Содержание

- 2. AGENDA Conch Maintenance Seminar Erection and Installation Breakdown Maintenance Preventive Maintenance Condition Based Maintenance Wear and

- 3. AGENDA Conch Maintenance Seminar Access to Feeder Controller CSC Troubleshooting TOPICS Part 2: Spare Part Management

- 4. OUR SERVICE PHILOSOPHY Our support does not end at the sale of the equipment but it’s

- 5. Customer Service - Field Service Support Erection and Installation

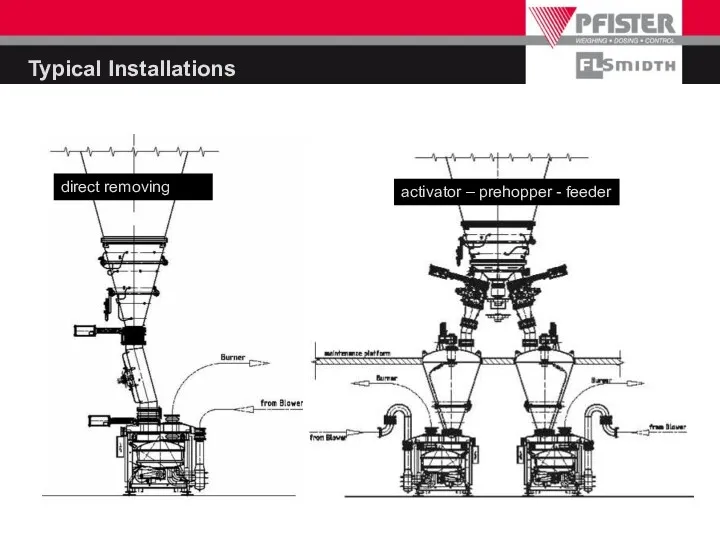

- 6. Typical Installations direct removing activator – prehopper - feeder

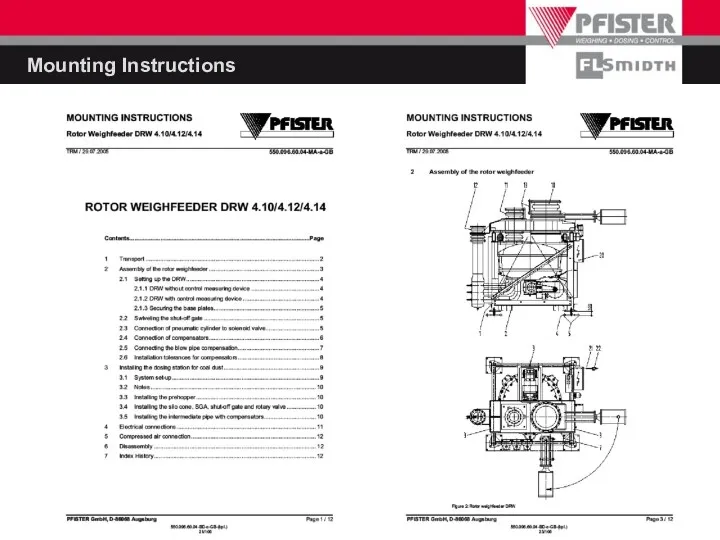

- 7. Mounting Instructions

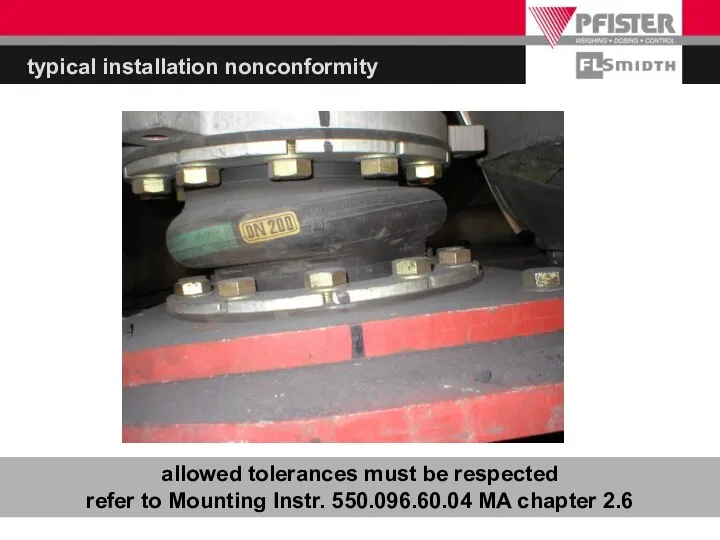

- 8. typical installation nonconformity allowed tolerances must be respected refer to Mounting Instr. 550.096.60.04 MA chapter 2.6

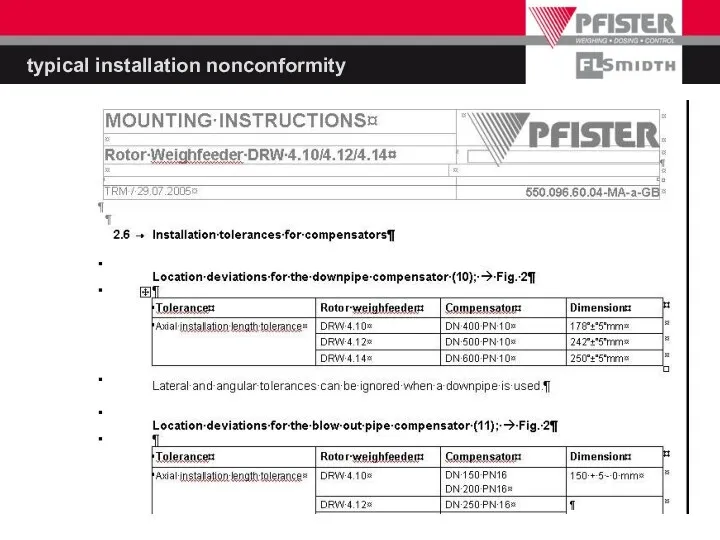

- 9. typical installation nonconformity

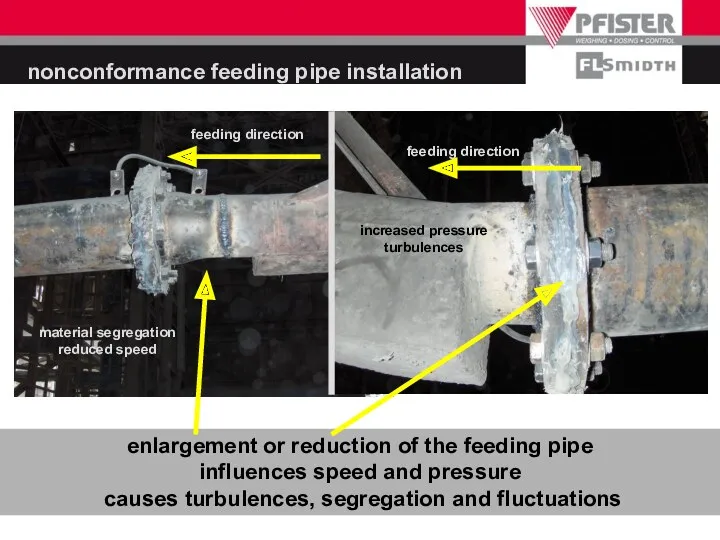

- 10. nonconformance feeding pipe installation enlargement or reduction of the feeding pipe influences speed and pressure causes

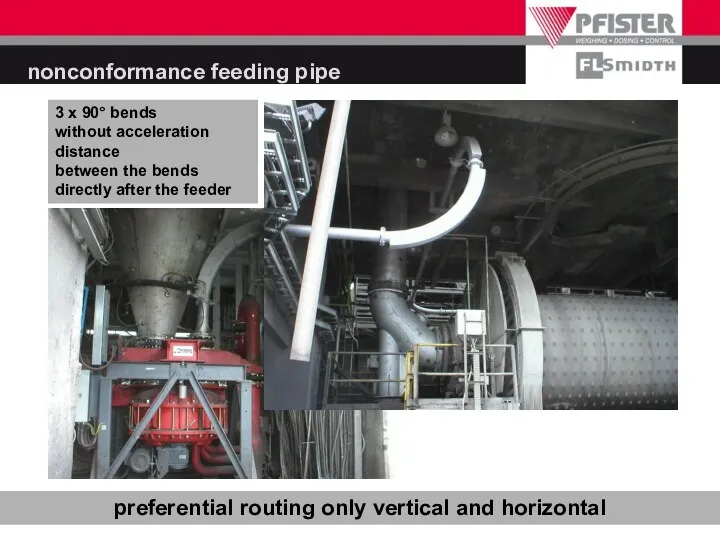

- 11. nonconformance feeding pipe preferential routing only vertical and horizontal 3 x 90° bends without acceleration distance

- 12. Installation nonconformity avoid water and condensation inside the rotor feeder drain water as early as possible

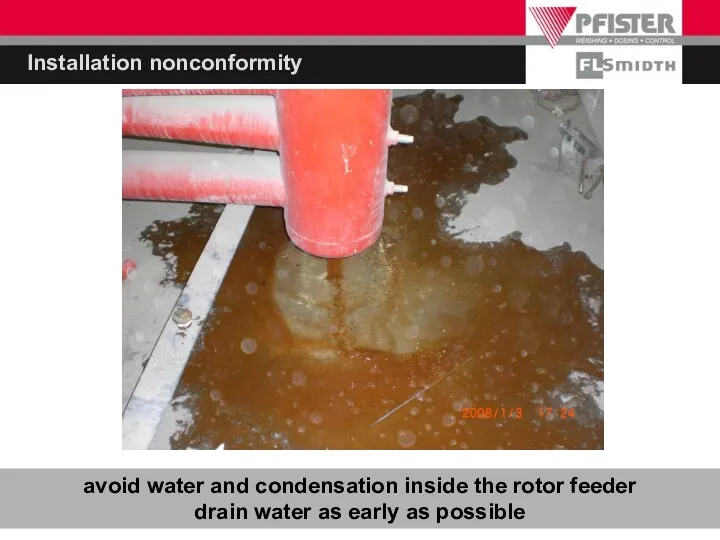

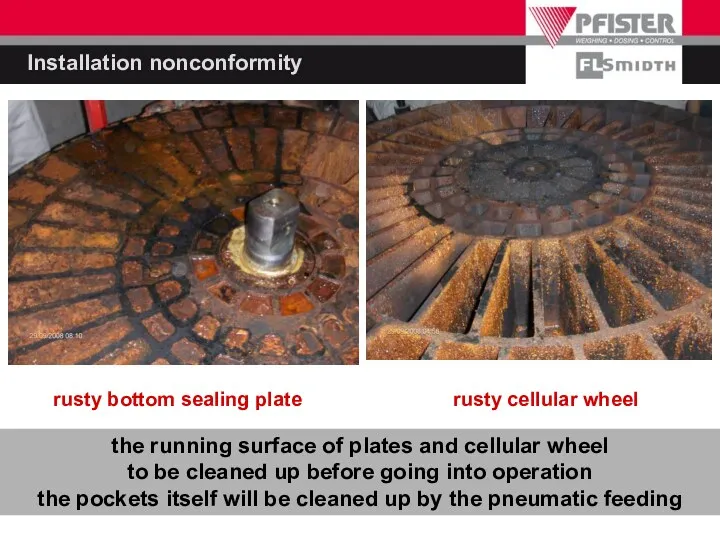

- 13. Installation nonconformity the running surface of plates and cellular wheel to be cleaned up before going

- 14. Focus on Maintenance关注维护 Maintenance on Electrical Panels 对电气原件的维护 - > Break Down Maintenance故障应急维护 Maintenance on Mechanical

- 15. Maintenance for panels and mechanics electric mechanic

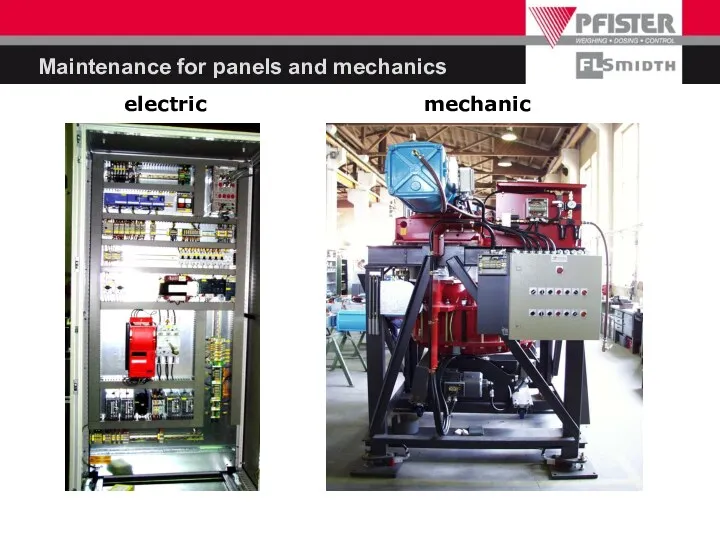

- 16. Maintenance Maintenance on Electrical Panels - > Break Down Maintenance Maintenance on Mechanical Equipment - >

- 17. Breakdown Maintenance故障应急维修 ‘s point of view我们的观点: Preventive maintenance is not adequate for most of 预见性的维护不能满足大部分的 electrical

