Содержание

- 2. Minimum Essential Quality Elements Navigation Navigation Click green arrows to go to next slide. Click green

- 3. OVERVIEW In this section…

- 4. Minimum Essential Quality Elements Overview Intended Audience Distributor personnel with Service activities

- 5. Minimum Essential Quality Elements Overview The purpose of this course is to cover minimum essential elements

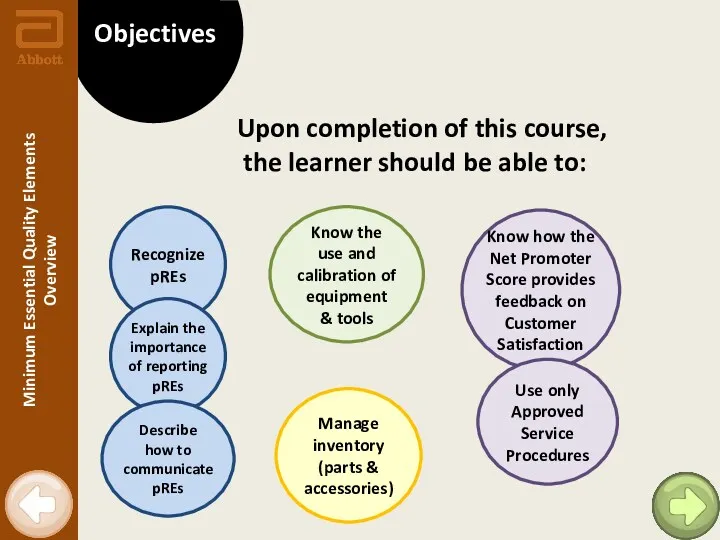

- 6. Manage inventory (parts & accessories) Minimum Essential Quality Elements Overview Objectives Upon completion of this course,

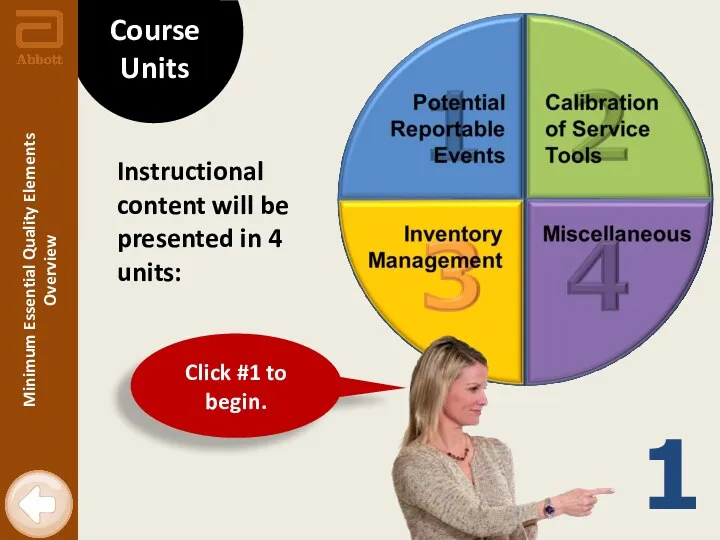

- 7. Minimum Essential Quality Elements Overview Instructional content will be presented in 4 units: Course Units Click

- 8. POTENTIAL REPORTABLE EVENTS In this section… What are pREs? Why we report pREs How to recognize

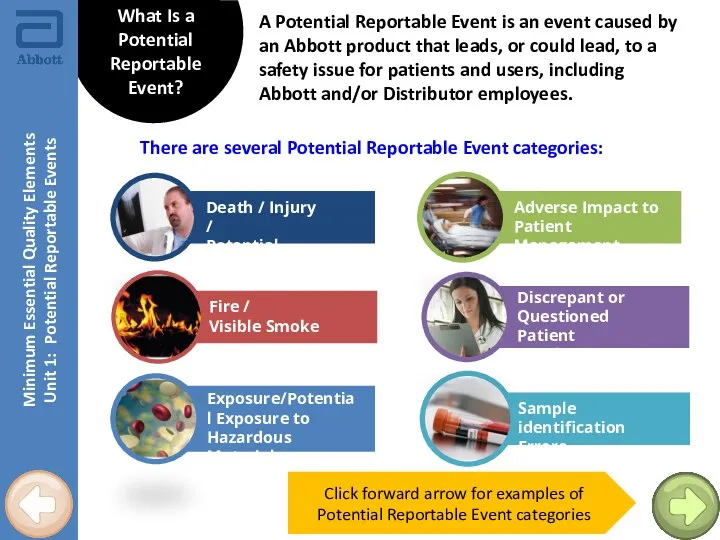

- 9. Minimum Essential Quality Elements Unit 1: Potential Reportable Events What Is a Potential Reportable Event? A

- 10. Minimum Essential Quality Elements Unit 1: Potential Reportable Events Death / Injury / Potential Injury Potential

- 11. Minimum Essential Quality Elements Unit 1: Potential Reportable Events Potential Reportable Event Example WHILE TROUBLESHOOTING A

- 12. Minimum Essential Quality Elements Unit 1: Potential Reportable Events Potential Reportable Event Example LIQUID WASTE CONTAINER

- 13. Minimum Essential Quality Elements Unit 1: Potential Reportable Events Potential Reportable Event Example CUSTOMER CONFIRMED EXCESSIVE

- 14. Minimum Essential Quality Elements Unit 1: Potential Reportable Events Potential Reportable Event Example A PATIENT SAMPLE

- 15. Minimum Essential Quality Elements Unit 1: Potential Reportable Events Potential Reportable Event Example ARCHITECT BARCODE MISREAD

- 16. Minimum Essential Quality Elements Unit 1: Potential Reportable Events Why Do I Have to Report pREs?

- 17. Minimum Essential Quality Elements Unit 1: Potential Reportable Events Why Do I Have to Report pREs?

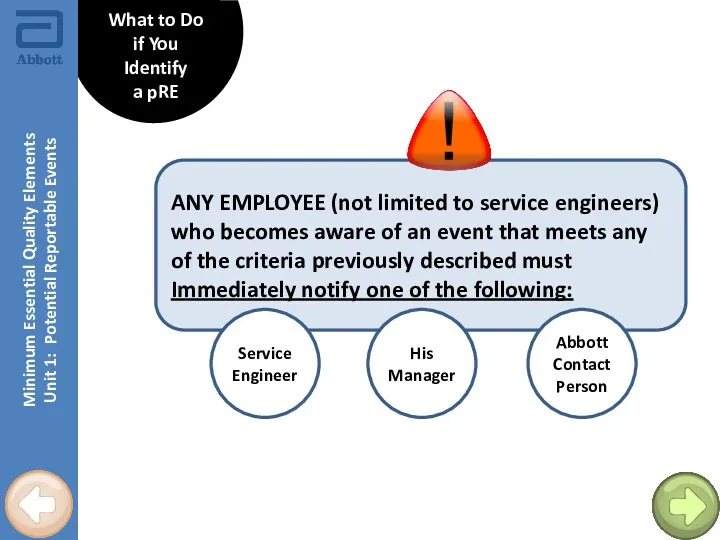

- 18. Minimum Essential Quality Elements Unit 1: Potential Reportable Events What to Do if You Identify a

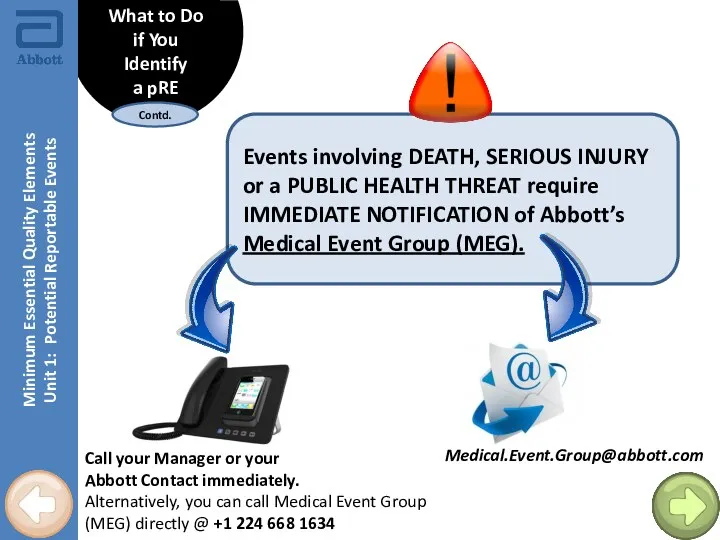

- 19. Minimum Essential Quality Elements Unit 1: Potential Reportable Events What to Do if You Identify a

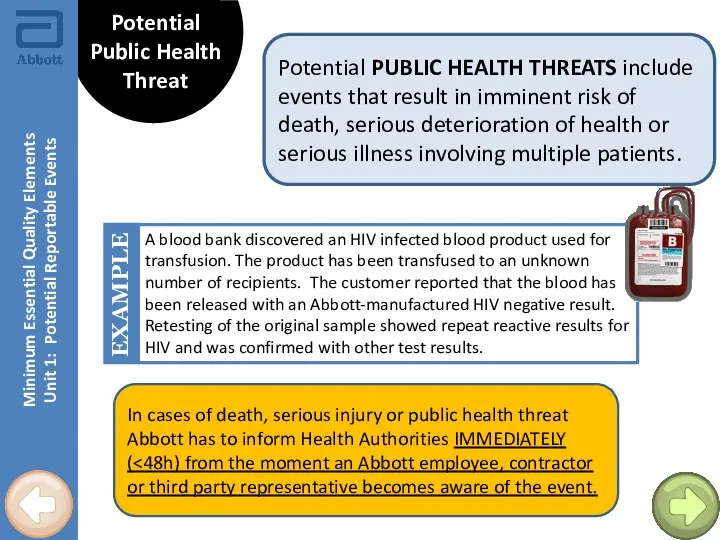

- 20. Minimum Essential Quality Elements Unit 1: Potential Reportable Events Potential Public Health Threat Potential PUBLIC HEALTH

- 21. POTENTIAL REPORTABLE EVENTS SCENARIOS In the following scenarios, you will determine whether or not each is

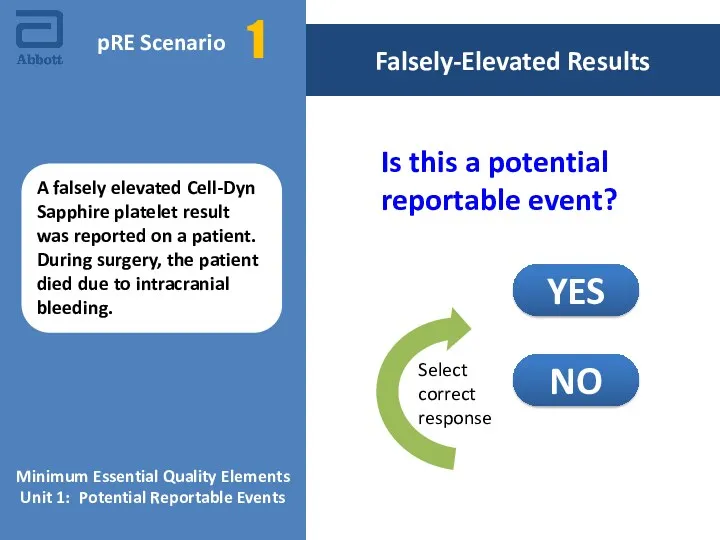

- 22. Minimum Essential Quality Elements Unit 1: Potential Reportable Events pRE Scenario 1 Falsely-Elevated Results A falsely

- 23. Minimum Essential Quality Elements Unit 1: Potential Reportable Events That is correct. An actual death occurred.

- 24. Minimum Essential Quality Elements Unit 1: Potential Reportable Events You did not select the correct response.

