Содержание

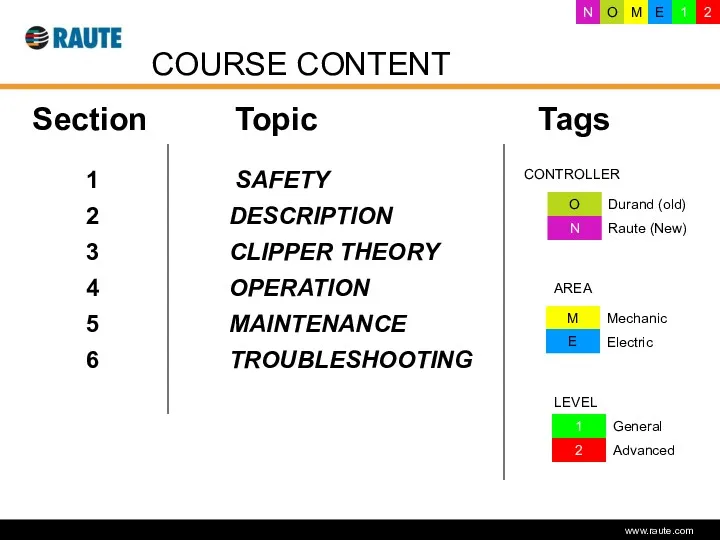

- 2. Version 1.0 - June 2006 COURSE CONTENT M E 1 2 N O SAFETY DESCRIPTION CLIPPER

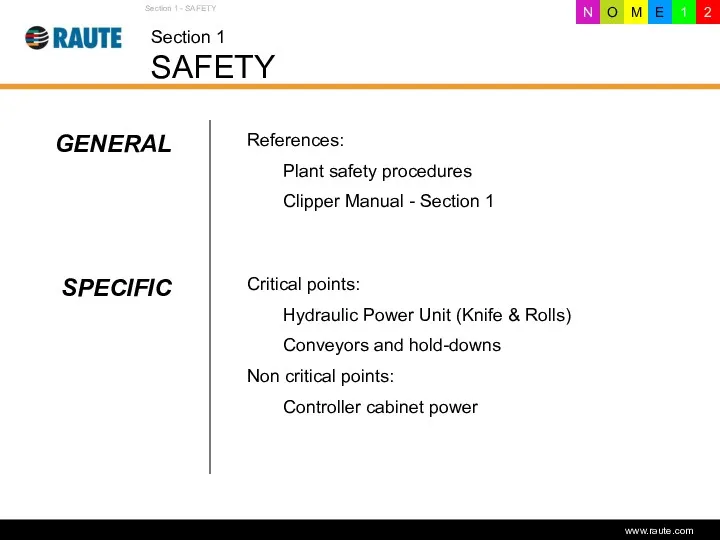

- 3. Version 1.0 - June 2006 Section 1 SAFETY GENERAL SPECIFIC References: Plant safety procedures Clipper Manual

- 4. Version 1.0 - June 2006 Section 1 SAFETY Section 1 - SAFETY M E 1 IMPORTANT:

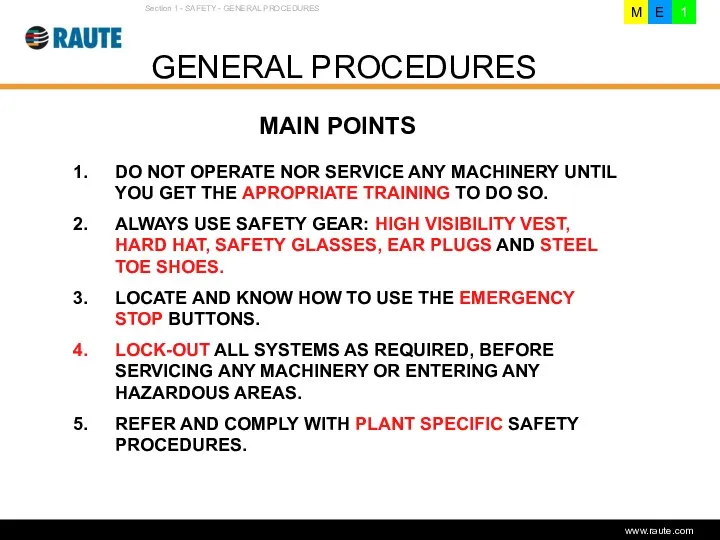

- 5. Version 1.0 - June 2006 GENERAL PROCEDURES Section 1 - SAFETY - GENERAL PROCEDURES M E

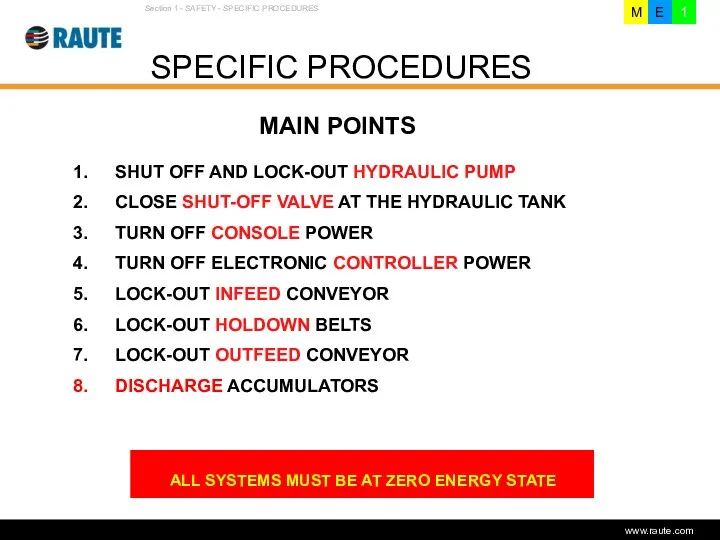

- 6. Version 1.0 - June 2006 SPECIFIC PROCEDURES Section 1 - SAFETY - SPECIFIC PROCEDURES M E

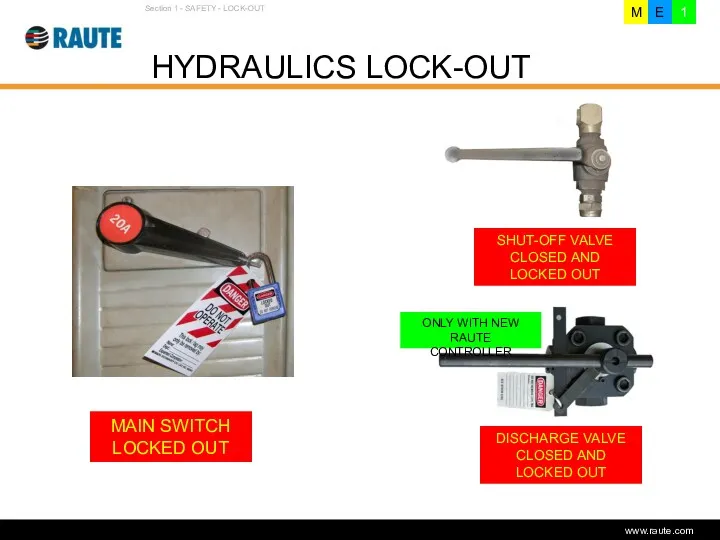

- 7. Version 1.0 - June 2006 HYDRAULICS LOCK-OUT Section 1 - SAFETY - LOCK-OUT M E 1

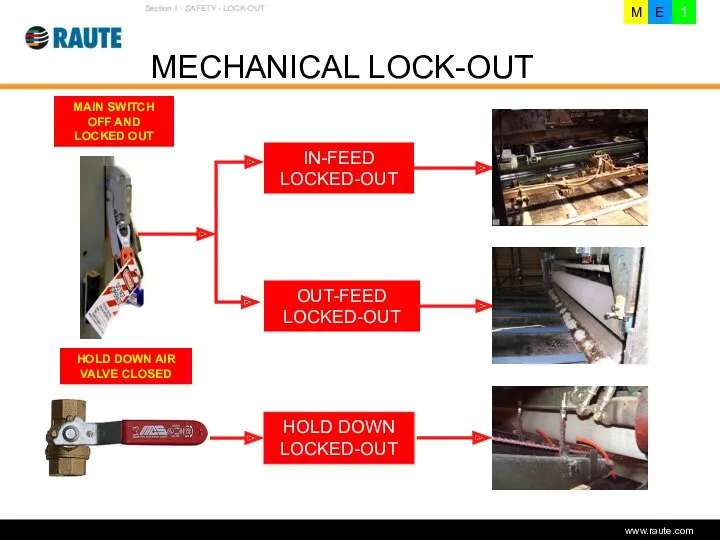

- 8. Version 1.0 - June 2006 MECHANICAL LOCK-OUT Section 1 - SAFETY - LOCK-OUT M E 1

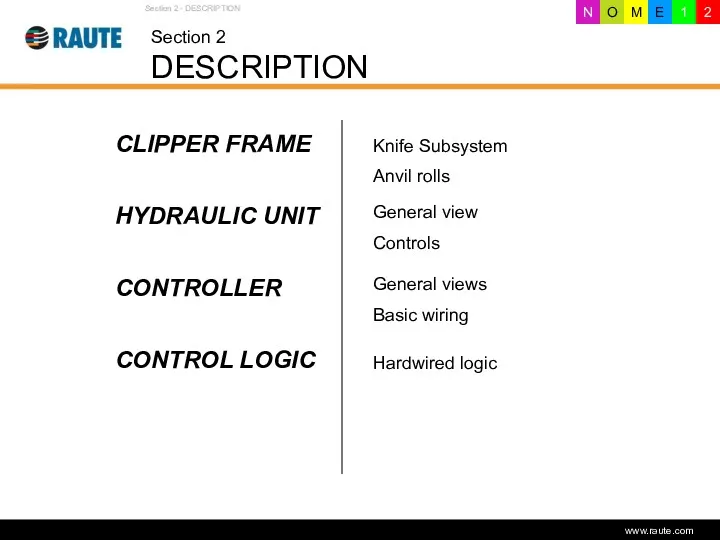

- 9. Version 1.0 - June 2006 Section 2 DESCRIPTION CLIPPER FRAME HYDRAULIC UNIT Knife Subsystem Anvil rolls

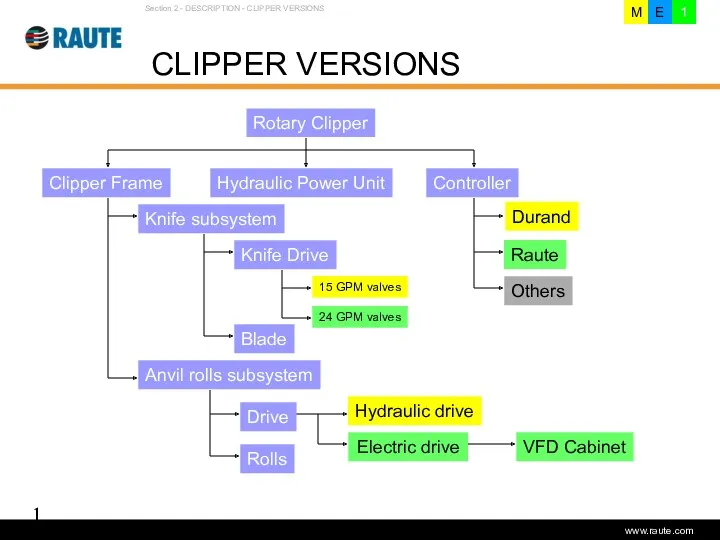

- 10. Version 1.0 - June 2006 CLIPPER VERSIONS Rotary Clipper Clipper Frame Knife subsystem Knife Drive Blade

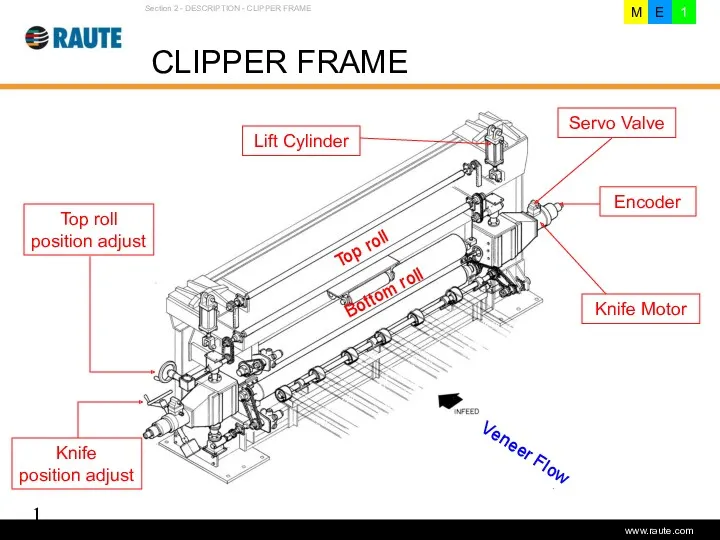

- 11. Version 1.0 - June 2006 CLIPPER FRAME Section 2 - DESCRIPTION - CLIPPER FRAME E 1

