Cost-Effective and Efficient Induction Motors with Combined Windings and Propulsion Engines презентация

Содержание

- 2. Innovative Character of the Underlying Technology The world's first induction wheel-hub motor Electric motors without permanent

- 3. Advantages at a glance 30 % lower production costs No use of rare earths Robust and

- 4. Application areas 1. Energy Production Wind energy Water energy 2. Drive technology E-Cars E-Bikes E-Boats E-Aircraft

- 5. Our experience Many years of experience in development Developments for public and private companies More than

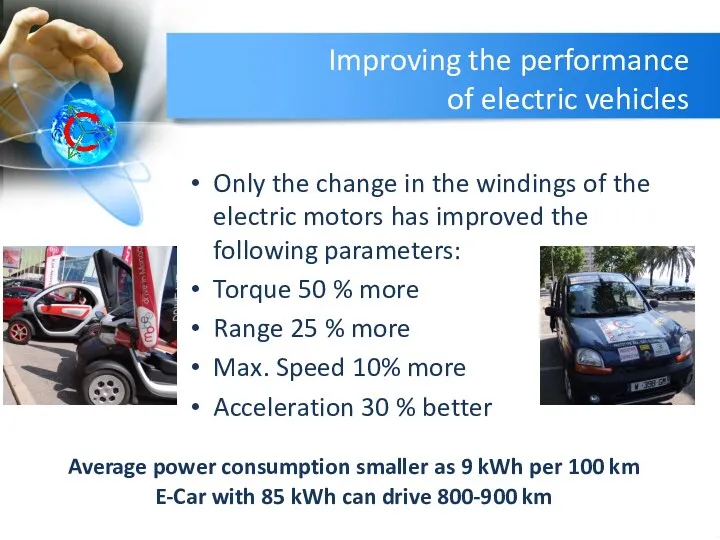

- 6. Improving the performance of electric vehicles Only the change in the windings of the electric motors

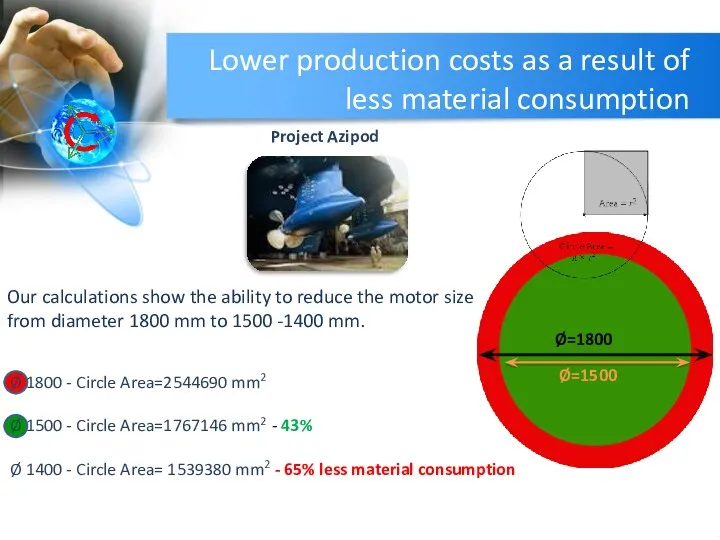

- 7. Lower production costs as a result of less material consumption Our calculations show the ability to

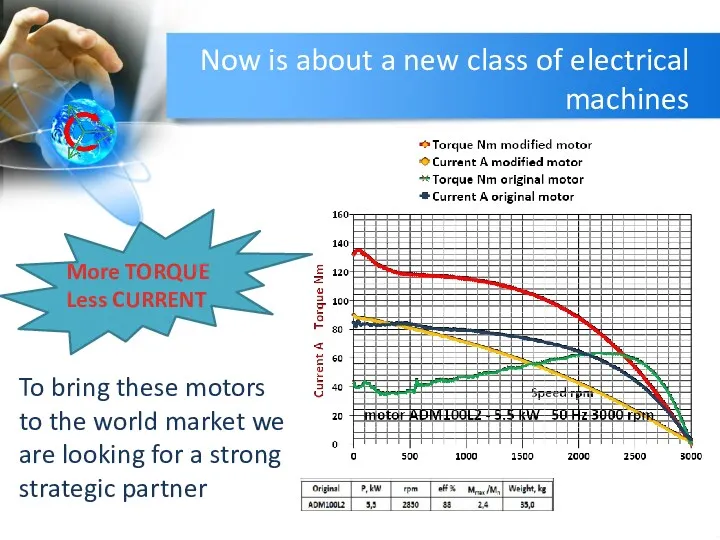

- 8. Now is about a new class of electrical machines To bring these motors to the world

