Содержание

- 2. A600 Everything for a perfect coffee Intro

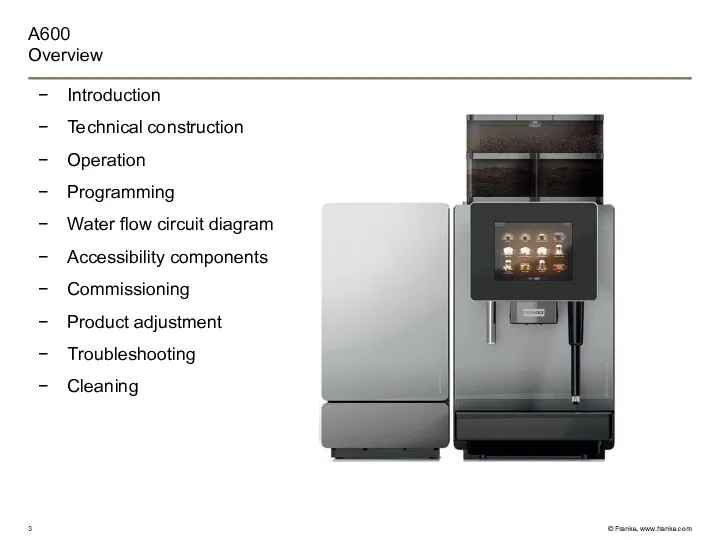

- 3. A600 Overview Introduction Technical construction Operation Programming Water flow circuit diagram Accessibility components Commissioning Product adjustment

- 4. A600 Positioning/target groups 150 - 250 cups/day 80 - 150 cups/day 250+ cups/day

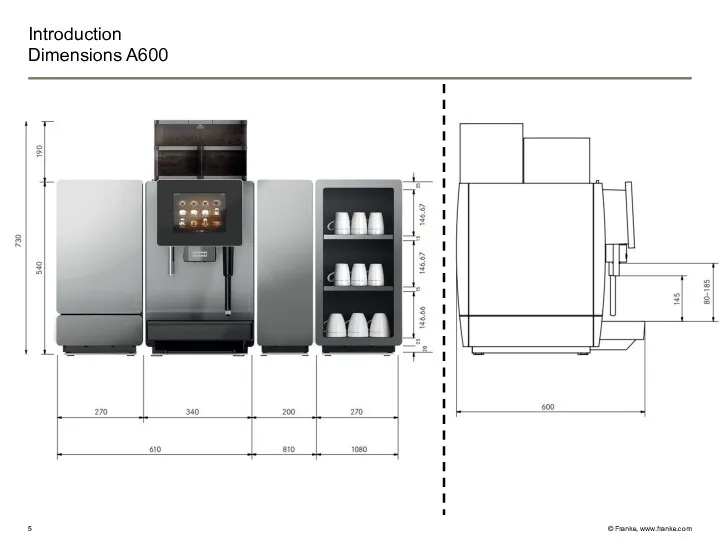

- 5. Introduction Dimensions A600

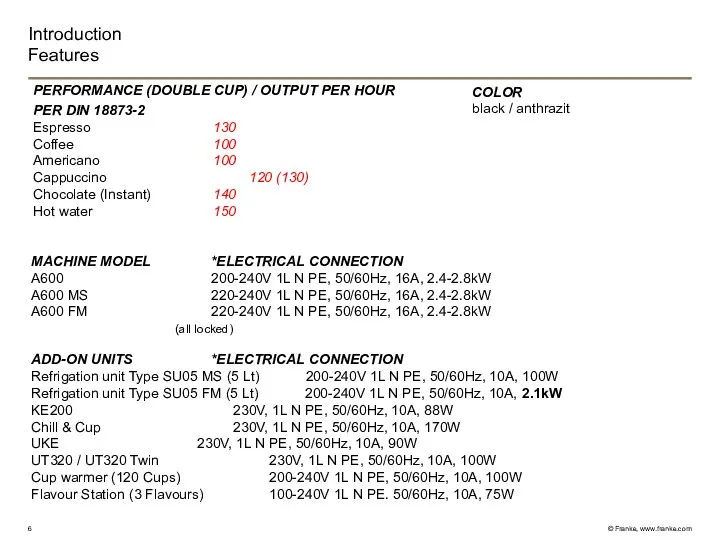

- 6. Introduction Features PERFORMANCE (DOUBLE CUP) / OUTPUT PER HOUR PER DIN 18873-2 Espresso 130 Coffee 100