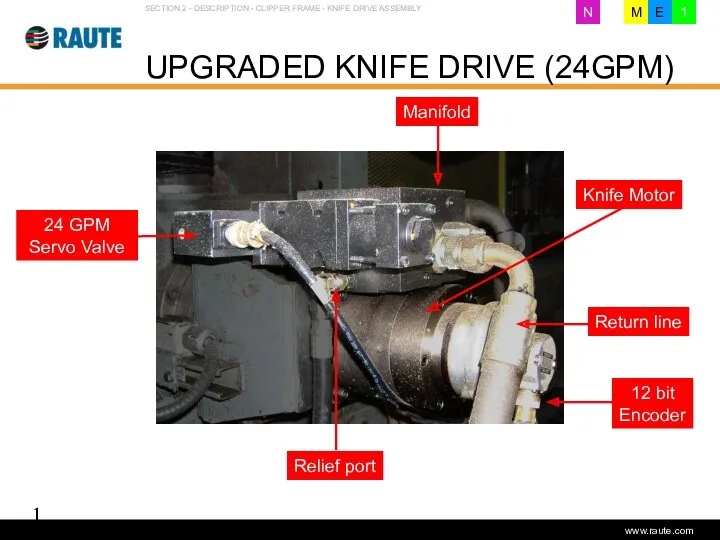

- 12. Version 1.0 - June 2006 UPGRADED KNIFE DRIVE (24GPM) SECTION 2 - DESCRIPTION - CLIPPER FRAME

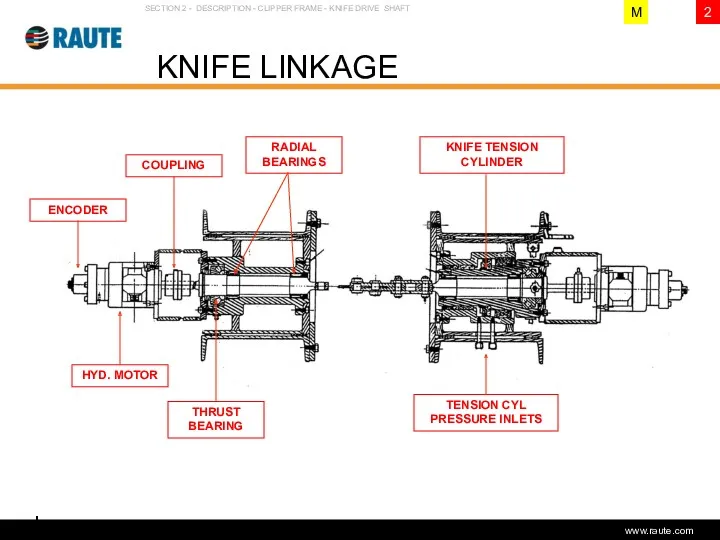

- 13. Version 1.0 - June 2006 KNIFE LINKAGE SECTION 2 - DESCRIPTION - CLIPPER FRAME - KNIFE

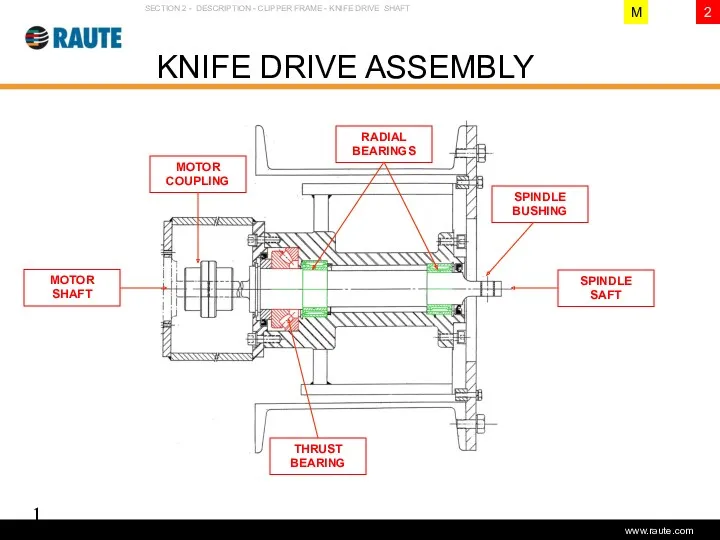

- 14. Version 1.0 - June 2006 KNIFE DRIVE ASSEMBLY SECTION 2 - DESCRIPTION - CLIPPER FRAME -

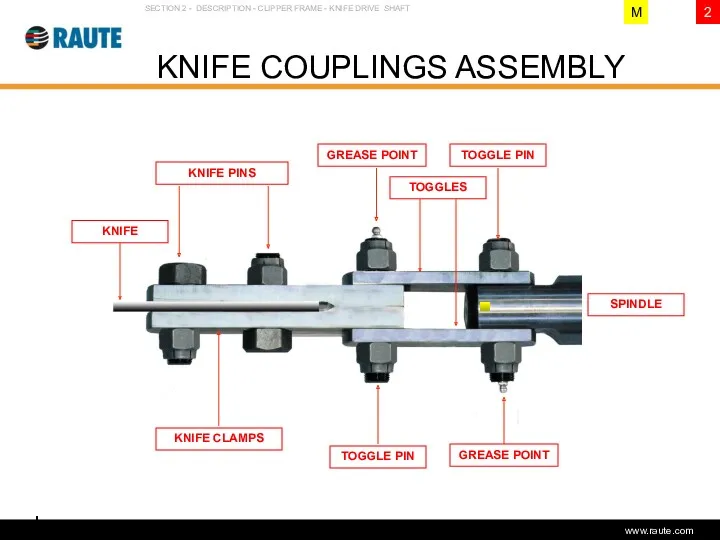

- 15. Version 1.0 - June 2006 KNIFE COUPLINGS ASSEMBLY SECTION 2 - DESCRIPTION - CLIPPER FRAME -

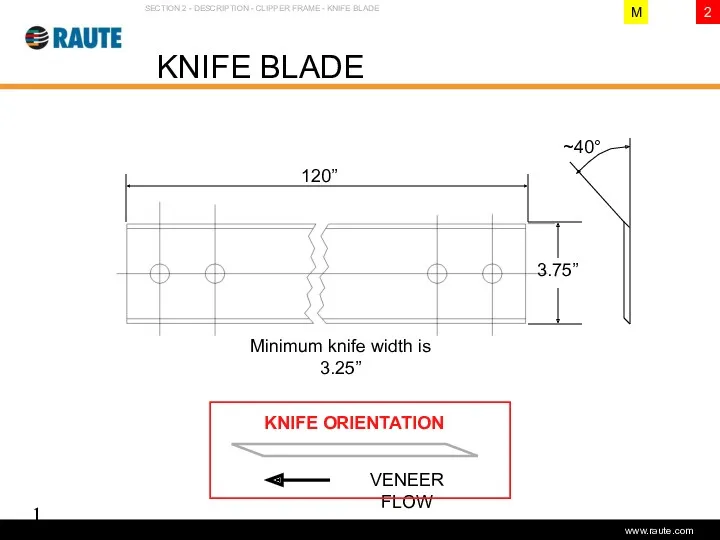

- 16. Version 1.0 - June 2006 KNIFE BLADE SECTION 2 - DESCRIPTION - CLIPPER FRAME - KNIFE

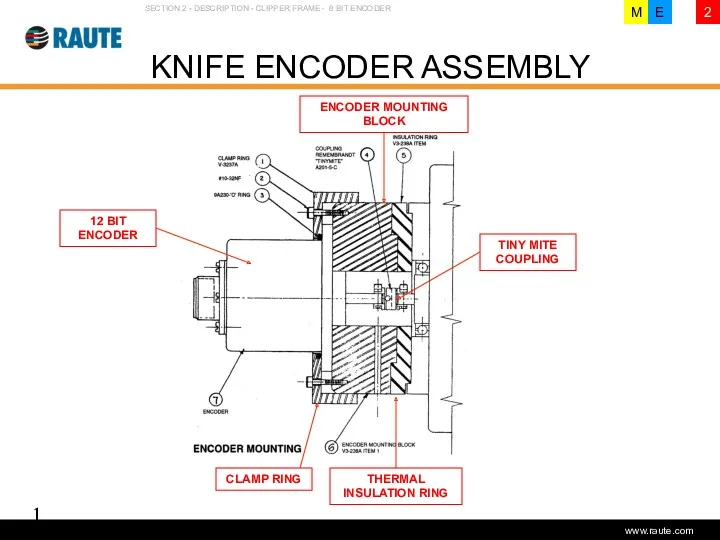

- 17. Version 1.0 - June 2006 KNIFE ENCODER ASSEMBLY SECTION 2 - DESCRIPTION - CLIPPER FRAME -

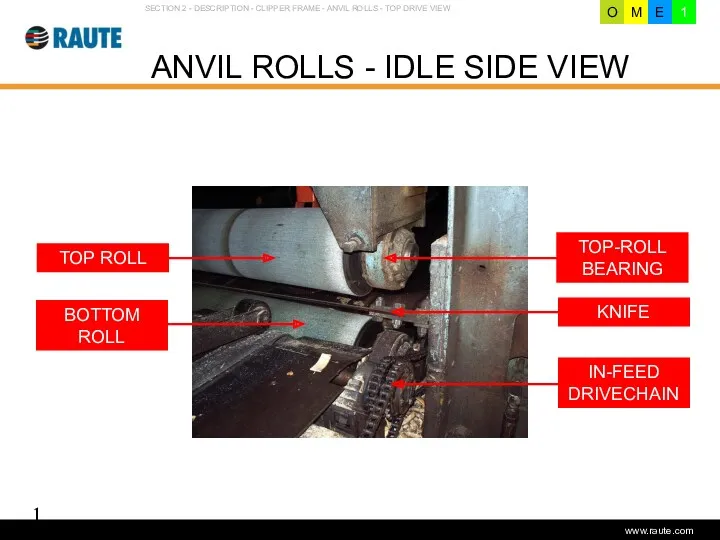

- 18. Version 1.0 - June 2006 ANVIL ROLLS - IDLE SIDE VIEW IN-FEED DRIVECHAIN SECTION 2 -

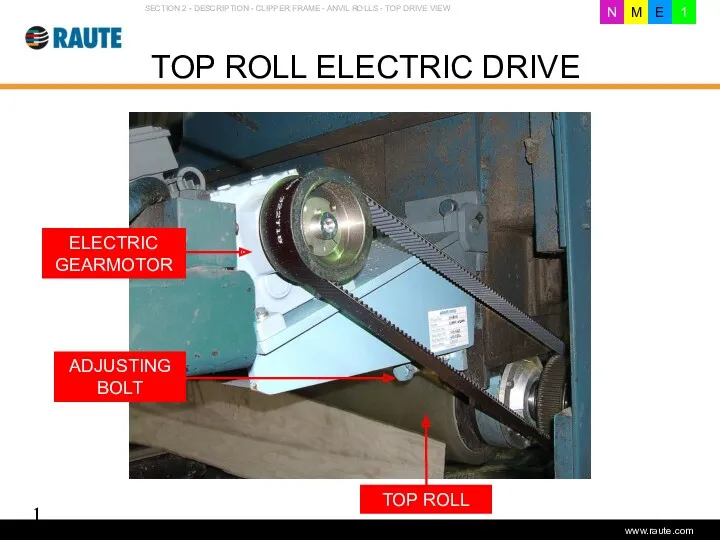

- 19. Version 1.0 - June 2006 TOP ROLL ELECTRIC DRIVE SECTION 2 - DESCRIPTION - CLIPPER FRAME

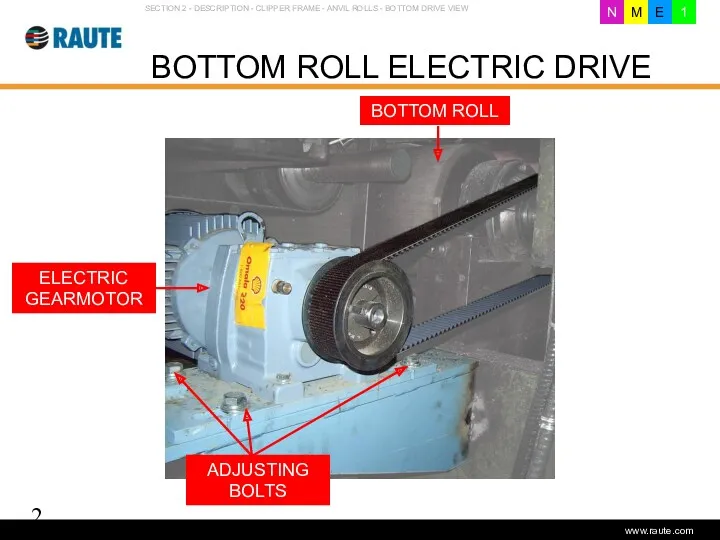

- 20. Version 1.0 - June 2006 BOTTOM ROLL ELECTRIC DRIVE SECTION 2 - DESCRIPTION - CLIPPER FRAME

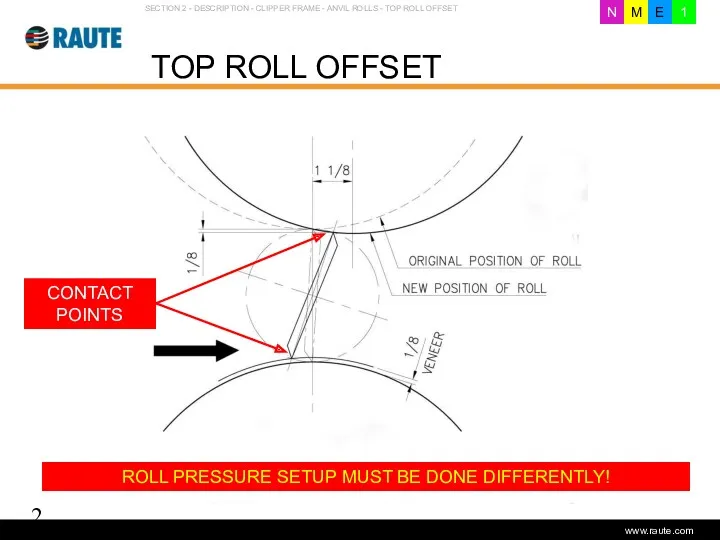

- 21. Version 1.0 - June 2006 TOP ROLL OFFSET SECTION 2 - DESCRIPTION - CLIPPER FRAME -

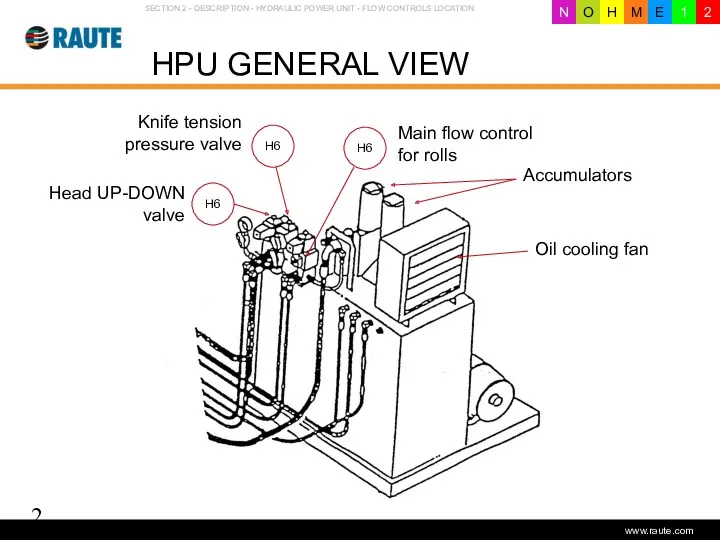

- 22. Version 1.0 - June 2006 HPU GENERAL VIEW SECTION 2 - DESCRIPTION - HYDRAULIC POWER UNIT

