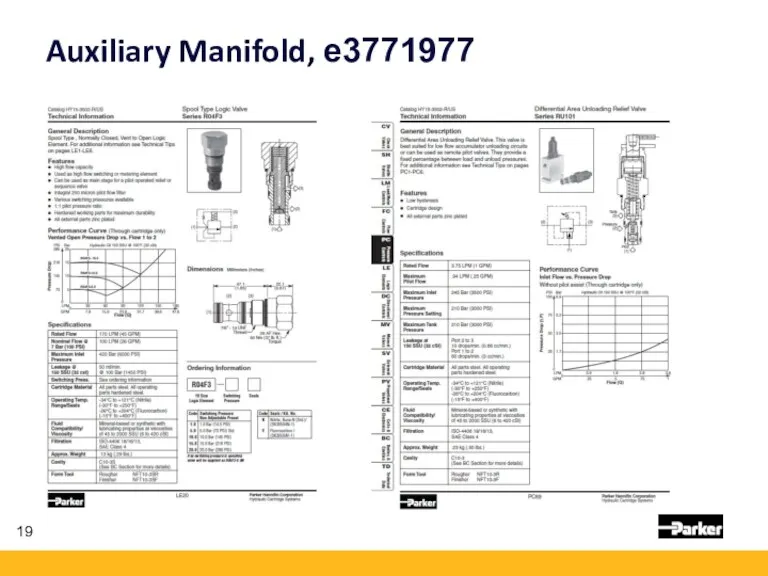

- 19. Auxiliary Manifold, e3771977

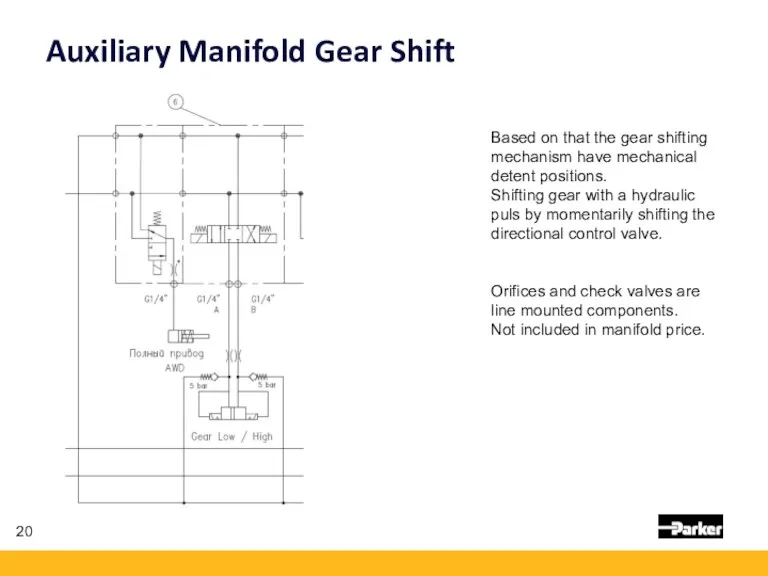

- 20. Auxiliary Manifold Gear Shift Based on that the gear shifting mechanism have mechanical detent positions. Shifting

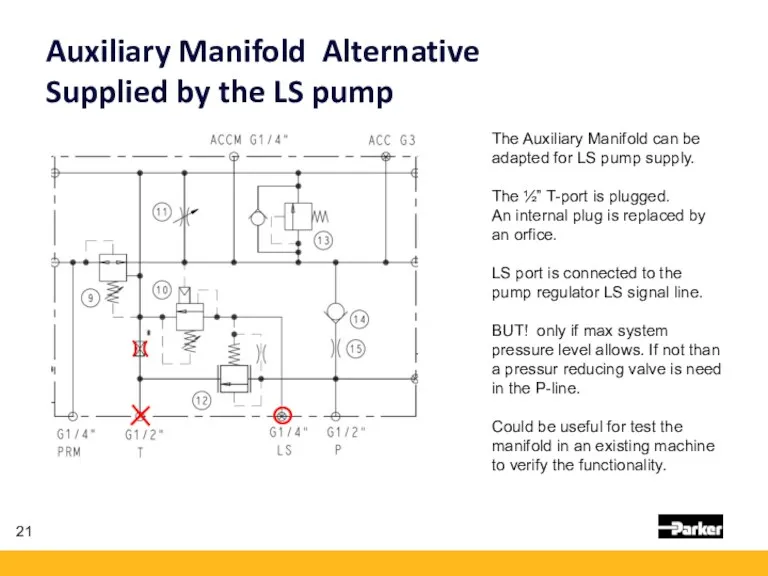

- 21. Auxiliary Manifold Alternative Supplied by the LS pump The Auxiliary Manifold can be adapted for LS