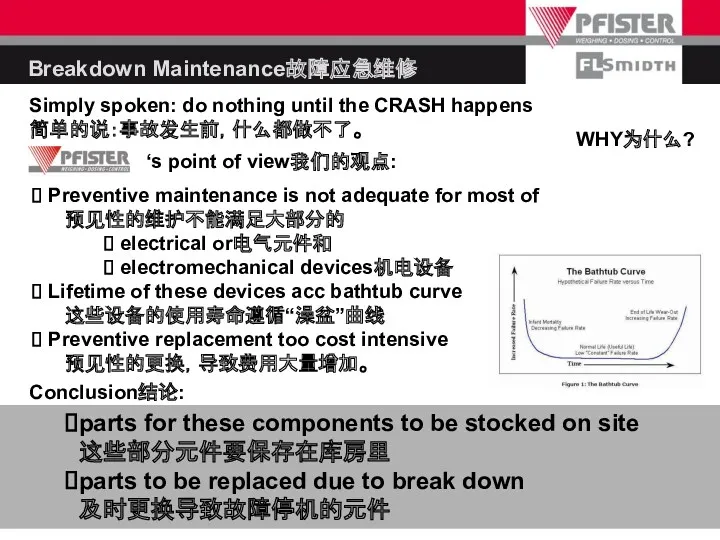

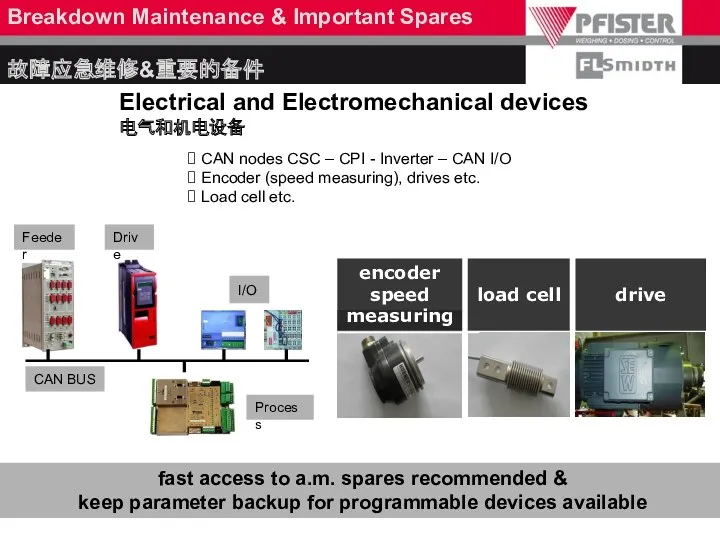

- 18. Breakdown Maintenance & Important Spares 故障应急维修&重要的备件 Electrical and Electromechanical devices 电气和机电设备 CAN nodes CSC – CPI

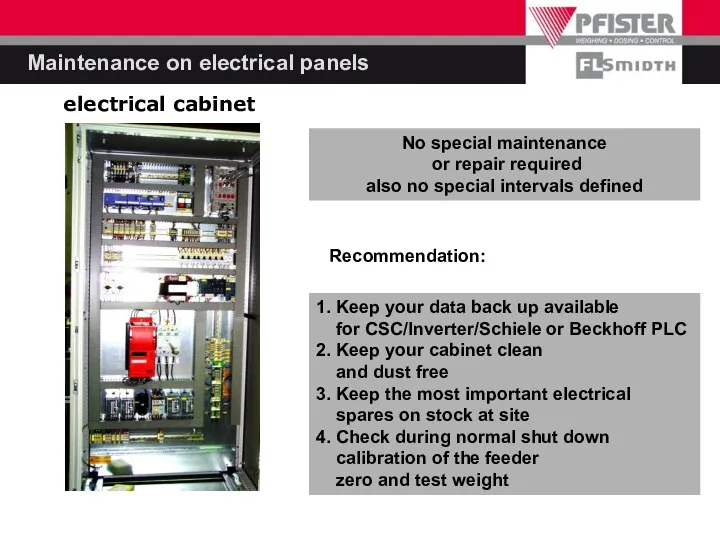

- 19. Maintenance on electrical panels electrical cabinet No special maintenance or repair required also no special intervals

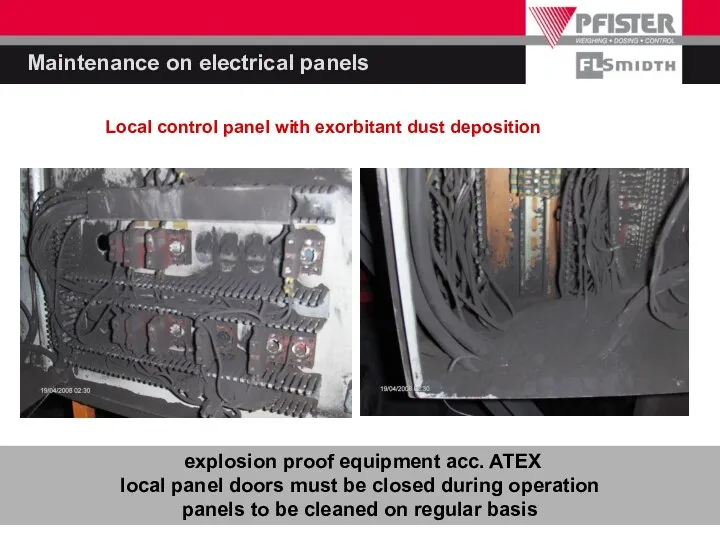

- 20. Maintenance on electrical panels explosion proof equipment acc. ATEX local panel doors must be closed during

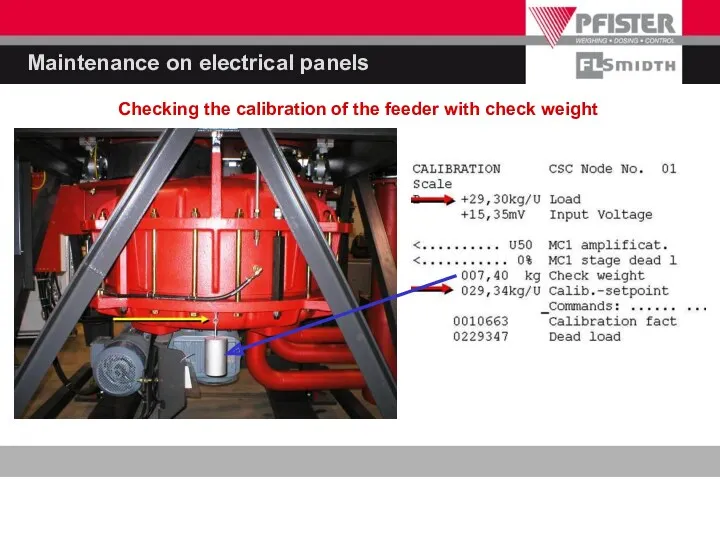

- 21. Maintenance on electrical panels Checking the calibration of the feeder with check weight

- 22. Maintenance Maintenance on Electrical Panels - > Break Down Maintenance Maintenance on Mechanical Equipment - >

- 23. Maintenance on mechanical parts

- 24. Maintenance instructions

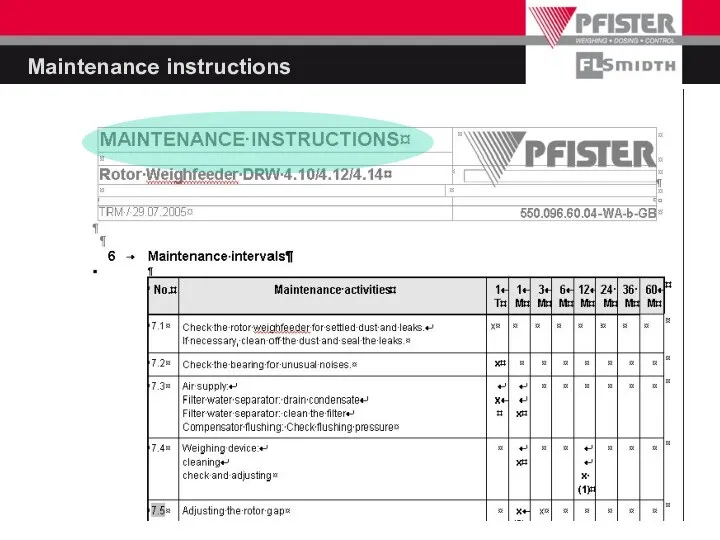

- 25. Maintenance on mechanical equipment 机械设备的维护 Lubrication润滑 case: shaft sealing and bearing轴密封和轴承 Weighing device称重机构 case: damper oil

- 26. Maintenance on mechanical equipment Blow out nozzle case: high inner chamber wear case: best air distribution

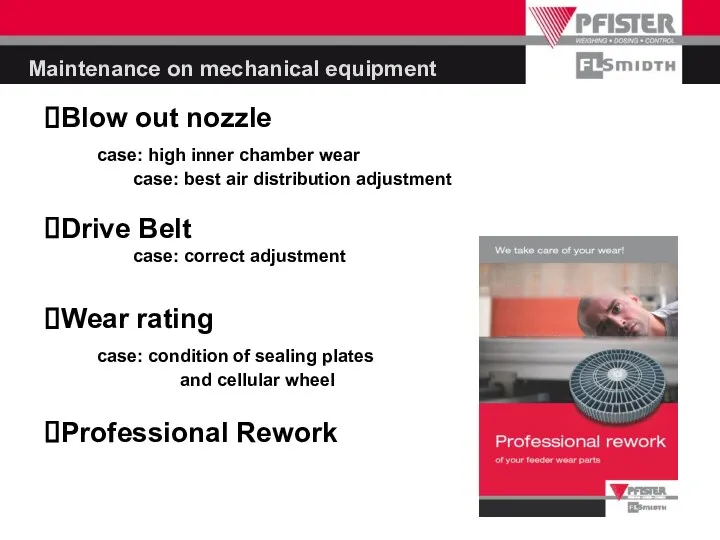

- 27. Maintenance on mechanical equipment Lubrication case: shaft sealing and bearing

- 28. Maintenance - Lubrication using the correct lubricant and observation of the lubrication interval extend the lifetime

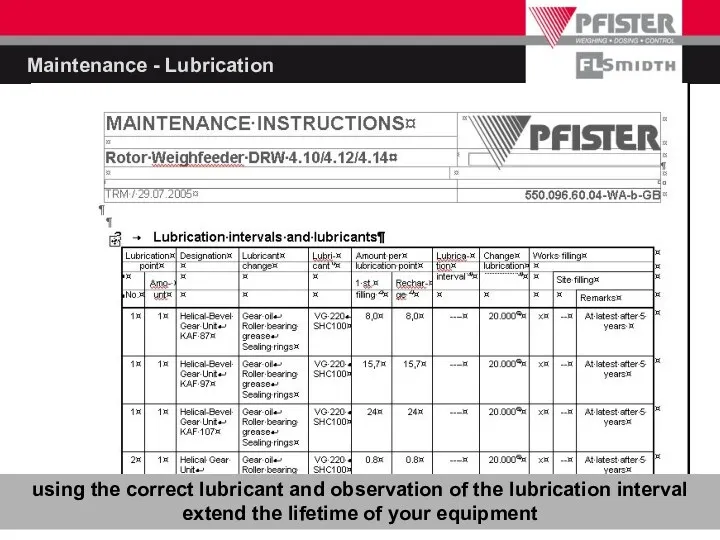

- 29. lubrication shaft sealing and bearing shaft bearing轴承 each 1000 oh (~40d) possible during operation in adjust

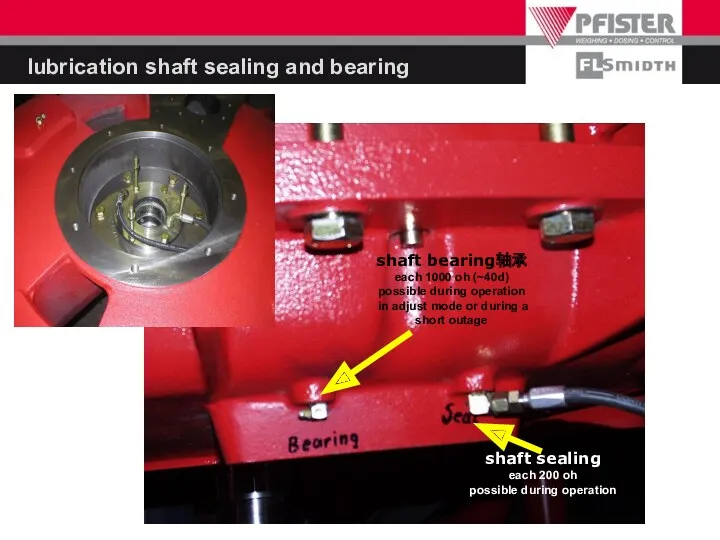

- 30. Lubrication problems exorbitant greasing to be avoided such as too less greasing Openings in the casing

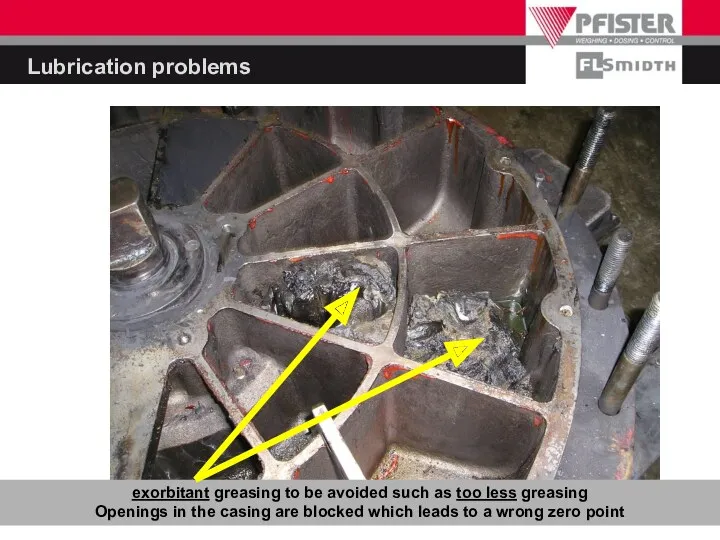

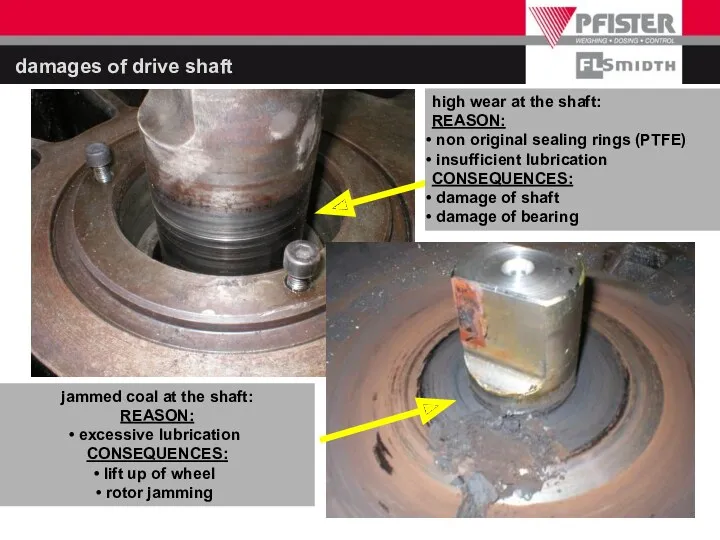

- 31. damages of drive shaft jammed coal at the shaft: REASON: excessive lubrication CONSEQUENCES: lift up of