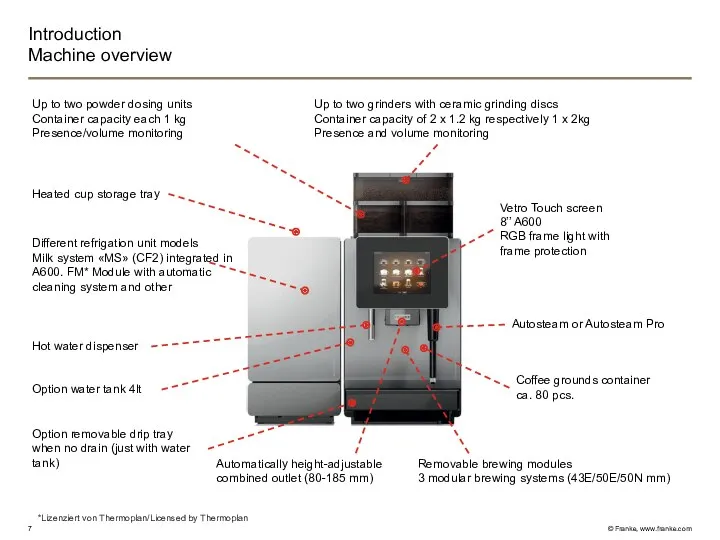

- 7. Introduction Machine overview Up to two powder dosing units Container capacity each 1 kg Presence/volume monitoring

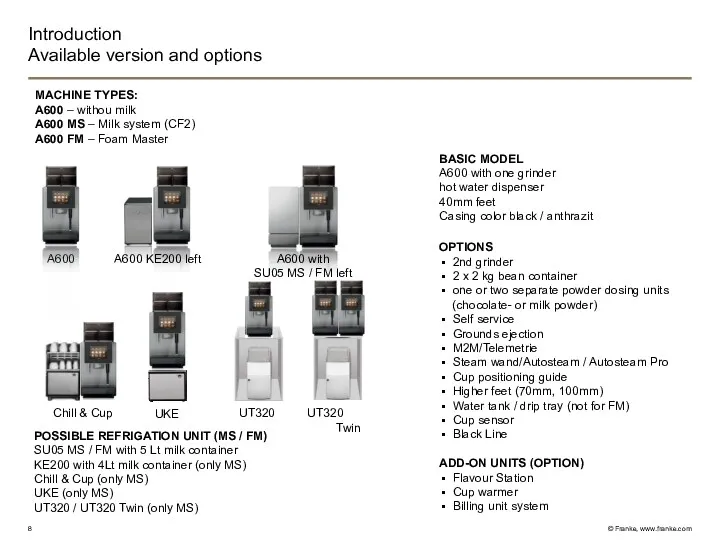

- 8. Introduction Available version and options MACHINE TYPES: A600 – withou milk A600 MS – Milk system

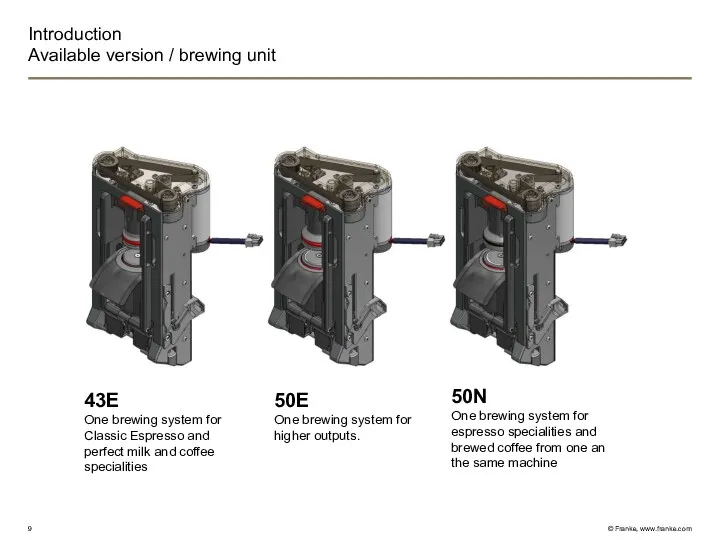

- 9. Introduction Available version / brewing unit 43E One brewing system for Classic Espresso and perfect milk