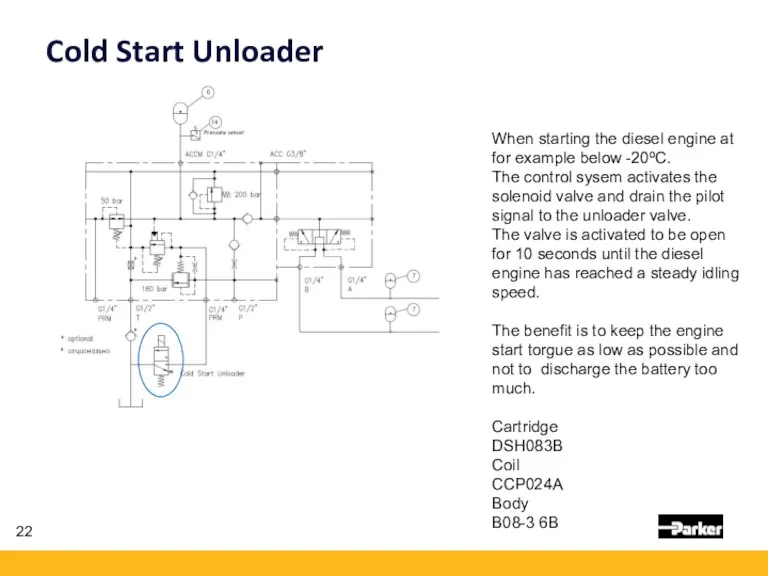

- 22. Cold Start Unloader When starting the diesel engine at for example below -20ºC. The control sysem