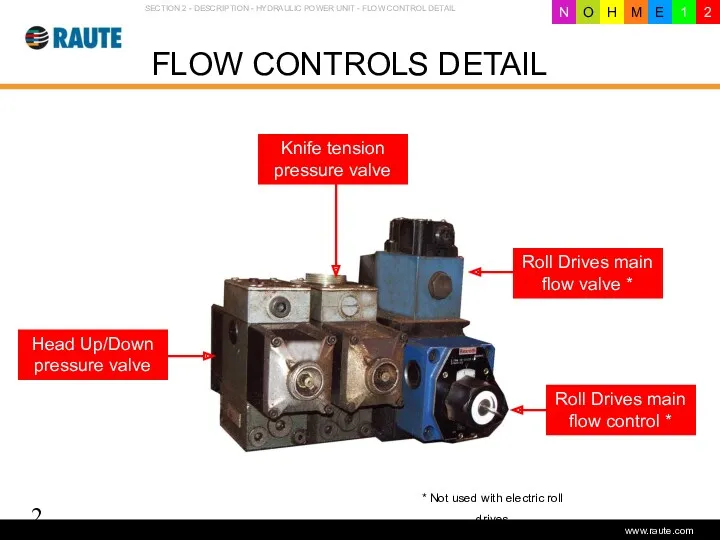

- 23. Version 1.0 - June 2006 FLOW CONTROLS DETAIL SECTION 2 - DESCRIPTION - HYDRAULIC POWER UNIT

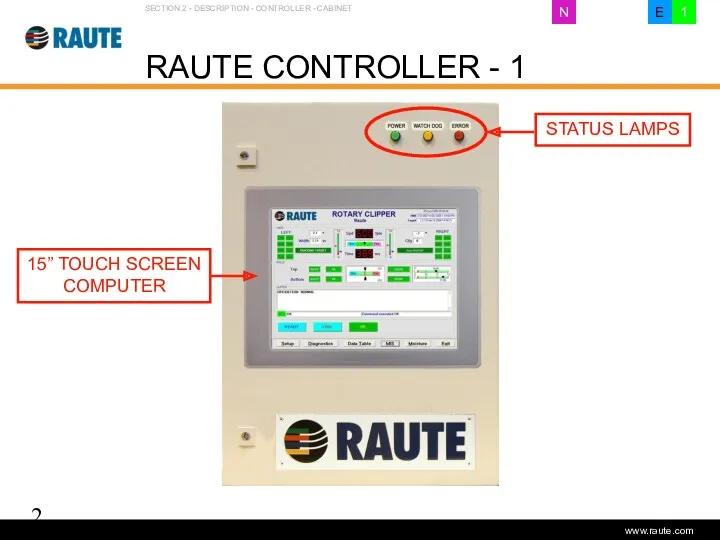

- 24. Version 1.0 - June 2006 RAUTE CONTROLLER - 1 SECTION 2 - DESCRIPTION - CONTROLLER -

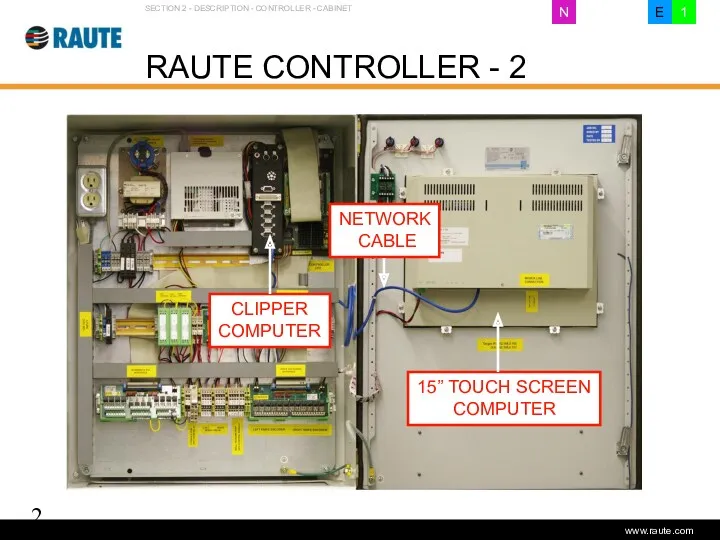

- 25. Version 1.0 - June 2006 RAUTE CONTROLLER - 2 SECTION 2 - DESCRIPTION - CONTROLLER -

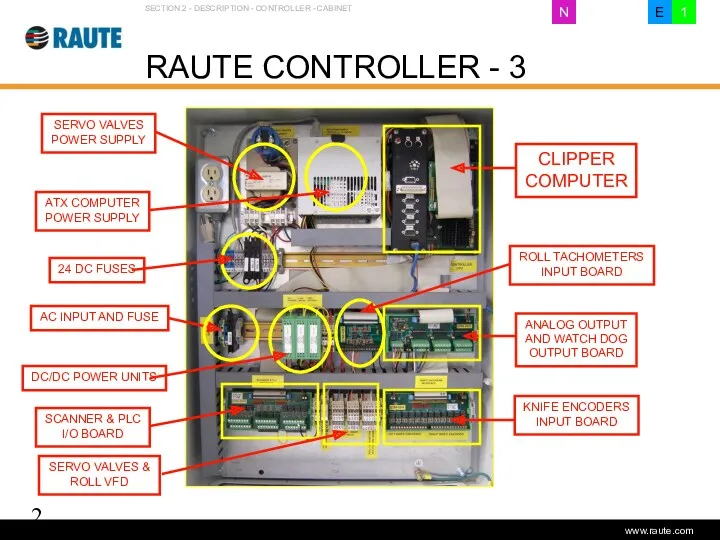

- 26. Version 1.0 - June 2006 RAUTE CONTROLLER - 3 SECTION 2 - DESCRIPTION - CONTROLLER -

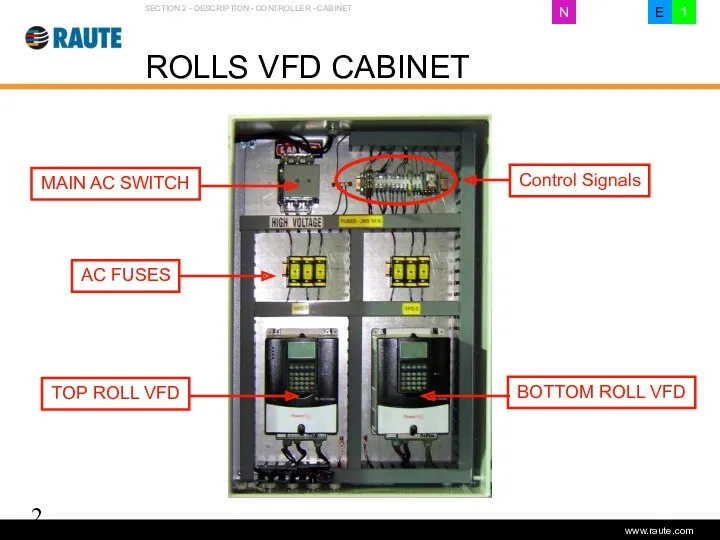

- 27. Version 1.0 - June 2006 ROLLS VFD CABINET SECTION 2 - DESCRIPTION - CONTROLLER - CABINET

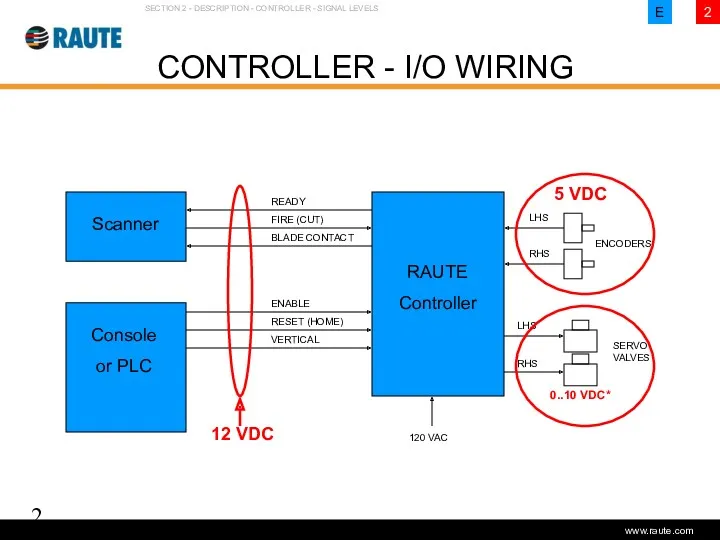

- 28. Version 1.0 - June 2006 CONTROLLER - I/O WIRING SECTION 2 - DESCRIPTION - CONTROLLER -

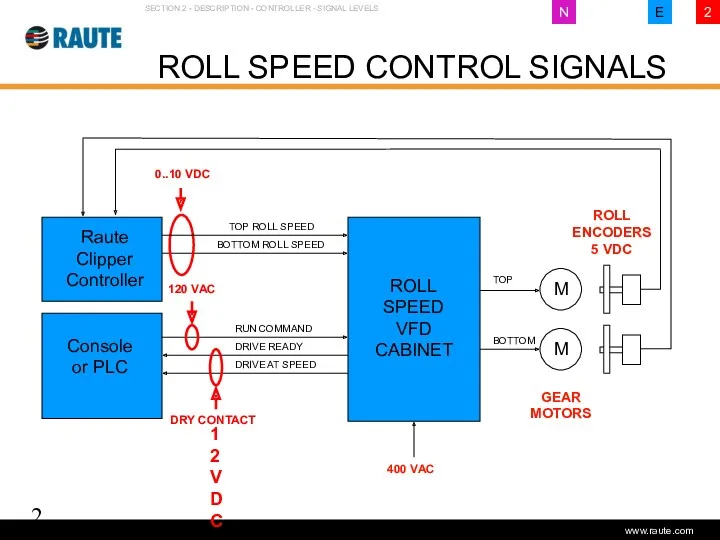

- 29. Version 1.0 - June 2006 ROLL SPEED CONTROL SIGNALS 12 VDC SECTION 2 - DESCRIPTION -

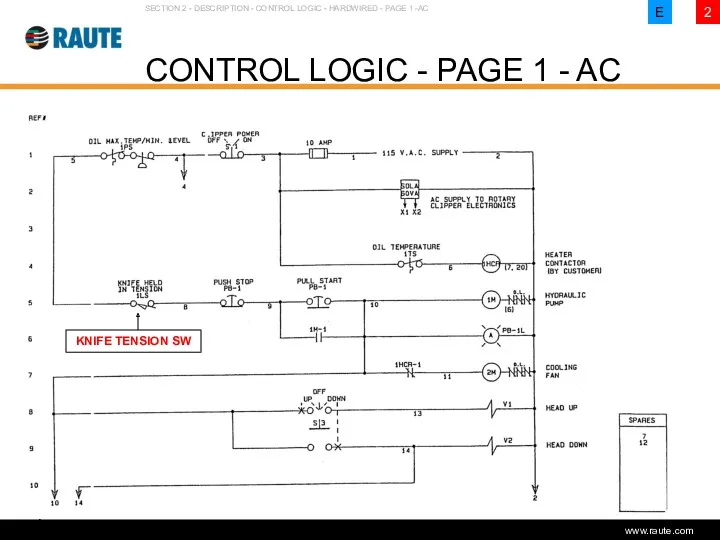

- 30. Version 1.0 - June 2006 CONTROL LOGIC - PAGE 1 - AC KNIFE TENSION SW SECTION

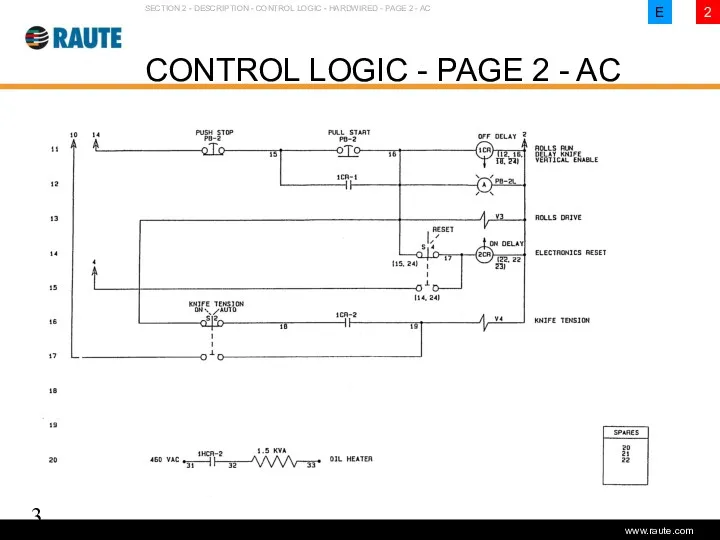

- 31. Version 1.0 - June 2006 SECTION 2 - DESCRIPTION - CONTROL LOGIC - HARDWIRED - PAGE

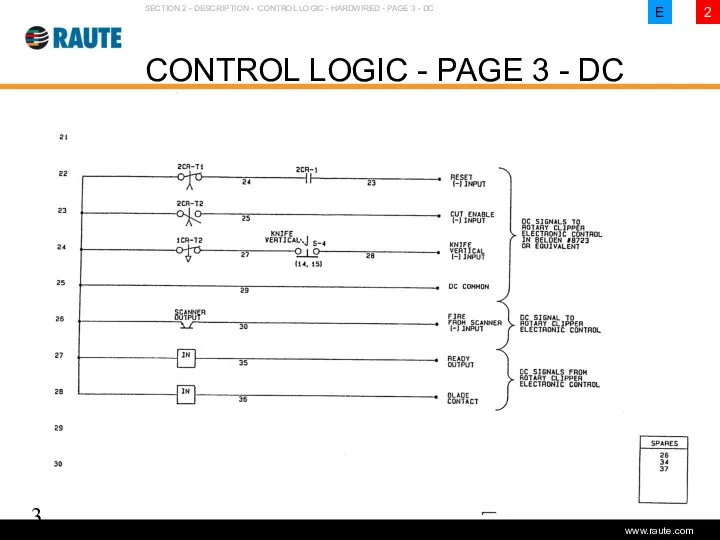

- 32. Version 1.0 - June 2006 SECTION 2 - DESCRIPTION - CONTROL LOGIC - HARDWIRED - PAGE

- 33. Version 1.0 - June 2006 SECTION 3 - CLIPPER THEORY CLIPPER GOALS Exact clip point Parallel