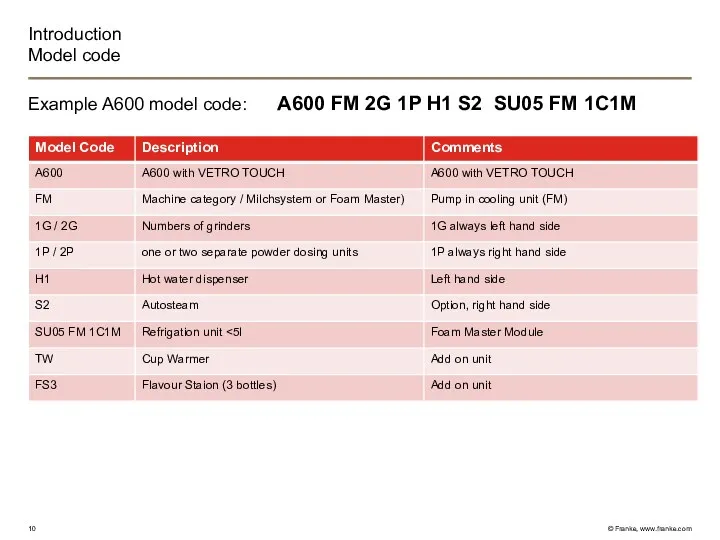

- 10. Introduction Model code Example A600 model code: A600 FM 2G 1P H1 S2 SU05 FM 1C1M

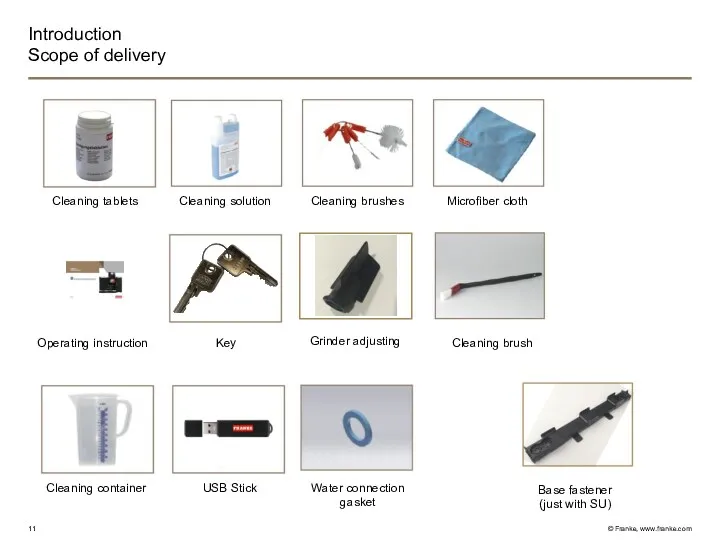

- 11. Introduction Scope of delivery Grinder adjusting Water connection gasket Cleaning brush Key Operating instruction Cleaning tablets

- 12. Introduction Hygiene Short milk tubes between refrigerator and coffee machine Milk pumps in the refrigerator Improved

- 13. Introduction Vetro Touch VETRO TOUCH SCREEN The A600 machines are equipped with a 8 inch touchscreen