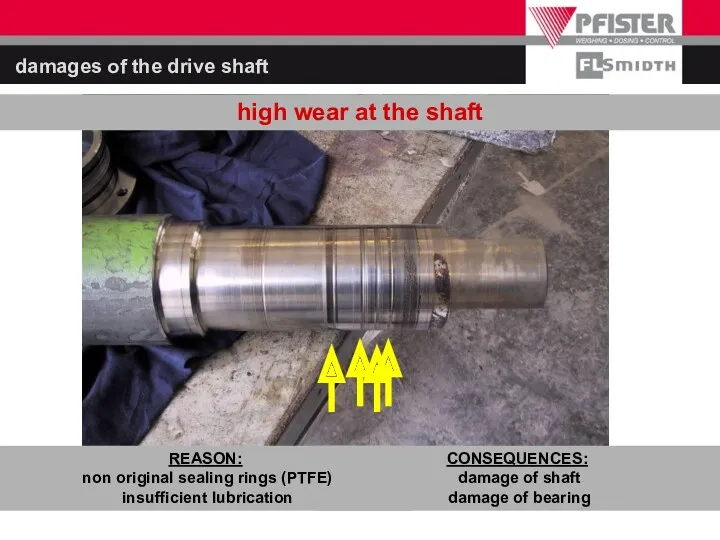

- 32. CONSEQUENCES: damage of shaft damage of bearing high wear at the shaft REASON: non original sealing

- 33. shaft sealing kit lubrication sealing rings lubrication bearing take care of the correct installation of the

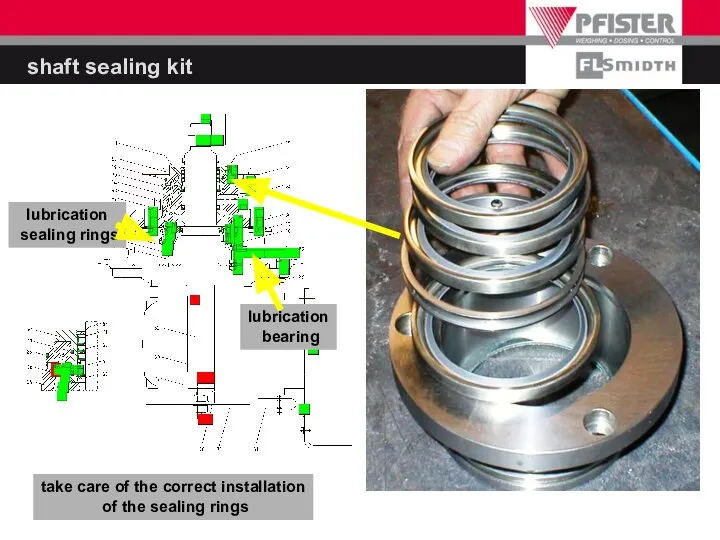

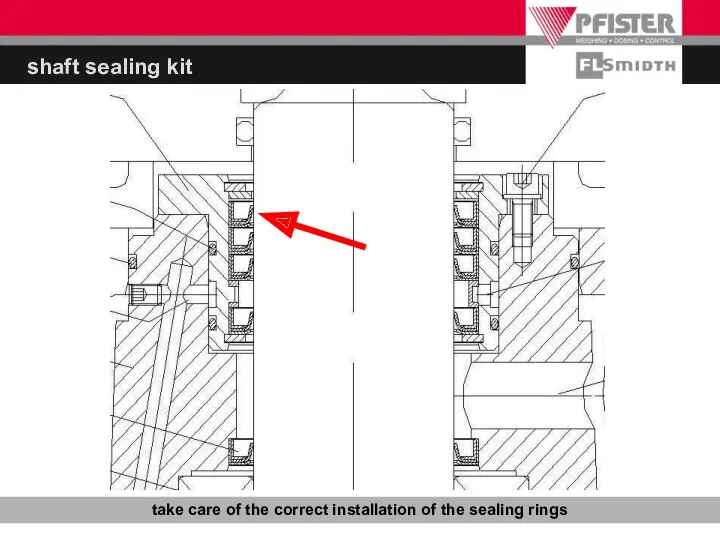

- 34. shaft sealing kit take care of the correct installation of the sealing rings

- 35. Maintenance on mechanical equipment Weighing device case: damper oil tank

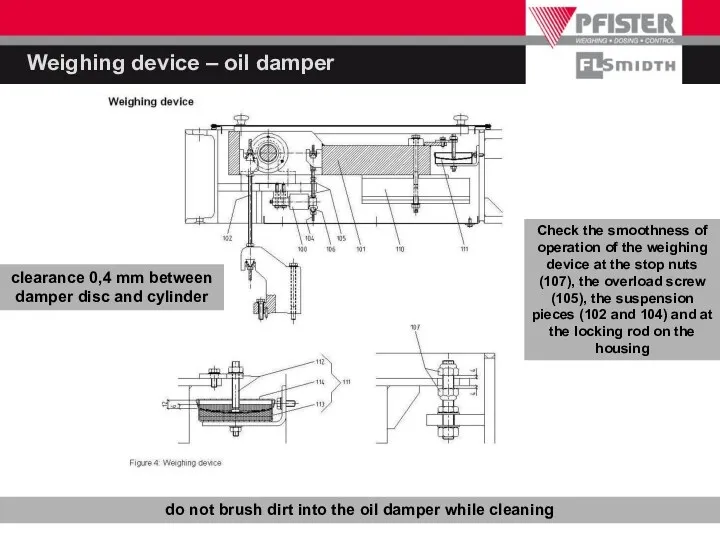

- 36. Weighing device – oil damper do not brush dirt into the oil damper while cleaning clearance

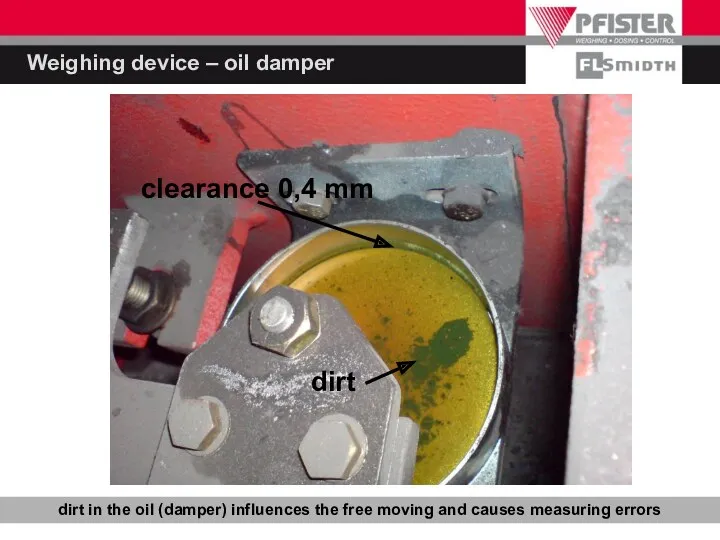

- 37. Weighing device – oil damper dirt in the oil (damper) influences the free moving and causes

- 38. Weighing device – oil damper Maintenance situation to be improved to avoid measuring errors

- 39. Weighing device – locking screw The locking rod must enable free movement the locking rod is

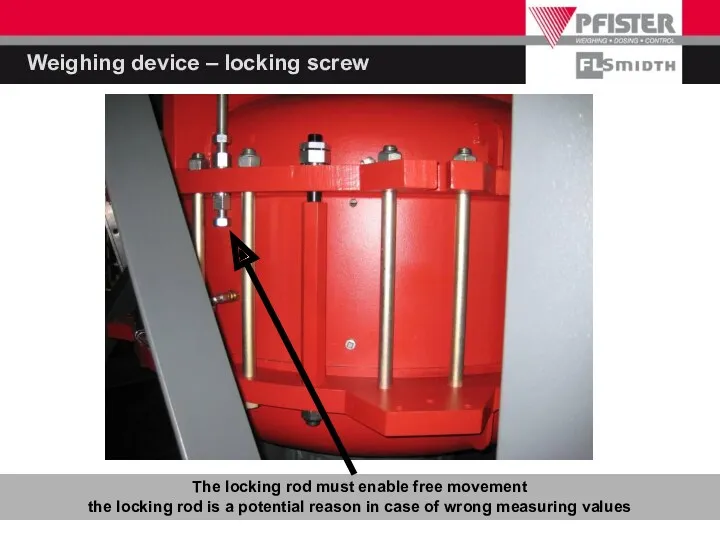

- 40. Maintenance on mechanical equipment Air supply case: outer pocket cleaning case: compensator cleaning case: mixing up

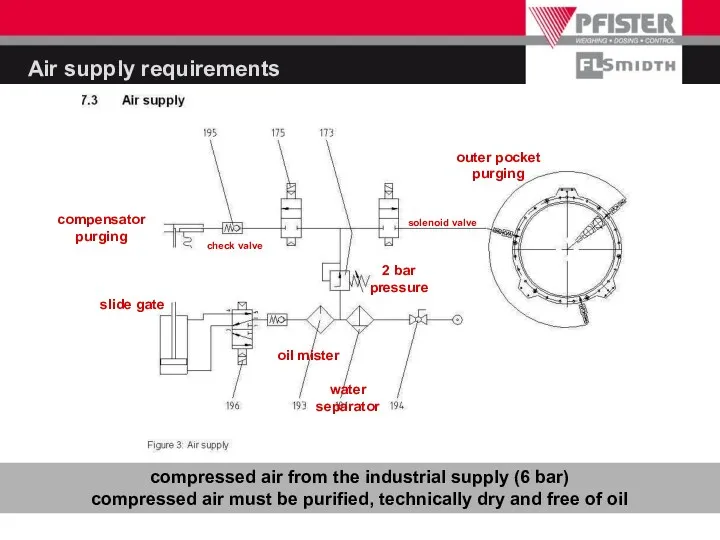

- 41. Air supply requirements compressed air from the industrial supply (6 bar) compressed air must be purified,

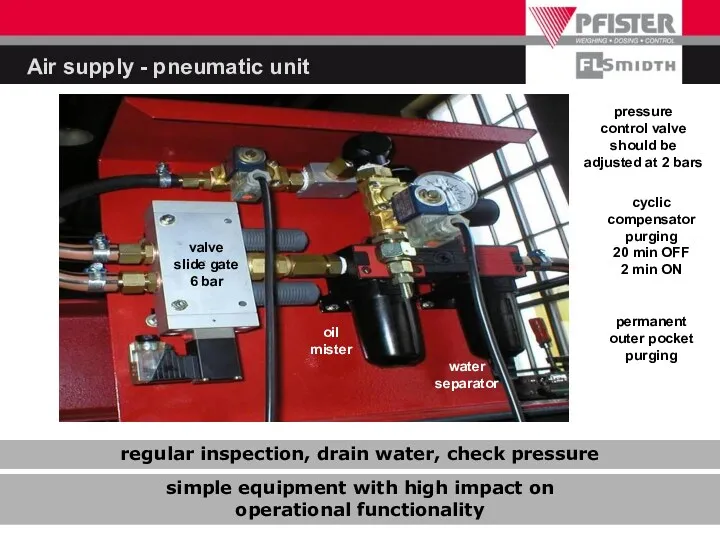

- 42. Air supply - pneumatic unit regular inspection, drain water, check pressure simple equipment with high impact

- 43. Maintenance situation to be improved to come back to reliable functionality Air supply - pneumatic unit

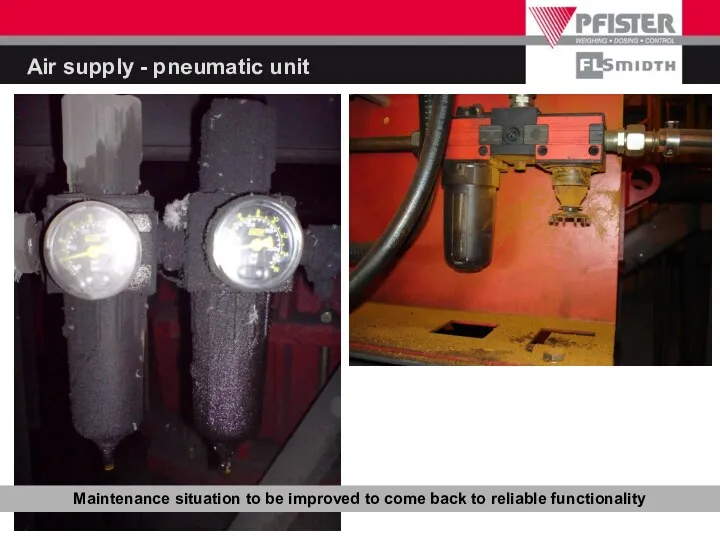

- 44. pneumatic unit and filter plates check air permeability of sinter plates recommended pressure at 2bar normally

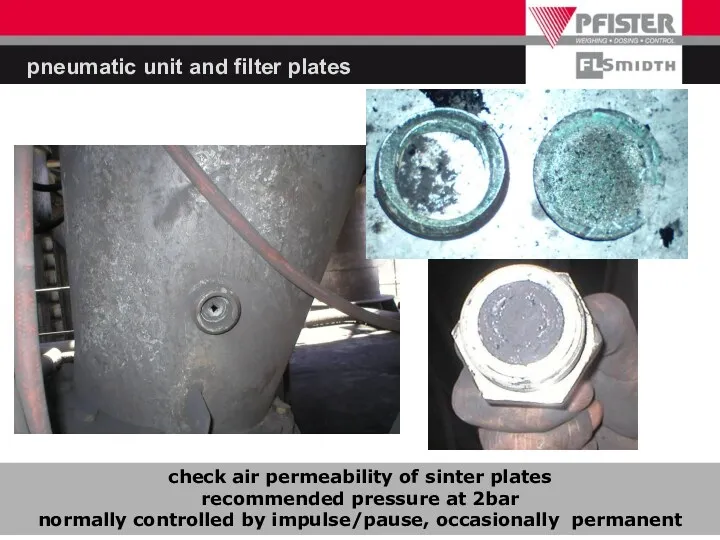

- 45. pneumatic unit and filter plates Water and rust in the air supply Wrong adjusted air supply

