Содержание

- 2. Introduction Basic question: How much to order & when needed to arrive Functions of Inventory: To

- 3. Objectives of Inventory Control Inadequate control of inventories can result in both under and overstocking of

- 4. Measurement of Inventory Performance – how often do we use up our raw materials inventory on

- 5. Requirements for Effective Inventory Management A system to safely store and use inventory- secure warehouse A

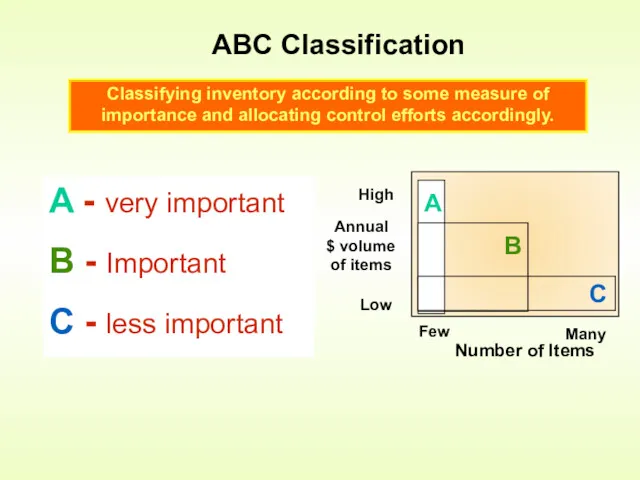

- 6. ABC Classification A - very important B - Important C - less important Classifying inventory according

- 7. WH Inventory Cycle Counting Control & knowledge of our inventory Determining the importance of each inventory

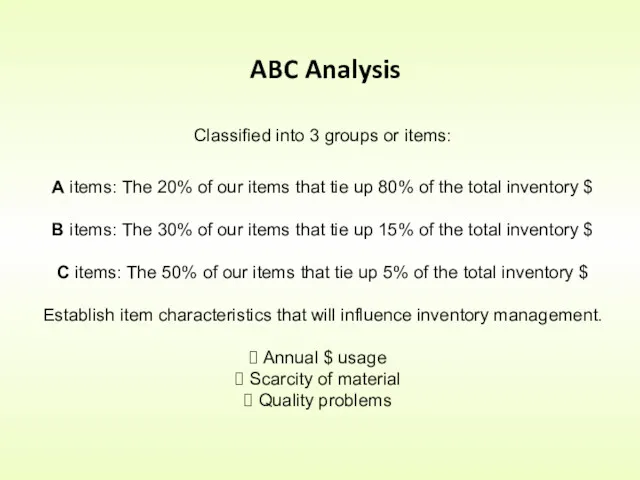

- 8. ABC Analysis Classified into 3 groups or items: A items: The 20% of our items that

- 9. ABC Analysis How to classify the items in our inventory: Determine the annual usage for each

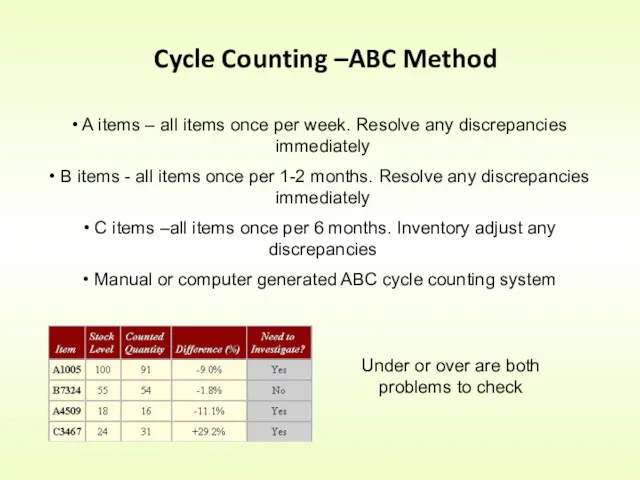

- 10. Cycle Counting –ABC Method A items – all items once per week. Resolve any discrepancies immediately

- 11. Periodic System Physical count of all items usually once a year Usually done to satisfy external