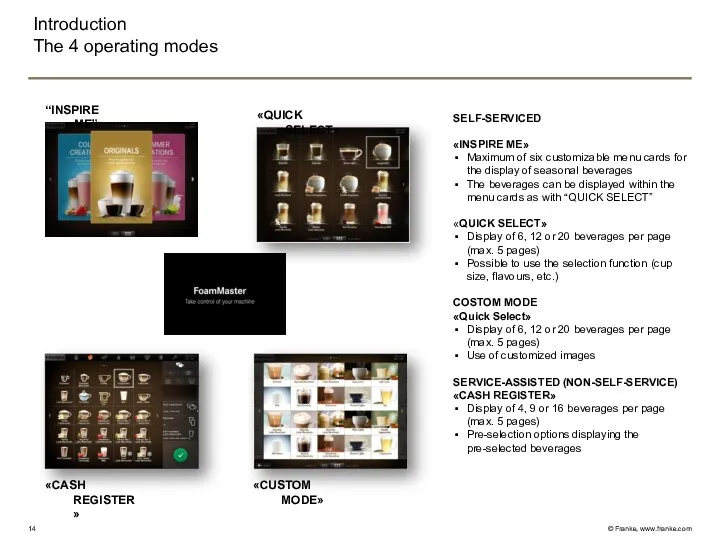

- 14. Introduction The 4 operating modes SELF-SERVICED «INSPIRE ME» Maximum of six customizable menu cards for the

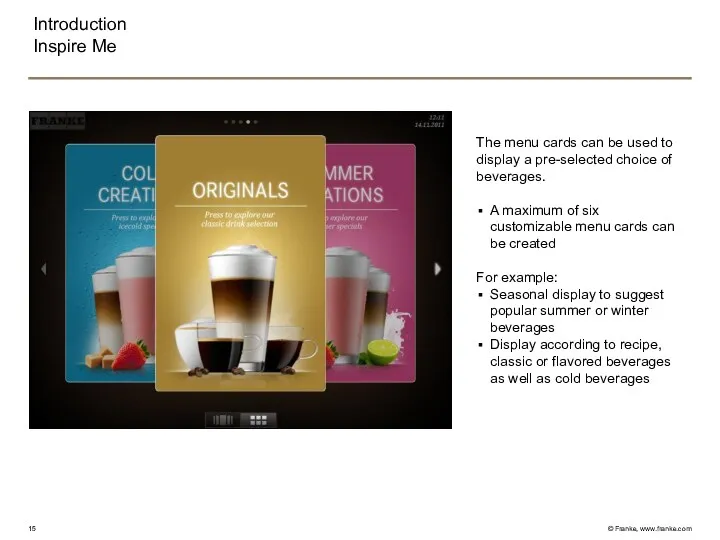

- 15. Introduction Inspire Me The menu cards can be used to display a pre-selected choice of beverages.

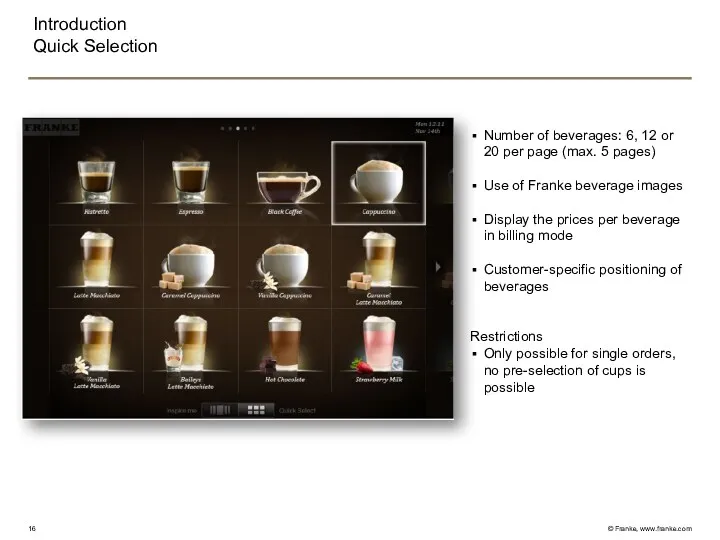

- 16. Introduction Quick Selection Number of beverages: 6, 12 or 20 per page (max. 5 pages) Use