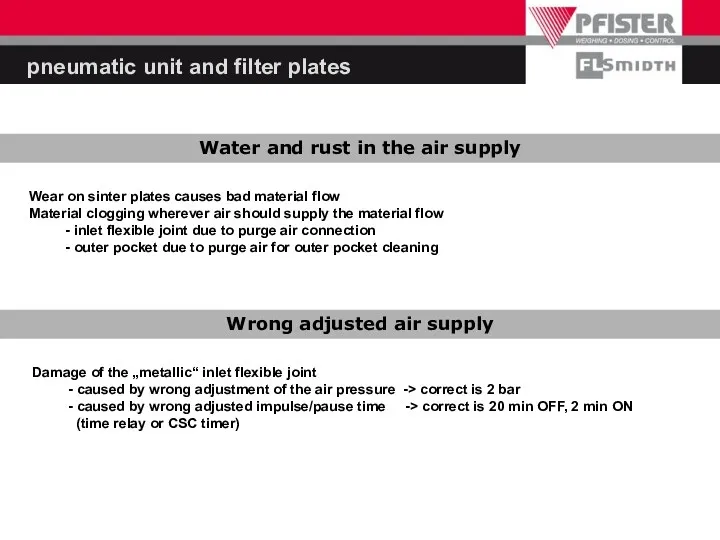

- 46. rotor jams caused by caked outer pockets indication: slowly increasing motor current after opening and cleaning

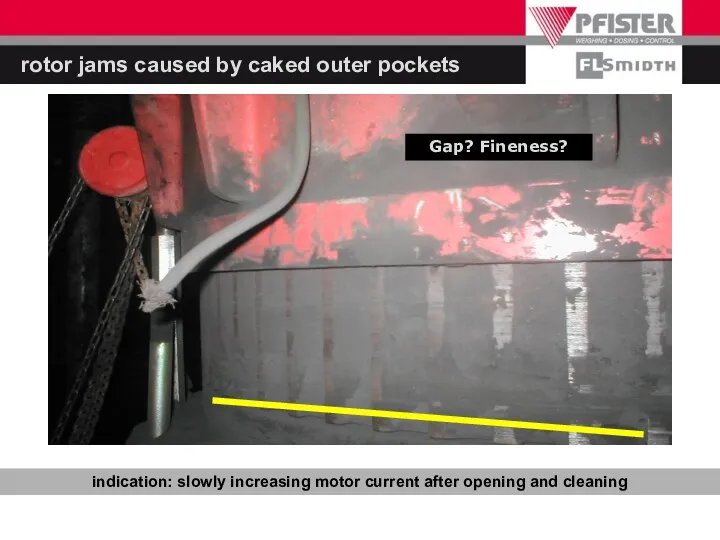

- 47. rotor jams caused by caked outer pockets missing outer pocket aeration effect like a drum brake

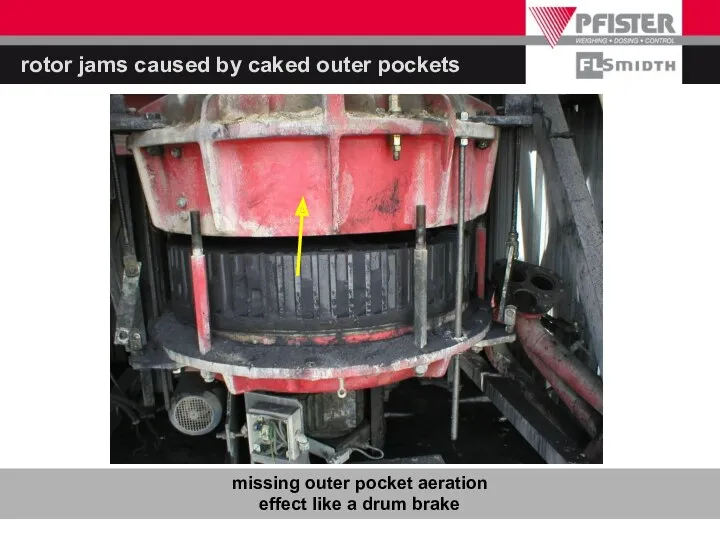

- 48. purge air for outer pockets cleaning deflector plate balancing weights from outside into the feeding pocket

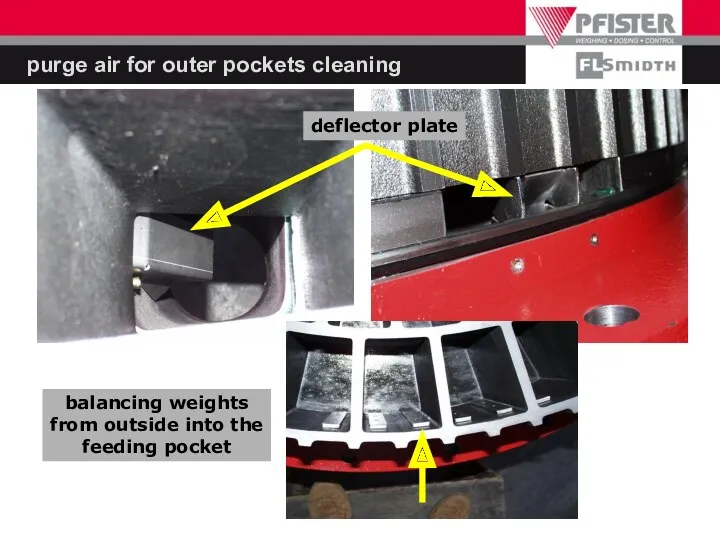

- 49. purge air for outer pockets cleaning installation of purge air at the circumference 3 check valves,

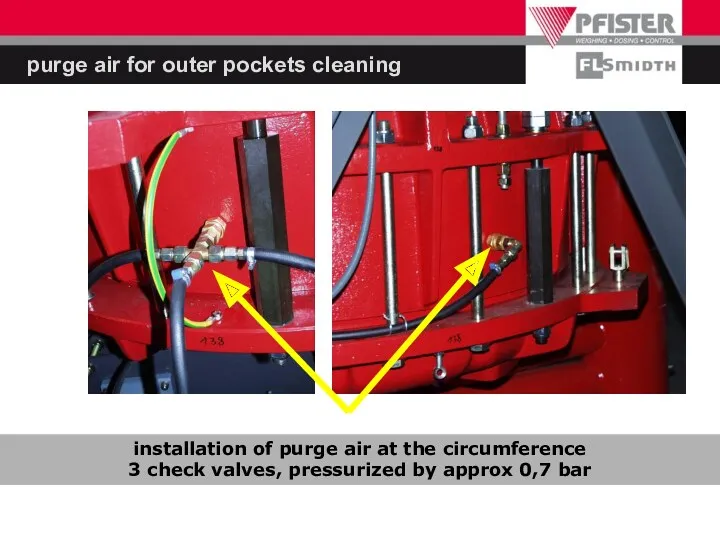

- 50. Wear especially coming from the outer chamber purge air stream What to do? Typical wear -

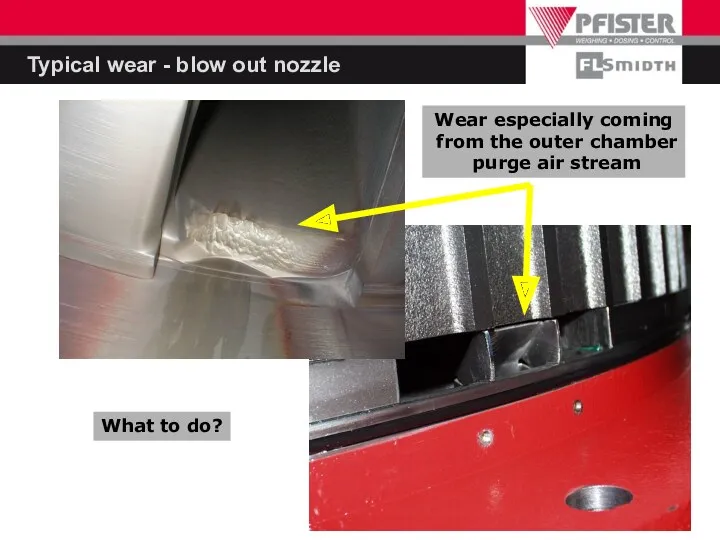

- 51. Counter measurements: reduce active area Typical wear - blow out nozzle

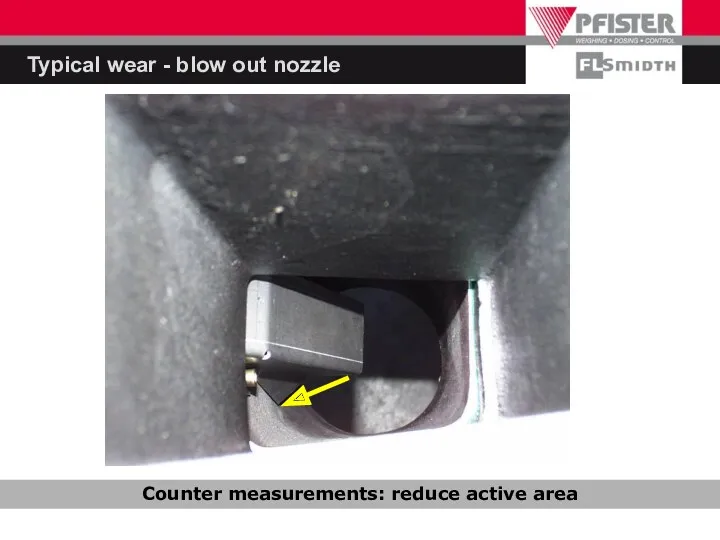

- 52. Permanent or cyclic purging installation failure mixing up purge air for inlet compensator and outer pocket

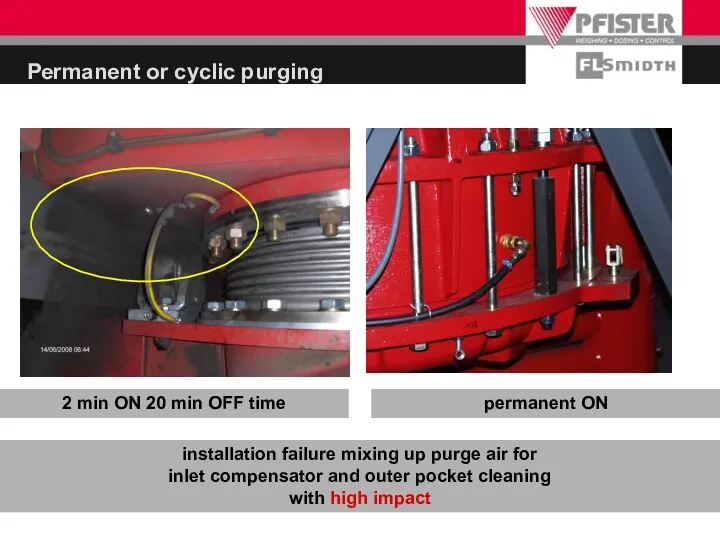

- 53. inlet compensator blown through by excessive purging air (interval and pressure) inlet compensator (flexible joint)

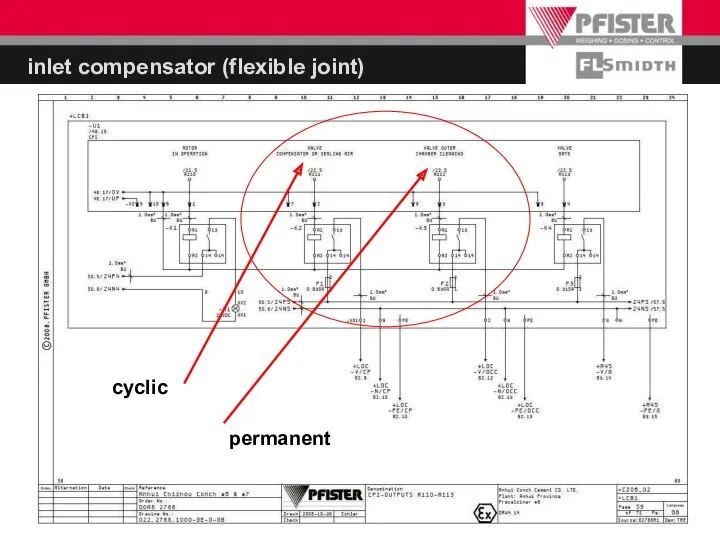

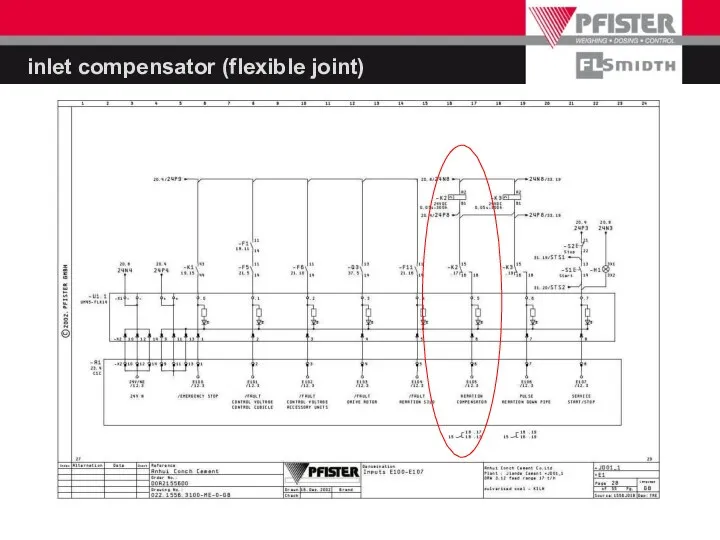

- 54. inlet compensator (flexible joint) cyclic permanent

- 55. inlet compensator (flexible joint)