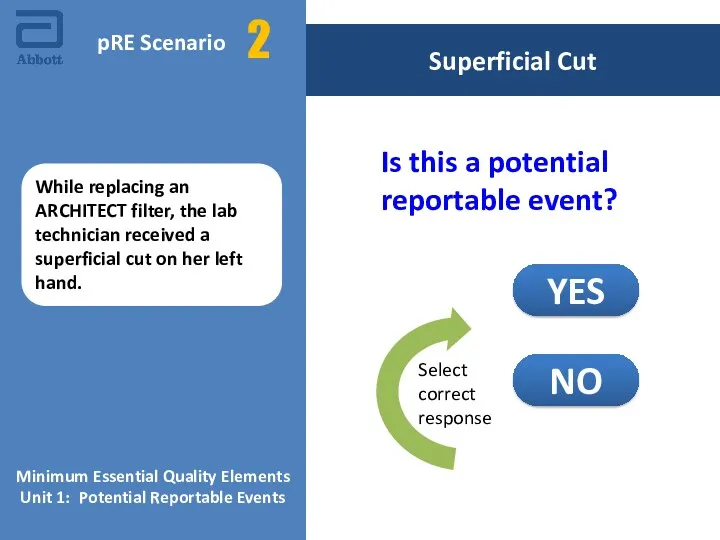

- 25. Superficial Cut Minimum Essential Quality Elements Unit 1: Potential Reportable Events pRE Scenario 2 While replacing

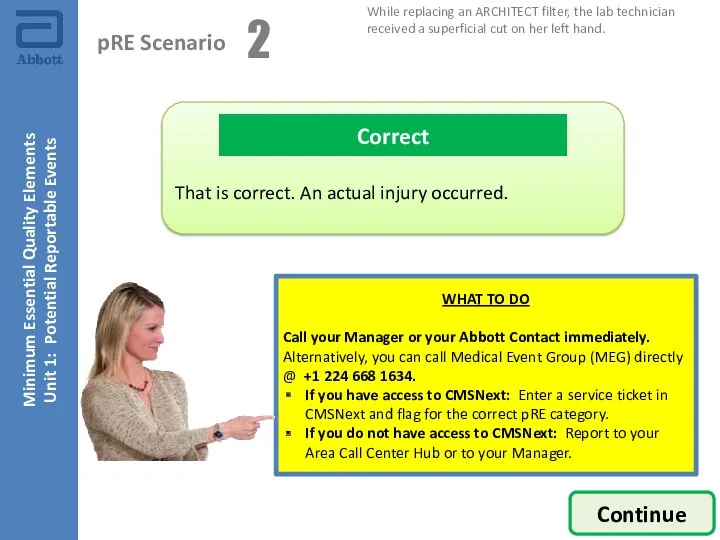

- 26. Minimum Essential Quality Elements Unit 1: Potential Reportable Events That is correct. An actual injury occurred.

- 27. Minimum Essential Quality Elements Unit 1: Potential Reportable Events You did not select the correct response.

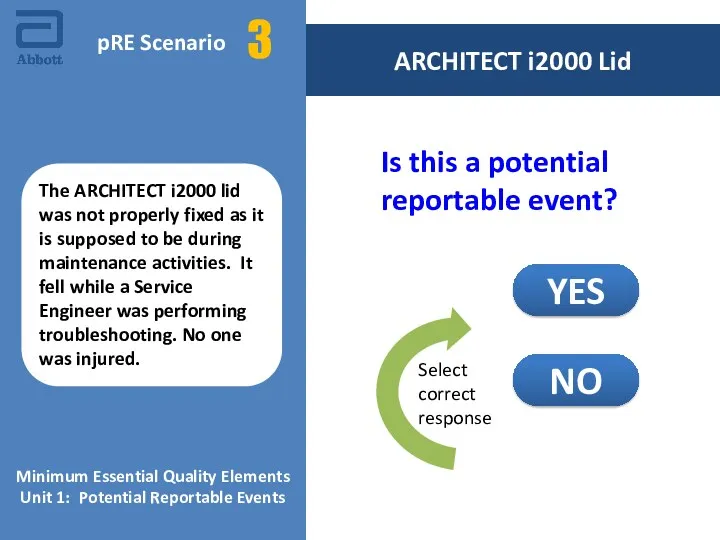

- 28. ARCHITECT i2000 Lid Minimum Essential Quality Elements Unit 1: Potential Reportable Events pRE Scenario 3 The

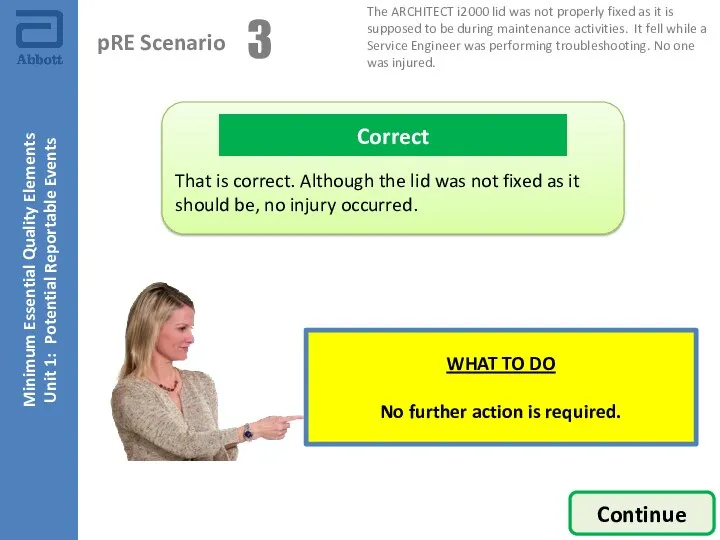

- 29. Minimum Essential Quality Elements Unit 1: Potential Reportable Events That is correct. Although the lid was

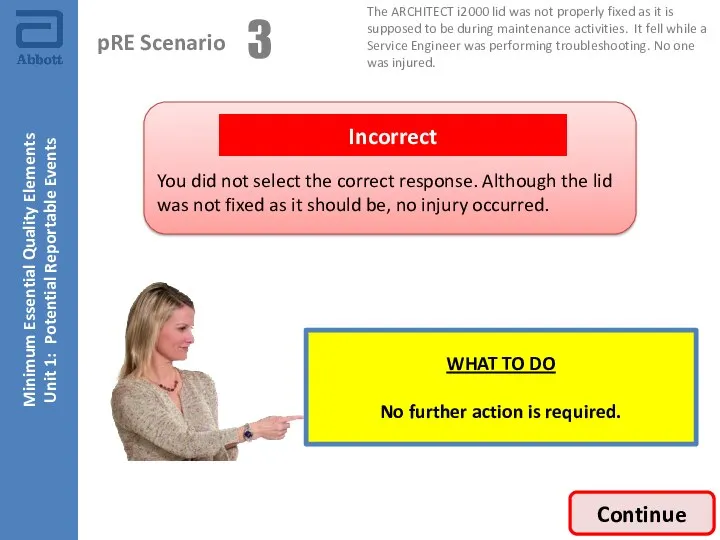

- 30. Minimum Essential Quality Elements Unit 1: Potential Reportable Events You did not select the correct response.

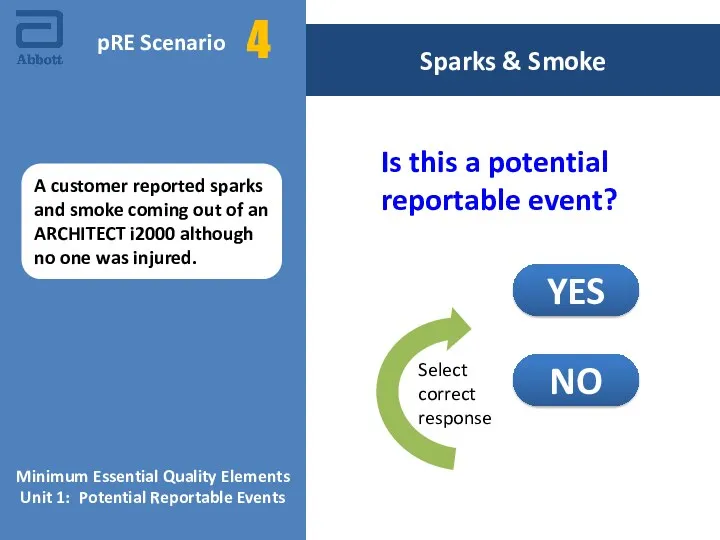

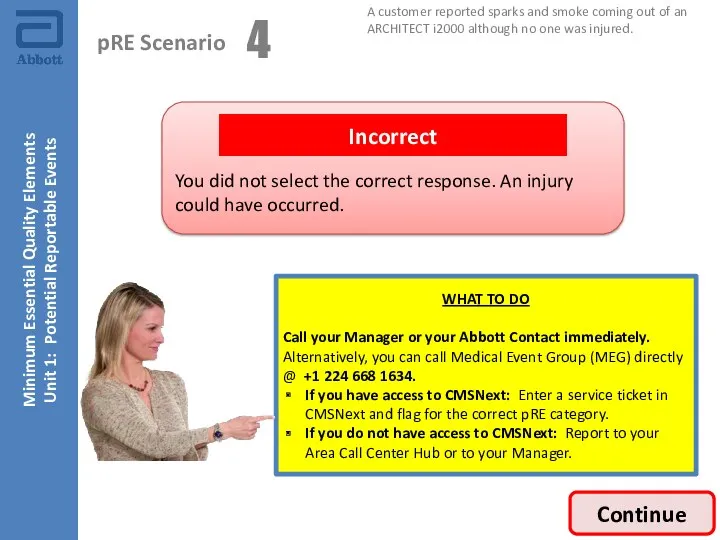

- 31. Sparks & Smoke Minimum Essential Quality Elements Unit 1: Potential Reportable Events pRE Scenario 4 A

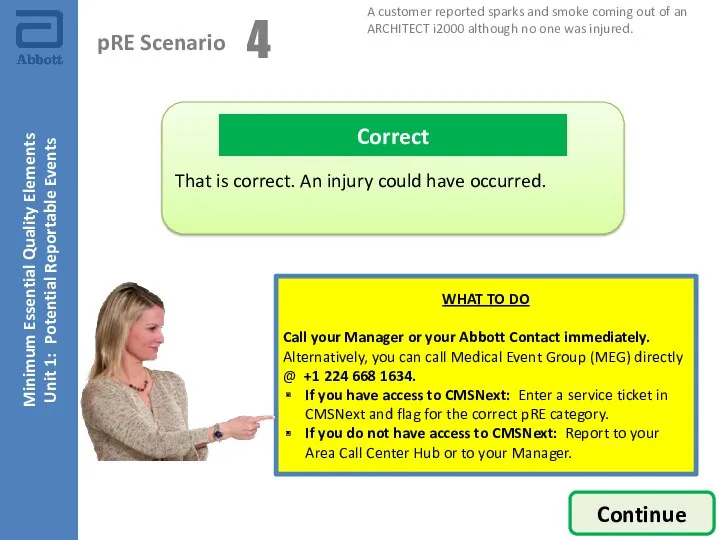

- 32. Minimum Essential Quality Elements Unit 1: Potential Reportable Events That is correct. An injury could have

- 33. Minimum Essential Quality Elements Unit 1: Potential Reportable Events You did not select the correct response.