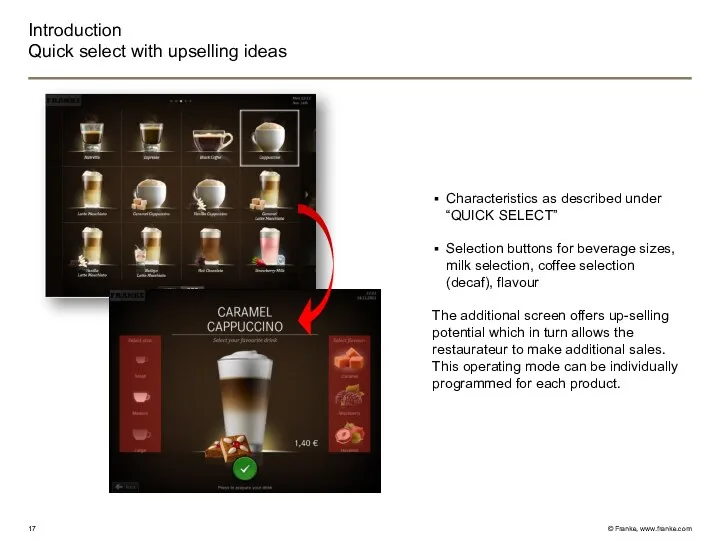

- 17. Introduction Quick select with upselling ideas Characteristics as described under “QUICK SELECT” Selection buttons for beverage

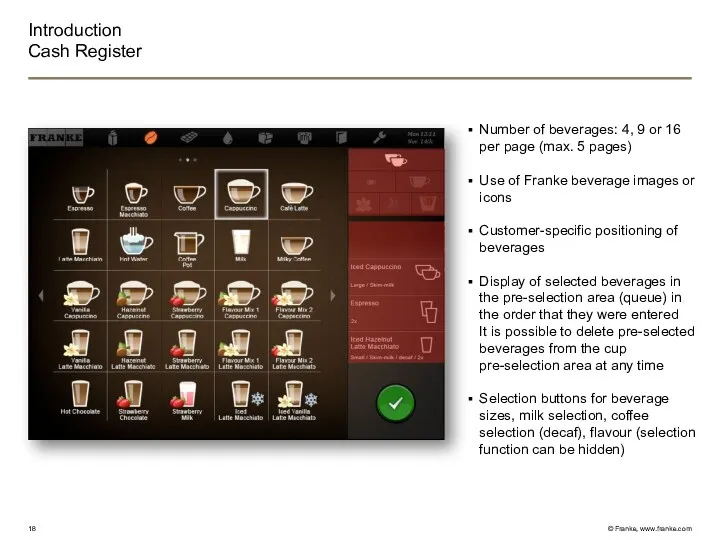

- 18. Introduction Cash Register Number of beverages: 4, 9 or 16 per page (max. 5 pages) Use

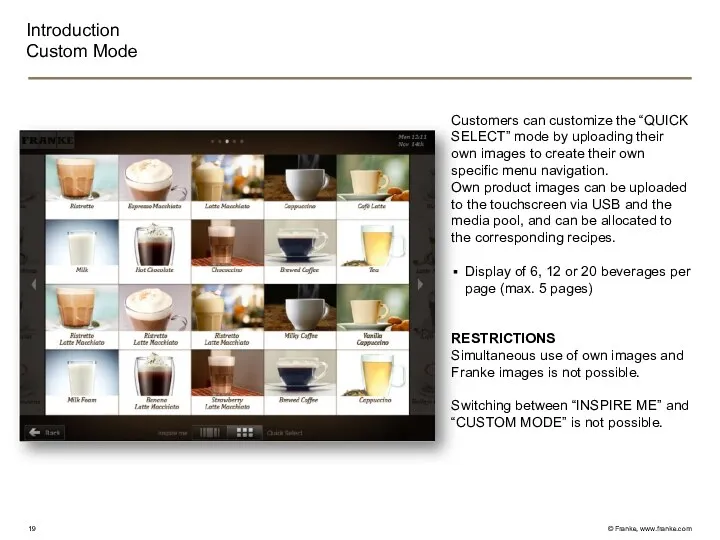

- 19. Customers can customize the “QUICK SELECT” mode by uploading their own images to create their own