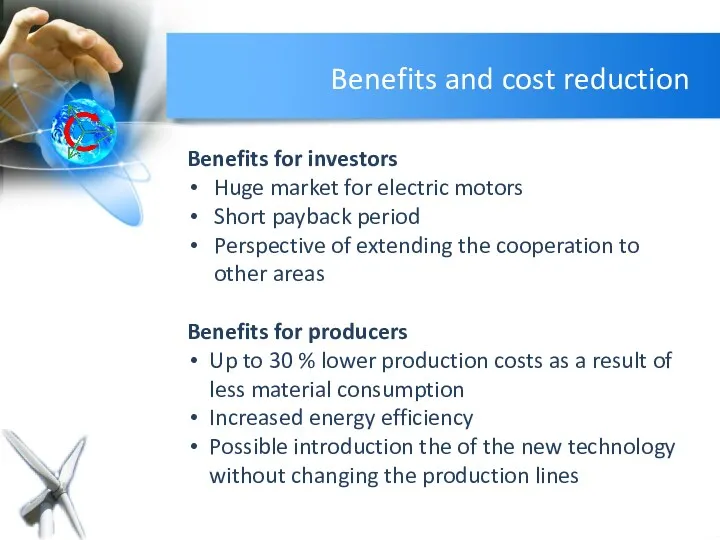

- 9. Benefits and cost reduction Benefits for investors Huge market for electric motors Short payback period Perspective

- 10. Our fields of activity and further opportunities for cooperation Hydrogen and Plasma Technology Diamond Coatings Electric

- 11. New Energy Strategy Development of high-efficiency electric motors of the new generation for industry Development of

- 13. Скачать презентацию

Испания, остров Майорка

Испания, остров Майорка ПРЕЗЕНТАЦИЯ дистрибьюторской компании ИП ПЕТИН К. П

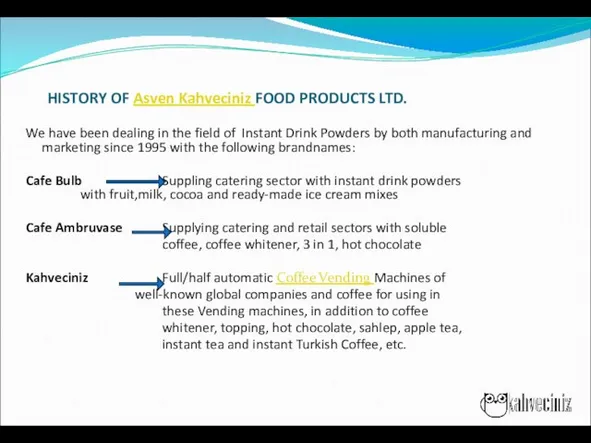

ПРЕЗЕНТАЦИЯ дистрибьюторской компании ИП ПЕТИН К. П History of Asven Kahveciniz Food products LTD

History of Asven Kahveciniz Food products LTD Online shopping behavior of customers

Online shopping behavior of customers Спілкування менеджера з клієнтом

Спілкування менеджера з клієнтом SMM стратегия (название бренда/продукта)

SMM стратегия (название бренда/продукта) Анализ рынка

Анализ рынка Коммуникационная политика. Реклама в системе маркетинговых коммуникаций

Коммуникационная политика. Реклама в системе маркетинговых коммуникаций Типология гостей