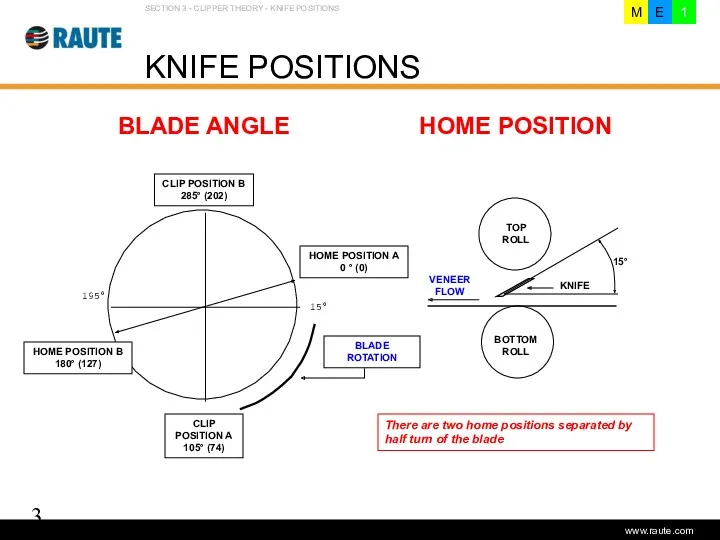

- 34. Version 1.0 - June 2006 KNIFE POSITIONS SECTION 3 - CLIPPER THEORY - KNIFE POSITIONS M

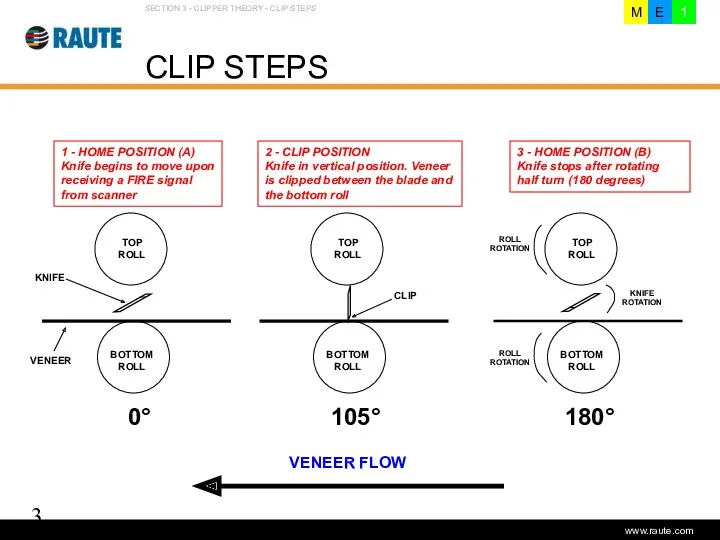

- 35. Version 1.0 - June 2006 CLIP STEPS SECTION 3 - CLIPPER THEORY - CLIP STEPS VENEER

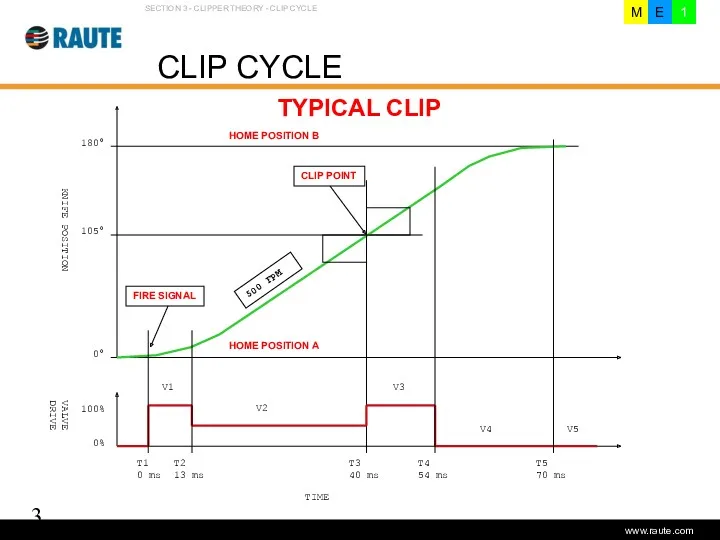

- 36. Version 1.0 - June 2006 CLIP CYCLE SECTION 3 - CLIPPER THEORY - CLIP CYCLE M

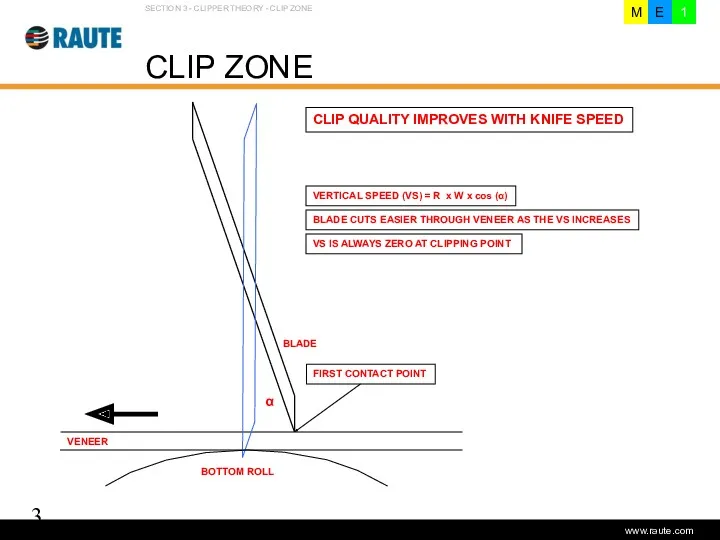

- 37. Version 1.0 - June 2006 CLIP ZONE VERTICAL SPEED (VS) = R x W x cos

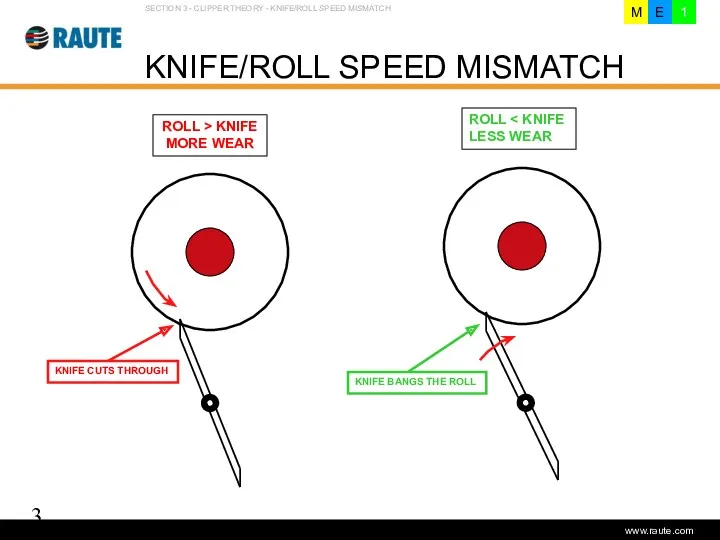

- 38. Version 1.0 - June 2006 KNIFE/ROLL SPEED MISMATCH SECTION 3 - CLIPPER THEORY - KNIFE/ROLL SPEED

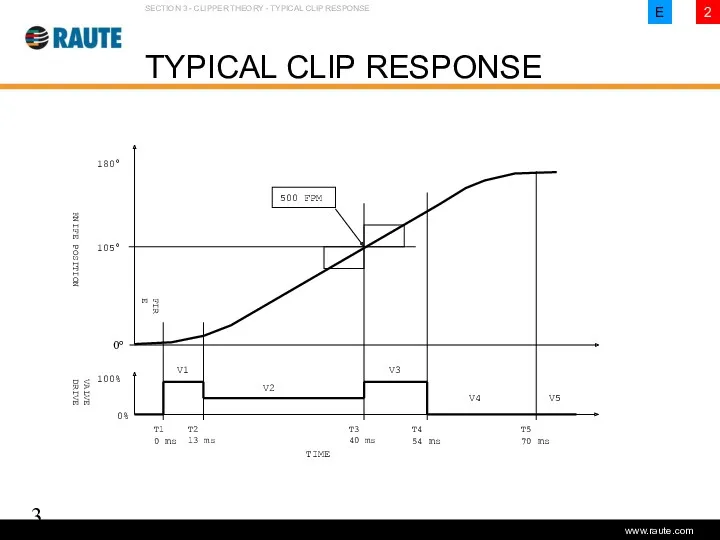

- 39. Version 1.0 - June 2006 TYPICAL CLIP RESPONSE SECTION 3 - CLIPPER THEORY - TYPICAL CLIP

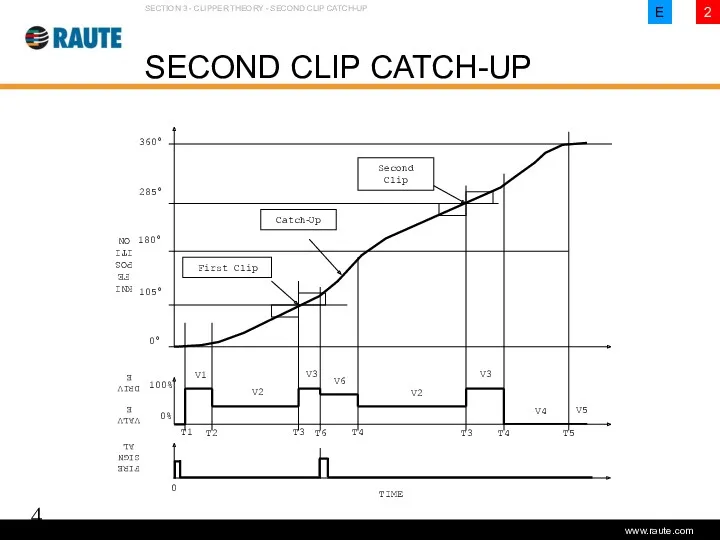

- 40. Version 1.0 - June 2006 SECOND CLIP CATCH-UP SECTION 3 - CLIPPER THEORY - SECOND CLIP

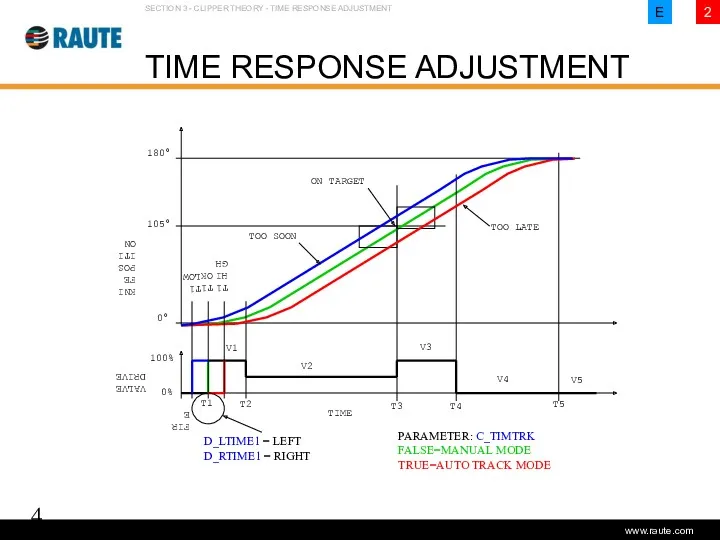

- 41. Version 1.0 - June 2006 TIME RESPONSE ADJUSTMENT SECTION 3 - CLIPPER THEORY - TIME RESPONSE

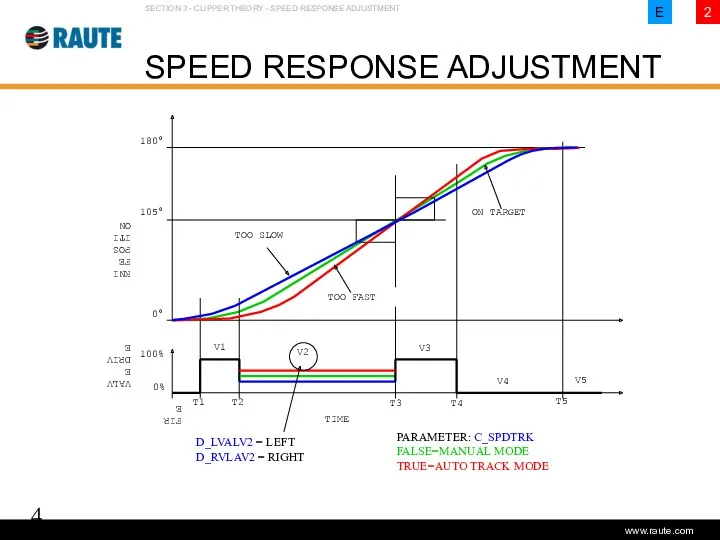

- 42. Version 1.0 - June 2006 SPEED RESPONSE ADJUSTMENT SECTION 3 - CLIPPER THEORY - SPEED RESPONSE

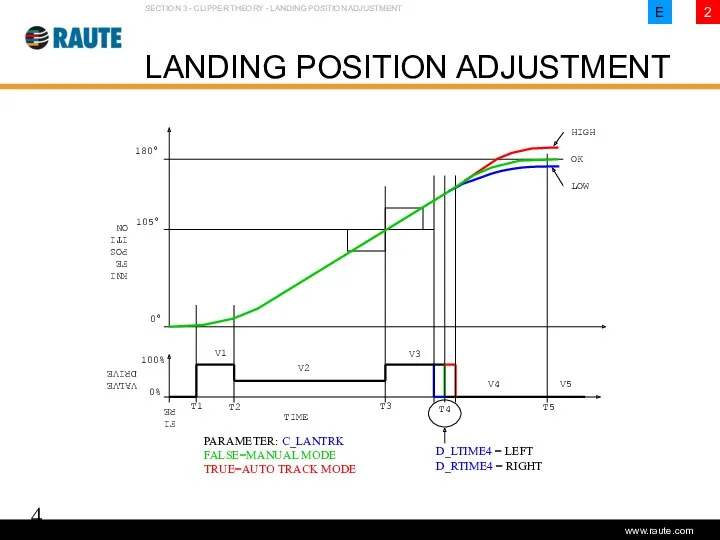

- 43. Version 1.0 - June 2006 LANDING POSITION ADJUSTMENT SECTION 3 - CLIPPER THEORY - LANDING POSITION

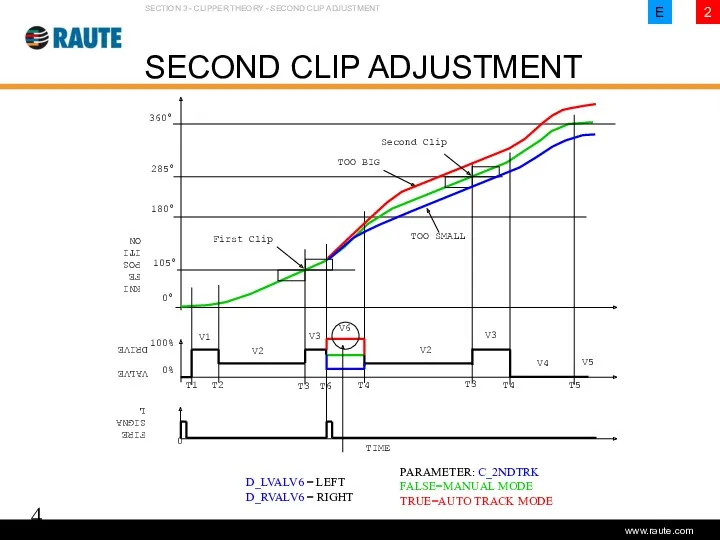

- 44. Version 1.0 - June 2006 SECOND CLIP ADJUSTMENT SECTION 3 - CLIPPER THEORY - SECOND CLIP

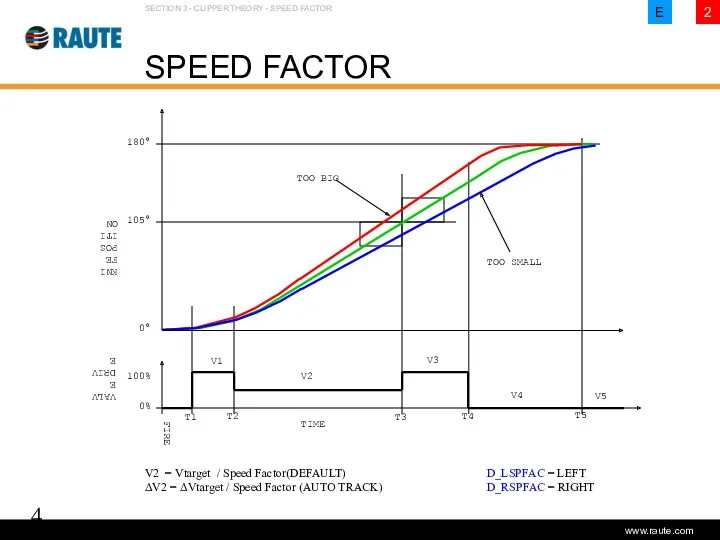

- 45. Version 1.0 - June 2006 SPEED FACTOR SECTION 3 - CLIPPER THEORY - SPEED FACTOR E

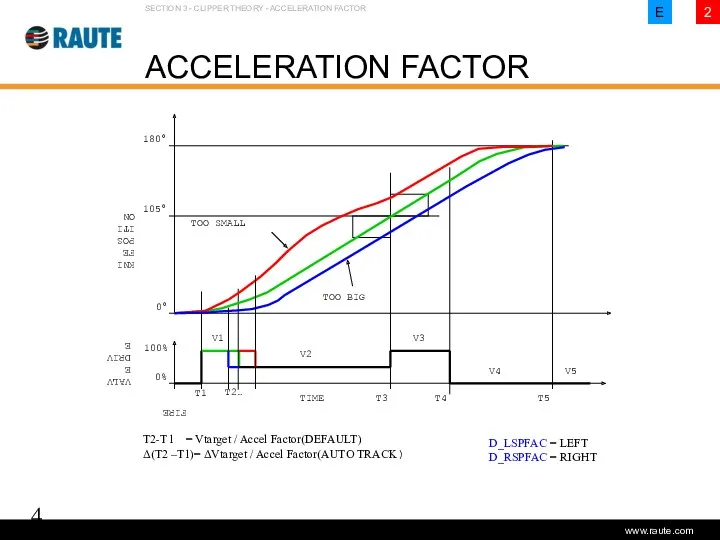

- 46. Version 1.0 - June 2006 ACCELERATION FACTOR SECTION 3 - CLIPPER THEORY - ACCELERATION FACTOR E

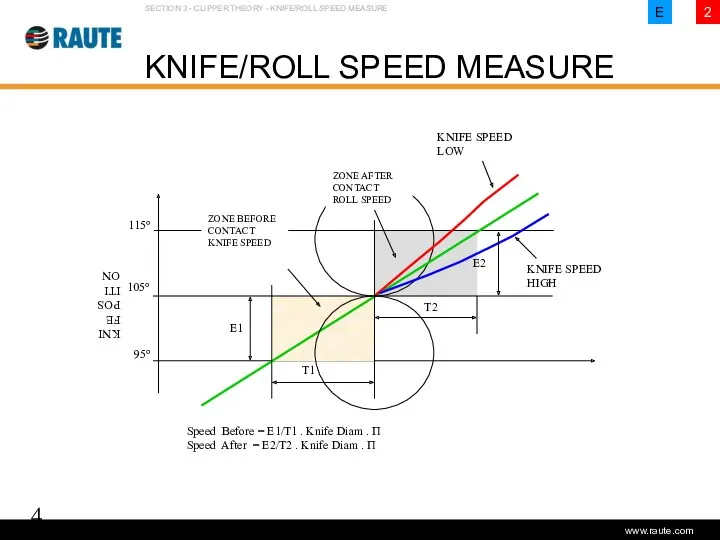

- 47. Version 1.0 - June 2006 KNIFE/ROLL SPEED MEASURE SECTION 3 - CLIPPER THEORY - KNIFE/ROLL SPEED

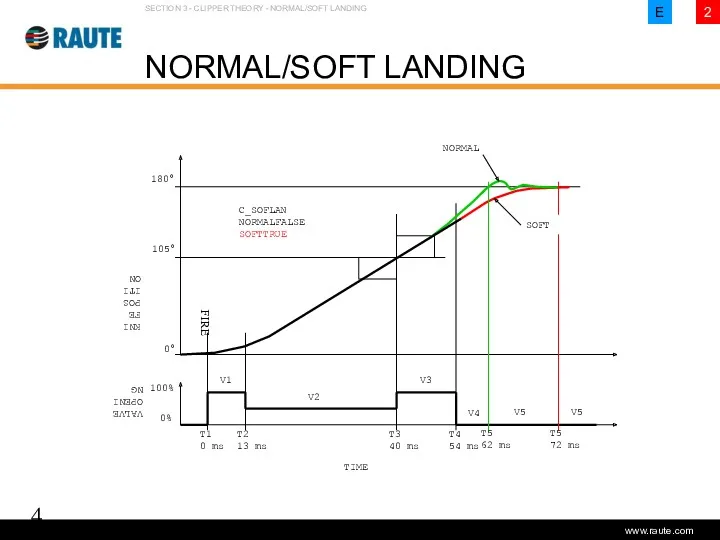

- 48. Version 1.0 - June 2006 NORMAL/SOFT LANDING SECTION 3 - CLIPPER THEORY - NORMAL/SOFT LANDING E

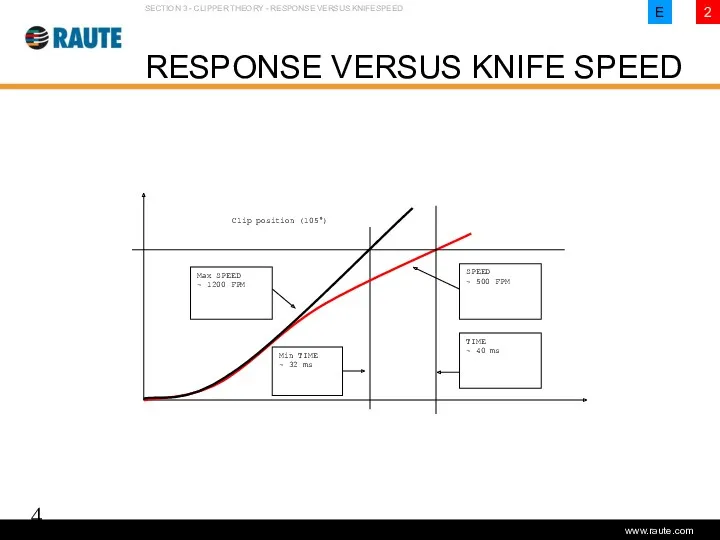

- 49. Version 1.0 - June 2006 RESPONSE VERSUS KNIFE SPEED SECTION 3 - CLIPPER THEORY - RESPONSE

- 50. Version 1.0 - June 2006 SECTION 4 OPERATION CONTROLLER Operator’s PB and SW console CLIPPER CONSOLE