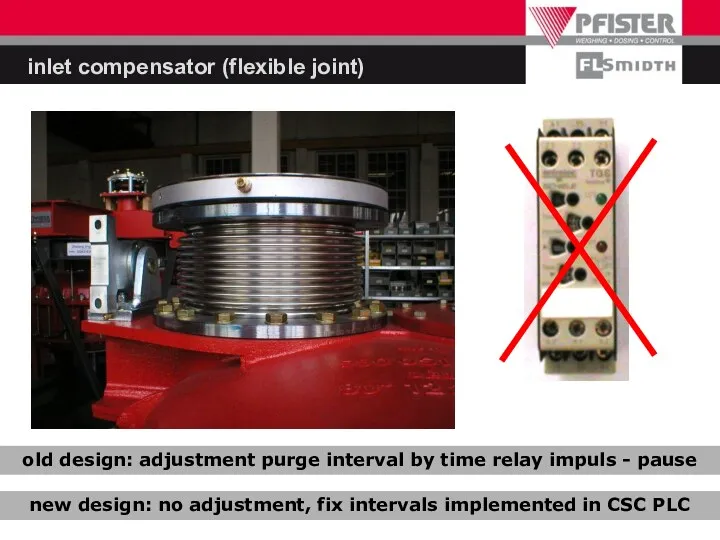

- 56. inlet compensator (flexible joint) old design: adjustment purge interval by time relay impuls - pause new

- 57. Maintenance on mechanical equipment Adjusting the rotor GAP

- 58. Adjusting the rotor gap adjusting screws (black) washers should be moveable by hand setting screws (red)

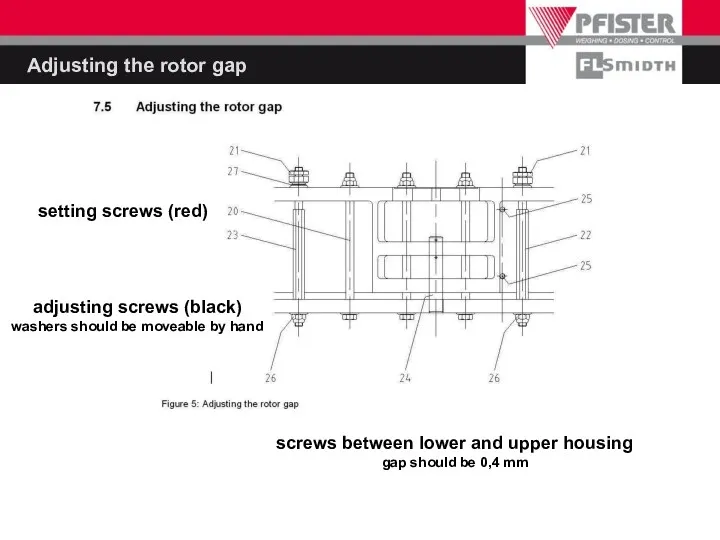

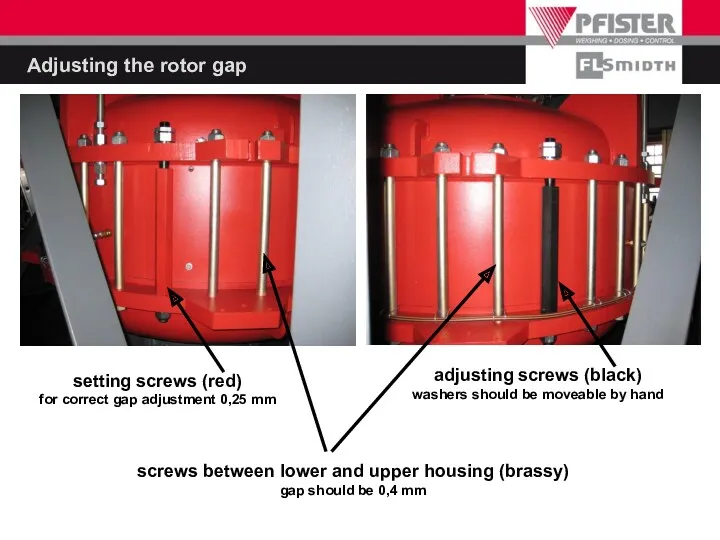

- 59. Adjusting the rotor gap adjusting screws (black) washers should be moveable by hand setting screws (red)

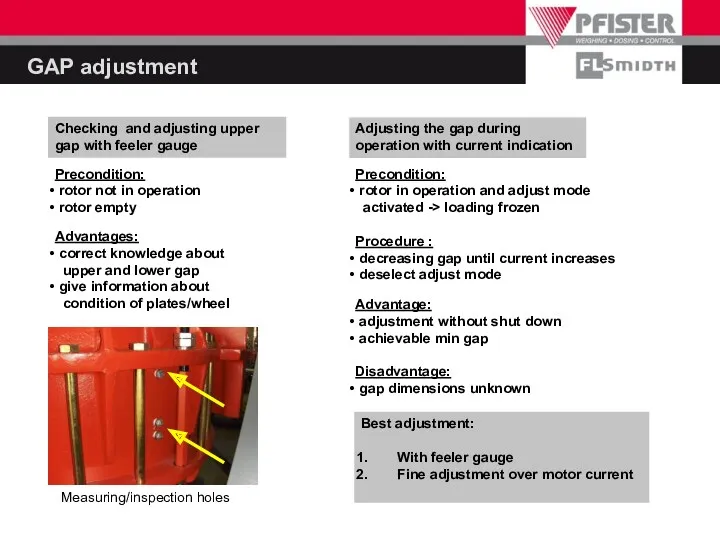

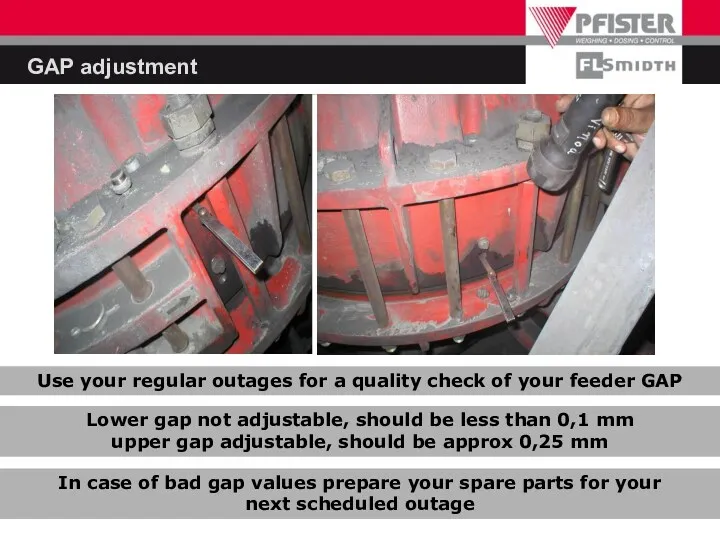

- 60. GAP adjustment Checking and adjusting upper gap with feeler gauge Precondition: rotor not in operation rotor

- 61. GAP adjustment Lower gap not adjustable, should be less than 0,1 mm upper gap adjustable, should

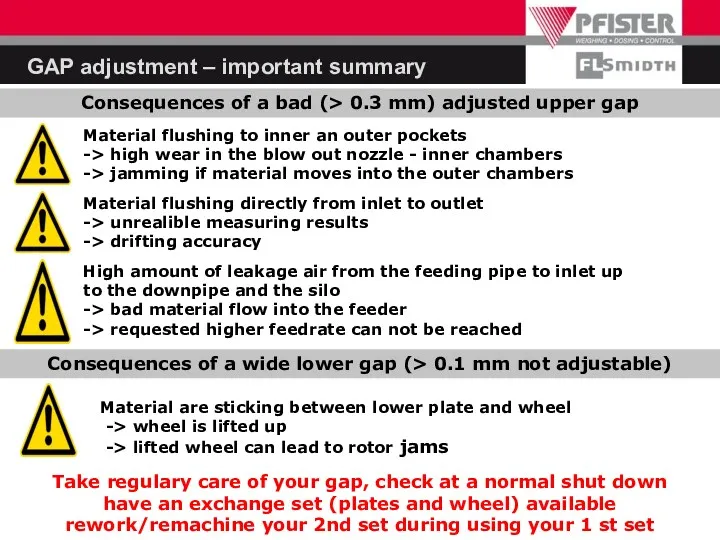

- 62. Consequences of a bad (> 0.3 mm) adjusted upper gap Material flushing to inner an outer

- 63. Maintenance on mechanical equipment Blow out nozzle case: high inner chamber wear case: best air distribution

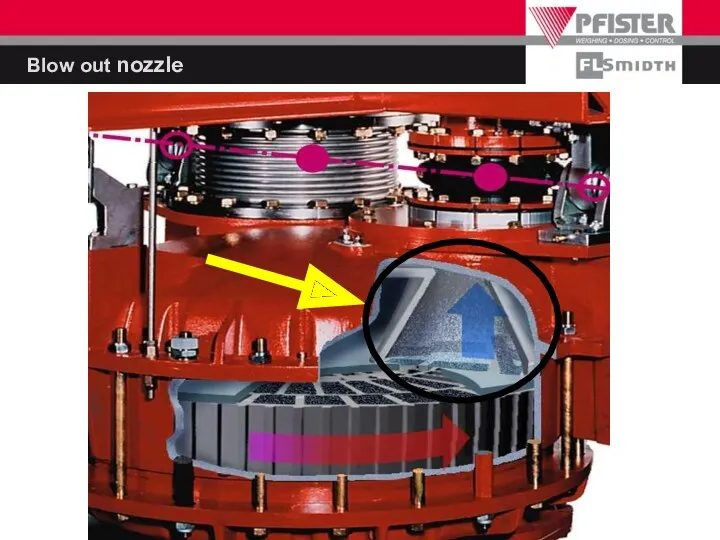

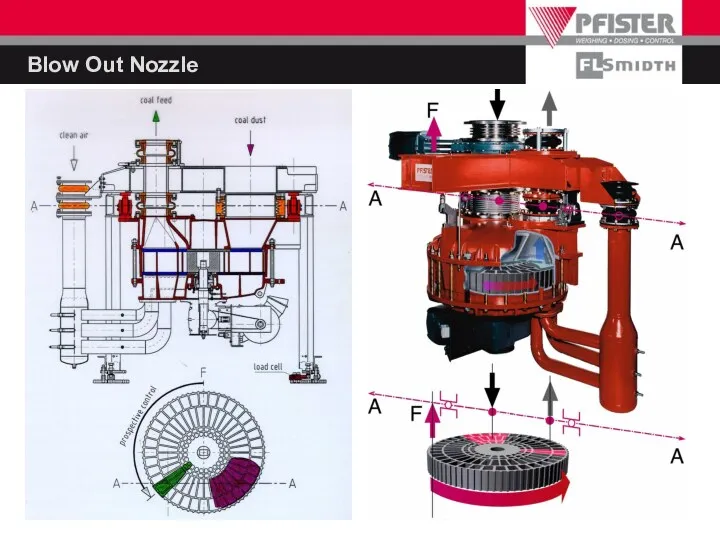

- 64. Blow out nozzle

- 65. Blow Out Nozzle

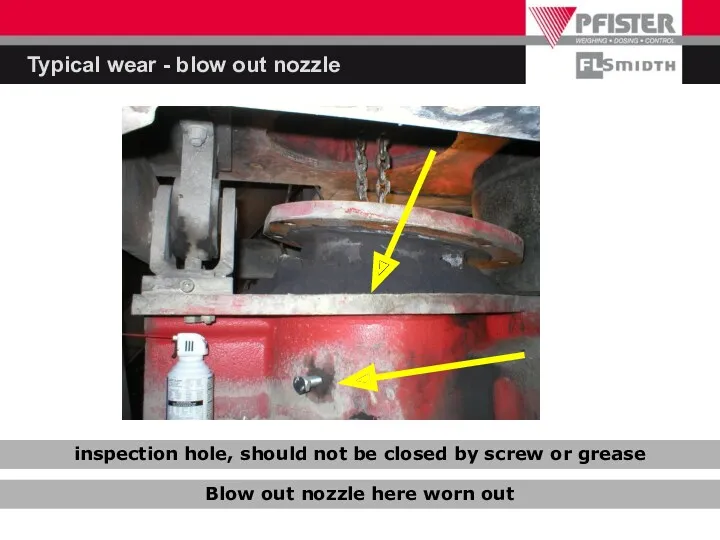

- 66. Typical wear - blow out nozzle inspection hole, should not be closed by screw or grease

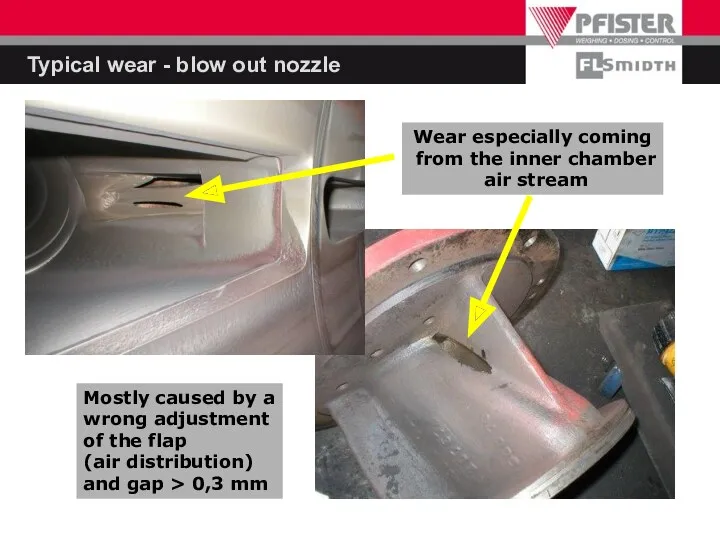

- 67. Typical wear - blow out nozzle Wear especially coming from the inner chamber air stream Mostly

- 68. best adjustment of air speed DRW 3.12/4.12

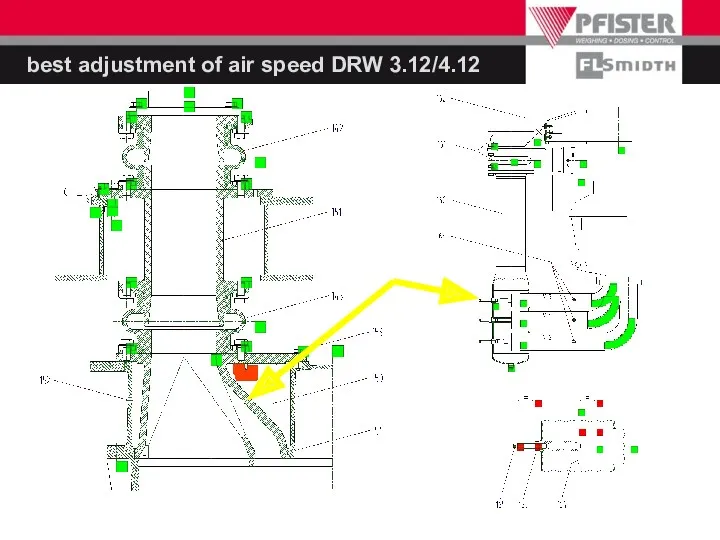

- 69. Anemometer for air speed measuring 3 adjusting screws 3 control flaps best adjustment of air speed