- 12. Fixed Order Quantity/Reorder Point Model An order of a fixed size is placed when the amount

- 13. Lead Time time interval between ordering and receiving the order – supplier’s manufacturing time plus shipping

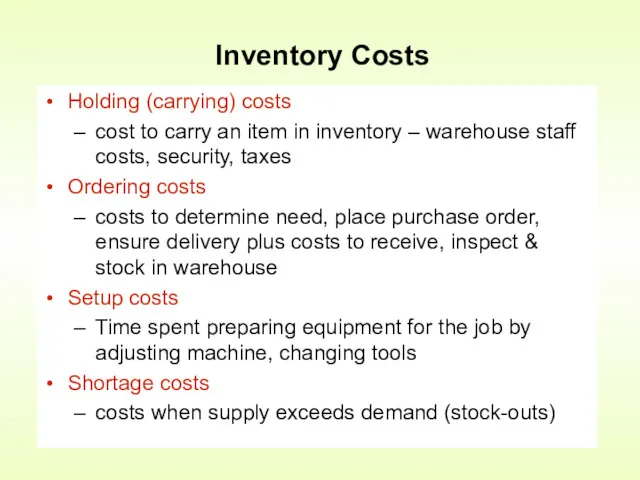

- 14. Holding (carrying) costs cost to carry an item in inventory – warehouse staff costs, security, taxes

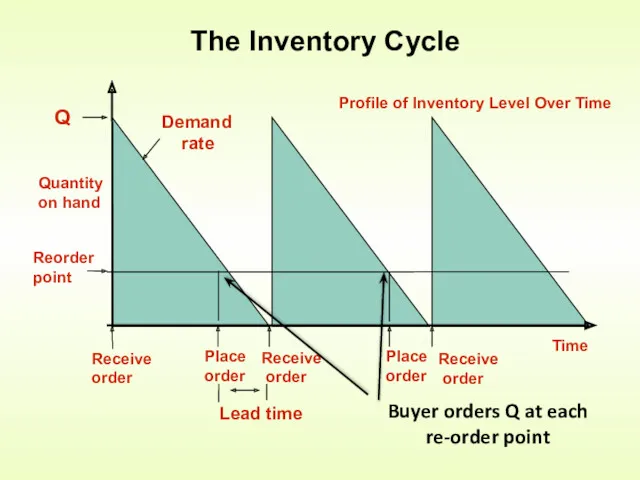

- 15. The Inventory Cycle Buyer orders Q at each re-order point

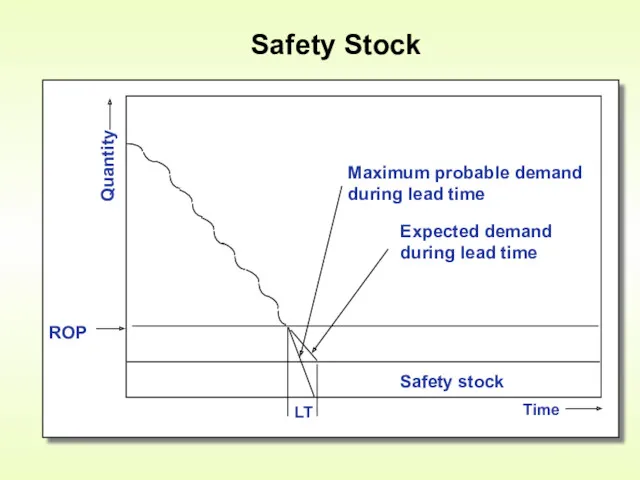

- 16. Safety Stock

- 17. Orders are placed at fixed time intervals (example – once per week like home milk delivery)

- 18. Single period model model for ordering of perishables and other items with limited useful lives Shortage

- 19. Quantity cannot be changed Supplier’s pre-determined batch size or case size (example – carton of dozen

- 20. Too much inventory Tends to hide problems – quality, efficiency Easier to live with problems than

- 22. Скачать презентацию

Обучение на позицию старшего специалиста по сервису

Обучение на позицию старшего специалиста по сервису Кейс менеджмент и программы профилактики ВИЧ для уязвимых групп населения