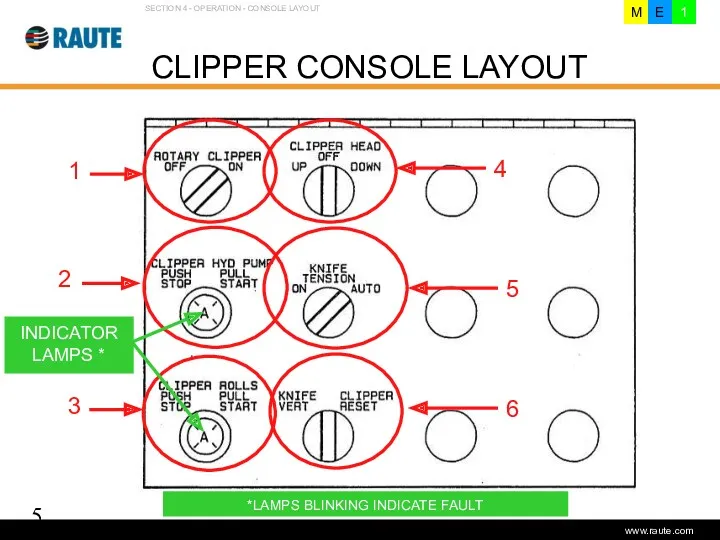

- 51. Version 1.0 - June 2006 CLIPPER CONSOLE LAYOUT SECTION 4 - OPERATION - CONSOLE LAYOUT M

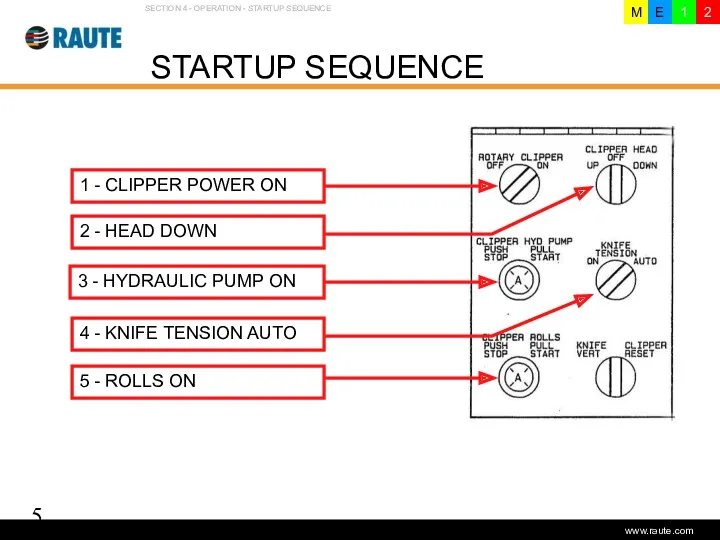

- 52. Version 1.0 - June 2006 STARTUP SEQUENCE SECTION 4 - OPERATION - STARTUP SEQUENCE M E

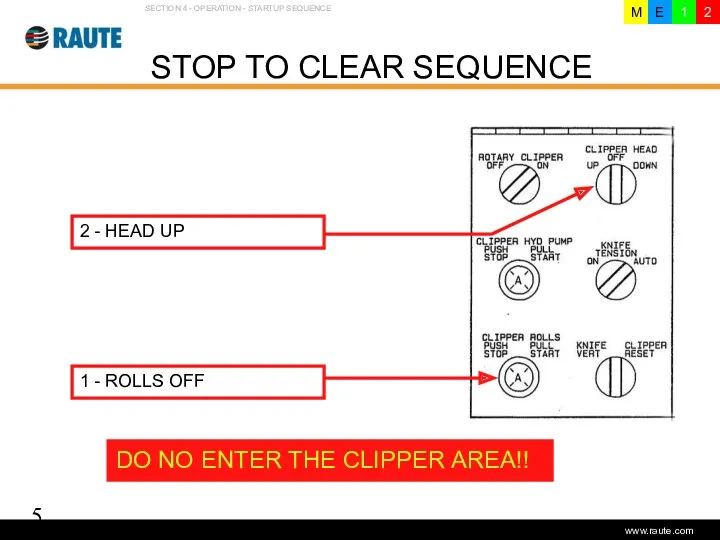

- 53. Version 1.0 - June 2006 STOP TO CLEAR SEQUENCE SECTION 4 - OPERATION - STARTUP SEQUENCE

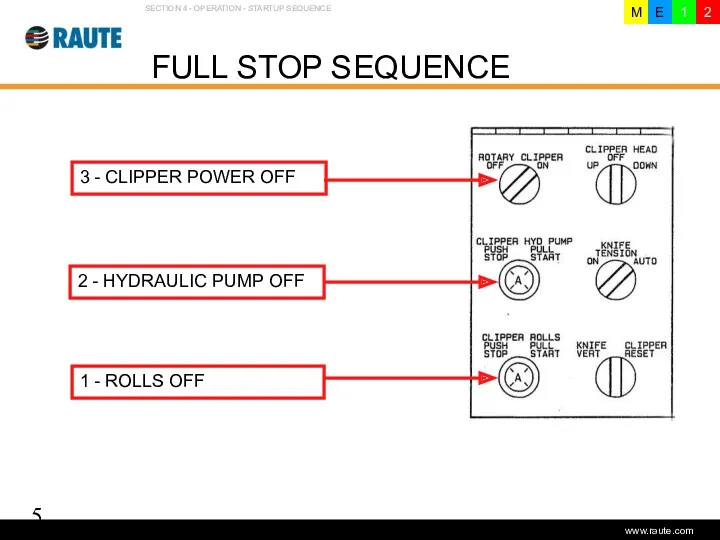

- 54. Version 1.0 - June 2006 FULL STOP SEQUENCE SECTION 4 - OPERATION - STARTUP SEQUENCE M

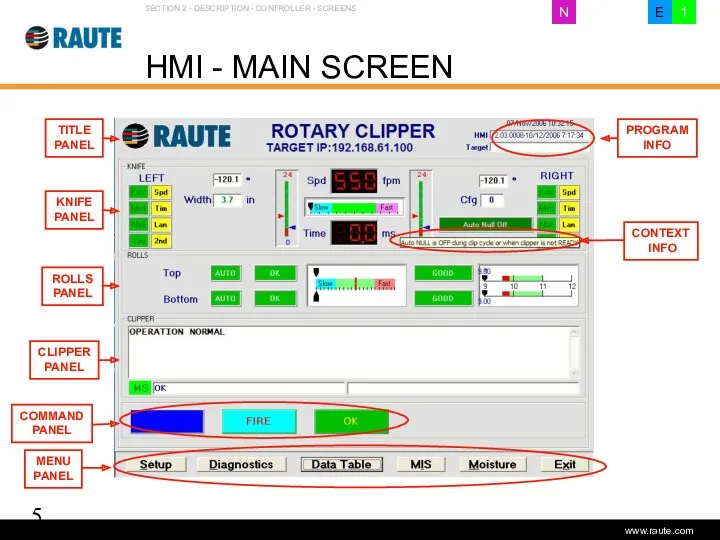

- 55. Version 1.0 - June 2006 HMI - MAIN SCREEN SECTION 2 - DESCRIPTION - CONTROLLER -

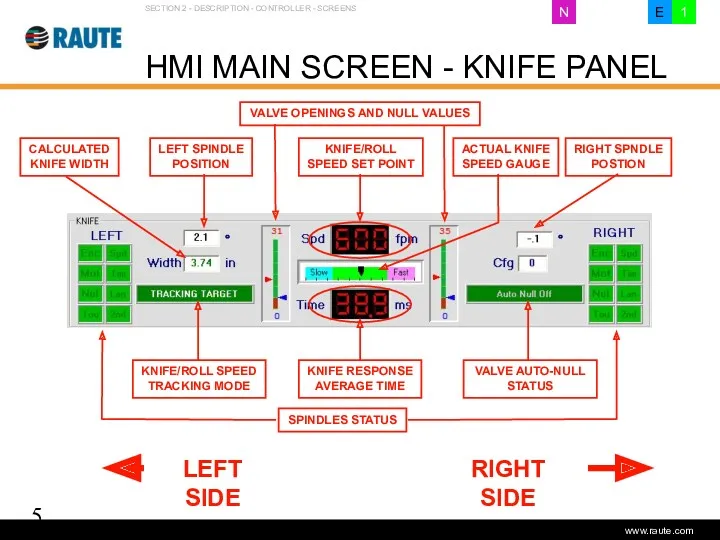

- 56. Version 1.0 - June 2006 HMI MAIN SCREEN - KNIFE PANEL SECTION 2 - DESCRIPTION -

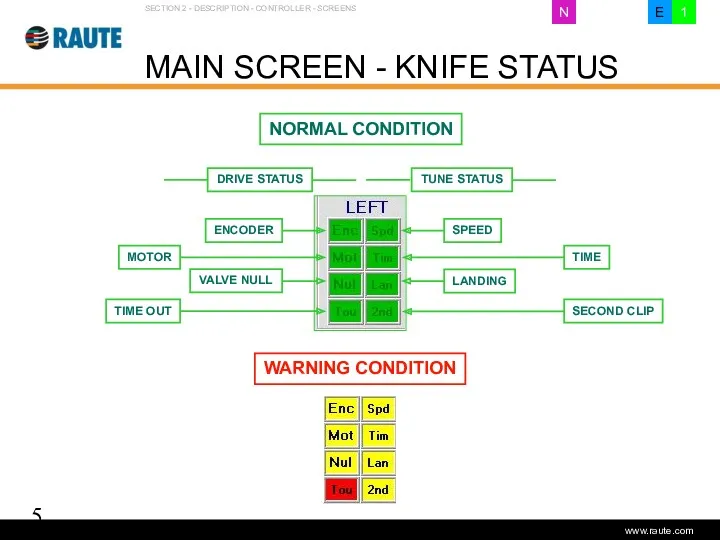

- 57. Version 1.0 - June 2006 MAIN SCREEN - KNIFE STATUS SECTION 2 - DESCRIPTION - CONTROLLER

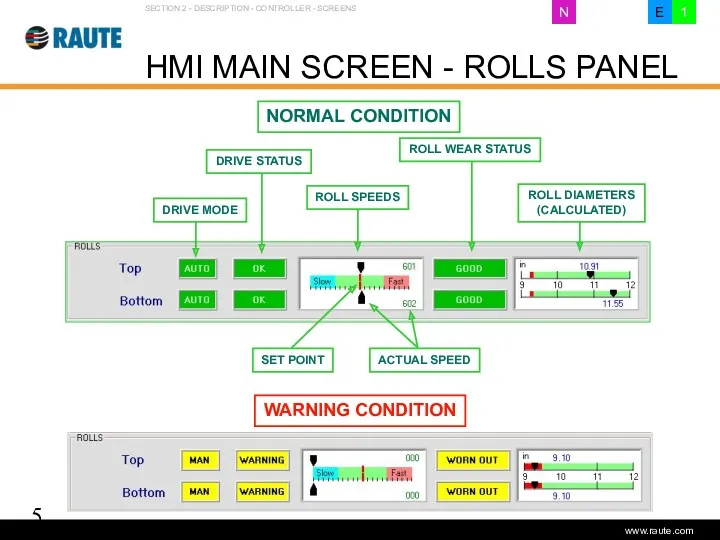

- 58. Version 1.0 - June 2006 HMI MAIN SCREEN - ROLLS PANEL SECTION 2 - DESCRIPTION -

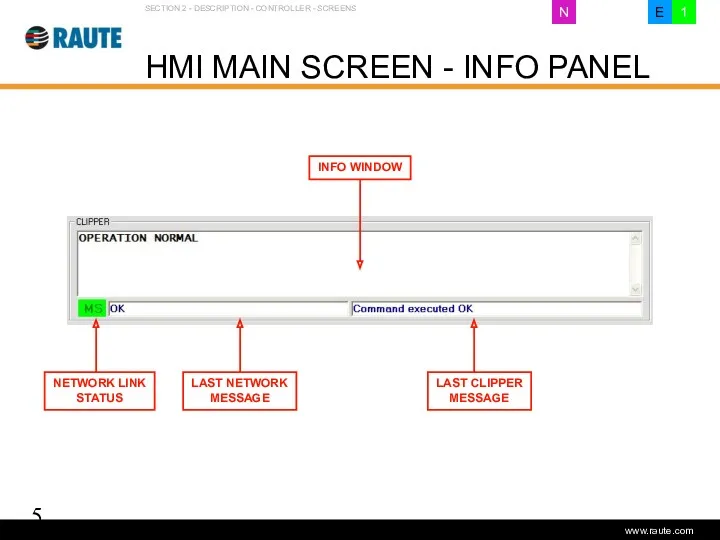

- 59. Version 1.0 - June 2006 HMI MAIN SCREEN - INFO PANEL SECTION 2 - DESCRIPTION -

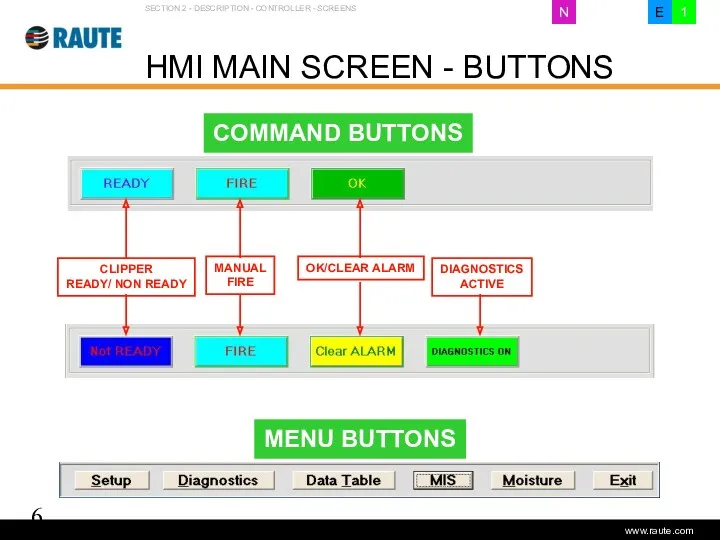

- 60. Version 1.0 - June 2006 HMI MAIN SCREEN - BUTTONS SECTION 2 - DESCRIPTION - CONTROLLER

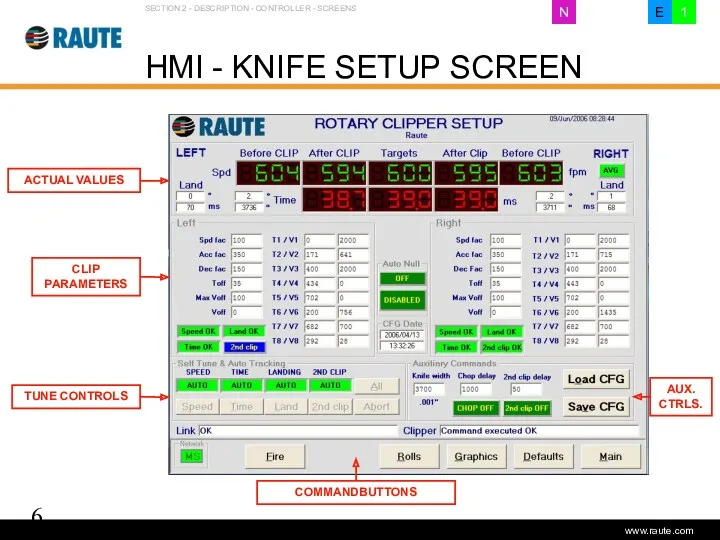

- 61. Version 1.0 - June 2006 HMI - KNIFE SETUP SCREEN SECTION 2 - DESCRIPTION - CONTROLLER

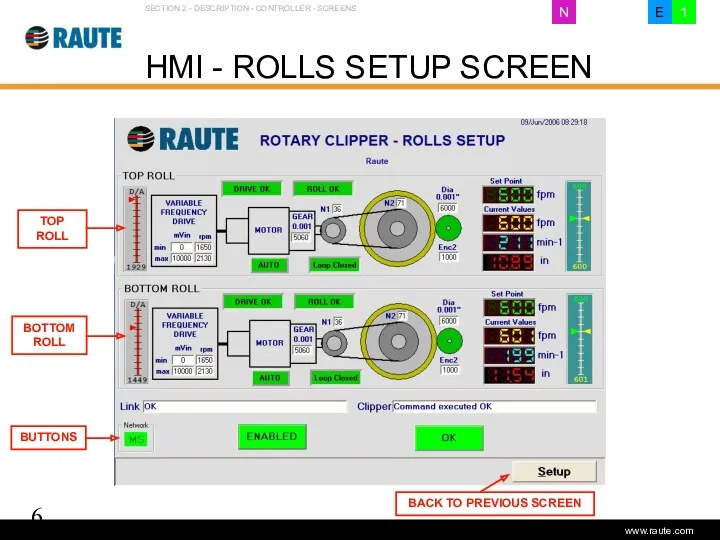

- 62. Version 1.0 - June 2006 HMI - ROLLS SETUP SCREEN SECTION 2 - DESCRIPTION - CONTROLLER

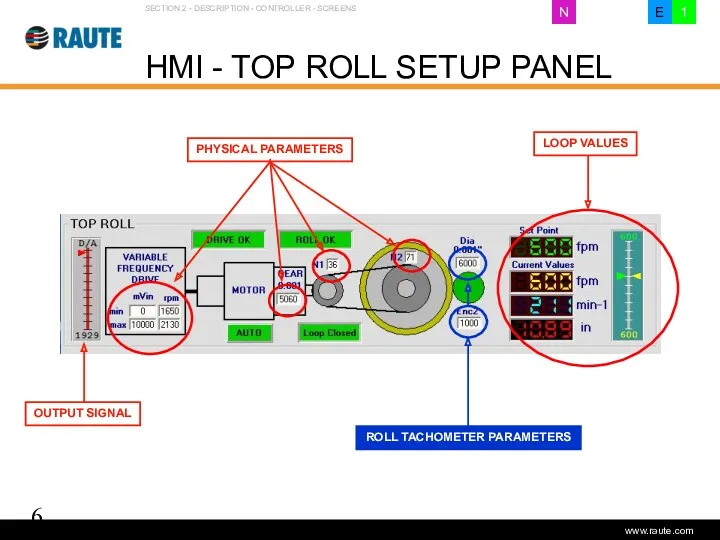

- 63. Version 1.0 - June 2006 HMI - TOP ROLL SETUP PANEL SECTION 2 - DESCRIPTION -

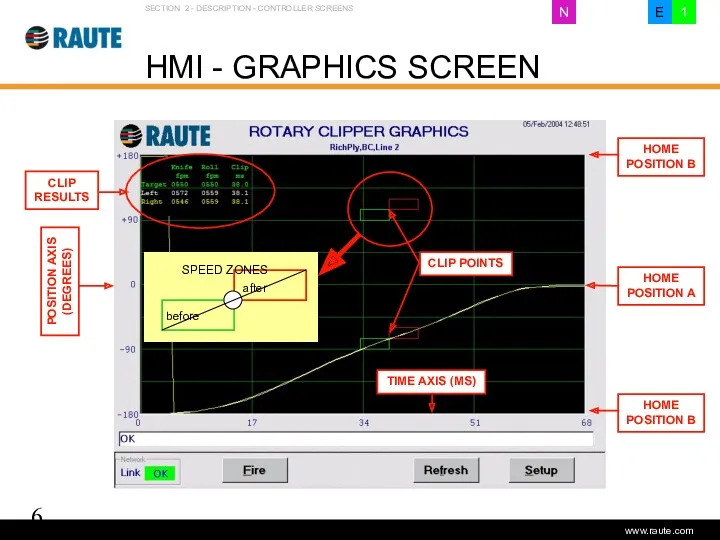

- 64. Version 1.0 - June 2006 HMI - GRAPHICS SCREEN SECTION 2 - DESCRIPTION - CONTROLLER SCREENS

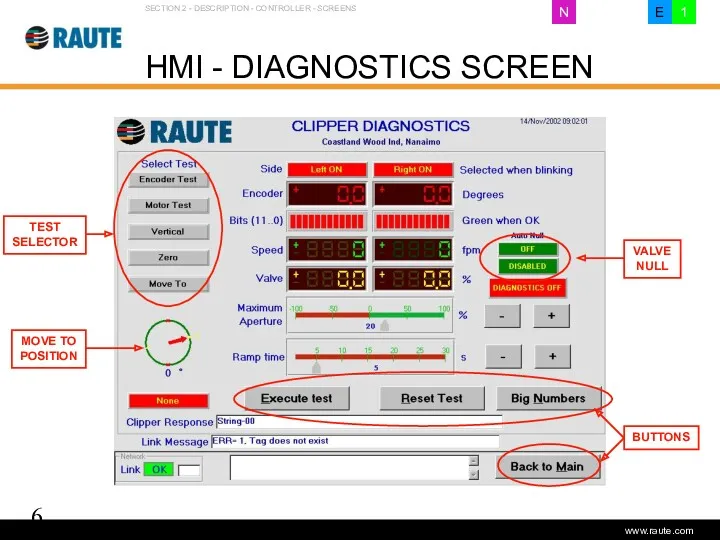

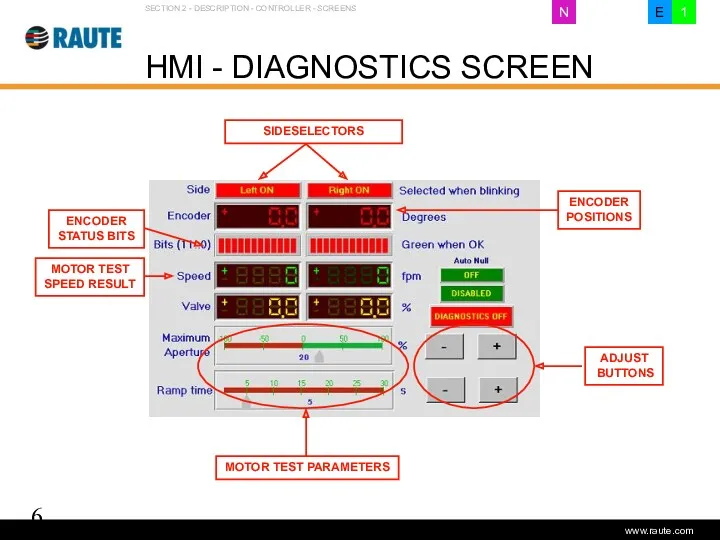

- 65. Version 1.0 - June 2006 HMI - DIAGNOSTICS SCREEN SECTION 2 - DESCRIPTION - CONTROLLER -

- 66. Version 1.0 - June 2006 HMI - DIAGNOSTICS SCREEN SECTION 2 - DESCRIPTION - CONTROLLER -

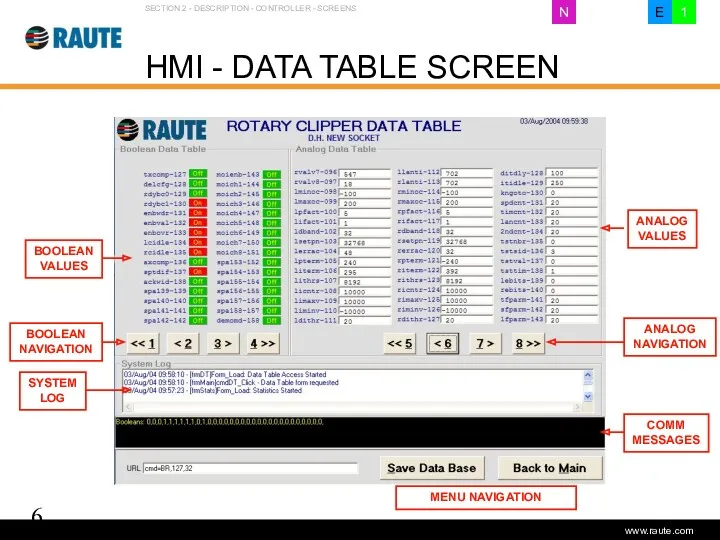

- 67. Version 1.0 - June 2006 HMI - DATA TABLE SCREEN SECTION 2 - DESCRIPTION - CONTROLLER

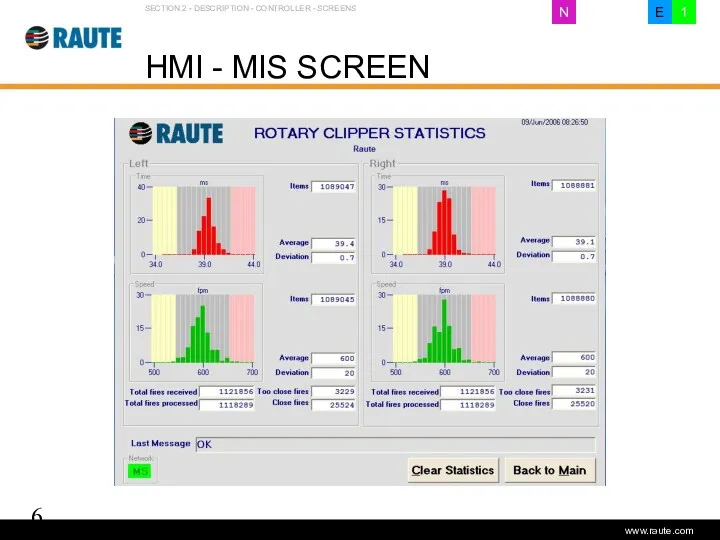

- 68. Version 1.0 - June 2006 HMI - MIS SCREEN SECTION 2 - DESCRIPTION - CONTROLLER -

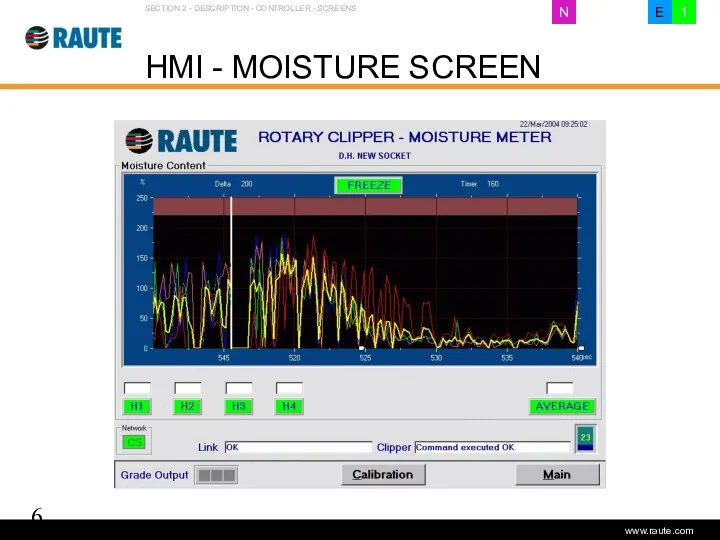

- 69. Version 1.0 - June 2006 HMI - MOISTURE SCREEN SECTION 2 - DESCRIPTION - CONTROLLER -

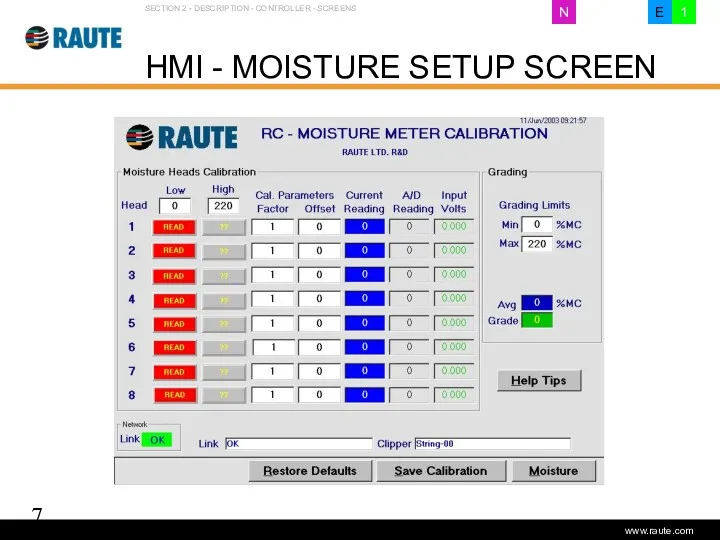

- 70. Version 1.0 - June 2006 HMI - MOISTURE SETUP SCREEN SECTION 2 - DESCRIPTION - CONTROLLER

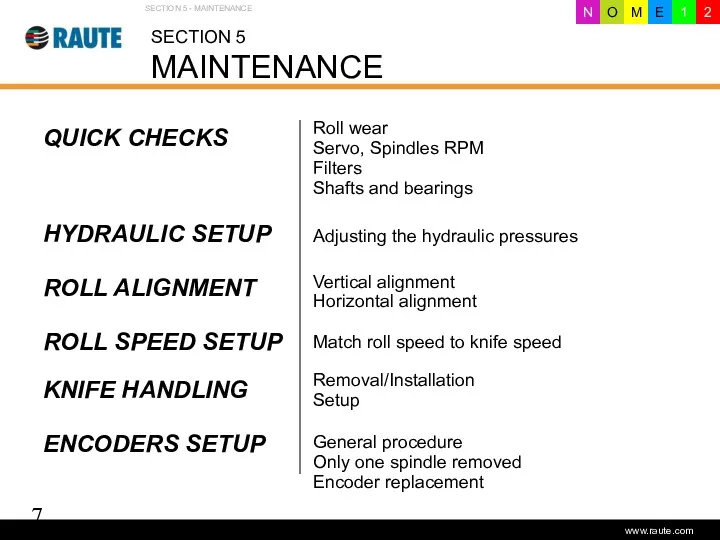

- 71. Version 1.0 - June 2006 SECTION 5 MAINTENANCE ROLL ALIGNMENT KNIFE HANDLING Roll wear Servo, Spindles