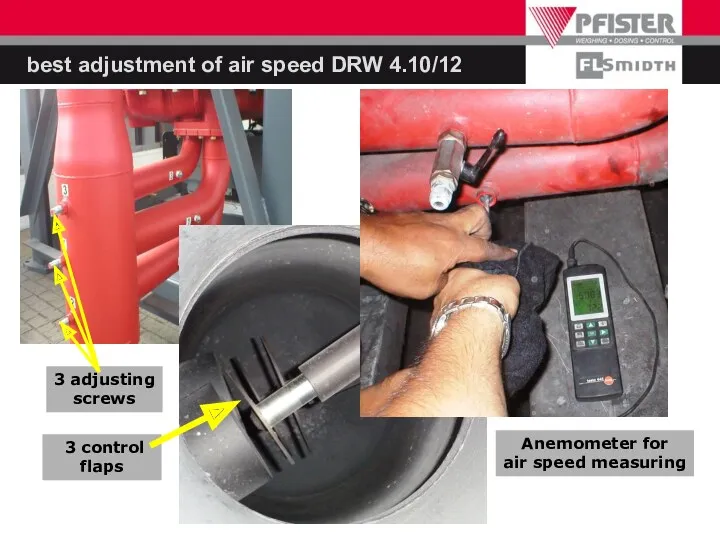

- 70. best adjustment of air speed DRW 3.14/4.14 1 adjusting screws 1 control flap

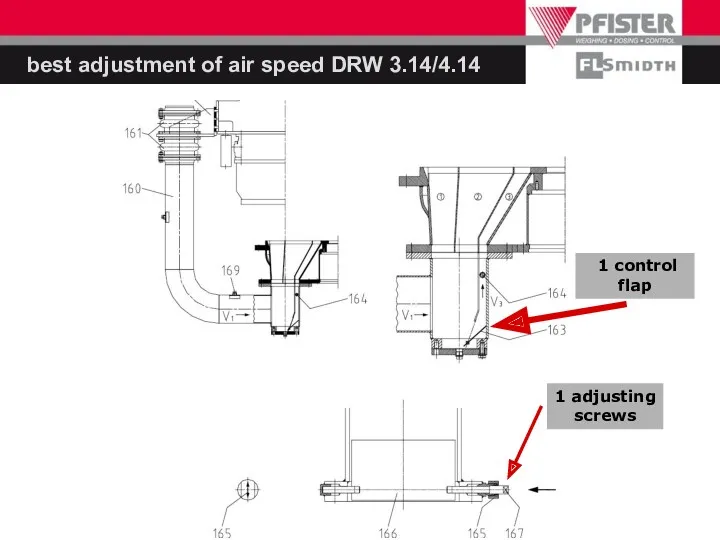

- 71. deflector plate measuring hole V3 adjusting screw best adjustment of air speed DRW 3.14/4.14

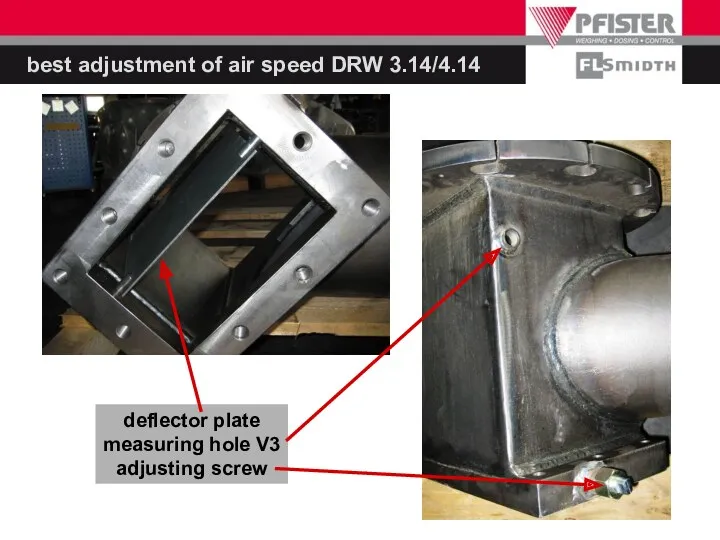

- 72. air speed standard limit blow out nozzle In case that the standard max speed V blow

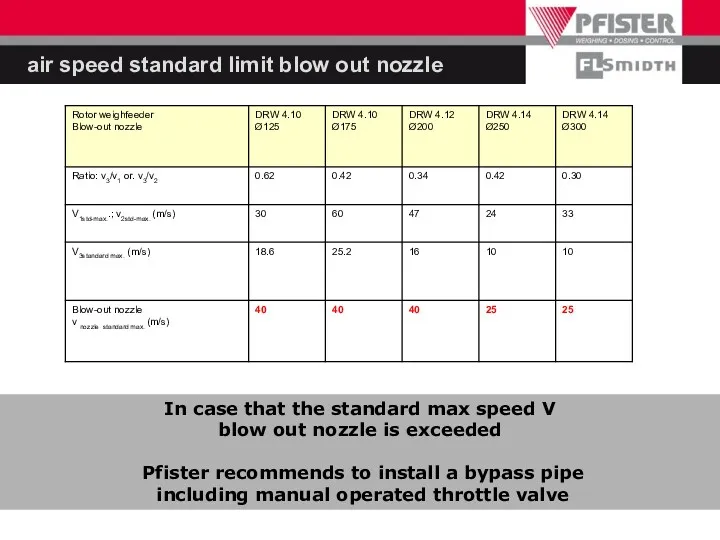

- 73. bypass solution

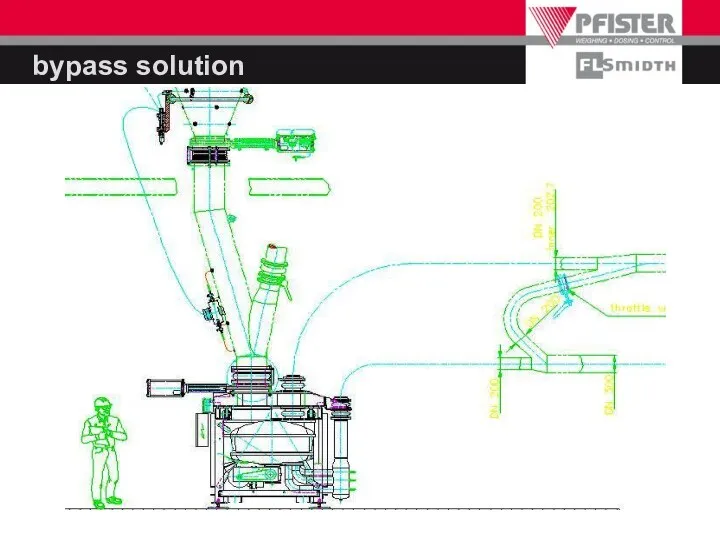

- 74. blower and blow pipe design We offer free of charge to calculate the design of your

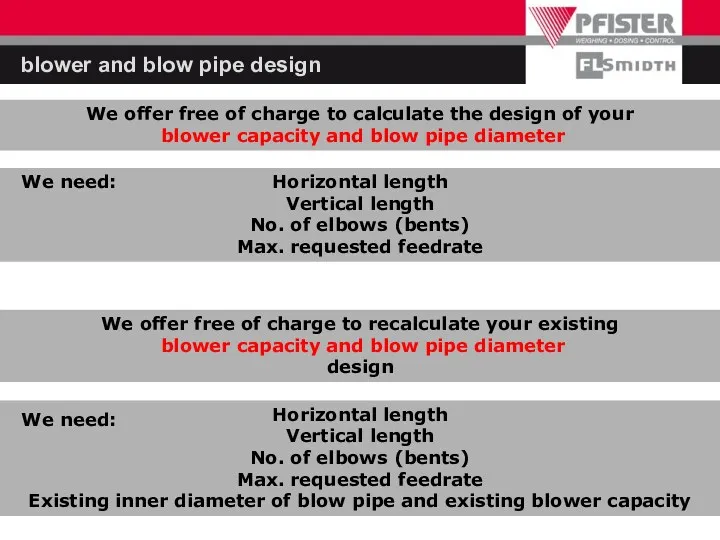

- 75. WEAR part – Blow out nozzle and flexible joints smaller holes can be welded inspection hole

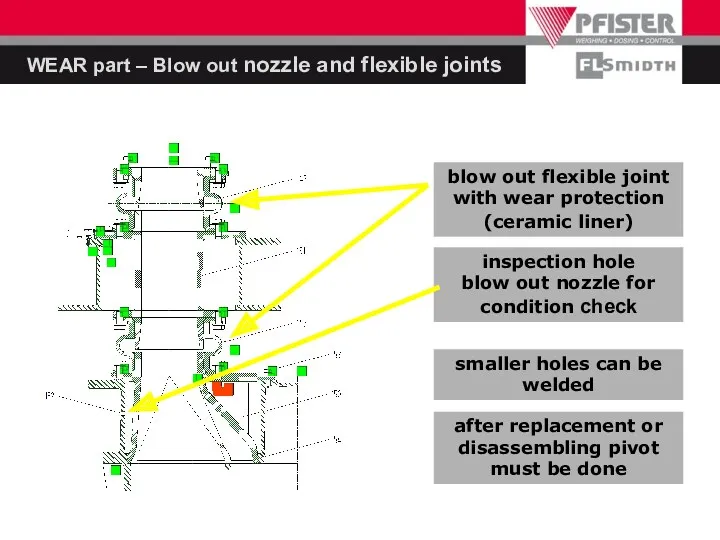

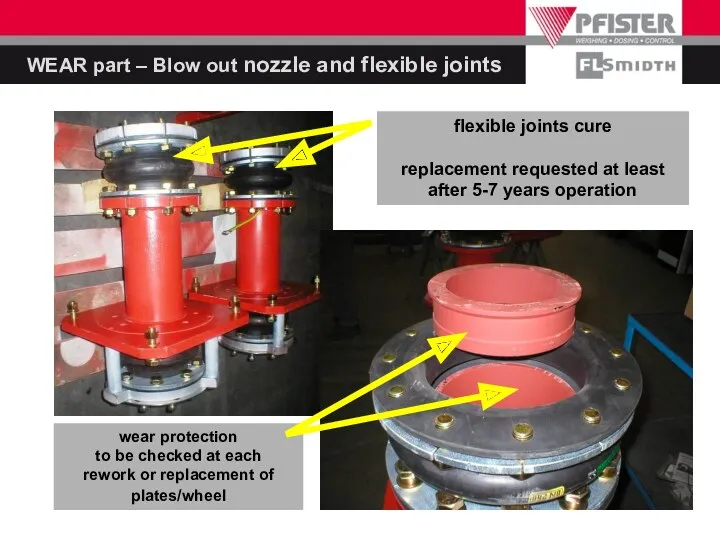

- 76. Maintenance PIVOT Replacing the inlet compensator means adjusting the pivot (symmetry) newly refer to 550.096.60.04 IS

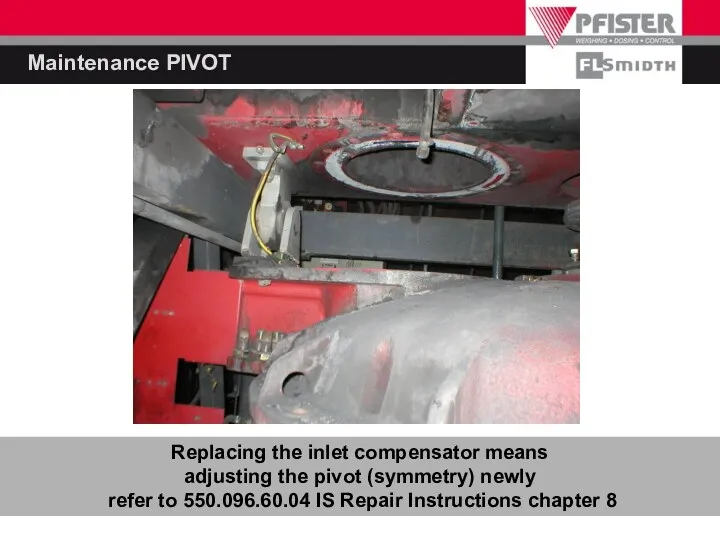

- 77. flexible joints cure replacement requested at least after 5-7 years operation wear protection to be checked

- 78. Maintenance on electrical parts

- 79. Maintenance on mechanical equipment Drive Belt case: correct adjustment

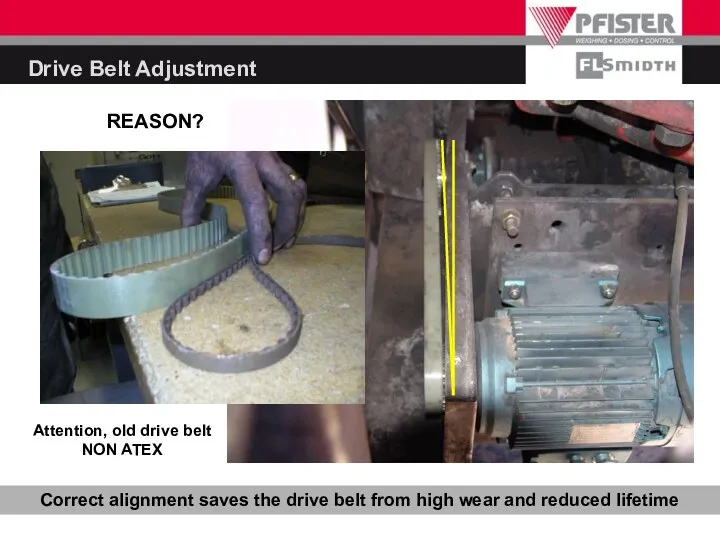

- 80. Drive Belt Adjustment drive belt according ATEX with correct no. of tooth's and length correct tension