- 34. Invalid Results Minimum Essential Quality Elements Unit 1: Potential Reportable Events pRE Scenario 5 The Cell-Dyn

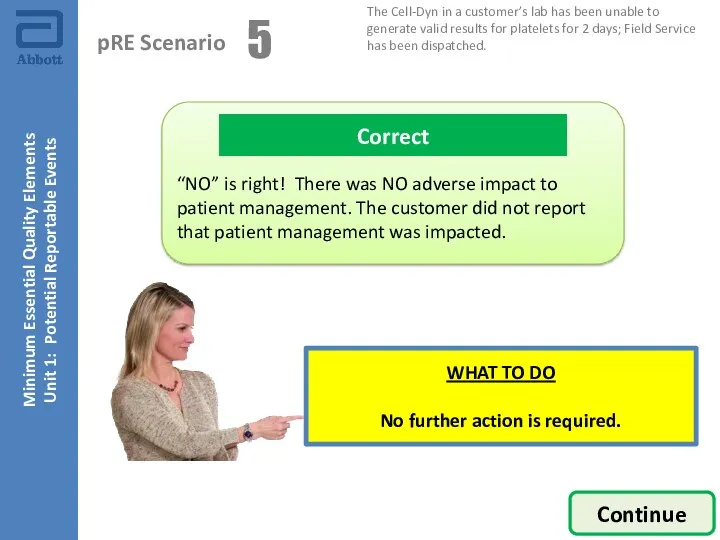

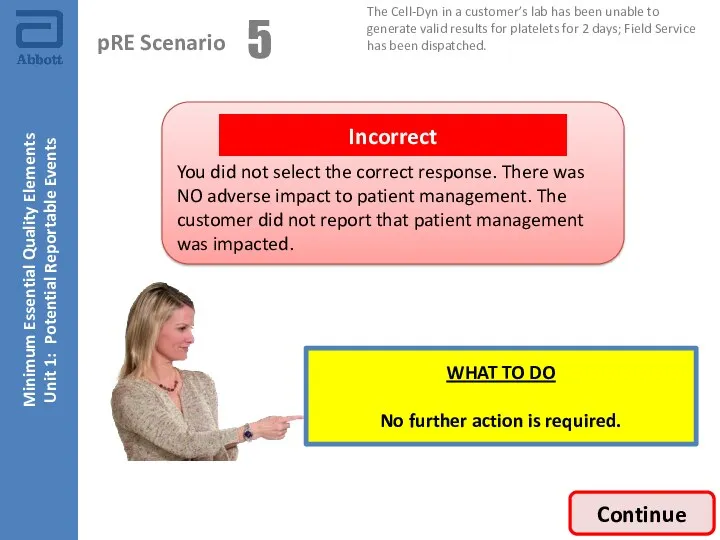

- 35. Minimum Essential Quality Elements Unit 1: Potential Reportable Events “NO” is right! There was NO adverse

- 36. Minimum Essential Quality Elements Unit 1: Potential Reportable Events You did not select the correct response.

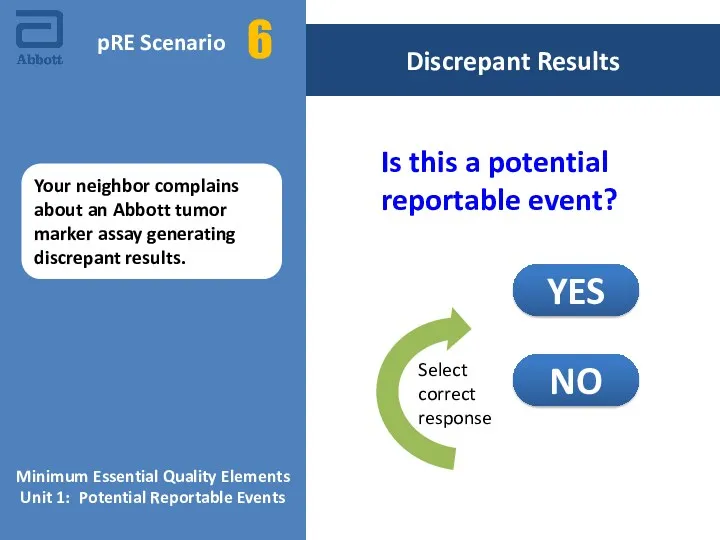

- 37. Discrepant Results Minimum Essential Quality Elements Unit 1: Potential Reportable Events pRE Scenario 6 Your neighbor

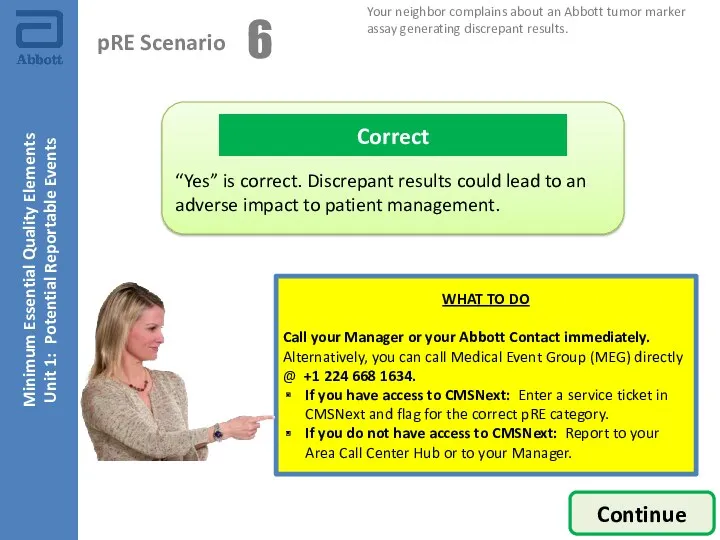

- 38. Minimum Essential Quality Elements Unit 1: Potential Reportable Events “Yes” is correct. Discrepant results could lead

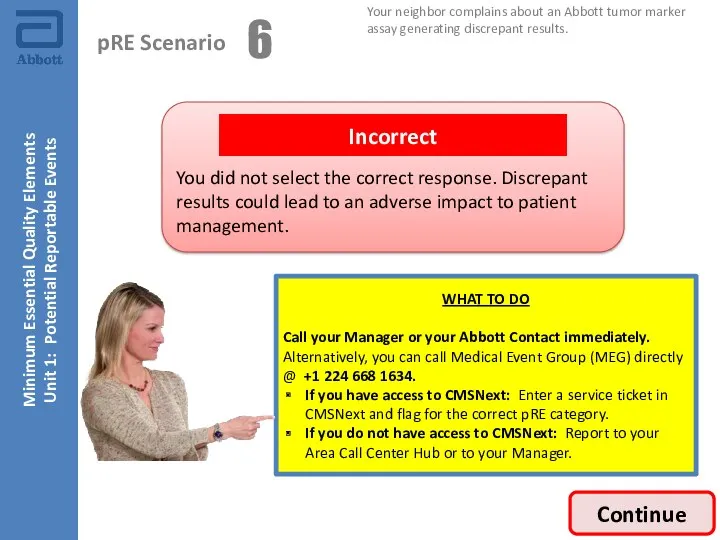

- 39. Minimum Essential Quality Elements Unit 1: Potential Reportable Events You did not select the correct response.

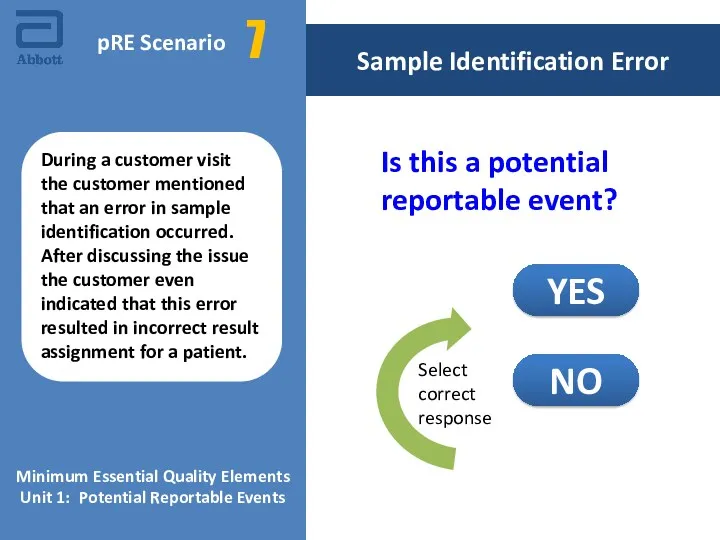

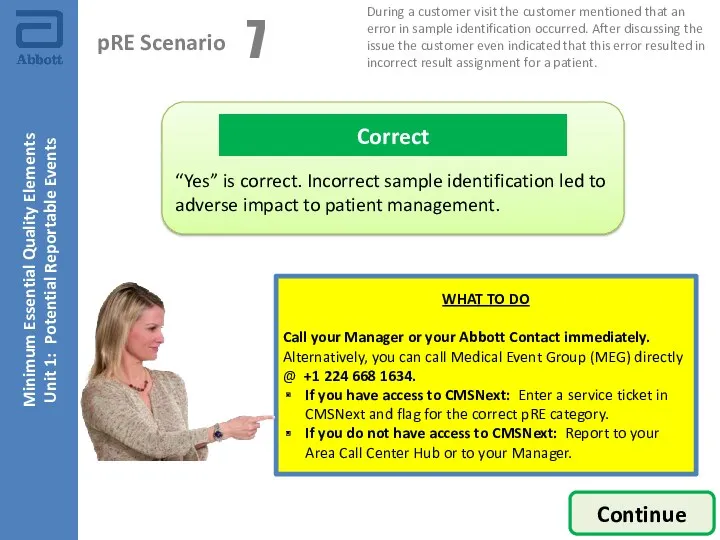

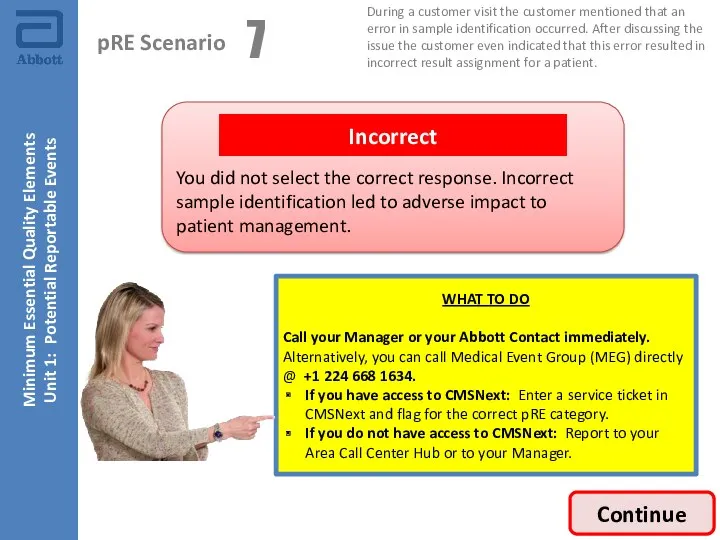

- 40. Sample Identification Error Minimum Essential Quality Elements Unit 1: Potential Reportable Events pRE Scenario 7 During

- 41. Minimum Essential Quality Elements Unit 1: Potential Reportable Events “Yes” is correct. Incorrect sample identification led

- 42. Minimum Essential Quality Elements Unit 1: Potential Reportable Events You did not select the correct response.