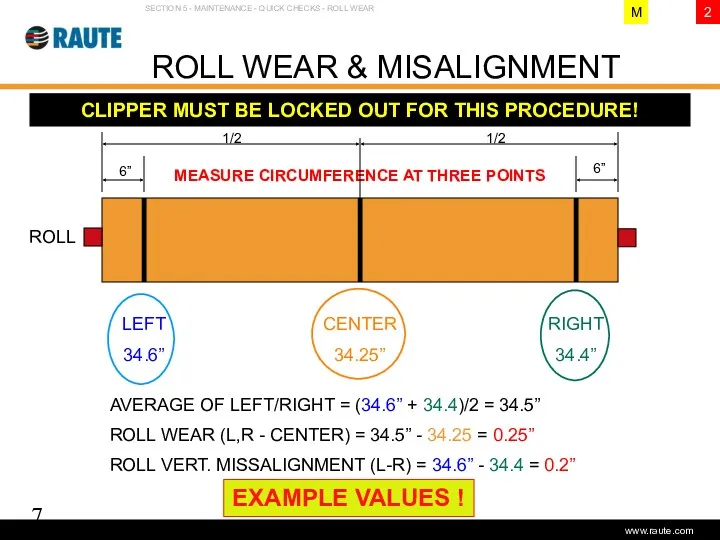

- 72. Version 1.0 - June 2006 ROLL WEAR & MISALIGNMENT SECTION 5 - MAINTENANCE - QUICK CHECKS

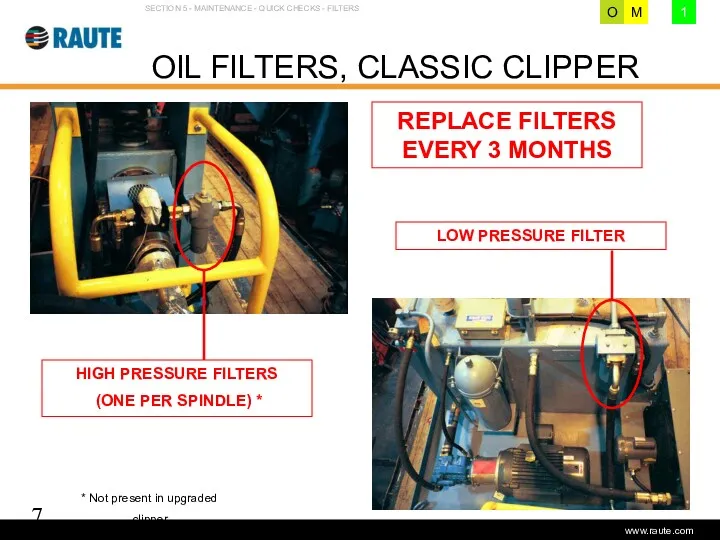

- 73. Version 1.0 - June 2006 OIL FILTERS, CLASSIC CLIPPER SECTION 5 - MAINTENANCE - QUICK CHECKS

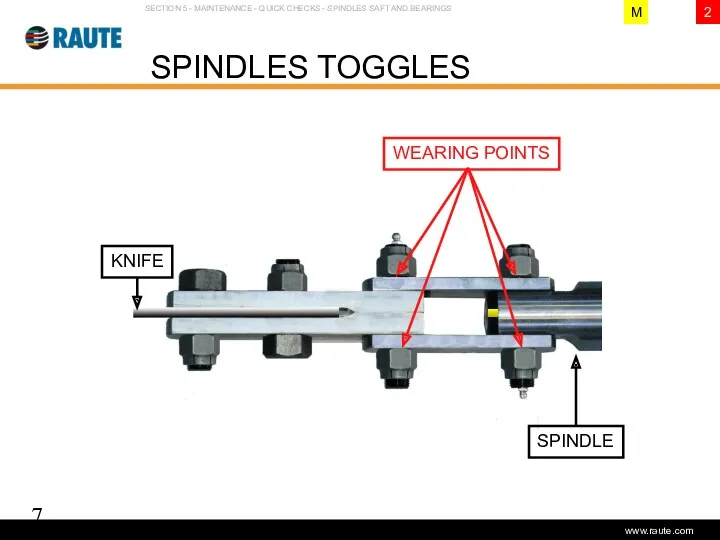

- 74. Version 1.0 - June 2006 SPINDLES TOGGLES SECTION 5 - MAINTENANCE - QUICK CHECKS - SPINDLES

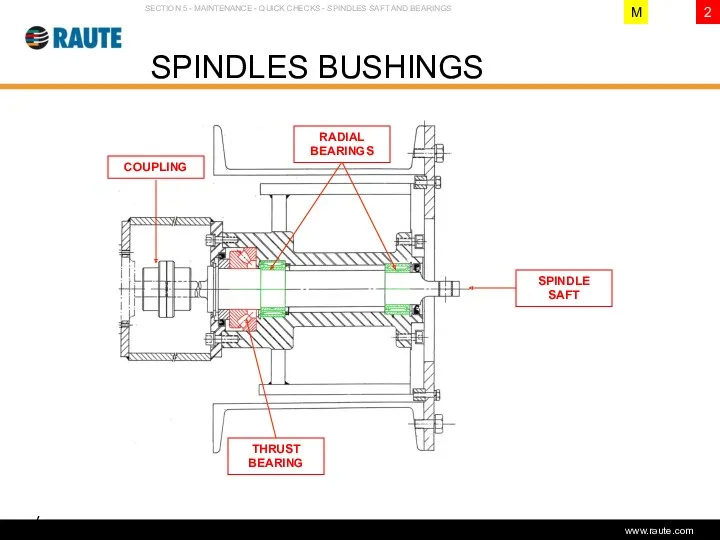

- 75. Version 1.0 - June 2006 SPINDLES BUSHINGS SECTION 5 - MAINTENANCE - QUICK CHECKS - SPINDLES

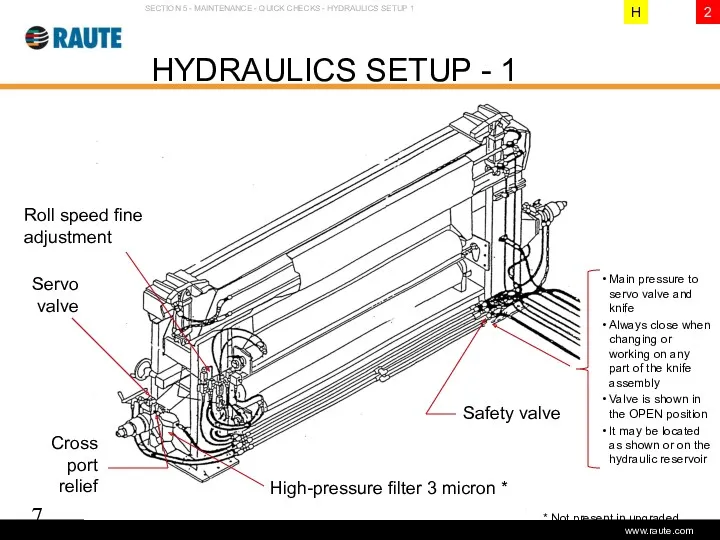

- 76. Version 1.0 - June 2006 HYDRAULICS SETUP - 1 Main pressure to servo valve and knife

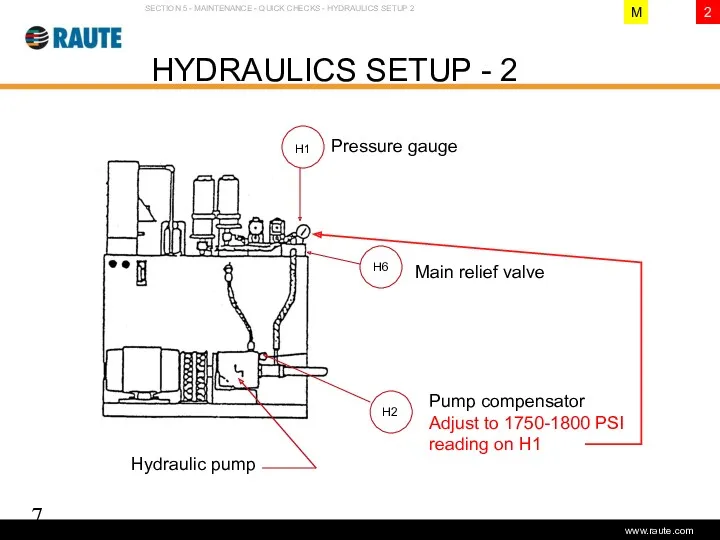

- 77. Version 1.0 - June 2006 HYDRAULICS SETUP - 2 M 2 SECTION 5 - MAINTENANCE -

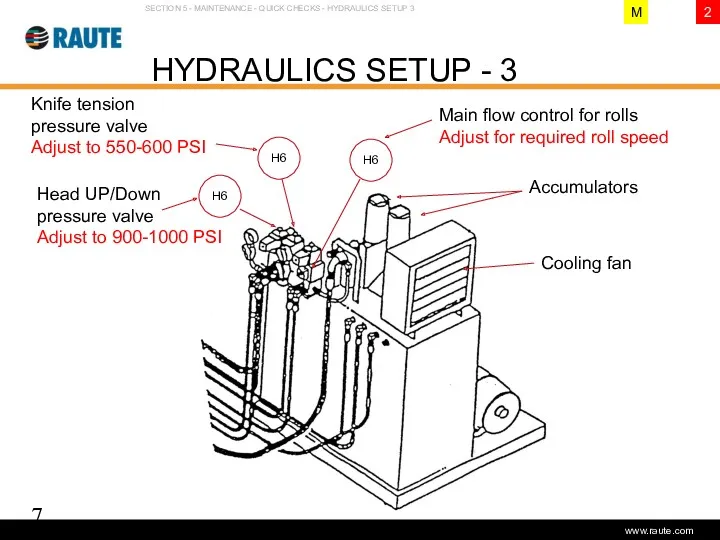

- 78. Version 1.0 - June 2006 HYDRAULICS SETUP - 3 H6 H6 H6 Head UP/Down pressure valve

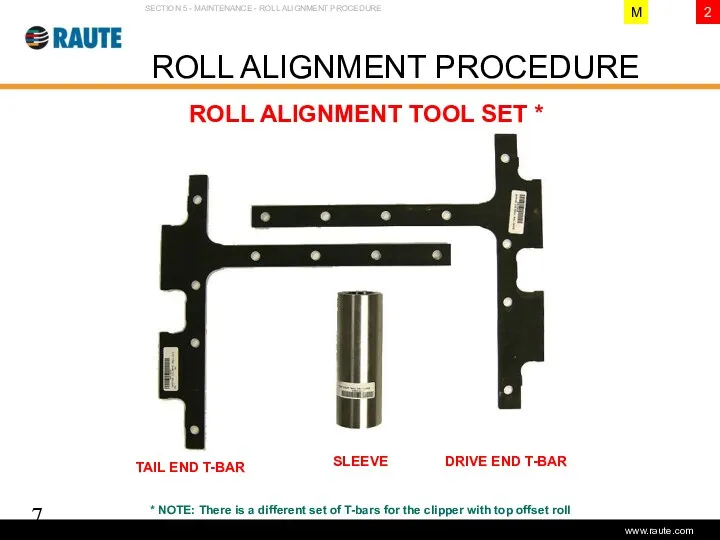

- 79. Version 1.0 - June 2006 ROLL ALIGNMENT PROCEDURE SECTION 5 - MAINTENANCE - ROLL ALIGNMENT PROCEDURE

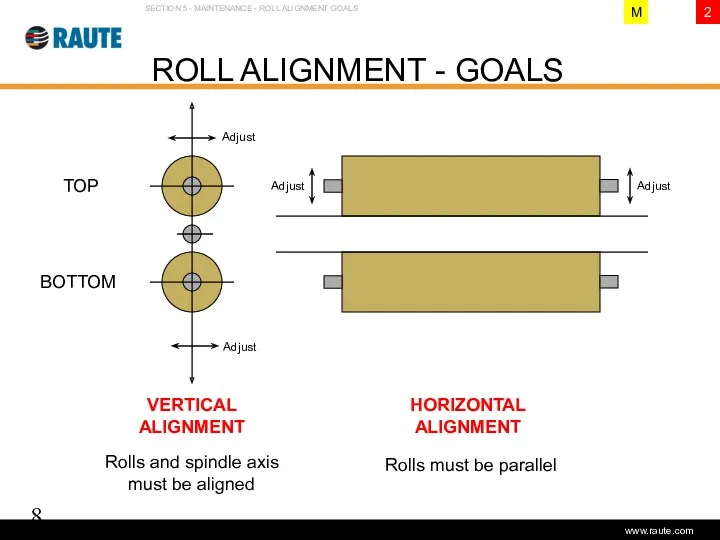

- 80. Version 1.0 - June 2006 ROLL ALIGNMENT - GOALS 2 SECTION 5 - MAINTENANCE - ROLL

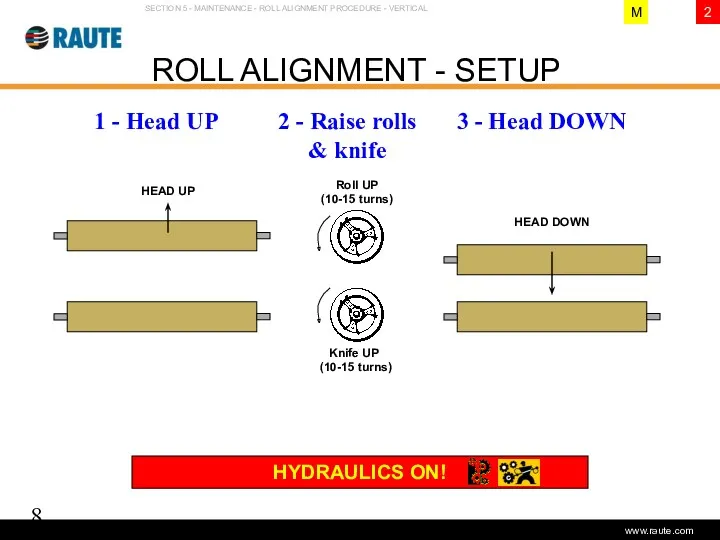

- 81. Version 1.0 - June 2006 ROLL ALIGNMENT - SETUP 2 SECTION 5 - MAINTENANCE - ROLL

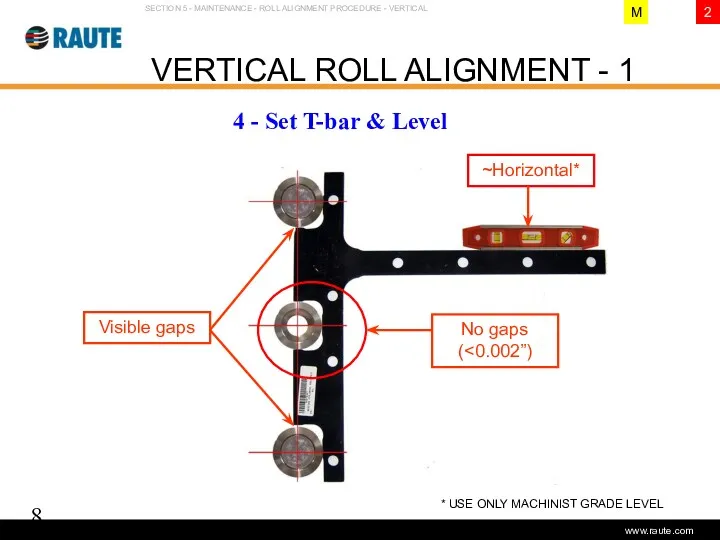

- 82. Version 1.0 - June 2006 VERTICAL ROLL ALIGNMENT - 1 2 SECTION 5 - MAINTENANCE -

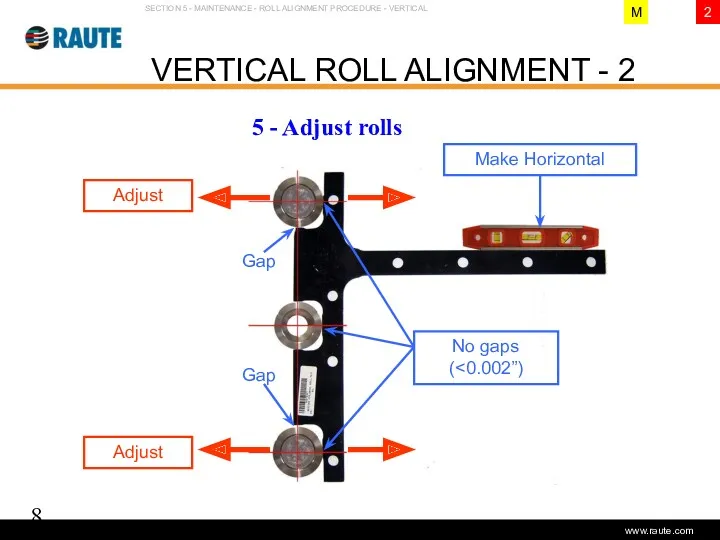

- 83. Version 1.0 - June 2006 VERTICAL ROLL ALIGNMENT - 2 2 SECTION 5 - MAINTENANCE -

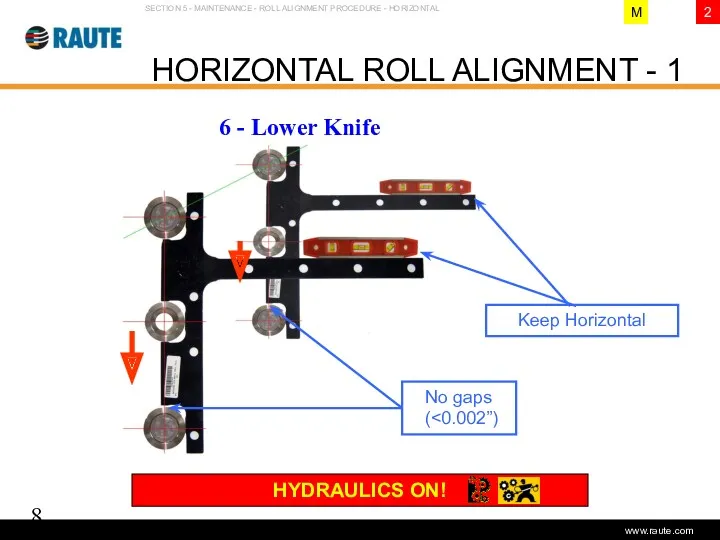

- 84. Version 1.0 - June 2006 HORIZONTAL ROLL ALIGNMENT - 1 HYDRAULICS ON! SECTION 5 - MAINTENANCE

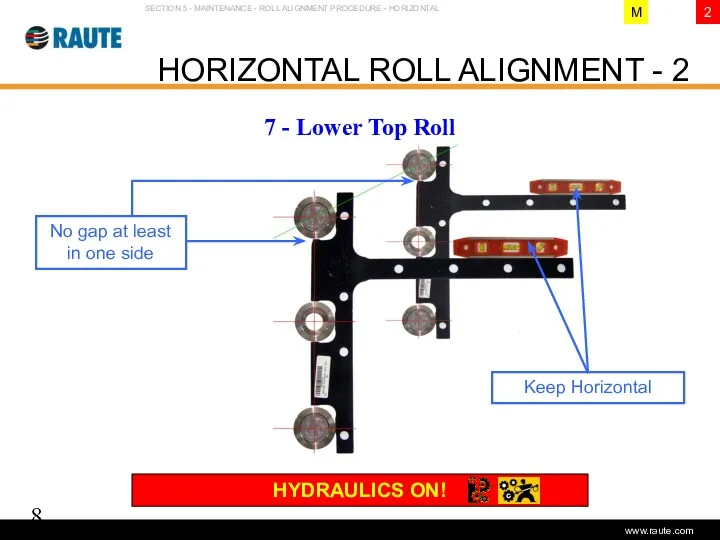

- 85. Version 1.0 - June 2006 HORIZONTAL ROLL ALIGNMENT - 2 HYDRAULICS ON! 7 - Lower Top