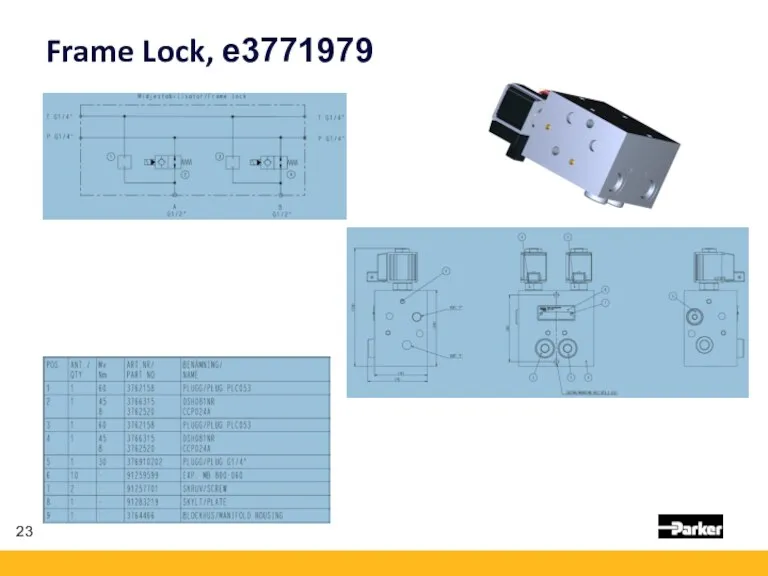

- 23. Frame Lock, e3771979

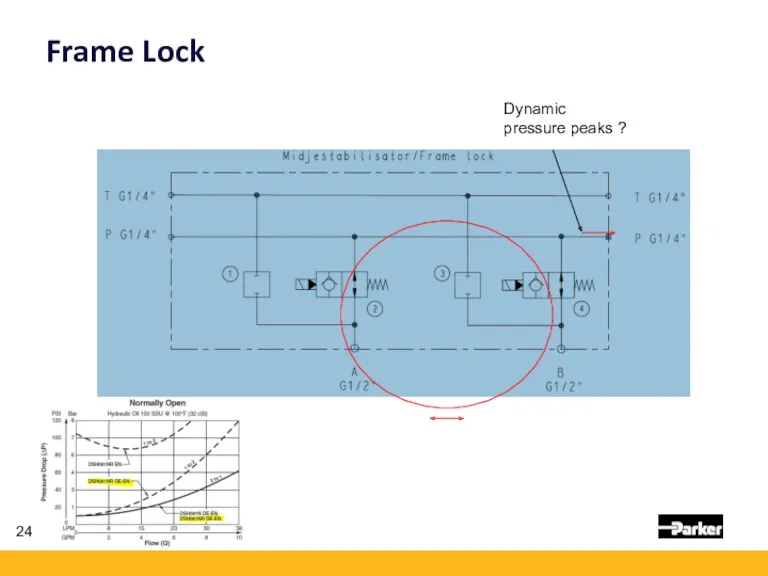

- 24. Frame Lock Dynamic pressure peaks ?

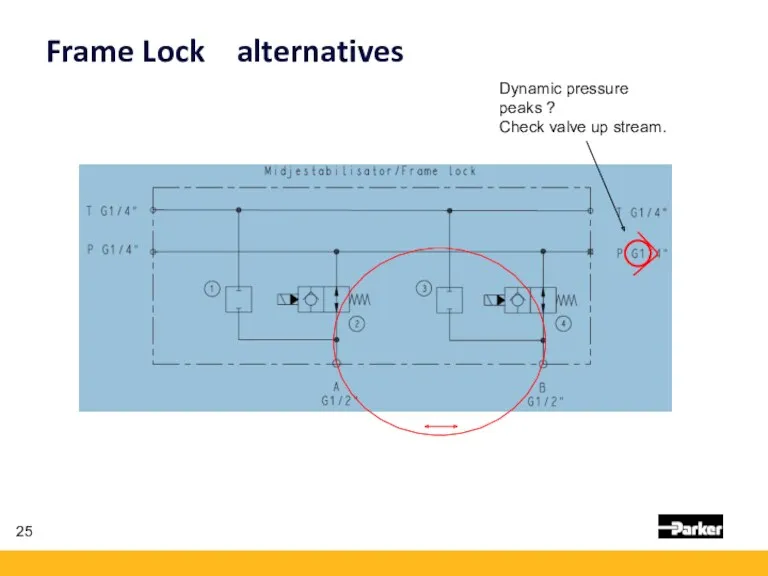

- 25. Frame Lock alternatives Dynamic pressure peaks ? Check valve up stream.

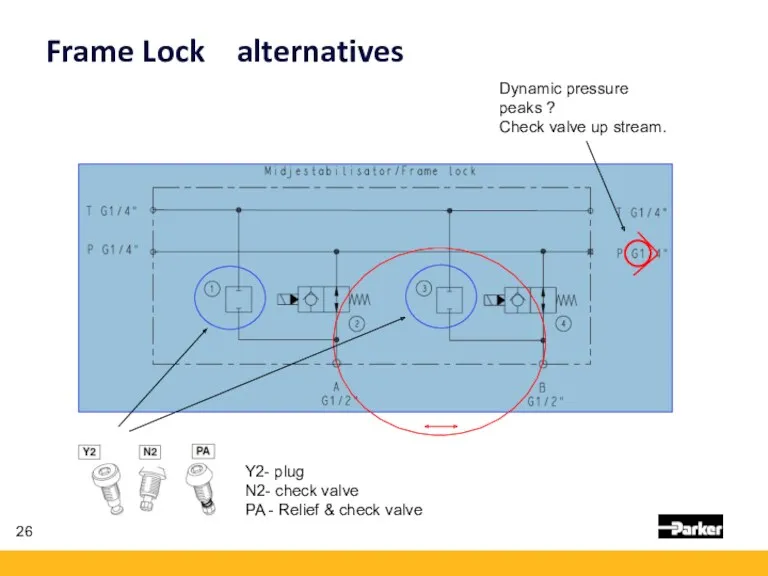

- 26. Frame Lock alternatives Y2- plug N2- check valve PA - Relief & check valve Dynamic pressure