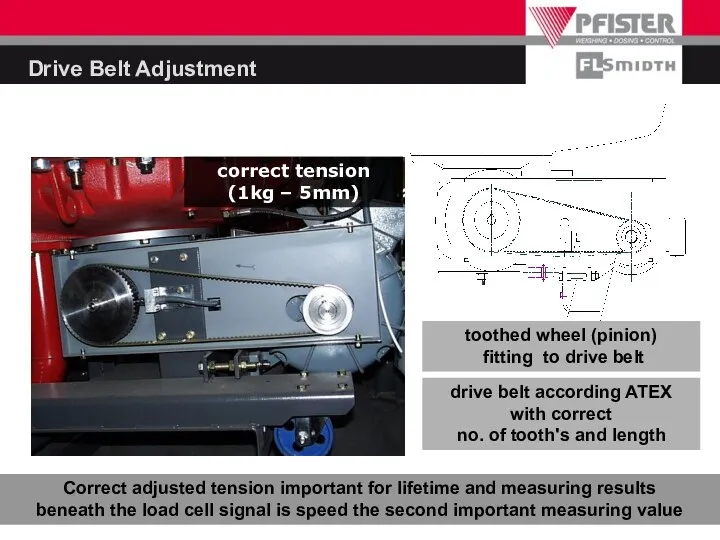

- 81. Correct alignment saves the drive belt from high wear and reduced lifetime REASON? Drive Belt Adjustment

- 82. Correct drive belt tension, condition of the pinions Over tension causes high wear at the drive

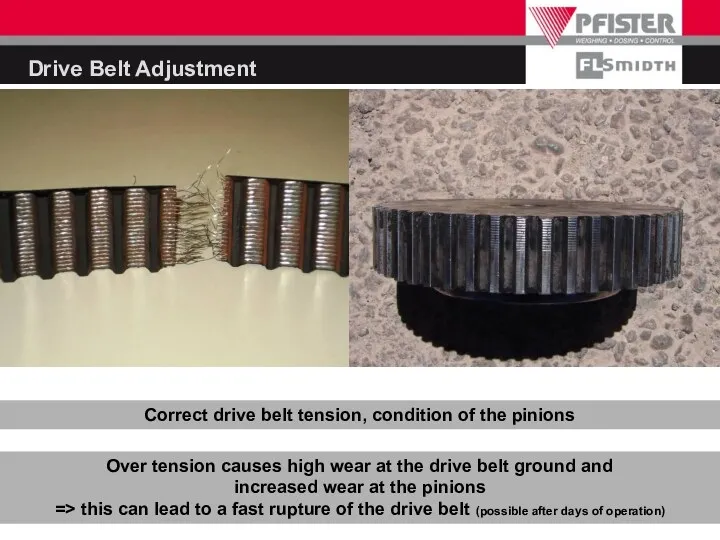

- 83. New drive belt for DRW 4.14 acc. ATEX (conductive) only in black color available

- 84. Maintenance on mechanical equipment Wear rating case: condition of sealing plates and cellular wheel

- 85. Maintenance theory维护原理 – wear parts磨损部件 Mechanical Maintenance机械维护

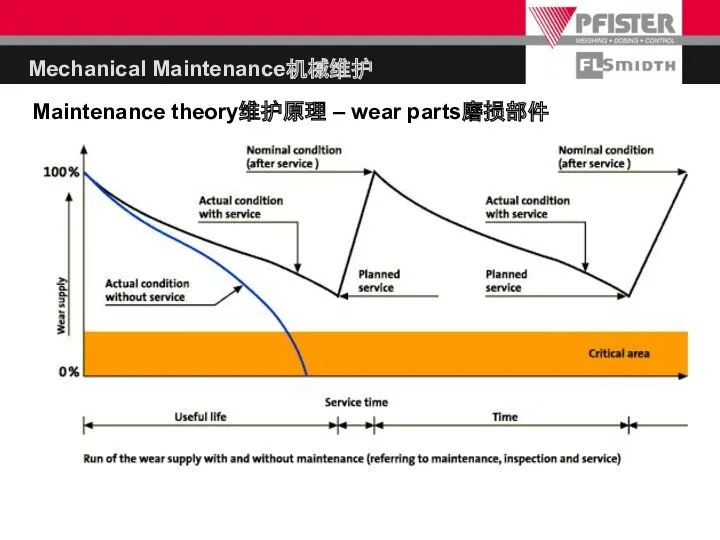

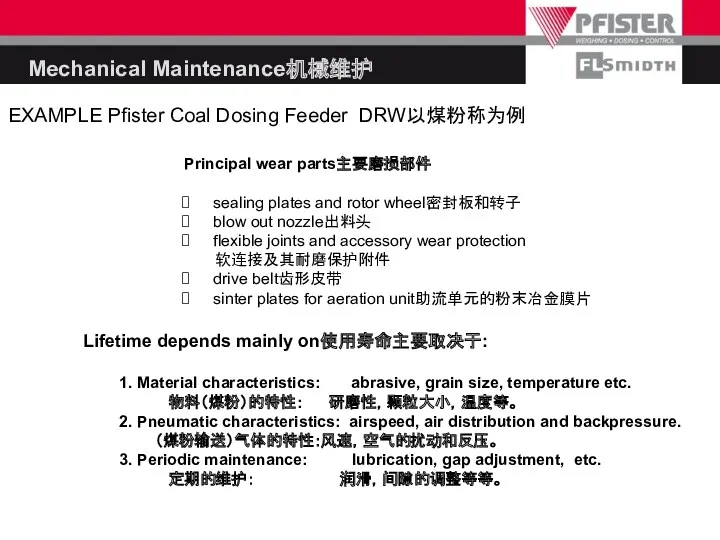

- 86. Mechanical Maintenance机械维护 Principal wear parts主要磨损部件 sealing plates and rotor wheel密封板和转子 blow out nozzle出料头 flexible joints and

- 87. Mechanical Maintenance - condition based 机械维护-基于状态的 Condition based maintenance is not that easy, because the condition

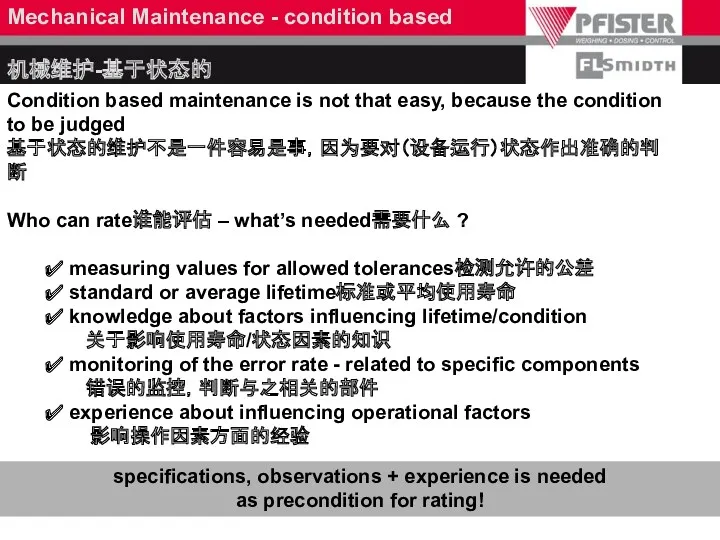

- 88. Mechanical Maintenance – Repair Instructions

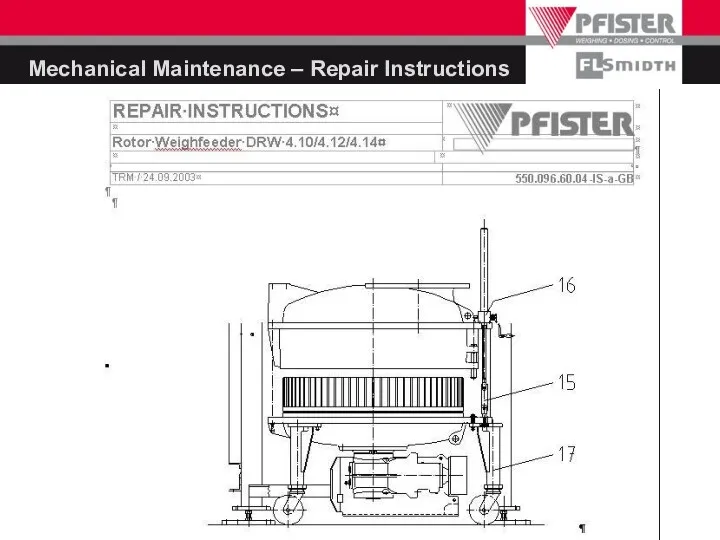

- 89. Preventive Maintenance - condition based 定期维护-基于状态的 recommendation to machine always the 4 sides推荐只加工4个面 upper side of

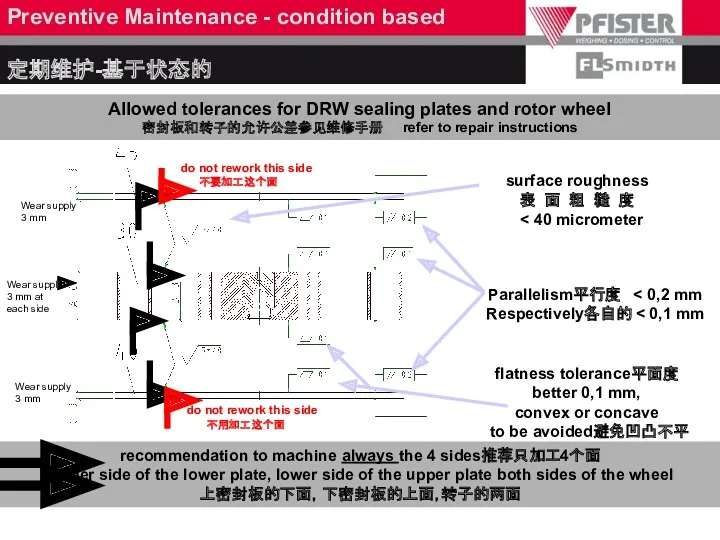

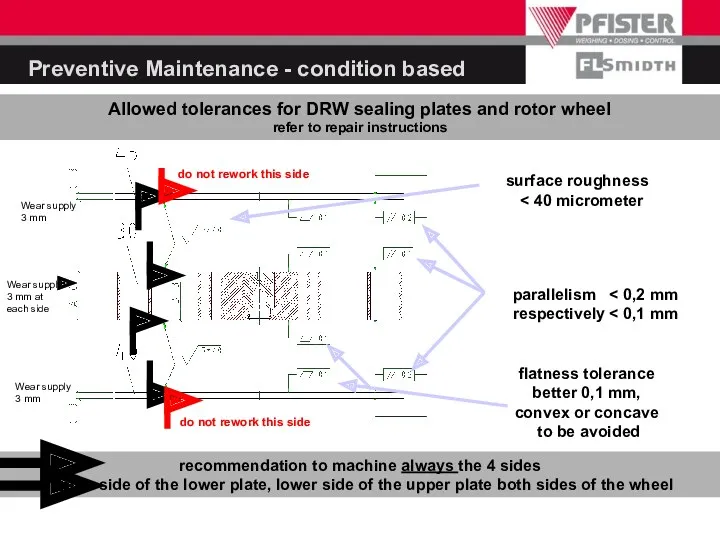

- 90. WEAR part – rotor wheel Standard lifetime approx. 2-3 years depends on: 1. material characteristics 2.

- 91. WEAR parts – lower and upper sealing plate high accuracy parts for correct gap adjustment correct

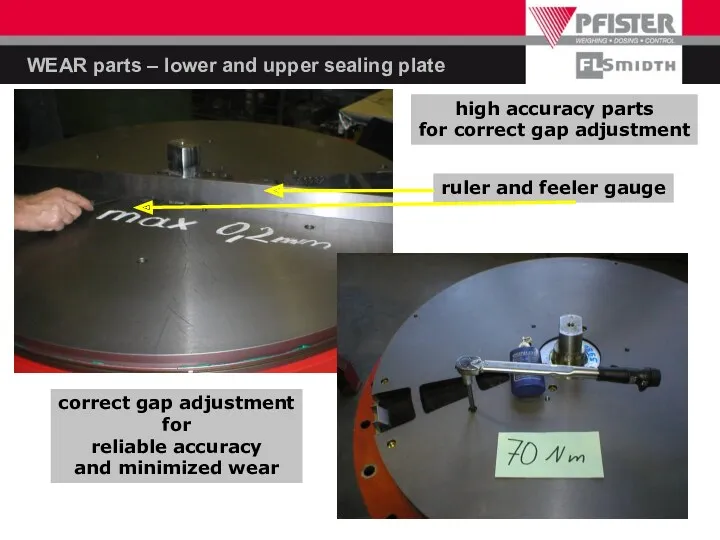

- 92. Quality of reworked wear parts Quality of reworked sealing plates and cellular wheel should be verified

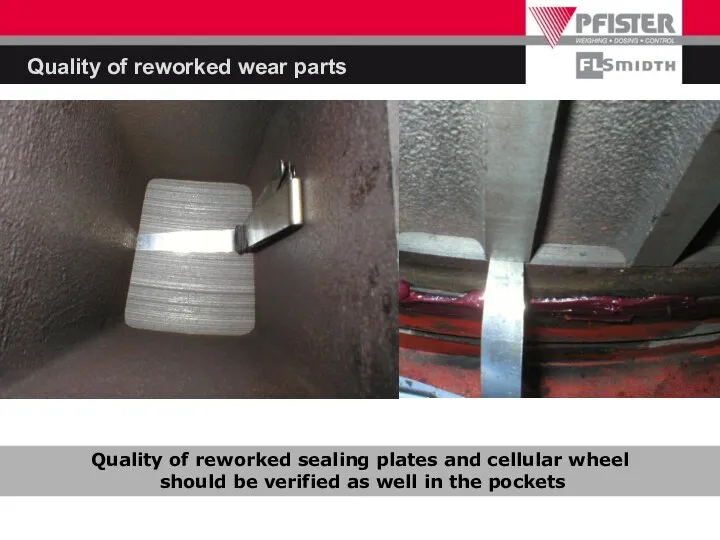

- 93. Wear rating Replace - rework - other action for DRW sealing plate? optical impression like a