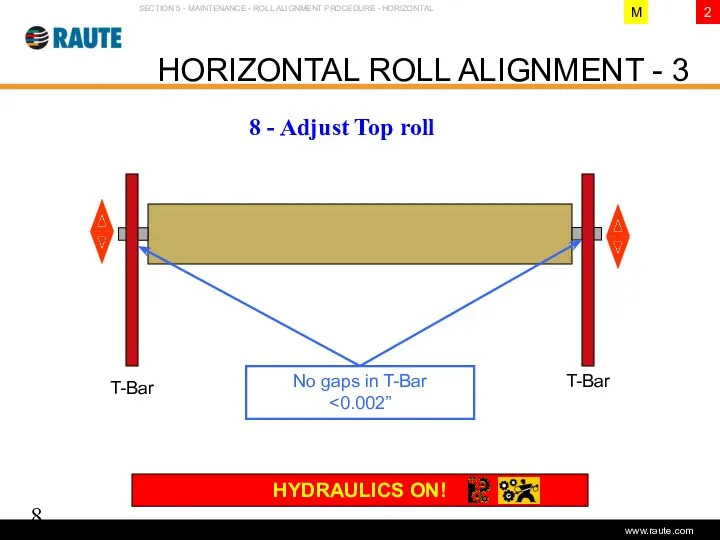

- 86. Version 1.0 - June 2006 8 - Adjust Top roll HYDRAULICS ON! SECTION 5 - MAINTENANCE

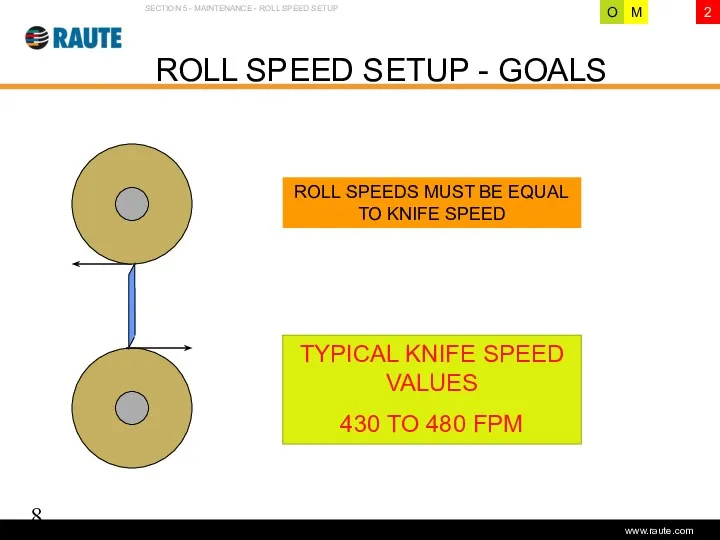

- 87. Version 1.0 - June 2006 ROLL SPEED SETUP - GOALS SECTION 5 - MAINTENANCE - ROLL

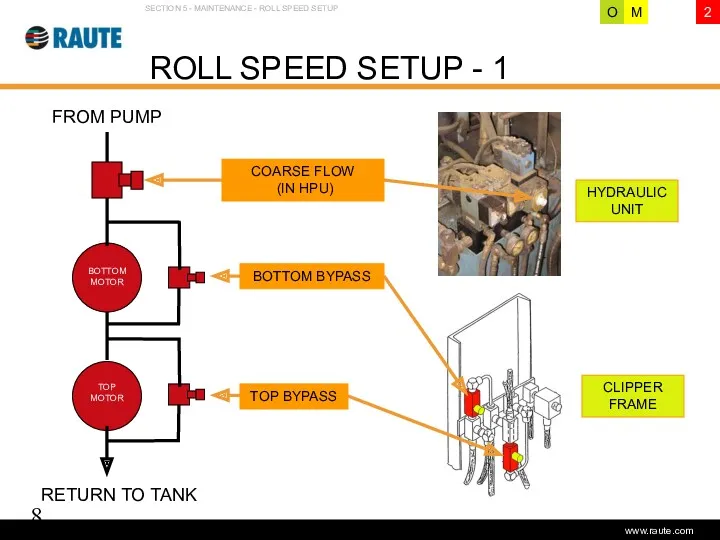

- 88. Version 1.0 - June 2006 ROLL SPEED SETUP - 1 SECTION 5 - MAINTENANCE - ROLL

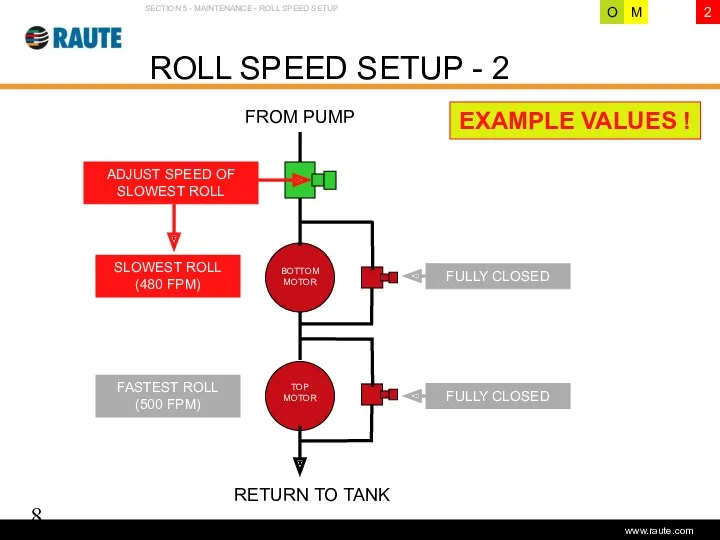

- 89. Version 1.0 - June 2006 ROLL SPEED SETUP - 2 SECTION 5 - MAINTENANCE - ROLL

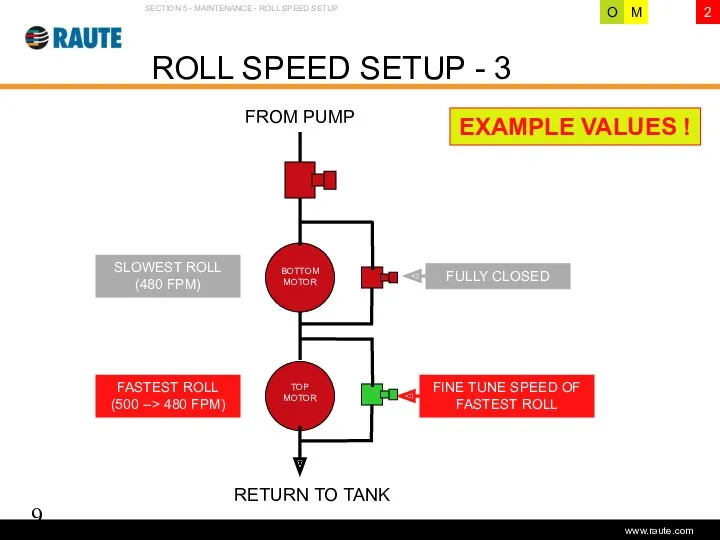

- 90. Version 1.0 - June 2006 ROLL SPEED SETUP - 3 SECTION 5 - MAINTENANCE - ROLL

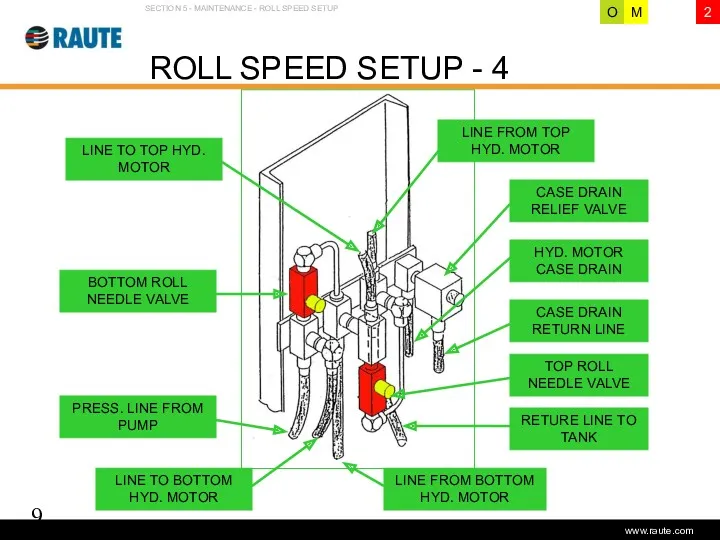

- 91. Version 1.0 - June 2006 ROLL SPEED SETUP - 4 SECTION 5 - MAINTENANCE - ROLL

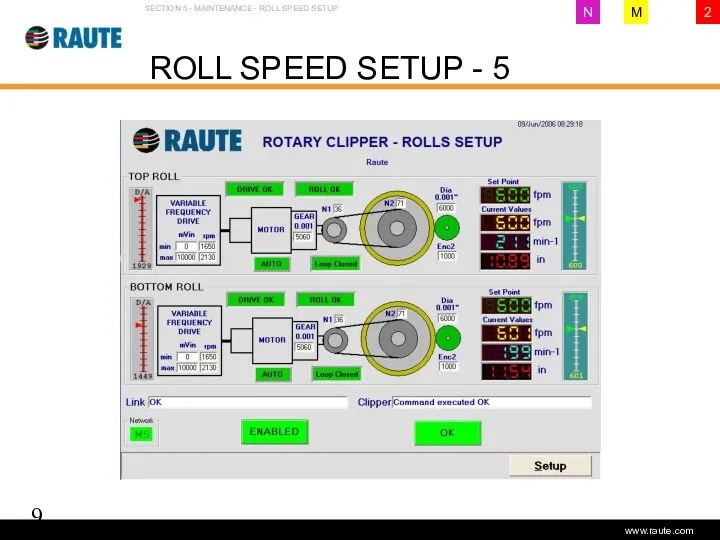

- 92. Version 1.0 - June 2006 ROLL SPEED SETUP - 5 SECTION 5 - MAINTENANCE - ROLL

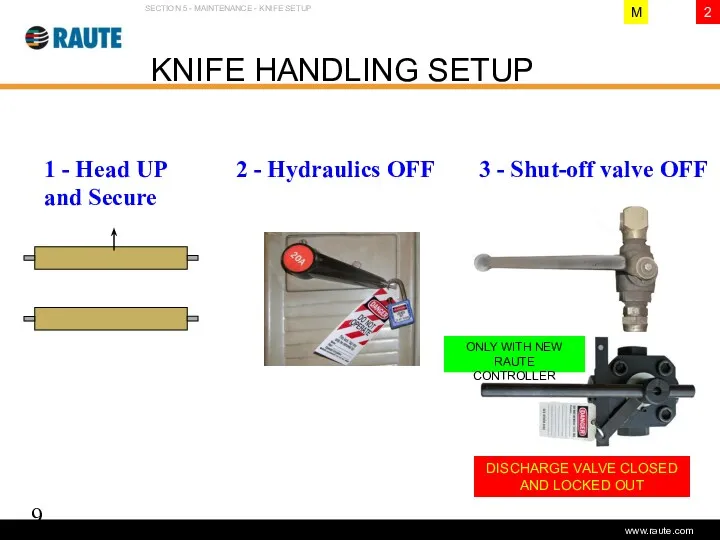

- 93. Version 1.0 - June 2006 KNIFE HANDLING SETUP SECTION 5 - MAINTENANCE - KNIFE SETUP 1

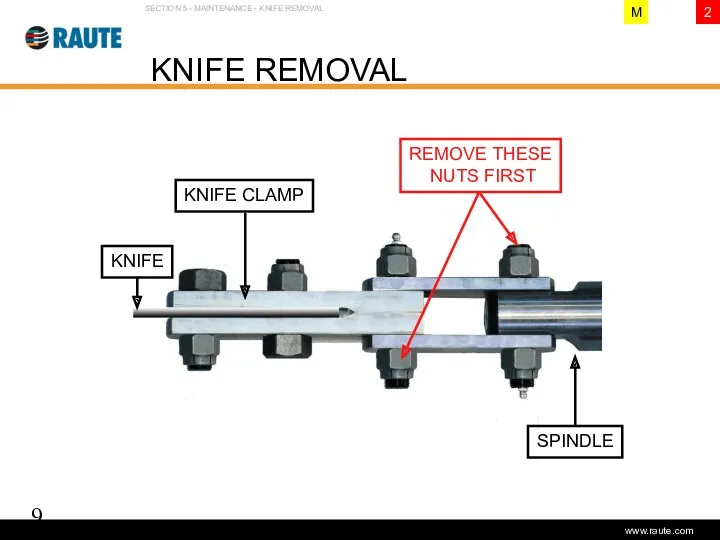

- 94. Version 1.0 - June 2006 KNIFE REMOVAL SECTION 5 - MAINTENANCE - KNIFE REMOVAL 2 M

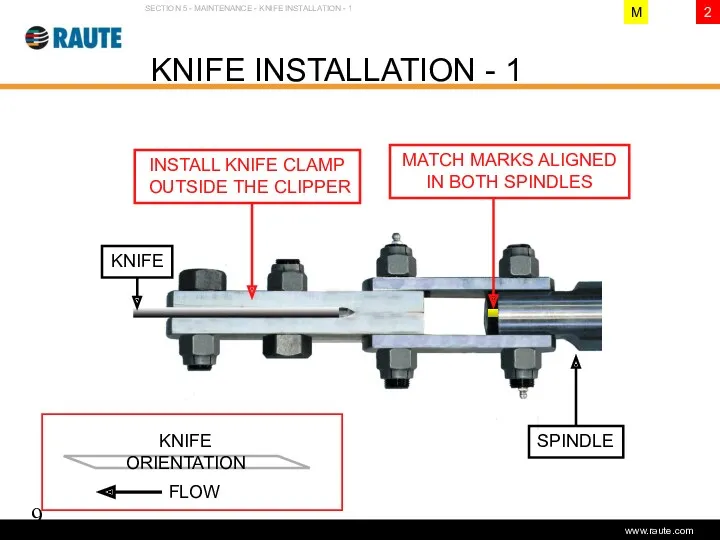

- 95. Version 1.0 - June 2006 KNIFE INSTALLATION - 1 SECTION 5 - MAINTENANCE - KNIFE INSTALLATION

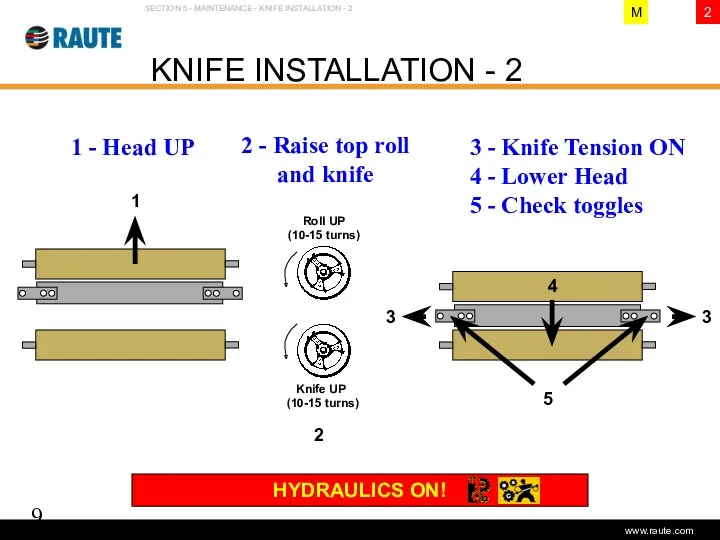

- 96. Version 1.0 - June 2006 KNIFE INSTALLATION - 2 SECTION 5 - MAINTENANCE - KNIFE INSTALLATION

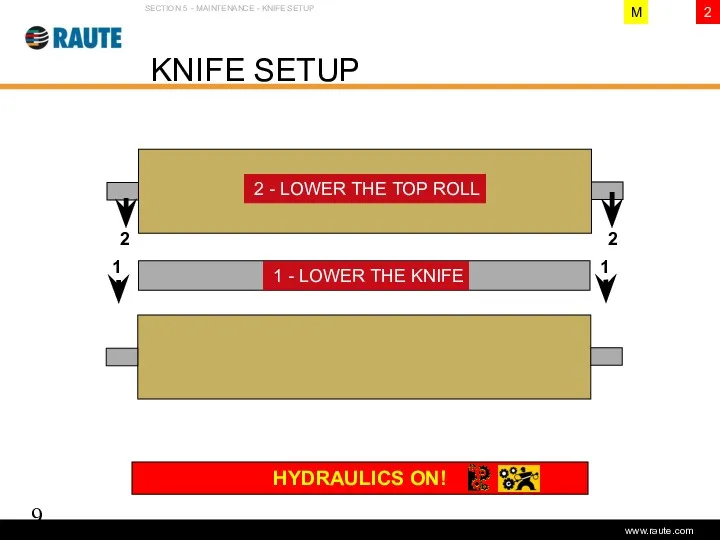

- 97. Version 1.0 - June 2006 KNIFE SETUP SECTION 5 - MAINTENANCE - KNIFE SETUP 2 M

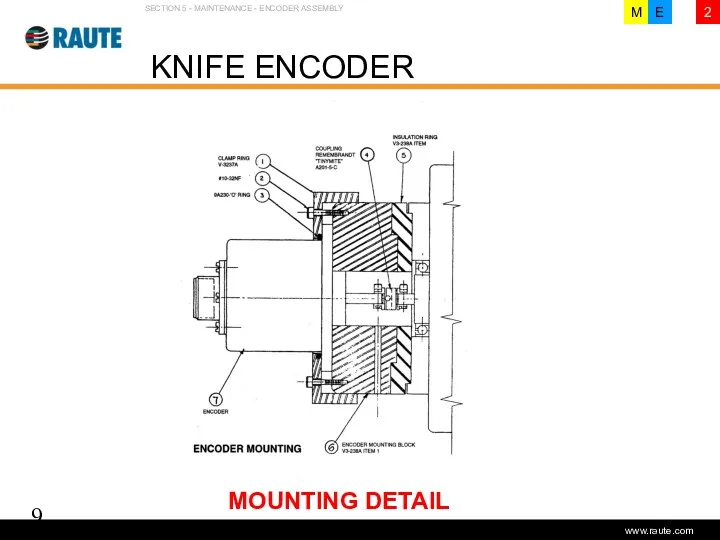

- 98. Version 1.0 - June 2006 KNIFE ENCODER MOUNTING DETAIL SECTION 5 - MAINTENANCE - ENCODER ASSEMBLY

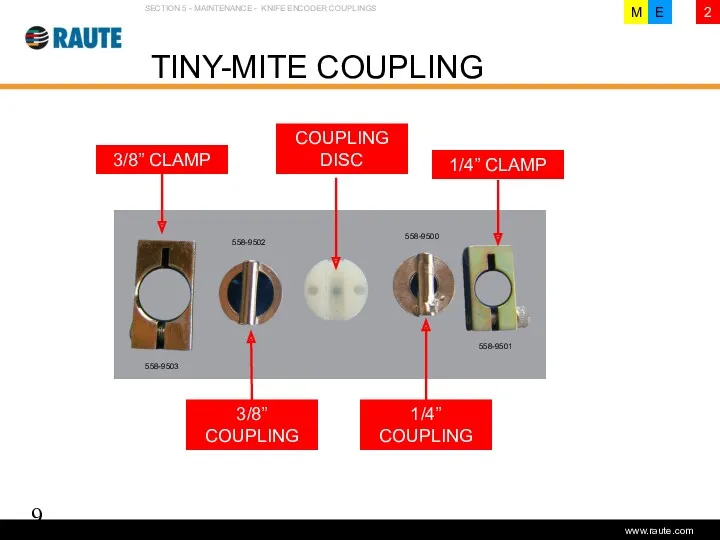

- 99. Version 1.0 - June 2006 TINY-MITE COUPLING SECTION 5 - MAINTENANCE - KNIFE ENCODER COUPLINGS M

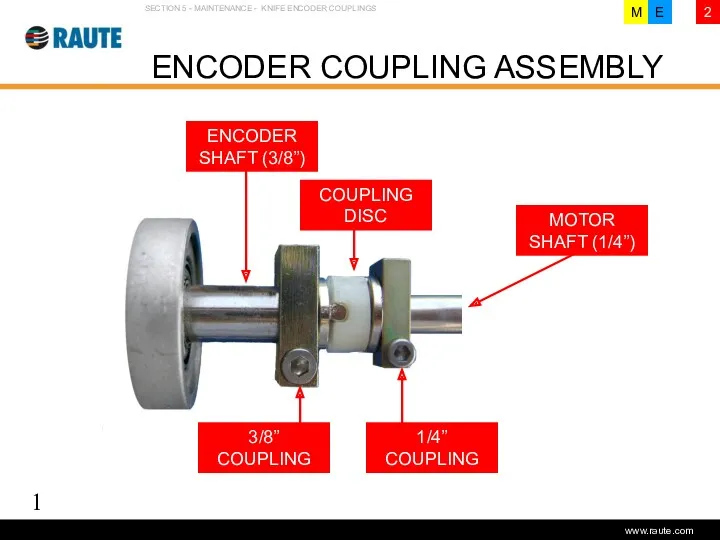

- 100. Version 1.0 - June 2006 ENCODER COUPLING ASSEMBLY SECTION 5 - MAINTENANCE - KNIFE ENCODER COUPLINGS

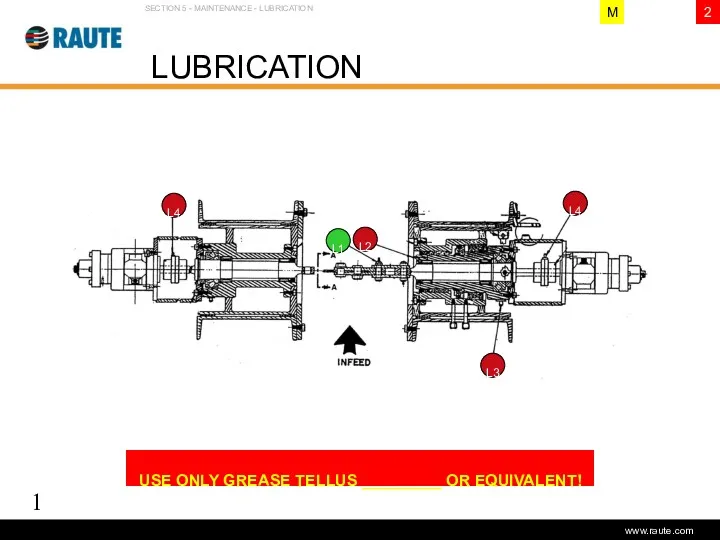

- 101. Version 1.0 - June 2006 LUBRICATION SECTION 5 - MAINTENANCE - LUBRICATION M 2 USE ONLY

- 102. Version 1.0 - June 2006 Section 6 TROUBLESHOOTING SECTION 5 - TROUBLESHOOTING M E 1 2