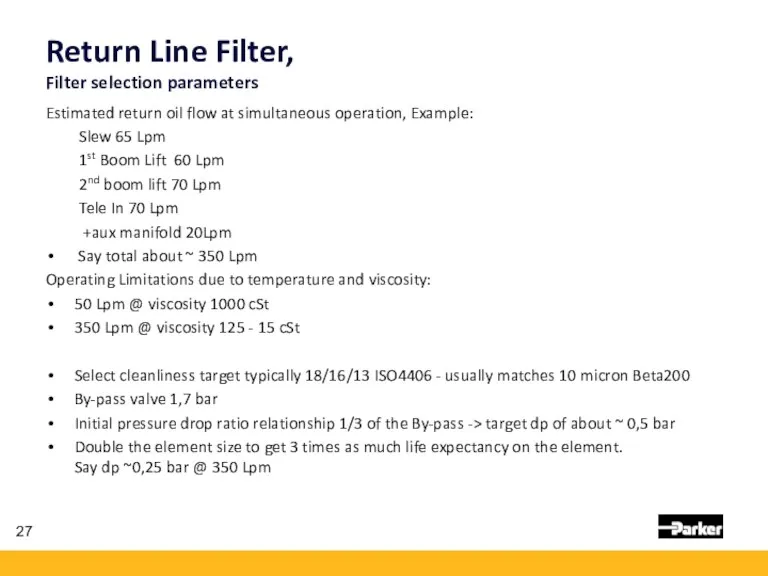

- 27. Return Line Filter, Filter selection parameters Estimated return oil flow at simultaneous operation, Example: Slew 65

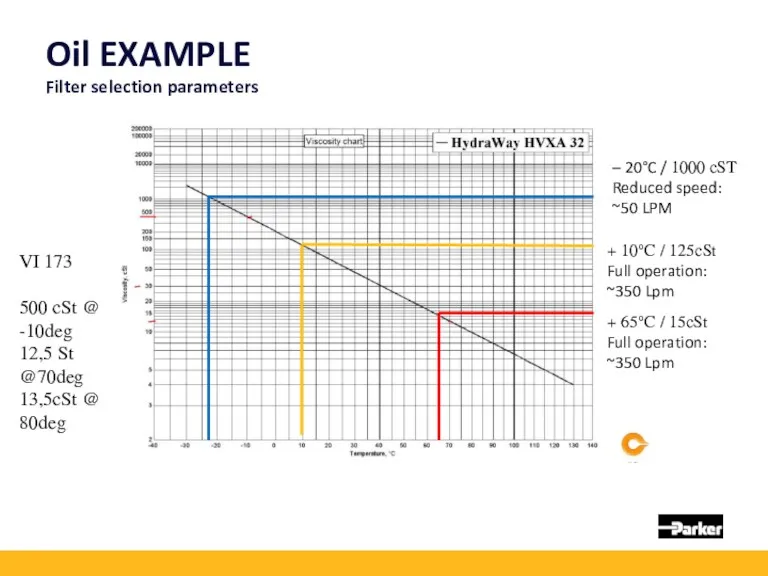

- 28. Oil EXAMPLE Filter selection parameters + 65°C / 15cSt Full operation: ~350 Lpm

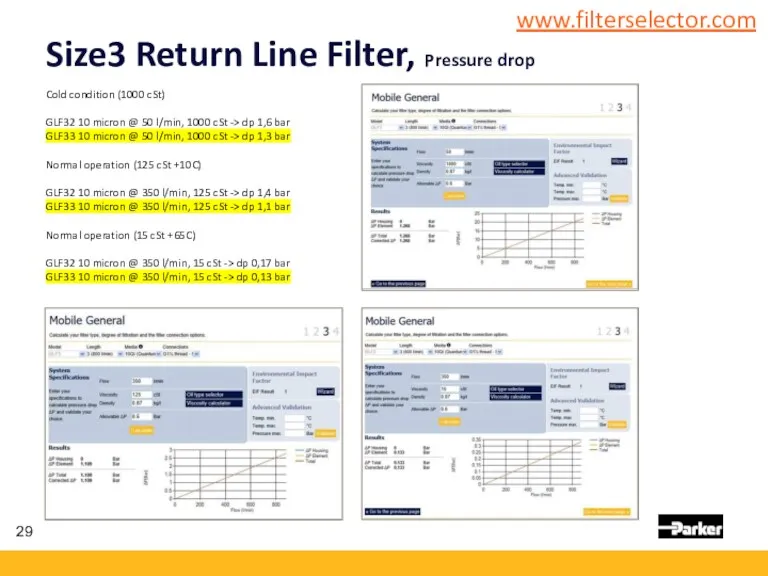

- 29. Cold condition (1000 cSt) GLF32 10 micron @ 50 l/min, 1000 cSt -> dp 1,6 bar