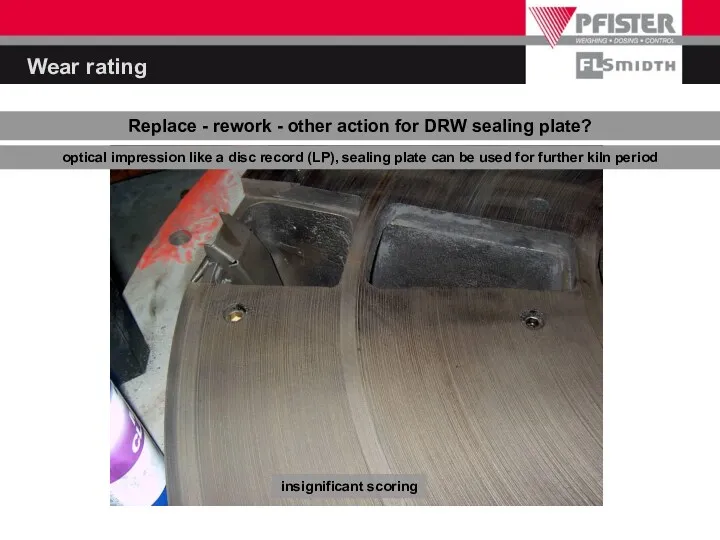

- 94. Wear rating Replace - rework - other action for DRW lower sealing plate? allowed tolerances exceeded

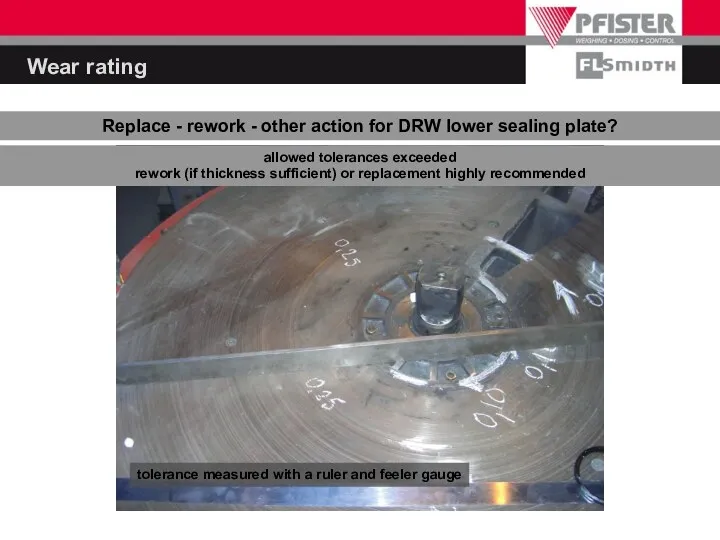

- 95. Wear rating Replace - rework - other action for DRW rotor wheel? measuring difficult, optical impression

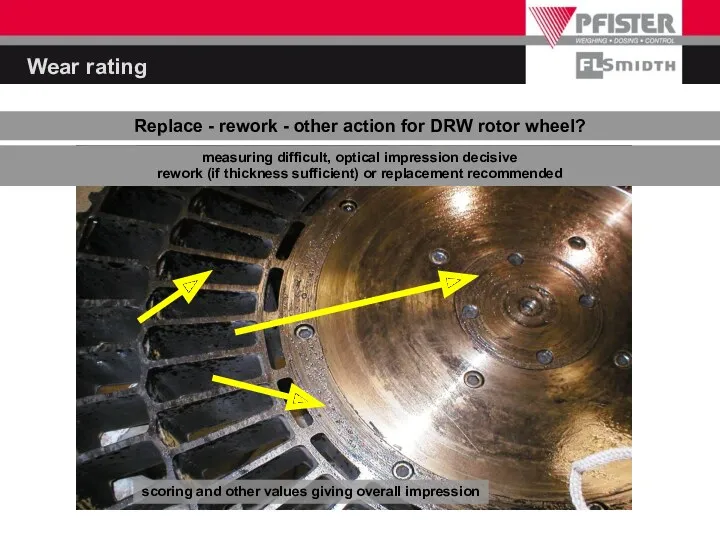

- 96. Wear rating Replace - rework - other action for DRW sealing plate? measuring difficult, optical impression

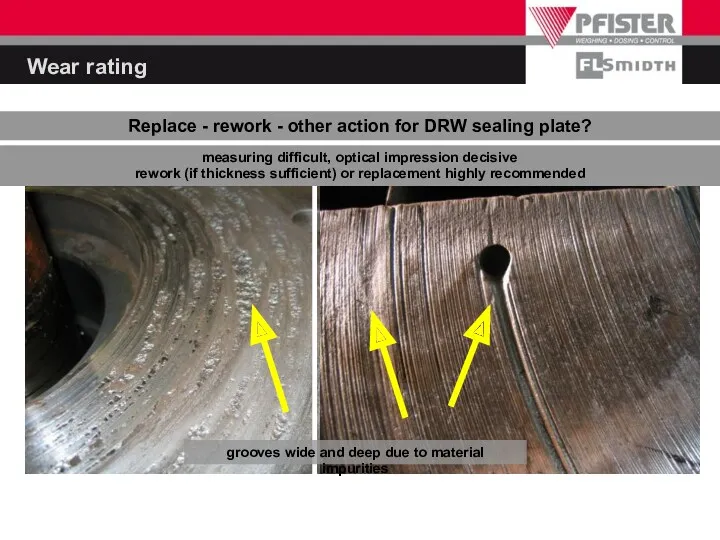

- 97. Wear rating air stream Replace - rework - other action for DRW sealing plate? measuring the

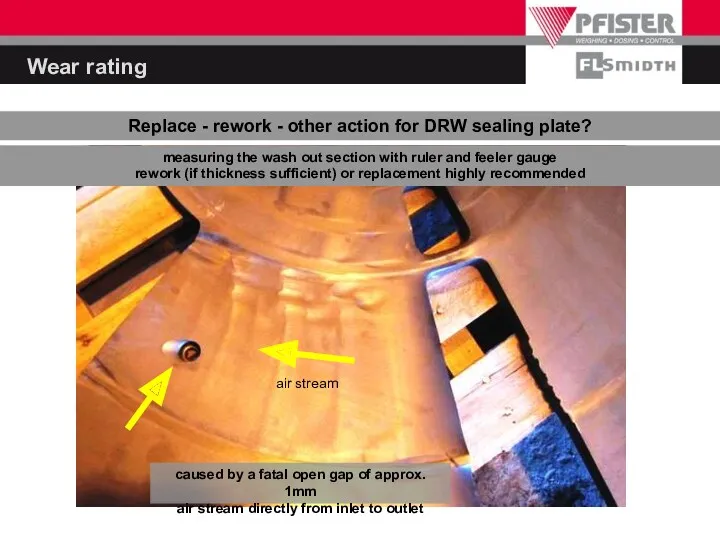

- 98. Wear rating Replace - rework - other action for DRW sealing plate? immediate replacement highly recommended

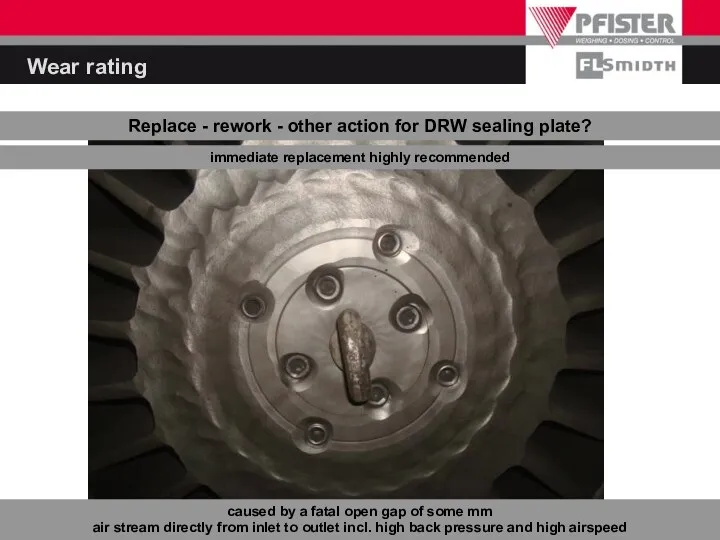

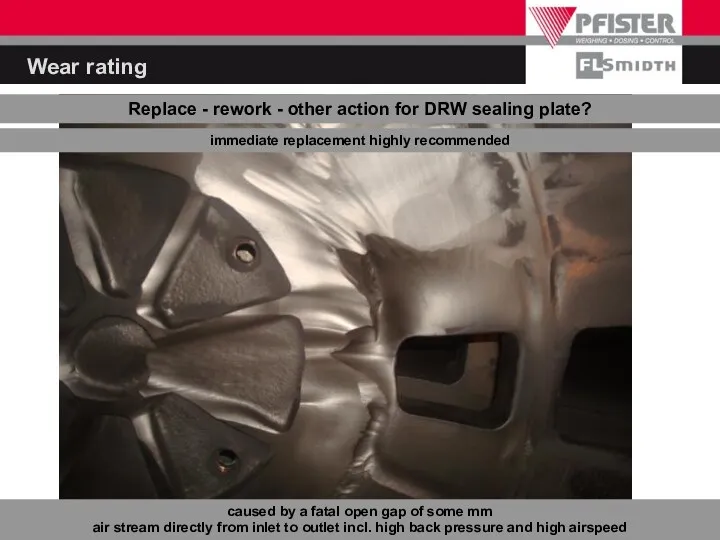

- 99. Wear rating Replace - rework - other action for DRW sealing plate? immediate replacement highly recommended

- 100. Preventive Maintenance - condition based recommendation to machine always the 4 sides upper side of the

- 101. Professional Rework Our team at Pfister Qingdao offers a professional rework of sealing plates and cellular

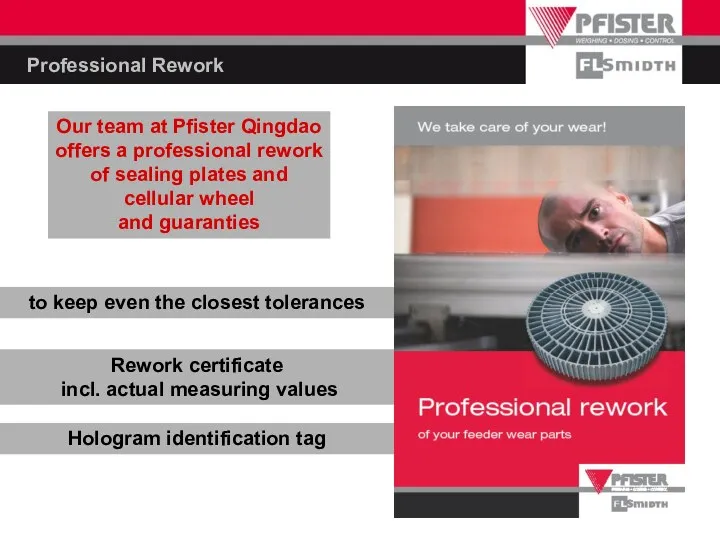

- 102. Most important documents Maintenance instructions 550.096.60.04. WA Repair instructions 550.096.60.04. IS

- 104. Скачать презентацию

Санкт-Петербургский государственный университет сервиса и экономики

Санкт-Петербургский государственный университет сервиса и экономики Развивающие цели урока

Развивающие цели урока Программы центра дополнительного образования детей, г. Череповец

Программы центра дополнительного образования детей, г. Череповец Программа государственной итоговой аттестации по направлению подготовки Государственное и муниципальное управление

Программа государственной итоговой аттестации по направлению подготовки Государственное и муниципальное управление Направление Сервис недвижимости

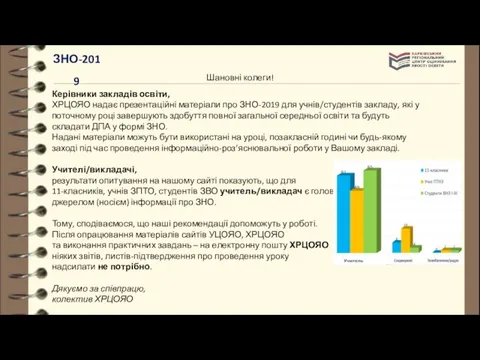

Направление Сервис недвижимости Матеріали про ЗНО-2019

Матеріали про ЗНО-2019 Виды самостоятельной работы и их характеристика

Виды самостоятельной работы и их характеристика Фарзандлар таълими!

Фарзандлар таълими! Відкрий свої двері до Європи - навчайся в Польщі

Відкрий свої двері до Європи - навчайся в Польщі Рабочие программы в соответствии с ФГОС и утвержденными изменениями

Рабочие программы в соответствии с ФГОС и утвержденными изменениями Жалпы білім беретін орта сыныптағы оқушылардың дене дайындылығының аймақтық аспектілері

Жалпы білім беретін орта сыныптағы оқушылардың дене дайындылығының аймақтық аспектілері Организация самостоятельной работы в ВУЗе

Организация самостоятельной работы в ВУЗе Родительское собрание во 2 классе

Родительское собрание во 2 классе г. Данилов Ярославская область. Районное методическое объединение ФГОС идёт в детский сад

г. Данилов Ярославская область. Районное методическое объединение ФГОС идёт в детский сад Понятие стратегического управления и его базовые модели

Понятие стратегического управления и его базовые модели Финал регионального чемпионата среди обучающихся общеобразовательных организаций и организаций дополнительного образования

Финал регионального чемпионата среди обучающихся общеобразовательных организаций и организаций дополнительного образования Методы и приемы организации ситуации успеха как одно из направлений повышения социализации учащихся.

Методы и приемы организации ситуации успеха как одно из направлений повышения социализации учащихся. Причины плохой успеваемости в школе

Причины плохой успеваемости в школе Выпускная квалификационная работа (дипломная работа). Макет

Выпускная квалификационная работа (дипломная работа). Макет Интерактивные методы обучения презентация

Интерактивные методы обучения презентация Дипломное проектирование

Дипломное проектирование Презентация Несколько слов о детских страхах

Презентация Несколько слов о детских страхах Викторина. Своя игра

Викторина. Своя игра Проектная деятельность во 2 классе на уроках и во внеурочное время

Проектная деятельность во 2 классе на уроках и во внеурочное время Виробнича психологічна діагностико-корекційна практика

Виробнича психологічна діагностико-корекційна практика Статья Создание единого информационного пространства школы как фактор повышения качества образования

Статья Создание единого информационного пространства школы как фактор повышения качества образования Презентация Олимпиадная школа

Презентация Олимпиадная школа До свидания, 1 класс

До свидания, 1 класс