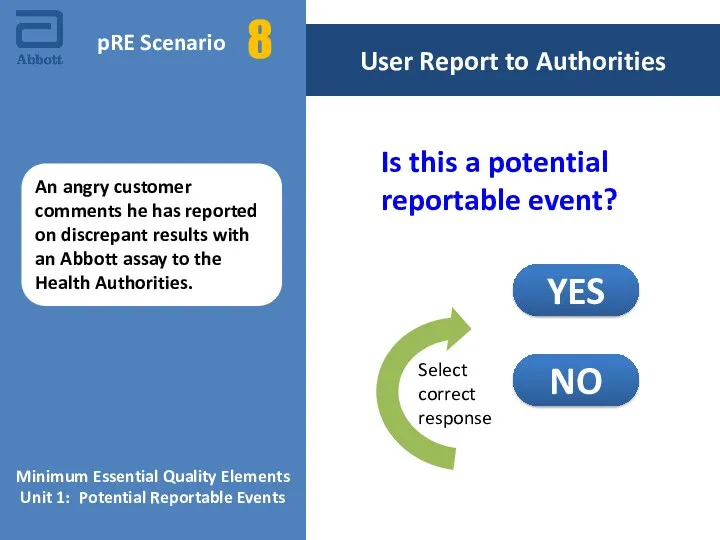

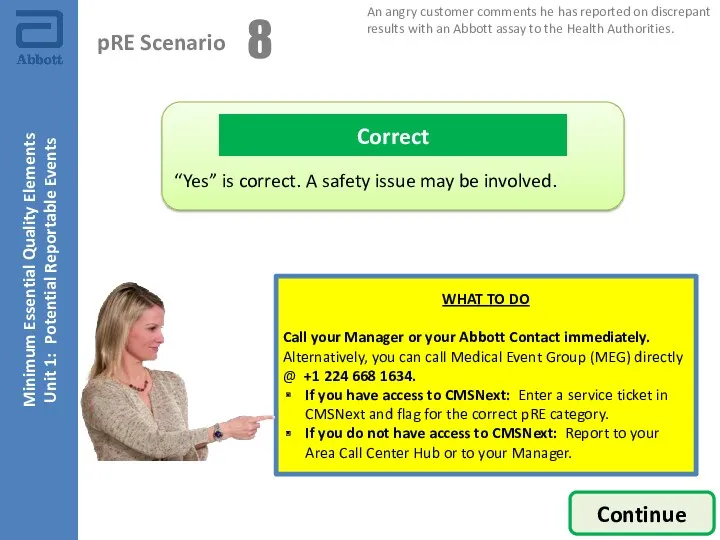

- 43. User Report to Authorities Minimum Essential Quality Elements Unit 1: Potential Reportable Events pRE Scenario 8

- 44. Minimum Essential Quality Elements Unit 1: Potential Reportable Events “Yes” is correct. A safety issue may

- 45. Minimum Essential Quality Elements Unit 1: Potential Reportable Events You did not select the correct response.

- 46. Minimum Essential Quality Elements Unit 1: Potential Reportable Events End of Unit 1 This concludes Unit

- 47. CALIBRATION OF SERVICE TOOLS In this unit… Measuring & Test Equipment Identifying Calibrated Equipment Calibration Intervals

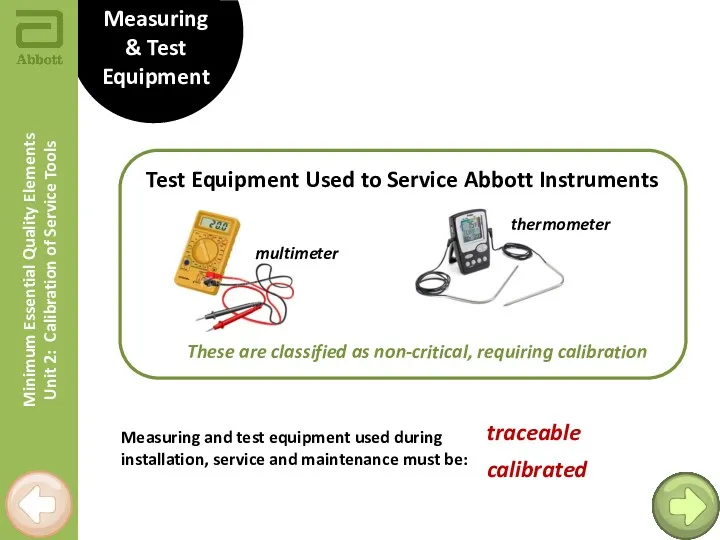

- 48. Minimum Essential Quality Elements Unit 2: Calibration of Service Tools Measuring & Test Equipment Test Equipment

- 49. Minimum Essential Quality Elements Unit 2: Calibration of Service Tools Physical Identification of Calibrated Equipment What

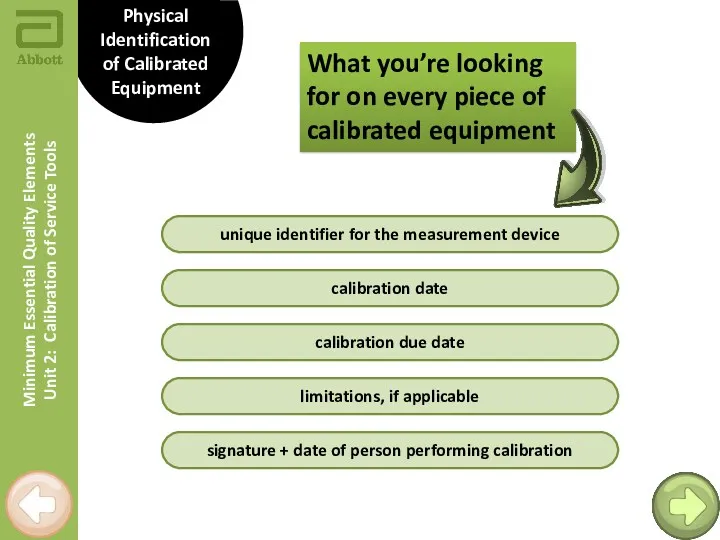

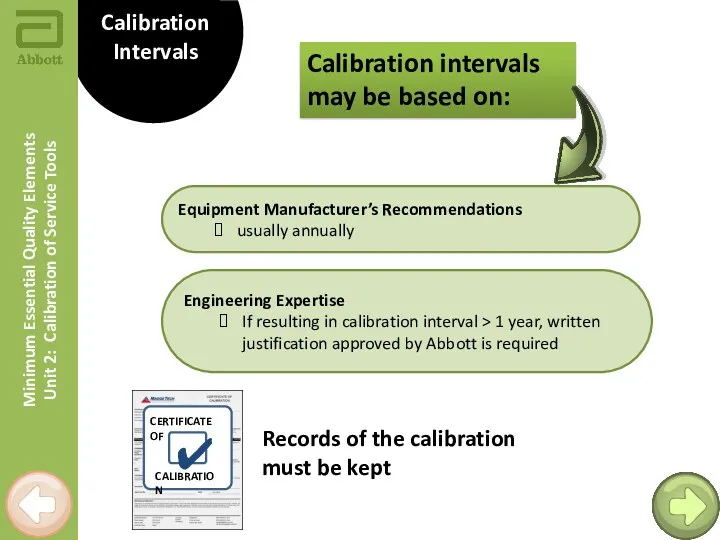

- 50. Minimum Essential Quality Elements Unit 2: Calibration of Service Tools Calibration Intervals Calibration intervals may be

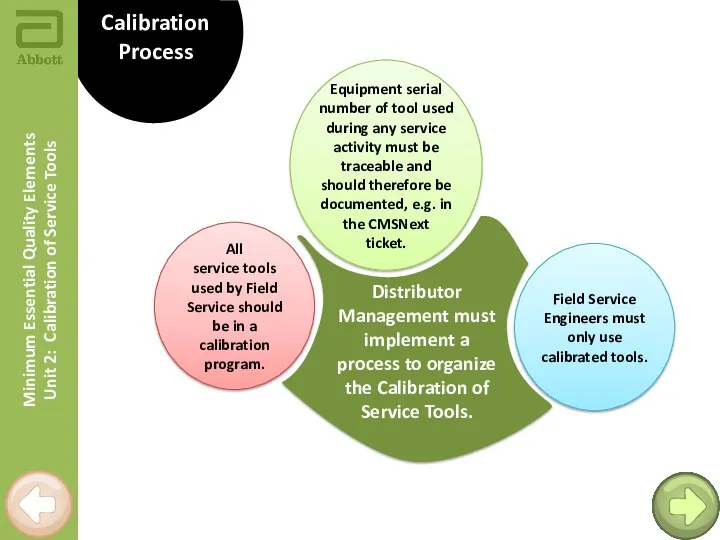

- 51. Minimum Essential Quality Elements Unit 2: Calibration of Service Tools Calibration Process Distributor Management must implement

- 52. End of Unit 2 This concludes Unit 2, “Calibration of Service Tools” Minimum Essential Quality Elements

- 53. INVENTORY MANAGEMENT In this unit… Spare Parts Depot Parts return/defective parts destruction/defacing Abbott logos Process for

- 54. Minimum Essential Quality Elements Unit 3: Inventory Management Instrument Spare Parts There are spare parts, accessories

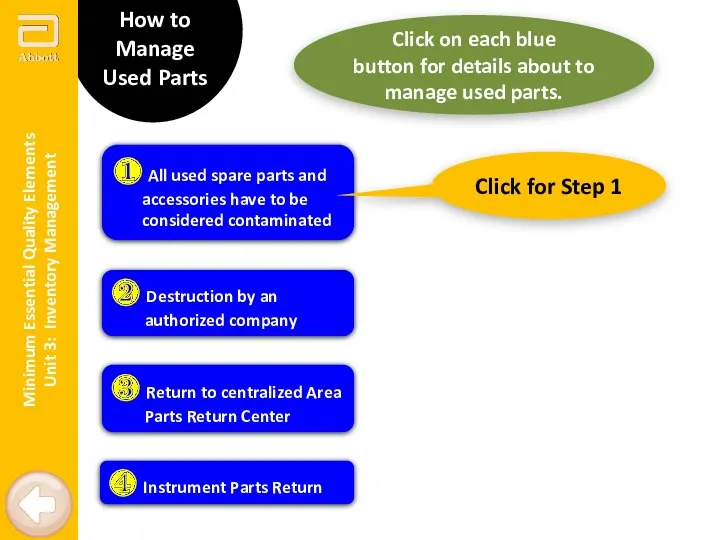

- 55. How to Manage Used Parts Click on each blue button for details about to manage used

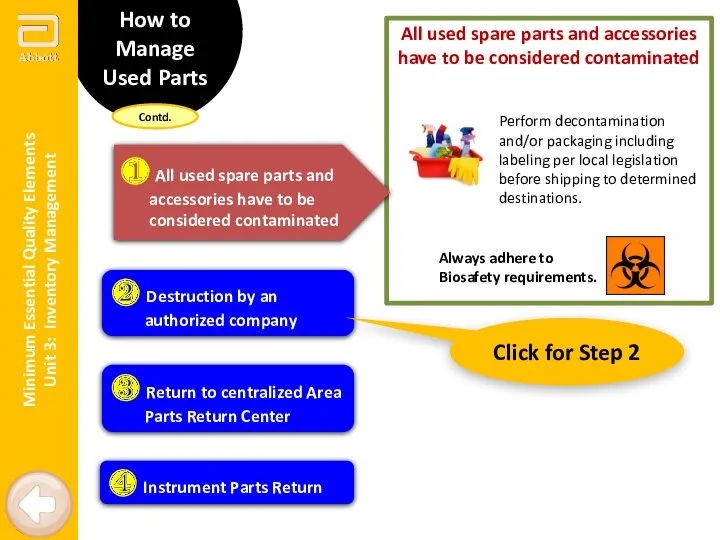

- 56. All used spare parts and accessories have to be considered contaminated How to Manage Used Parts

- 57. Destruction by an authorized company Destruction certificate is required. How to Manage Used Parts Minimum Essential

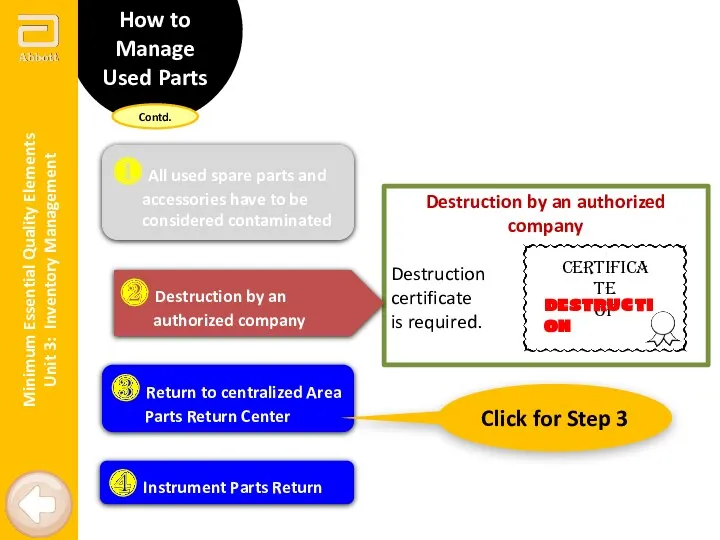

- 58. How to Manage Used Parts Minimum Essential Quality Elements Unit 3: Inventory Management Contd. ❶ All