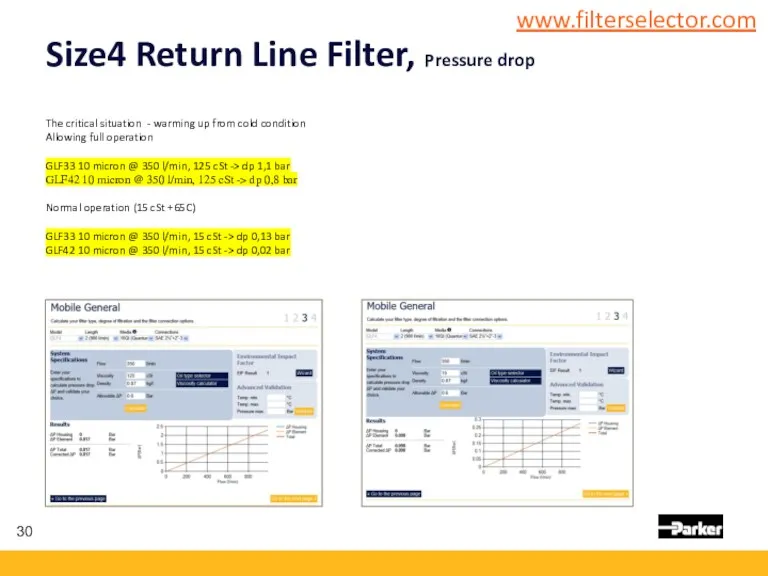

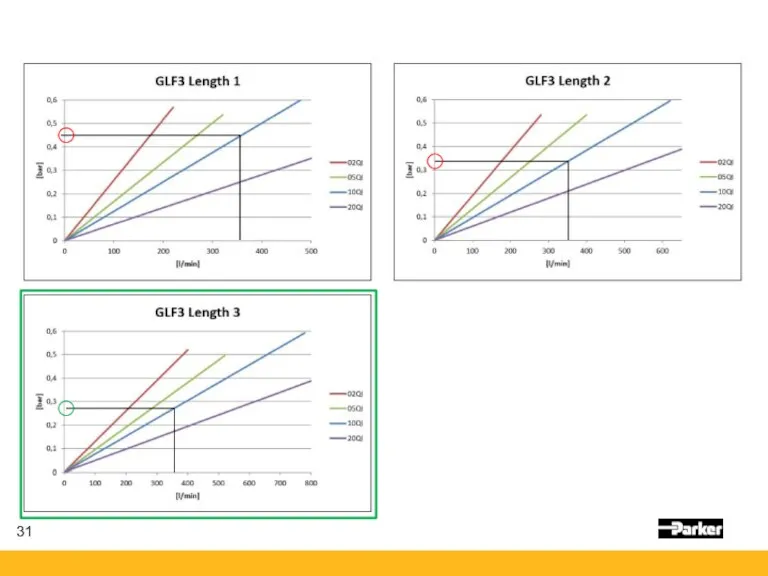

- 30. Size4 Return Line Filter, Pressure drop The critical situation - warming up from cold condition Allowing

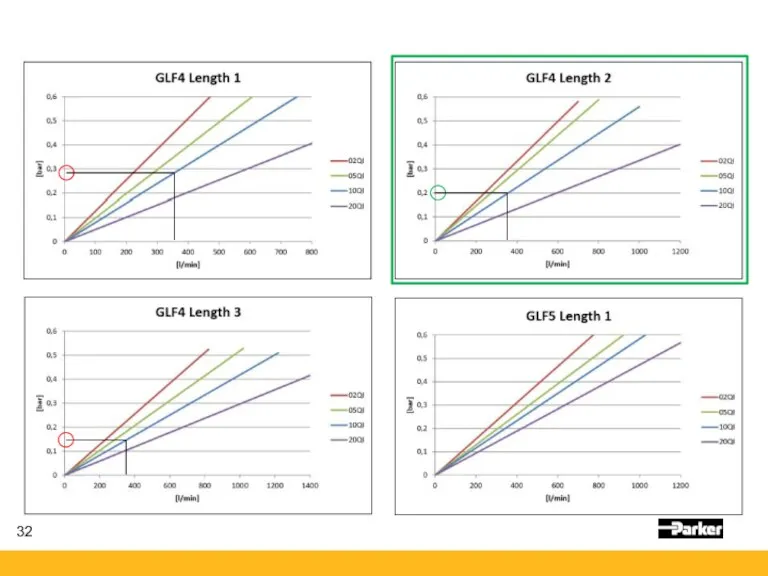

- 33. Filter configuration: GLF4 Length2, ( alternatively GLF3 Length3) Funnel Magnet column Filling port GLI version instead