- 103. Version 1.0 - June 2006 GENERAL NORMAL FAILURES Originated by a single element (e.g.: broken spindle)

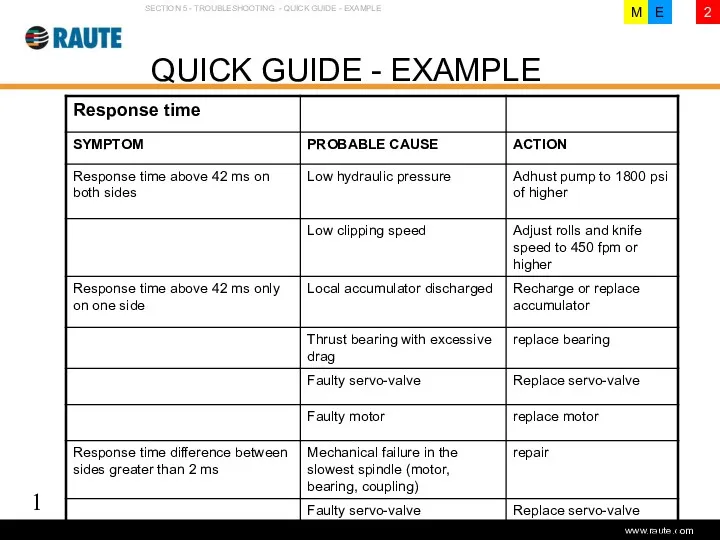

- 104. Version 1.0 - June 2006 QUICK GUIDE - EXAMPLE SECTION 5 - TROUBLESHOOTING - QUICK GUIDE

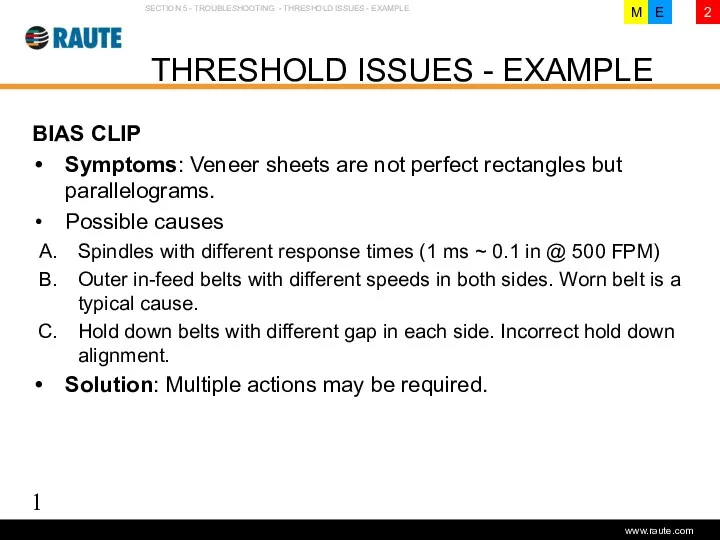

- 105. Version 1.0 - June 2006 THRESHOLD ISSUES - EXAMPLE SECTION 5 - TROUBLESHOOTING - THRESHOLD ISSUES

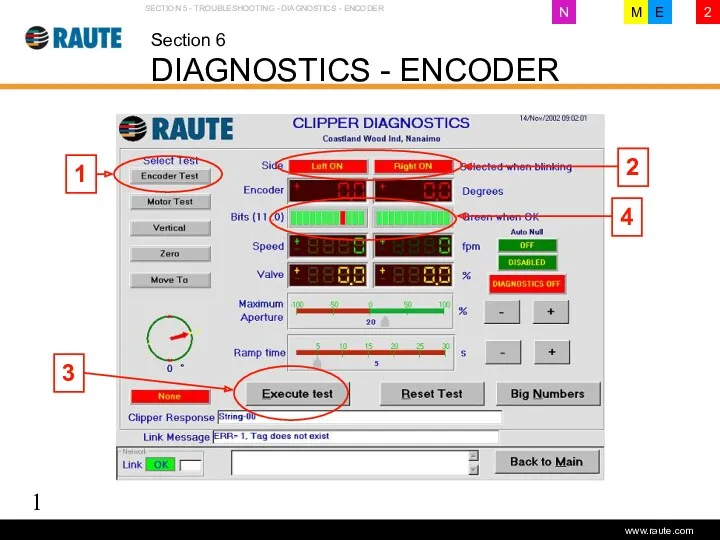

- 106. Version 1.0 - June 2006 Section 6 DIAGNOSTICS - ENCODER SECTION 5 - TROUBLESHOOTING - DIAGNOSTICS

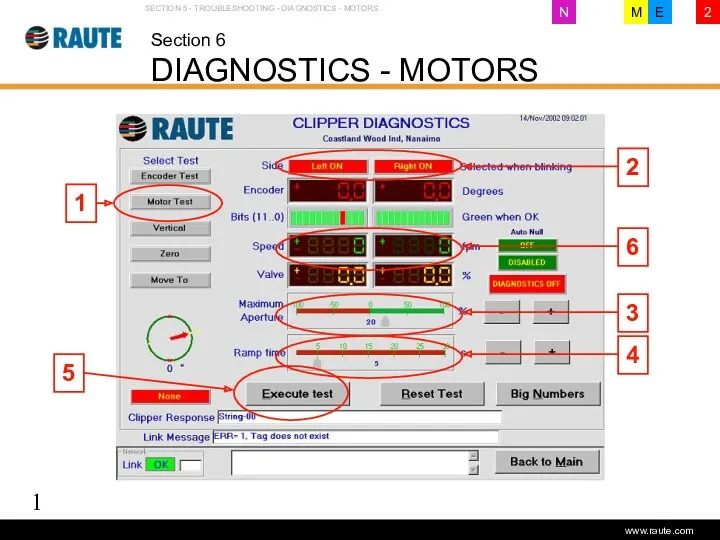

- 107. Version 1.0 - June 2006 Section 6 DIAGNOSTICS - MOTORS SECTION 5 - TROUBLESHOOTING - DIAGNOSTICS

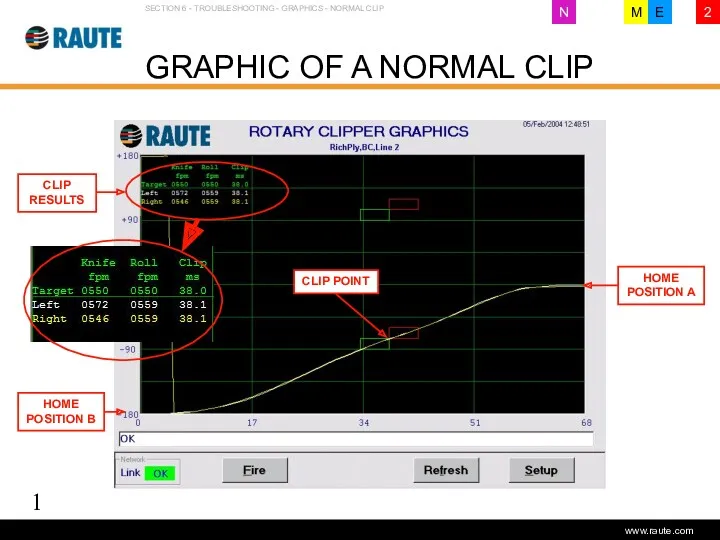

- 108. Version 1.0 - June 2006 GRAPHIC OF A NORMAL CLIP SECTION 6 - TROUBLESHOOTING - GRAPHICS

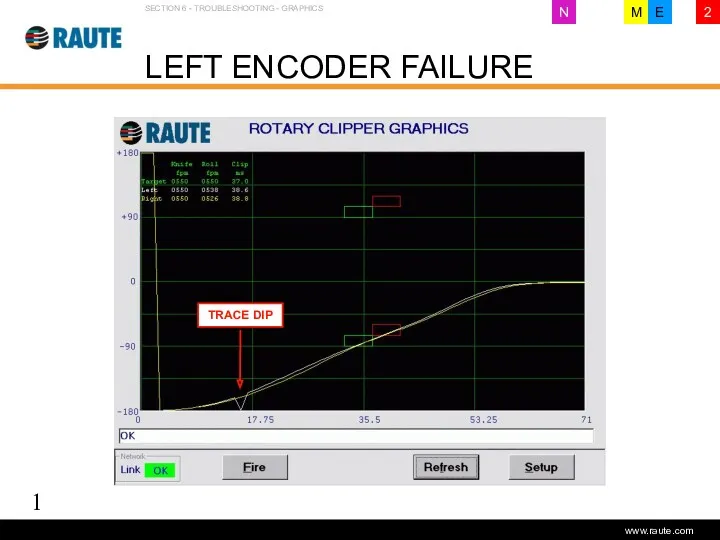

- 109. Version 1.0 - June 2006 LEFT ENCODER FAILURE SECTION 6 - TROUBLESHOOTING - GRAPHICS E N

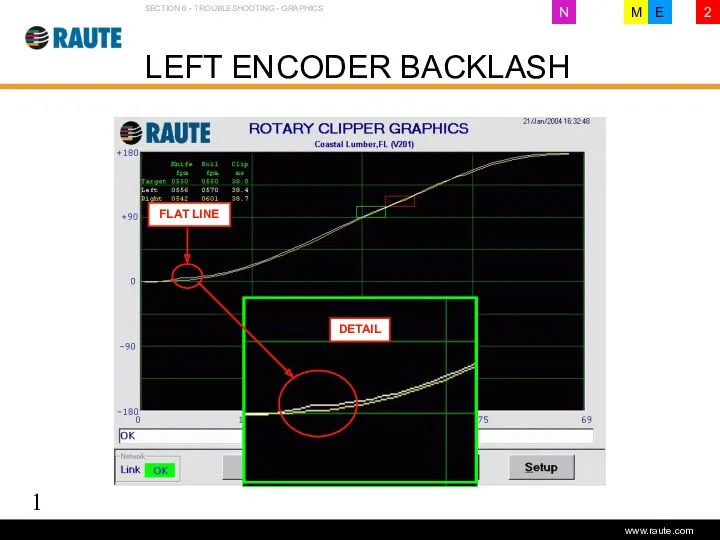

- 110. Version 1.0 - June 2006 LEFT ENCODER BACKLASH SECTION 6 - TROUBLESHOOTING - GRAPHICS E N

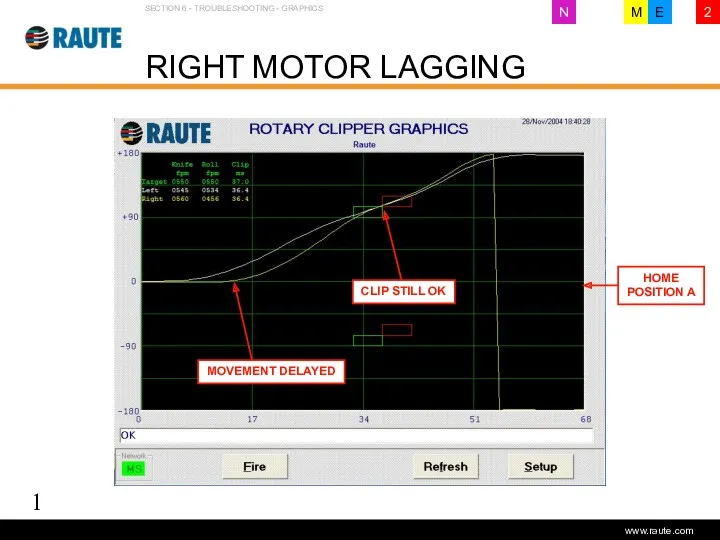

- 111. Version 1.0 - June 2006 RIGHT MOTOR LAGGING SECTION 6 - TROUBLESHOOTING - GRAPHICS E N

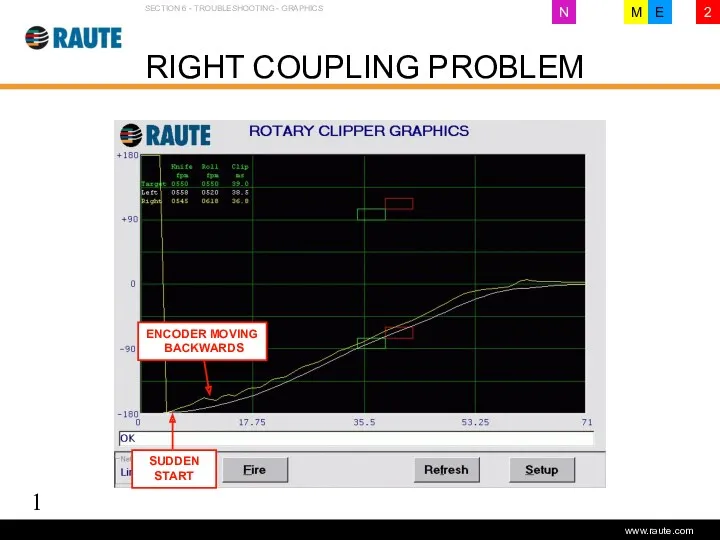

- 112. Version 1.0 - June 2006 RIGHT COUPLING PROBLEM SECTION 6 - TROUBLESHOOTING - GRAPHICS E N

- 113. Version 1.0 - June 2006 Section 7 APPENDIX SECTION 7 - APENDIX

- 114. Version 1.0 - June 2006 SECTION 7 - APENDIX QUALITY RAUTE PARTS PARTS

- 116. Скачать презентацию

Стратегические ориентиры развития образования города Жодино

Стратегические ориентиры развития образования города Жодино Сходство и различия немецких и российских школ

Сходство и различия немецких и российских школ Молодежные обмены в Германии - как принять участие?

Молодежные обмены в Германии - как принять участие? Education in Sweden

Education in Sweden Информация по дистанционному обучению в 2020-2021 учебном году

Информация по дистанционному обучению в 2020-2021 учебном году Организация самостоятельной работы на уроке в условиях малокомплектной школы

Организация самостоятельной работы на уроке в условиях малокомплектной школы Метод проектів у процесі навчання технологій. (Лекція 9)

Метод проектів у процесі навчання технологій. (Лекція 9) Дидактическая игра Найди домашних животных (презентация)

Дидактическая игра Найди домашних животных (презентация) Отчет-презентация о работе ШМО учителей русского языка и литературы

Отчет-презентация о работе ШМО учителей русского языка и литературы Основные тенденции развития вузовских библиотек на современном этапе

Основные тенденции развития вузовских библиотек на современном этапе Исследование на тему: Влияние спокойной музыки на память, внимание и скорость произвольной двигательной реакции

Исследование на тему: Влияние спокойной музыки на память, внимание и скорость произвольной двигательной реакции Клуб парламентских дебатов. Анализ темы. Акторный анализ

Клуб парламентских дебатов. Анализ темы. Акторный анализ Образовательные технологии, методы и средства, применяемые в МАОУ Гимназии №73

Образовательные технологии, методы и средства, применяемые в МАОУ Гимназии №73 Н.Оңдасынов атындағы “Дарын” мектеп-интернаты туралы

Н.Оңдасынов атындағы “Дарын” мектеп-интернаты туралы Программа кандидатов с ССФ ГиМУ XVlll созыва

Программа кандидатов с ССФ ГиМУ XVlll созыва Оценивание

Оценивание Анализ современного урока. Лекция 6 .2

Анализ современного урока. Лекция 6 .2 Петрозаводский государственный университет. Институт Филологии. Кафедра прибалтийско-финской филологии

Петрозаводский государственный университет. Институт Филологии. Кафедра прибалтийско-финской филологии Школа безопасности как форма деятельности по формированию здорового и безопасного образа жизни обучающихся.

Школа безопасности как форма деятельности по формированию здорового и безопасного образа жизни обучающихся. Правила СХ–викторины

Правила СХ–викторины Разработка организационно-функциональной модели центра непрерывного повышения профессионального мастерства педагогов

Разработка организационно-функциональной модели центра непрерывного повышения профессионального мастерства педагогов Организационные формы обучения по ФГОСУ

Организационные формы обучения по ФГОСУ Конструирование технологической карты урока истории с учетом требований ГОС организаций общего образования

Конструирование технологической карты урока истории с учетом требований ГОС организаций общего образования Новомосковский политехнический колледж

Новомосковский политехнический колледж Студенческий олимпиадный клуб

Студенческий олимпиадный клуб Психологические особенности современного урока

Психологические особенности современного урока МОУ Некрасовская СОШ им. А.А. Лукьянова

МОУ Некрасовская СОШ им. А.А. Лукьянова Анализ работы МО учителей начальных классов за 1 полугодие 2013-2014 учебного года.

Анализ работы МО учителей начальных классов за 1 полугодие 2013-2014 учебного года.