Кейс менеджмент и программы профилактики ВИЧ для уязвимых групп населения Стратегическое управление в городском хозяйстве

Стратегическое управление в городском хозяйстве Преимущества и недостатки применения технологии грейдинга

Преимущества и недостатки применения технологии грейдинга Кадры организации

Кадры организации Персональный менеджмент

Персональный менеджмент Закономерности, принципы и методы управления персоналом

Закономерности, принципы и методы управления персоналом Субъекты и структура управления персоналом

Субъекты и структура управления персоналом Внедрение принципов ХАССП на предприятиях малого бизнеса

Внедрение принципов ХАССП на предприятиях малого бизнеса Организация государственного налогового менеджмента

Организация государственного налогового менеджмента Завязовское. Материал по работе за 2 месяца 2023 года

Завязовское. Материал по работе за 2 месяца 2023 года Тайм-менеджмент. Время - деньги

Тайм-менеджмент. Время - деньги Логистика. Управление материальными и информационными потоками

Логистика. Управление материальными и информационными потоками Wynagradzanie pracowników

Wynagradzanie pracowników Внешняя среда организации

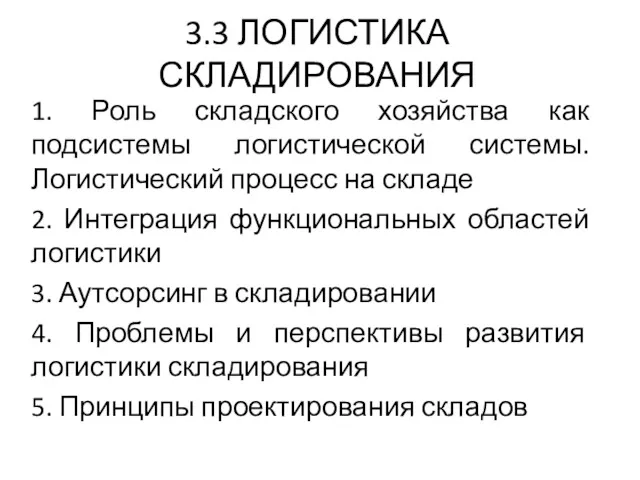

Внешняя среда организации Логистика складирования

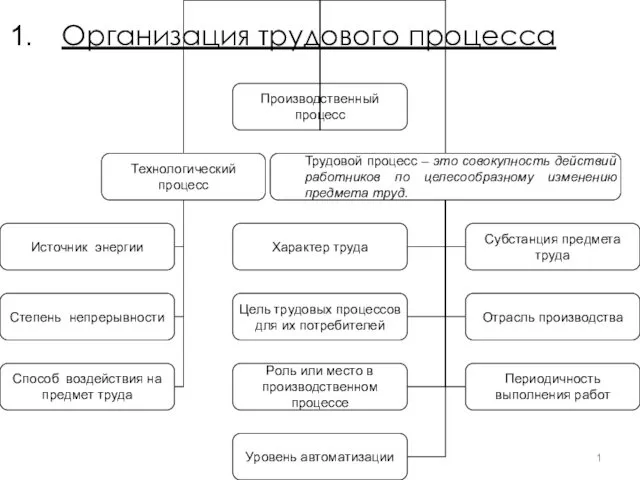

Логистика складирования Организация трудового процесса. Производственный процесс

Организация трудового процесса. Производственный процесс Структура та управління підприємством

Структура та управління підприємством Современные методы эффективного управления

Современные методы эффективного управления Видение, миссия и цели организации

Видение, миссия и цели организации Zarządzanie międzykulturowe

Zarządzanie międzykulturowe Социальная организация как объект управления. Внутренняя среда организации

Социальная организация как объект управления. Внутренняя среда организации Модели управления организационными изменениями

Модели управления организационными изменениями Роль оценки персонала в управлении

Роль оценки персонала в управлении Российские модели менеджмента

Российские модели менеджмента Разработка проекта

Разработка проекта Управление персоналом в образовании. Инновационный менеджмент в образовании

Управление персоналом в образовании. Инновационный менеджмент в образовании Основная цель компании

Основная цель компании