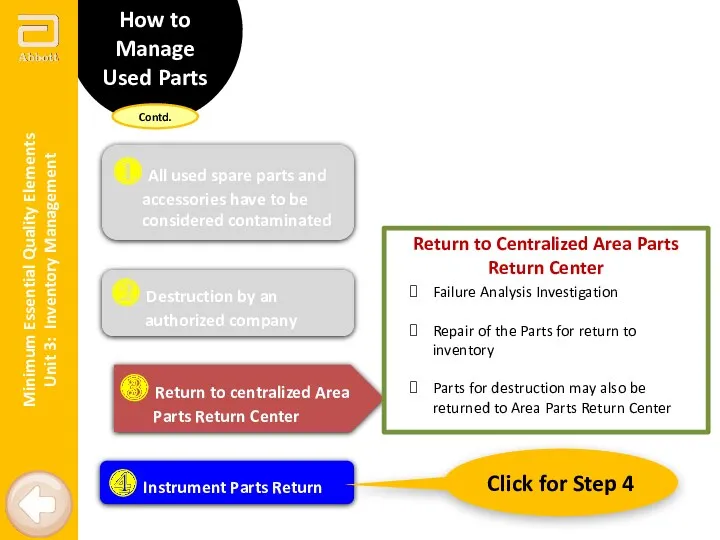

- 59. Instrument Parts Return Wipe down surface with disinfectant Drain items with contaminated fluid pathways, e.g. pumps;

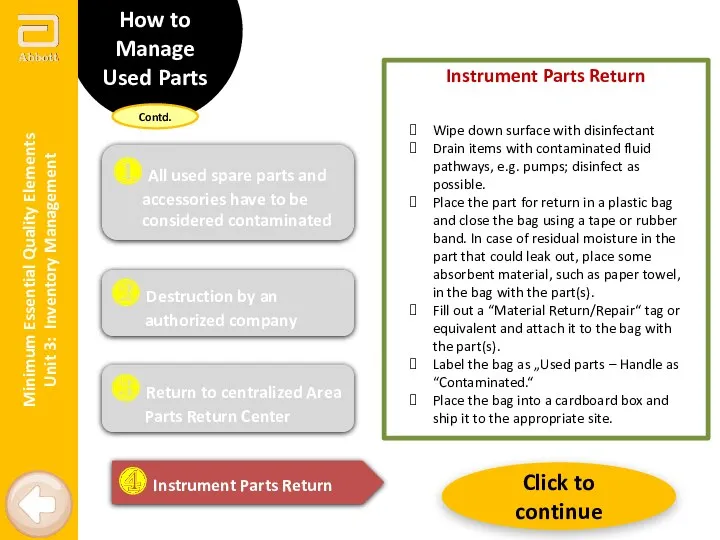

- 60. Minimum Essential Quality Elements Unit 3: Inventory Management Best Practices vs. Poor Practices The next few

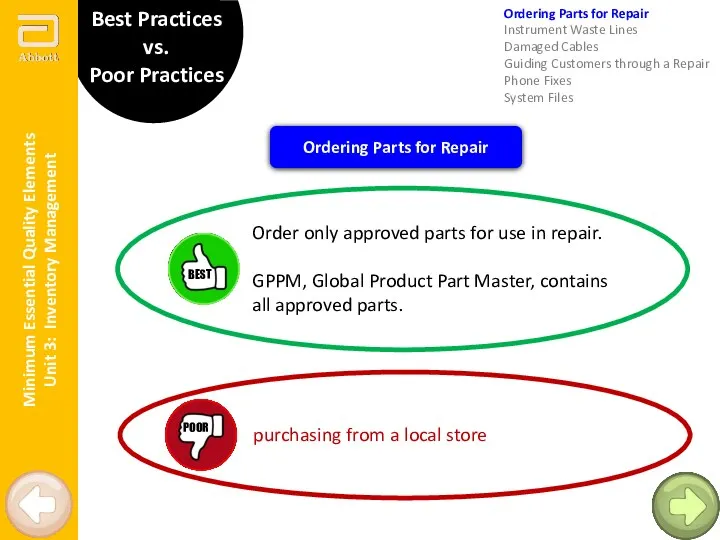

- 61. Minimum Essential Quality Elements Unit 3: Inventory Management Best Practices vs. Poor Practices Ordering Parts for

- 62. Minimum Essential Quality Elements Unit 3: Inventory Management Best Practices vs. Poor Practices Instrument Waste Lines

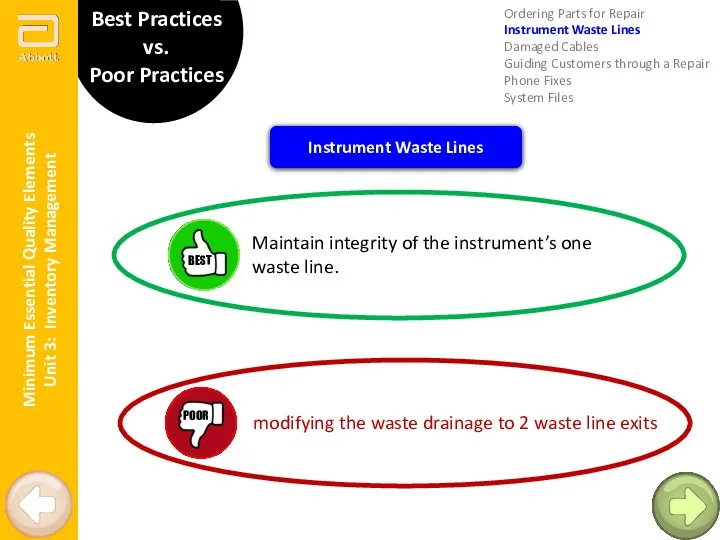

- 63. Minimum Essential Quality Elements Unit 3: Inventory Management Best Practices vs. Poor Practices Damaged Cables Order

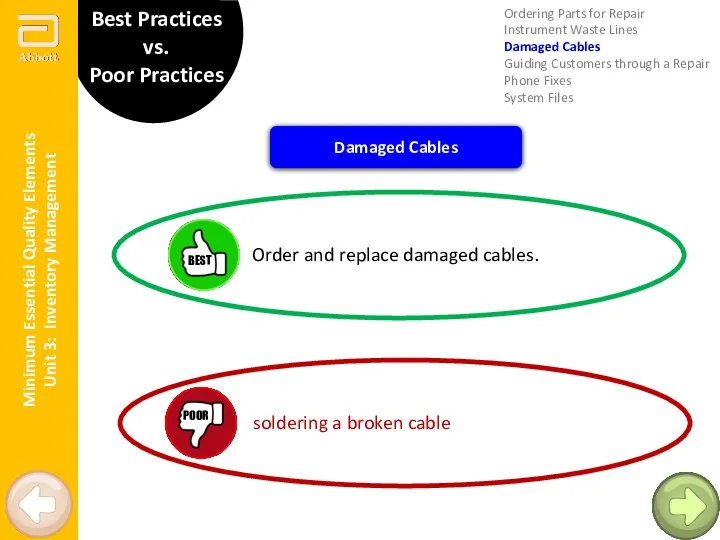

- 64. Minimum Essential Quality Elements Unit 3: Inventory Management Best Practices vs. Poor Practices Guiding Customers through

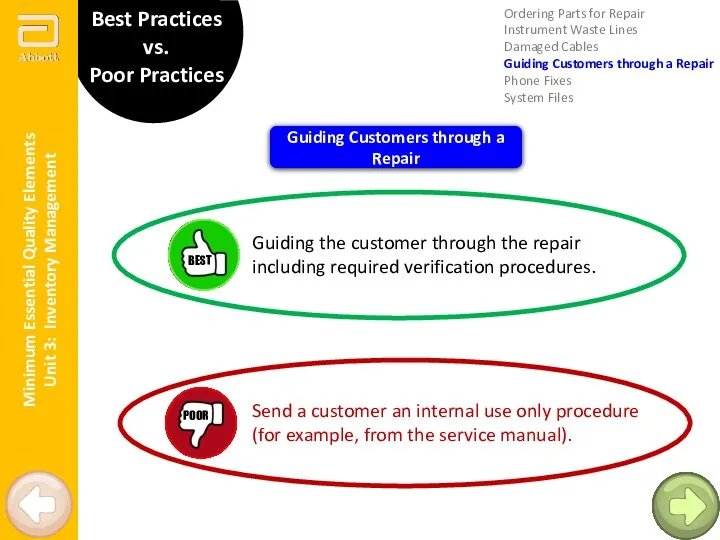

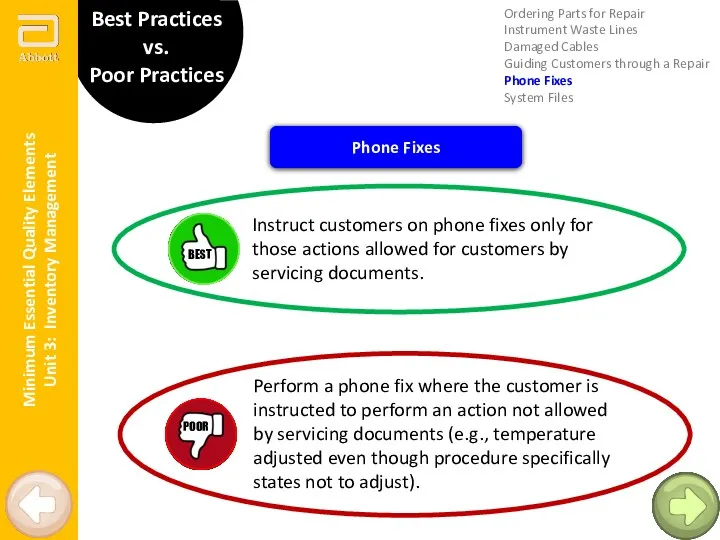

- 65. Minimum Essential Quality Elements Unit 3: Inventory Management Best Practices vs. Poor Practices Phone Fixes Instruct

- 66. Minimum Essential Quality Elements Unit 3: Inventory Management Best Practices vs. Poor Practices System Files Maintains

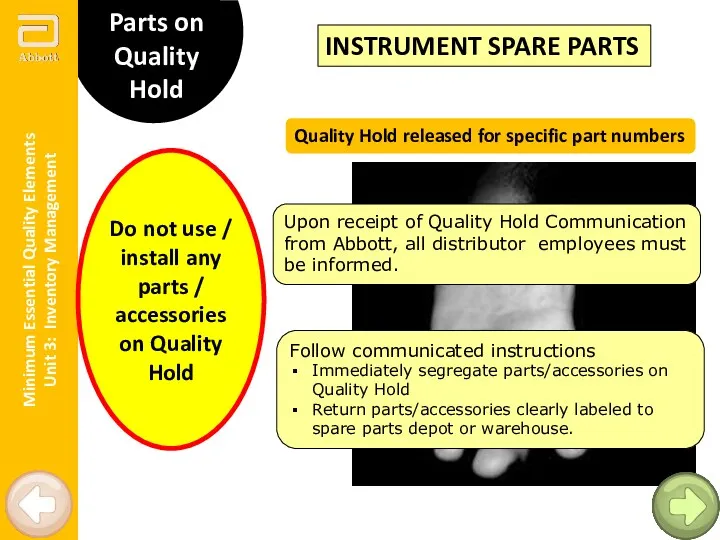

- 67. Minimum Essential Quality Elements Unit 3: Inventory Management Parts on Quality Hold INSTRUMENT SPARE PARTS Quality