- 35. Скачать презентацию

Продукция Atomy. Витамины, БАДы, диетическое питание

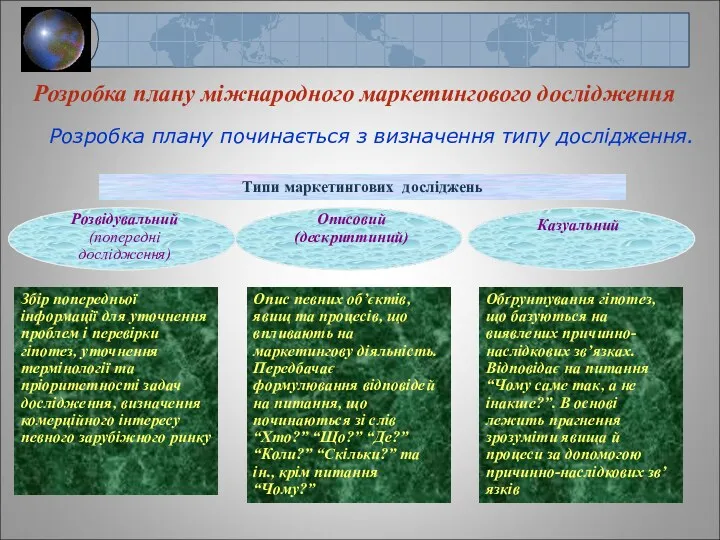

Продукция Atomy. Витамины, БАДы, диетическое питание Розробка плану міжнародного маркетингового дослідження

Розробка плану міжнародного маркетингового дослідження Industrial Hydraulic System Профессиональная промышленная гидравлика

Industrial Hydraulic System Профессиональная промышленная гидравлика AI-система эффективности цифрового маркетинга с учётом офлайн-продаж

AI-система эффективности цифрового маркетинга с учётом офлайн-продаж Реклама в туризме

Реклама в туризме Конференц зал. Пушкин отель. Уральск

Конференц зал. Пушкин отель. Уральск Rodeker DOB 360 beam bulbs dats. Lighting for future

Rodeker DOB 360 beam bulbs dats. Lighting for future Аппарат высокого давления Karcher

Аппарат высокого давления Karcher Основные ошибки оформления магазинов НК

Основные ошибки оформления магазинов НК Коммерческое предложение от компании Такском

Коммерческое предложение от компании Такском Эко-посуда

Эко-посуда Мастер пирогов

Мастер пирогов Клининговая компания Чистый дом

Клининговая компания Чистый дом Business computer systems

Business computer systems Привлечение клиентов через социальные сети. Курс Онлайн партнер Оriflame

Привлечение клиентов через социальные сети. Курс Онлайн партнер Оriflame Разработка позиционирования торговой марки

Разработка позиционирования торговой марки Приставки Smart TV Reflect

Приставки Smart TV Reflect Pitch deck. Re speecher

Pitch deck. Re speecher LIKE Центр Чита

LIKE Центр Чита Праздничное агентство АЗаrt-studio. Организация свадеб

Праздничное агентство АЗаrt-studio. Организация свадеб Київстар – мобільний оператор №1 та один з найкращих брендів України

Київстар – мобільний оператор №1 та один з найкращих брендів України Content management system (CMS) – cистема управления содержимым

Content management system (CMS) – cистема управления содержимым Личный бренд

Личный бренд Экспертиза и оценка качества лакокрасочных материалов, реализуемых в розничной торговой сети

Экспертиза и оценка качества лакокрасочных материалов, реализуемых в розничной торговой сети Формирование имиджа политического лидера

Формирование имиджа политического лидера Ладушки, Маша и медведь новая торговая марка на рынке соков и нектаров

Ладушки, Маша и медведь новая торговая марка на рынке соков и нектаров Маркетинговые и коммуникационные цели компании MIxit

Маркетинговые и коммуникационные цели компании MIxit Компания Мясо тут

Компания Мясо тут