Page

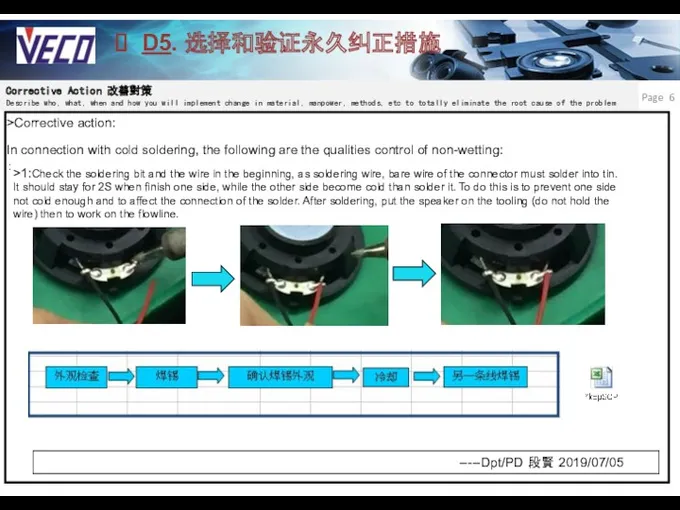

D5. 选择和验证永久纠正措施

Corrective Action 改善對策

Describe who, what, when and how

you will implement change in material, manpower, methods, etc to totally eliminate the root cause of the problem

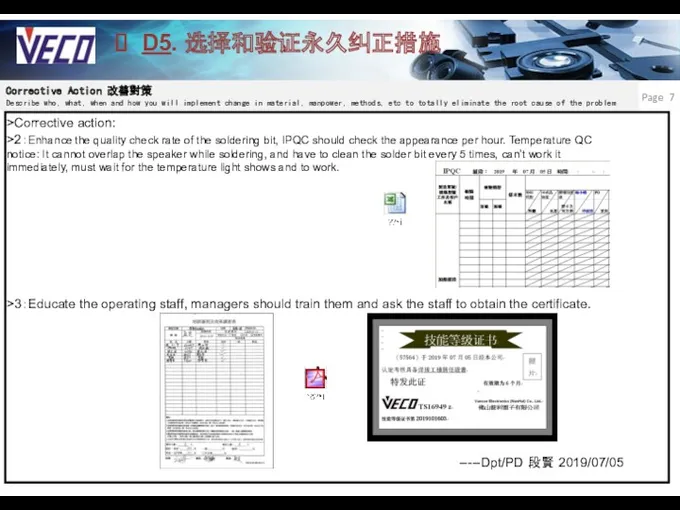

>Corrective action:

-----Dpt/PD 段賢 2019/07/05

>2:Enhance the quality check rate of the soldering bit, IPQC should check the appearance per hour. Temperature QC notice: It cannot overlap the speaker while soldering, and have to clean the solder bit every 5 times, can’t work it immediately, must wait for the temperature light shows and to work.

>3:Educate the operating staff, managers should train them and ask the staff to obtain the certificate.

N 104 Dune (Christian Dior)

N 104 Dune (Christian Dior) Сучасна реклама та фірмовий стиль: напрямки, стилі, тренди. Реклама. Психологія сприйняття реклами. Інфографіка

Сучасна реклама та фірмовий стиль: напрямки, стилі, тренди. Реклама. Психологія сприйняття реклами. Інфографіка Как улучшить гостеприимство в нашем кинотеатре

Как улучшить гостеприимство в нашем кинотеатре УК GR & Транспорт

УК GR & Транспорт Экзодерил® (противогрибковое средство)

Экзодерил® (противогрибковое средство) Эфирные масла dōTERRA

Эфирные масла dōTERRA Система учёта клиентов и сделок для отдела продаж amoCRM

Система учёта клиентов и сделок для отдела продаж amoCRM Сбытовая политика в комплексе маркетинга

Сбытовая политика в комплексе маркетинга Социальный медиарелиз

Социальный медиарелиз Project: Global Social Media Plan August Topic: Fresh Breeze Subline: Enjoy a fresh breeze in a Beetle Cabriolet Format: video

Project: Global Social Media Plan August Topic: Fresh Breeze Subline: Enjoy a fresh breeze in a Beetle Cabriolet Format: video Продвижение аккаунта в Instagram

Продвижение аккаунта в Instagram Lamoda. Фото чек-лист

Lamoda. Фото чек-лист Askona Trend - коллекция классических, проверенных временем матрасов

Askona Trend - коллекция классических, проверенных временем матрасов Медиаплан по выводу на рынок пастилы

Медиаплан по выводу на рынок пастилы Праздничная зимняя коллекция лимонадов Черноголовка

Праздничная зимняя коллекция лимонадов Черноголовка Розробка і просування фріланс-біржі Freelance24

Розробка і просування фріланс-біржі Freelance24 Продажи физических продуктов через социальные сети

Продажи физических продуктов через социальные сети Oriflame cosmetics. Каталог №1

Oriflame cosmetics. Каталог №1 Реклама в фильме Шоу Трумана (1998)

Реклама в фильме Шоу Трумана (1998) Samsung group

Samsung group Товарная политика аптеки в фармацевтическом маркетинге

Товарная политика аптеки в фармацевтическом маркетинге Инструкция по просмотру зарегистрированных данных по продажам в MCS 2.0

Инструкция по просмотру зарегистрированных данных по продажам в MCS 2.0 Выгодное M2M решение для вашего бизнеса

Выгодное M2M решение для вашего бизнеса Программа Мой первый год с AMWAY

Программа Мой первый год с AMWAY Інтерпайп сталь

Інтерпайп сталь Маркетинговая оценка земельного участка

Маркетинговая оценка земельного участка Общий - каталог ДорАгроМаш 2023

Общий - каталог ДорАгроМаш 2023 Предложение по аренде в торговом центре

Предложение по аренде в торговом центре