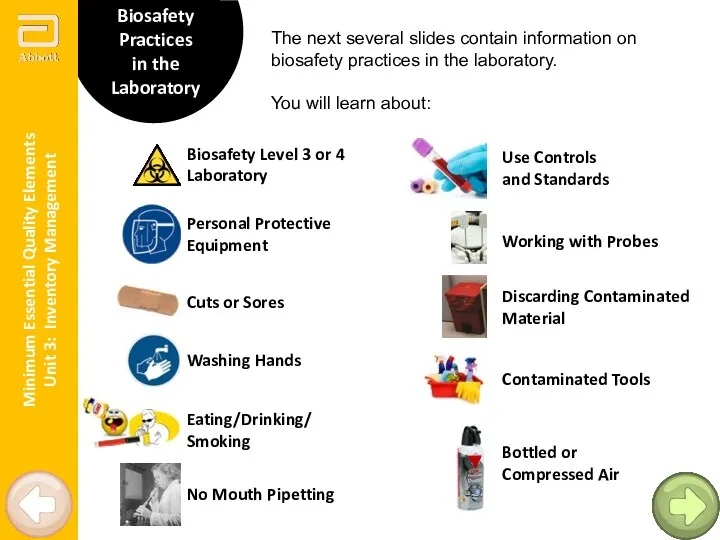

- 68. Biosafety Practices in the Laboratory The next several slides contain information on biosafety practices in the

- 69. Biosafety Practices in the Laboratory Biosafety Level 3 or 4 Laboratory Do not enter any Biosafety

- 70. Biosafety Practices in the Laboratory Personal Protective Equipment Wear appropriate personal protective equipment. Check laboratory signage

- 71. Biosafety Practices in the Laboratory Cuts or Sores Cover any cuts or sores on your hands

- 72. Biosafety Practices in the Laboratory Washing Hands Wash hands after removing your gloves, and when leaving

- 73. Biosafety Practices in the Laboratory Eating / Drinking / Smoking Do not eat, drink, smoke, apply

- 74. Biosafety Practices in the Laboratory No Mouth Pipetting Do not pipette by mouth. Do not touch

- 75. Biosafety Practices in the Laboratory Use Controls and Standards Avoid running customer samples on the instrument.

- 76. Biosafety Practices in the Laboratory Working with Probes Use extreme caution when working around probes. Rinse

- 77. Biosafety Practices in the Laboratory Discarding Contaminated Material Discard all contaminated material into the appropriate biohazard

- 78. Biosafety Practices in the Laboratory Contaminated Tools Disinfect contaminated tools prior to returning them to your

- 79. Biosafety Practices in the Laboratory Bottled or Compressed Air Never use bottled or compressed air to

- 80. Handling Biosafety Situations Click the blue button to learn how to handle this biosafety situation. Handling

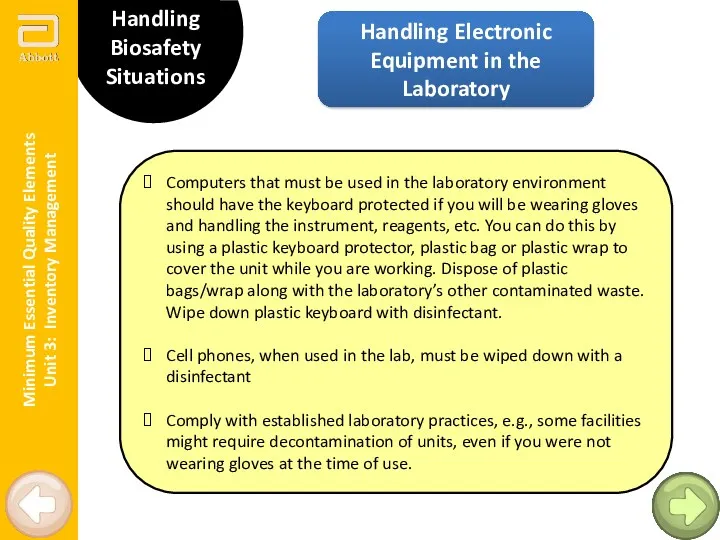

- 81. Handling Biosafety Situations Computers that must be used in the laboratory environment should have the keyboard

- 82. Handling Biosafety Situations Click the blue button to learn how to handle this biosafety situation. Handling

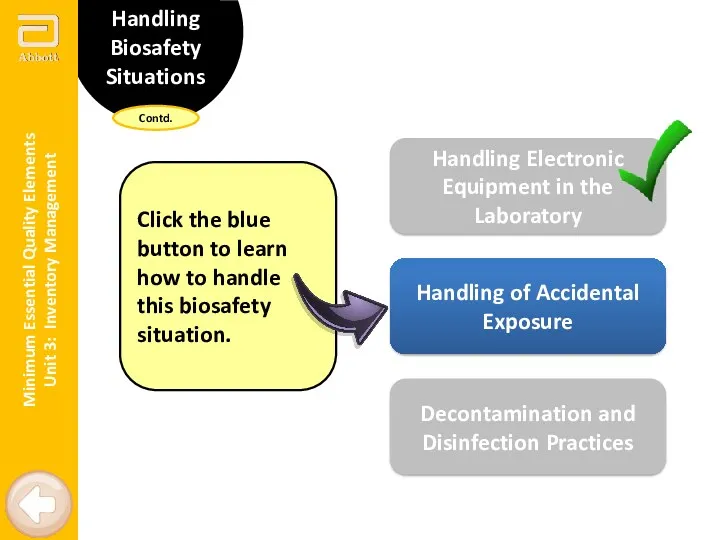

- 83. Handling Biosafety Situations Wash or rinse the affected area immediately. If exposure to any specimen/samples, make

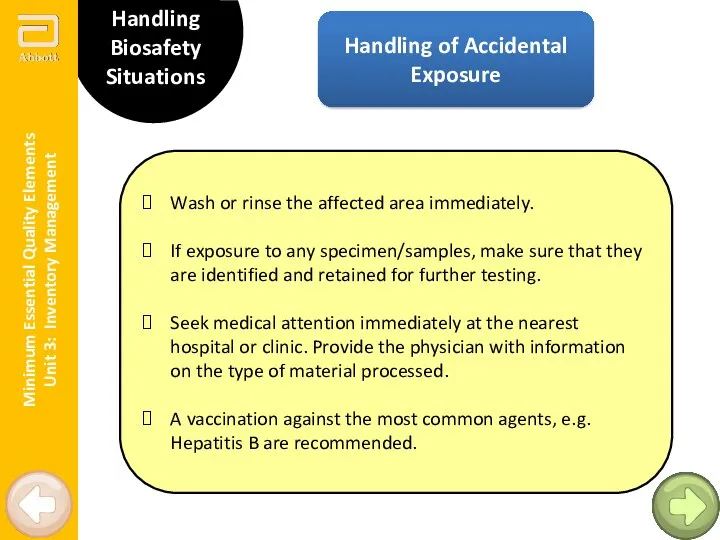

- 84. Handling Biosafety Situations Click the blue button to learn how to handle this biosafety situation. Handling

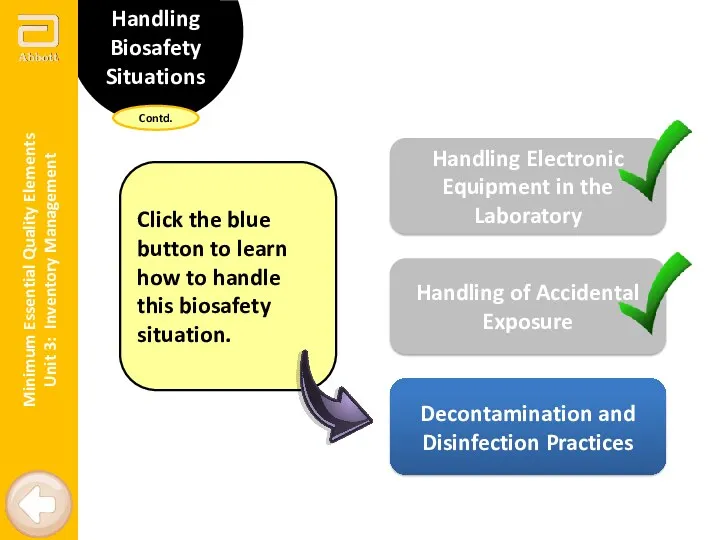

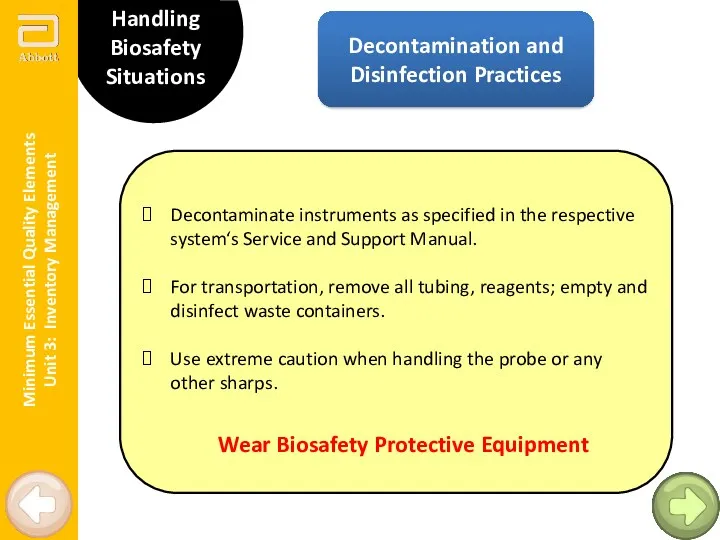

- 85. Handling Biosafety Situations Decontaminate instruments as specified in the respective system‘s Service and Support Manual. For

- 86. End of Unit 3 This concludes Unit 3, “Inventory Management” Minimum Essential Quality Elements Unit 3:

- 87. MISCELLANEOUS In this unit… Approved Service Procedures Net Promoter Score Minimum Essential Quality Elements Distributor Employees

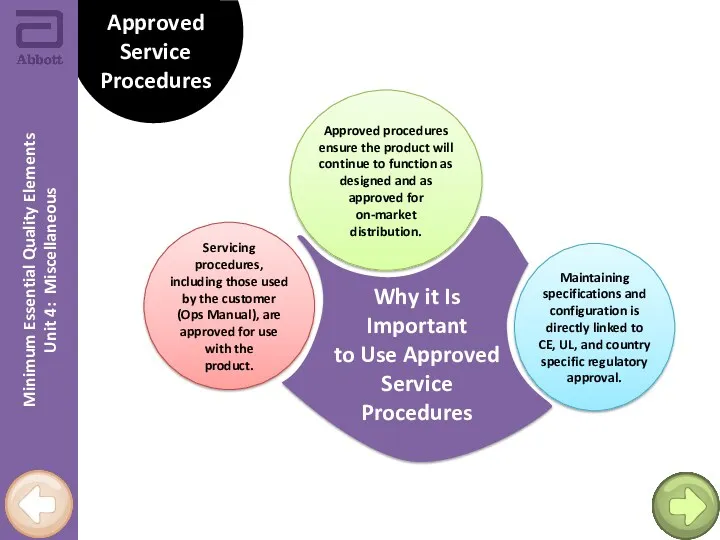

- 88. Minimum Essential Quality Elements Unit 4: Miscellaneous Approved Service Procedures Why it Is Important to Use

- 89. Minimum Essential Quality Elements Unit 4: Miscellaneous Approved Service Procedures Contd. Why It’s Important to Use