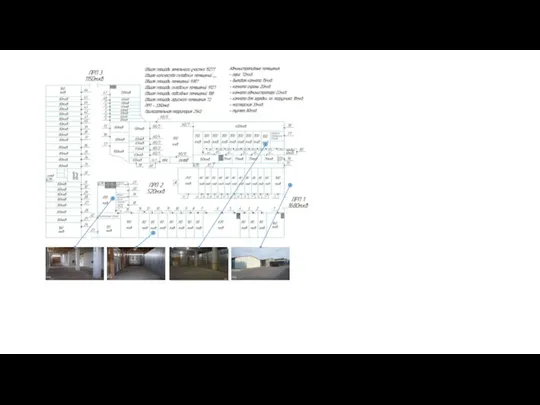

Типология гостей Сдача помещений в аренду

Сдача помещений в аренду Системный курс-практикум Маркетинг PRO. Модуль 15. Реклама и медиапланирование

Системный курс-практикум Маркетинг PRO. Модуль 15. Реклама и медиапланирование Key elements of brand Amazon Kindle

Key elements of brand Amazon Kindle Орифлейм компаниясының мүмкіндіктері

Орифлейм компаниясының мүмкіндіктері Управление инновационным проектом

Управление инновационным проектом Методы управления инновациями

Методы управления инновациями Дорожные сервисы

Дорожные сервисы ТОВ Ромни-Кондитер

ТОВ Ромни-Кондитер 97% природная алоэ-забота о коже и волосах. Компания ВИТЭКС

97% природная алоэ-забота о коже и волосах. Компания ВИТЭКС Моя микрозелень. Вертикальные фермы

Моя микрозелень. Вертикальные фермы Эффективная презентация компании и ее предложений. Занятие 3

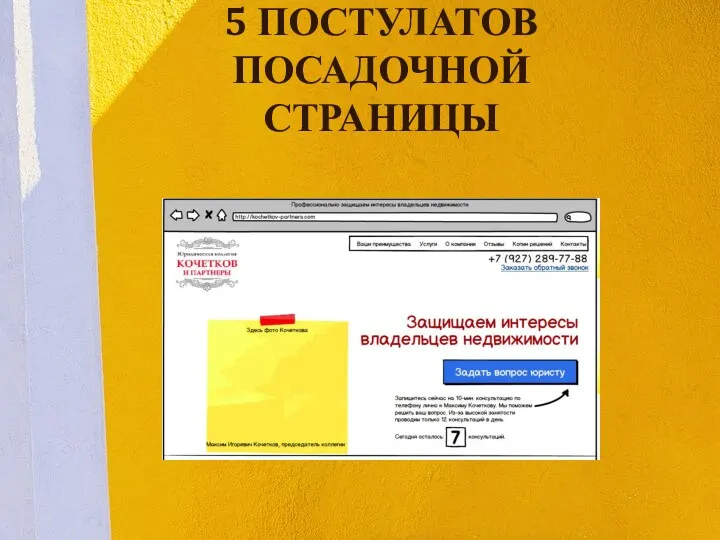

Эффективная презентация компании и ее предложений. Занятие 3 5 постулатов посадочной страницы

5 постулатов посадочной страницы Создание и продвижение бренда (на примере кондитерской фабрики Россия филиал, в г. Самара ООО Нестле Россия)

Создание и продвижение бренда (на примере кондитерской фабрики Россия филиал, в г. Самара ООО Нестле Россия) Маркетинговая деятельность как условие конкурентоспособности оптовой организации на рынке лекарственных препаратов

Маркетинговая деятельность как условие конкурентоспособности оптовой организации на рынке лекарственных препаратов Dspm. Фундаментальные основы продаж

Dspm. Фундаментальные основы продаж Создание туристского продукта. Маркетинг сельских территорий

Создание туристского продукта. Маркетинг сельских территорий Маркетинг в образовательной организации: актуальные проблемы реализации в современных условиях модернизации образования

Маркетинг в образовательной организации: актуальные проблемы реализации в современных условиях модернизации образования Холудексан

Холудексан AZIMUT Hotel Sochi – Ваш незабываемый отдых в Сочи

AZIMUT Hotel Sochi – Ваш незабываемый отдых в Сочи