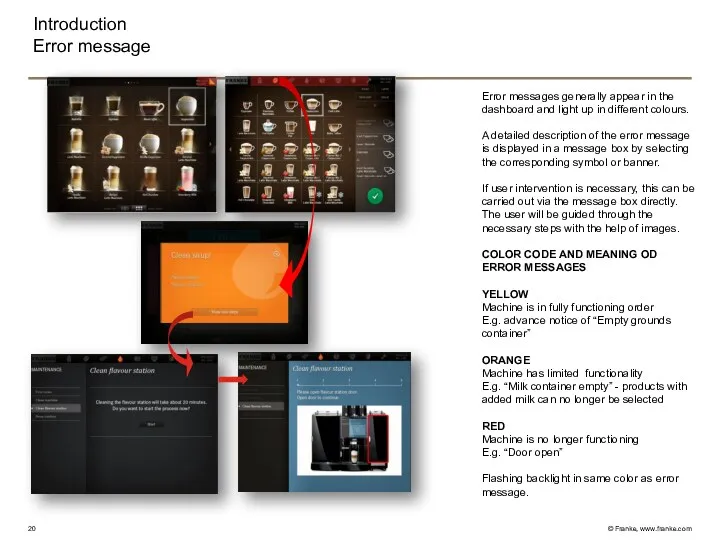

- 20. Error messages generally appear in the dashboard and light up in different colours. A detailed description

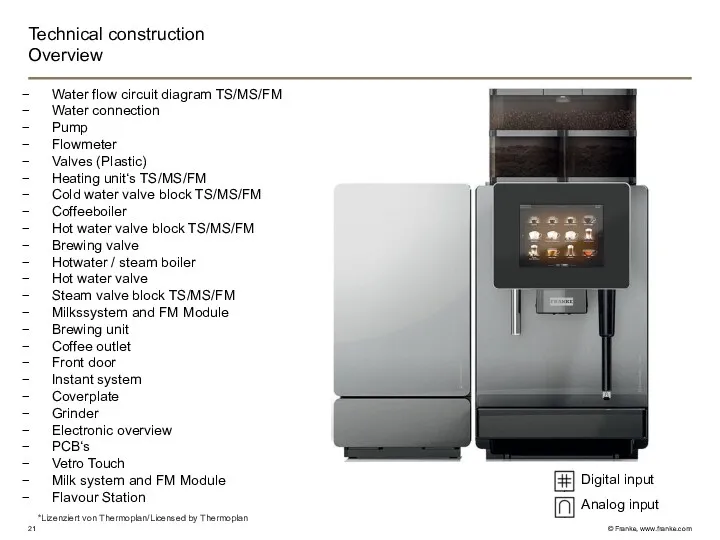

- 21. Technical construction Overview Water flow circuit diagram TS/MS/FM Water connection Pump Flowmeter Valves (Plastic) Heating unit‘s