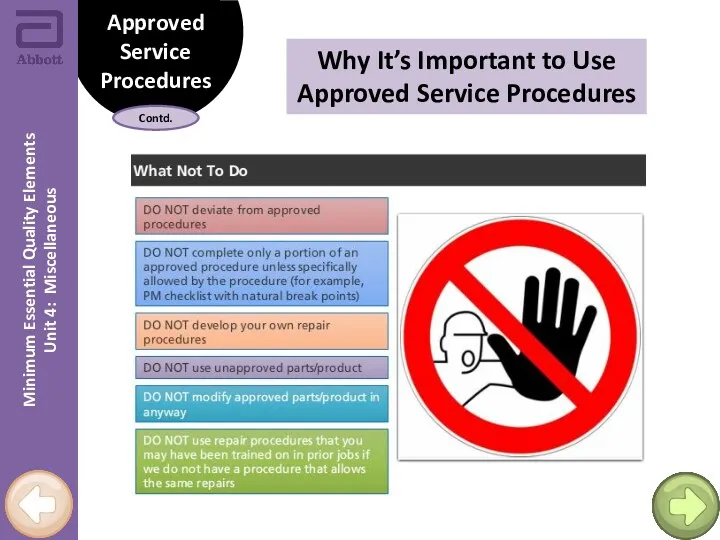

- 90. Minimum Essential Quality Elements Unit 4: Miscellaneous Approved Service Procedures Contd. KNOWLEDGE CHECK On the next

- 91. Knowledge Check Minimum Essential Quality Elements Unit 4: Miscellaneous While at a customer site, a Field

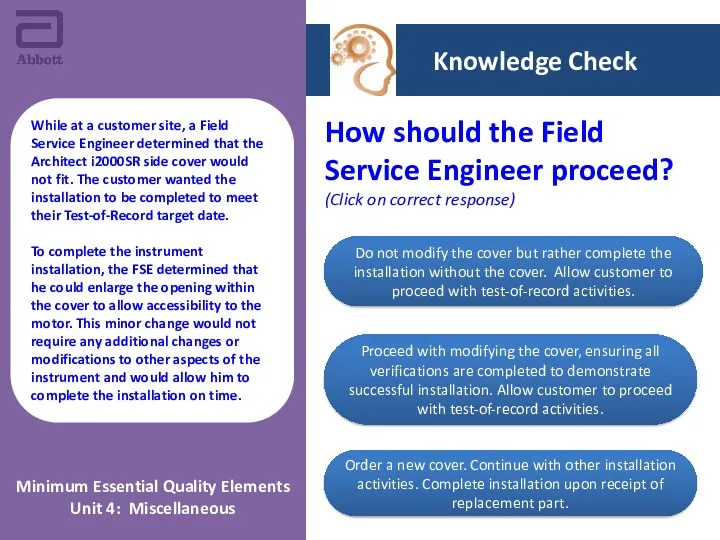

- 92. That's right! It is unacceptable to modify a part in any manner unless specifically allowed by

- 93. You did not select the correct response. It is unacceptable to modify a part in any

- 94. Minimum Essential Quality Elements Unit 4: Miscellaneous CMSNext CMSNext is Abbott's Call Management System to document

- 95. Minimum Essential Quality Elements Unit 4: Miscellaneous CMSNext Example of Logged Service Ticket Contd.

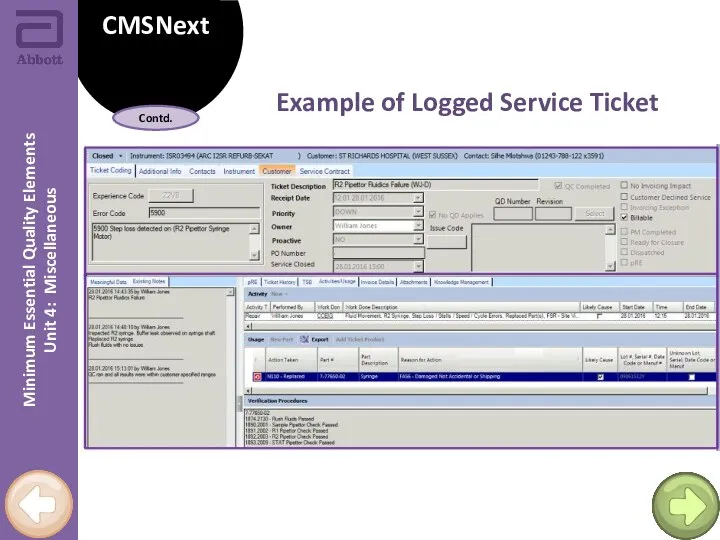

- 96. Net Promoter Score Customer Loyalty is… “Share of wallet, mind, and mouth.” - Richard D. Hanks,

- 97. The Net Promoter System® is based on a score which provides a measure of customer loyalty

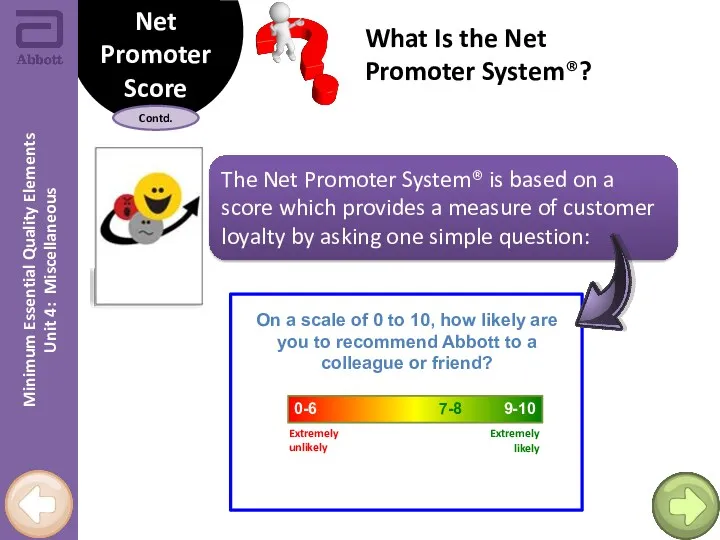

- 98. Customer Loyalty Profiles Based on their responses, customers are grouped into one of these 3 customer

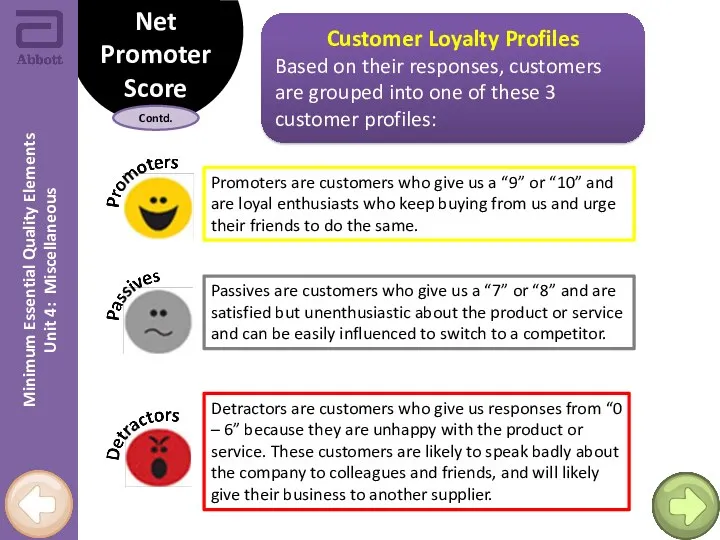

- 99. At ADD, we take customer concerns very seriously. Once a customer reports an issue through the

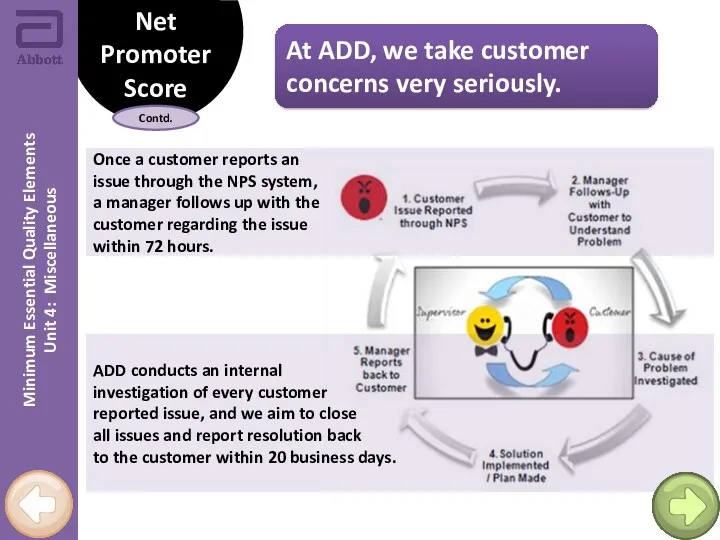

- 100. Minimum Essential Quality Elements Unit 4: Miscellaneous Net Promoter Score Contd. Net Promoter Score Summary Remember!

- 101. End of Unit 4 This concludes Unit 4, “Miscellaneous” Minimum Essential Quality Elements Unit 4: Miscellaneous

- 102. KNOWLEDGE CHECK In this unit… 4 knowledge check questions based on what you have learned in

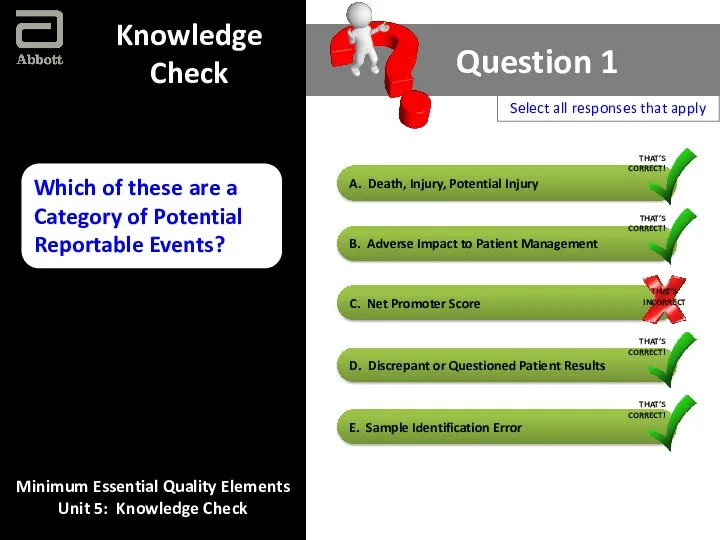

- 103. Minimum Essential Quality Elements Unit 5: Knowledge Check Knowledge Check Question 1 Which of these are

- 104. Minimum Essential Quality Elements Unit 5: Knowledge Check Knowledge Check Question 2 Parts for Failure Analysis

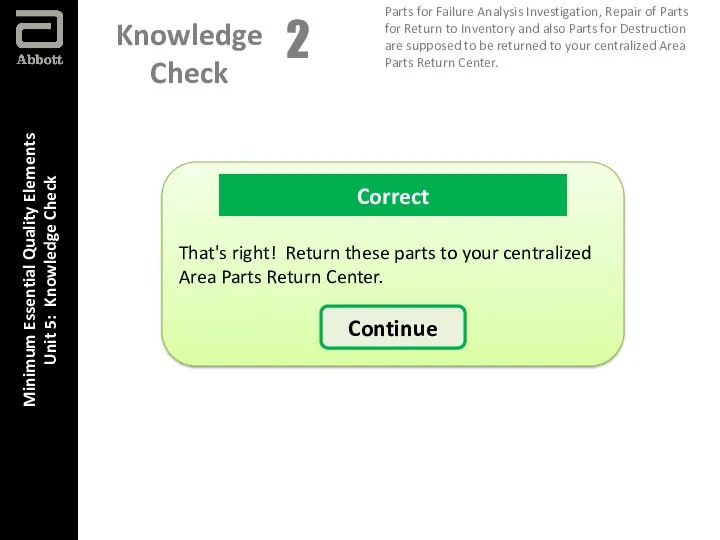

- 105. Minimum Essential Quality Elements Unit 5: Knowledge Check That's right! Return these parts to your centralized

- 106. Minimum Essential Quality Elements Unit 5: Knowledge Check You did not select the correct response. You

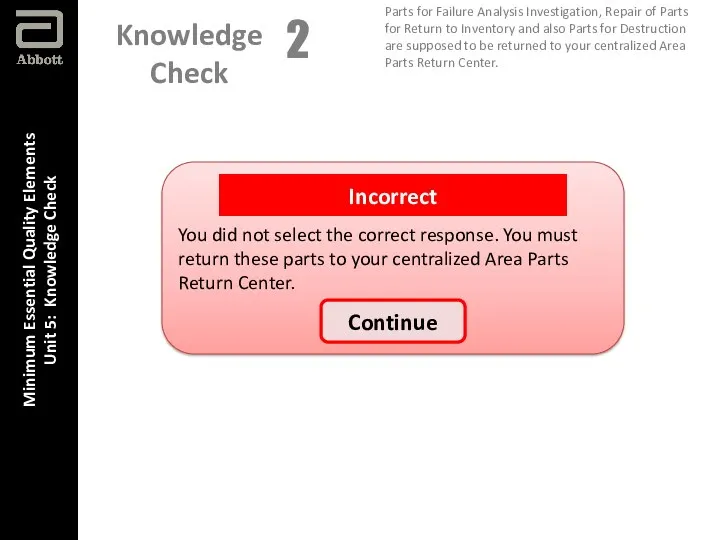

- 107. Minimum Essential Quality Elements Unit 5: Knowledge Check Knowledge Check Question 3 You are preparing your

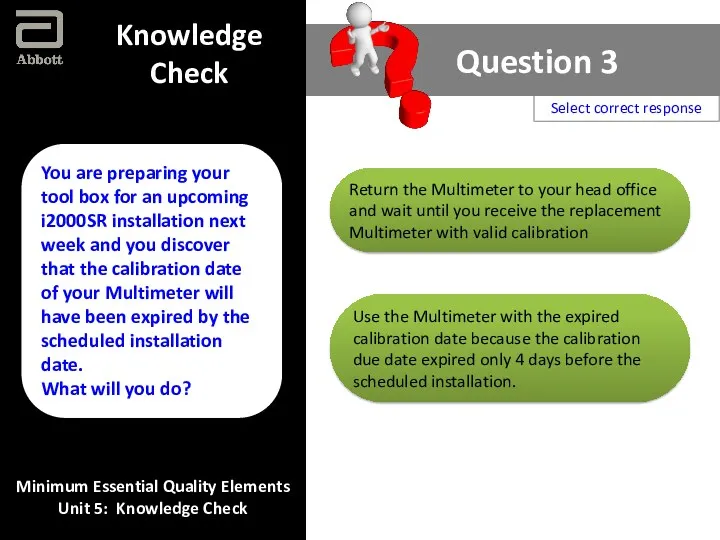

- 108. Minimum Essential Quality Elements Unit 5: Knowledge Check That's right! Only tools with valid calibration can

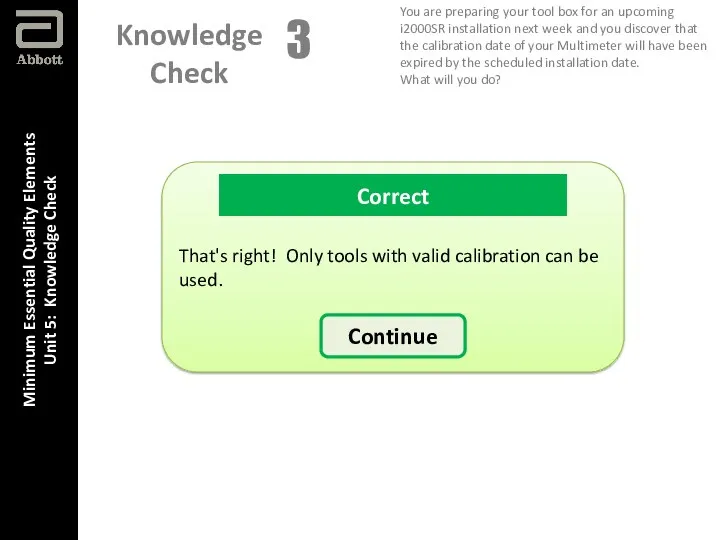

- 109. Minimum Essential Quality Elements Unit 5: Knowledge Check You did not select the correct response. Only

- 110. Minimum Essential Quality Elements Unit 5: Knowledge Check Knowledge Check Question 4 For the Net Promoter

- 111. Minimum Essential Quality Elements Unit 5: Knowledge Check That's right! A Detractor is disappointed with Abbott

- 112. Minimum Essential Quality Elements Unit 5: Knowledge Check You did not select the correct response. A

- 113. End of Unit 5 This concludes Unit 5, “Knowledge Check” Minimum Essential Quality Elements Unit 5:

- 115. Скачать презентацию

Прайс-лист музыкальной кавер-группы Хештег

Прайс-лист музыкальной кавер-группы Хештег Анализ конкурентов и маркетинговые войны

Анализ конкурентов и маркетинговые войны Комплекс систем для аэрофотографирования от LH Systems

Комплекс систем для аэрофотографирования от LH Systems Политический маркетинг

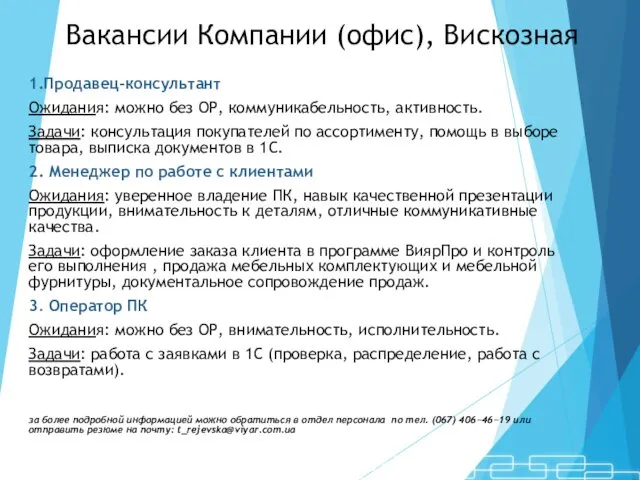

Политический маркетинг Вакансии компании

Вакансии компании Торговое оборудование - мебель

Торговое оборудование - мебель Товар в комплексе маркетинга

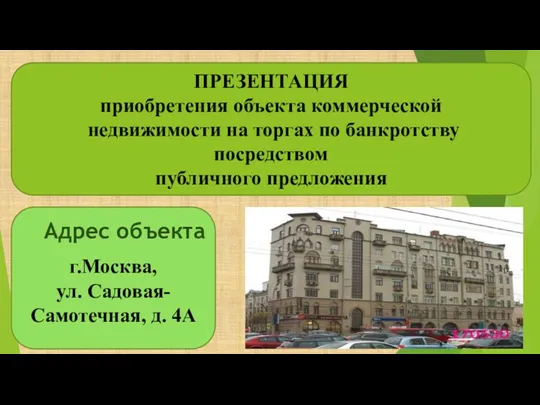

Товар в комплексе маркетинга Приобретение объекта коммерческой недвижимости на торгах по банкротству посредством публичного предложения

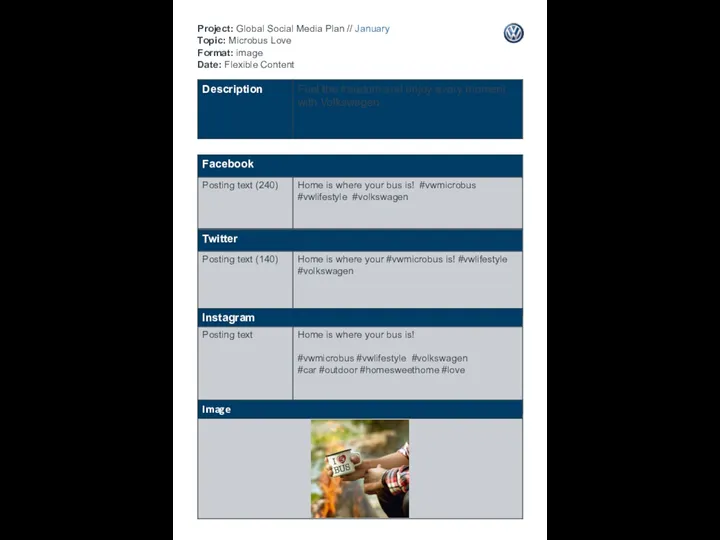

Приобретение объекта коммерческой недвижимости на торгах по банкротству посредством публичного предложения Microbus love

Microbus love Экомерчандайзер. Экологические товары

Экомерчандайзер. Экологические товары Сегментация рынка. Понятия и критерии

Сегментация рынка. Понятия и критерии Выявление требований и оценка удовлетворённости работодателей. Продвижение образовательных услуг

Выявление требований и оценка удовлетворённости работодателей. Продвижение образовательных услуг Как правильно работать с заказчиком

Как правильно работать с заказчиком Правила ресторанного этикета. Информационная часть, примеры и идеи

Правила ресторанного этикета. Информационная часть, примеры и идеи Торгово-технологический процесс продажи ювелирных изделий

Торгово-технологический процесс продажи ювелирных изделий Управление репутацией в интернете (ORM)

Управление репутацией в интернете (ORM) Магазин. Продукты

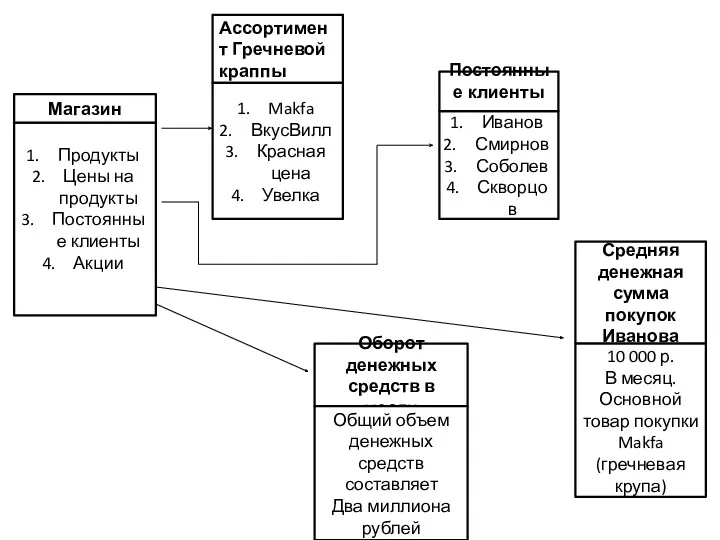

Магазин. Продукты Подарок-сюрприз в коробке - Magic Box

Подарок-сюрприз в коробке - Magic Box Маркетинговые стратегии

Маркетинговые стратегии LoveStory: Организация и оформление свадьбы

LoveStory: Организация и оформление свадьбы SPICK & SPAN автомойка

SPICK & SPAN автомойка Как привлекать 700+ клиентов в день с минимальными усилиями и небольшим бюджетом

Как привлекать 700+ клиентов в день с минимальными усилиями и небольшим бюджетом Маркетинг и продвижение программ на рынке образовательных услуг. Опыт и рекомендации

Маркетинг и продвижение программ на рынке образовательных услуг. Опыт и рекомендации МТС Коммуникатор

МТС Коммуникатор Что такое пиар-кампания, когда и зачем ее нужно внедрять

Что такое пиар-кампания, когда и зачем ее нужно внедрять Управление маркетингом: бюджет маркетинга, организация службы маркетинга

Управление маркетингом: бюджет маркетинга, организация службы маркетинга Пижама для женщин

Пижама для женщин ИП и организации. Базовые данные. Коммуникации и логистика. Ценообразование. ООО Маркисол

ИП и организации. Базовые данные. Коммуникации и логистика. Ценообразование. ООО Маркисол