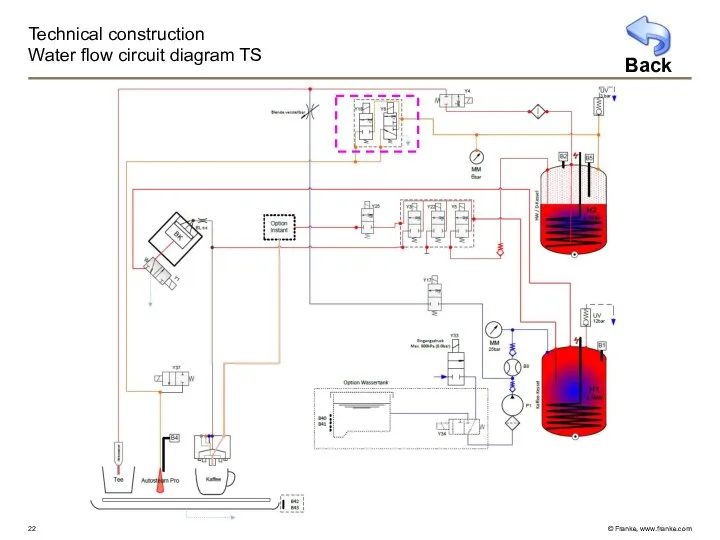

- 22. Technical construction Water flow circuit diagram TS Back

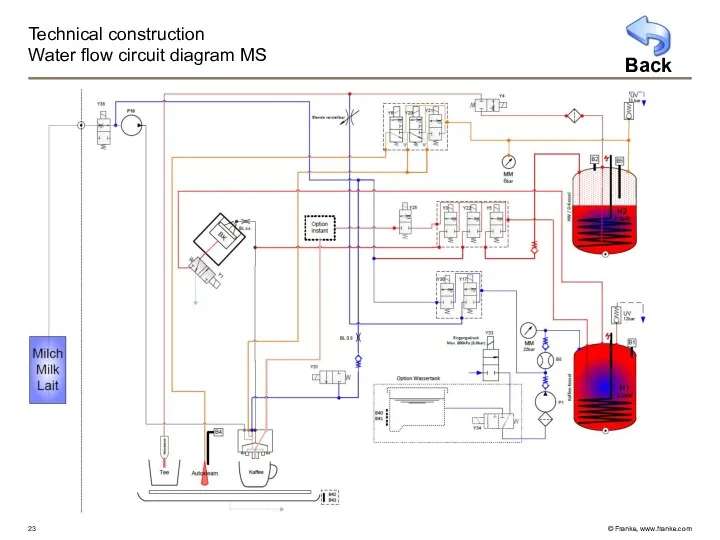

- 23. Technical construction Water flow circuit diagram MS Back

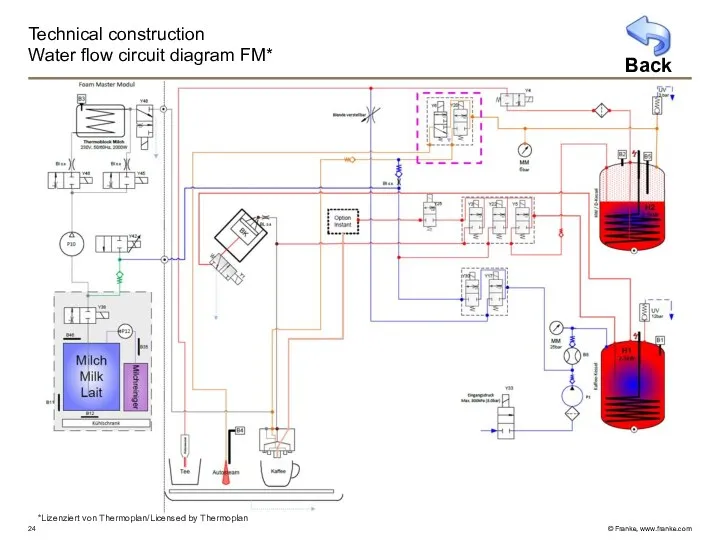

- 24. Technical construction Water flow circuit diagram FM* Back *Lizenziert von Thermoplan/Licensed by Thermoplan

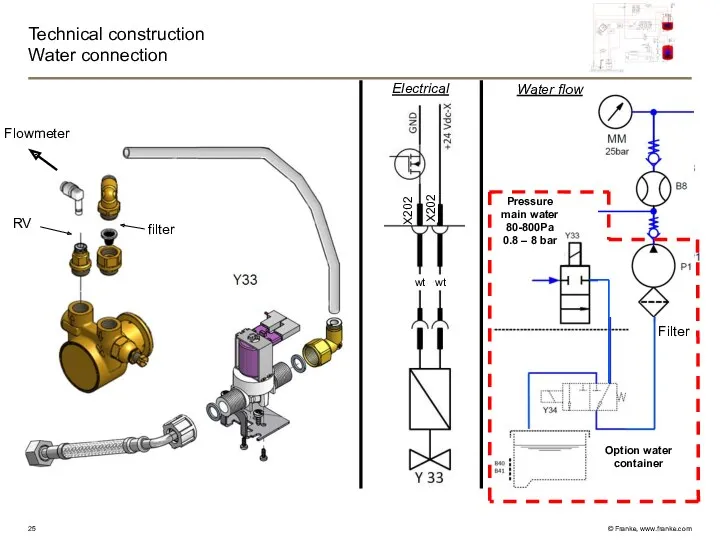

- 25. Technical construction Water connection Y33 Water flow Electrical filter Filter RV RV Flowmeter X202 X202 Pressure

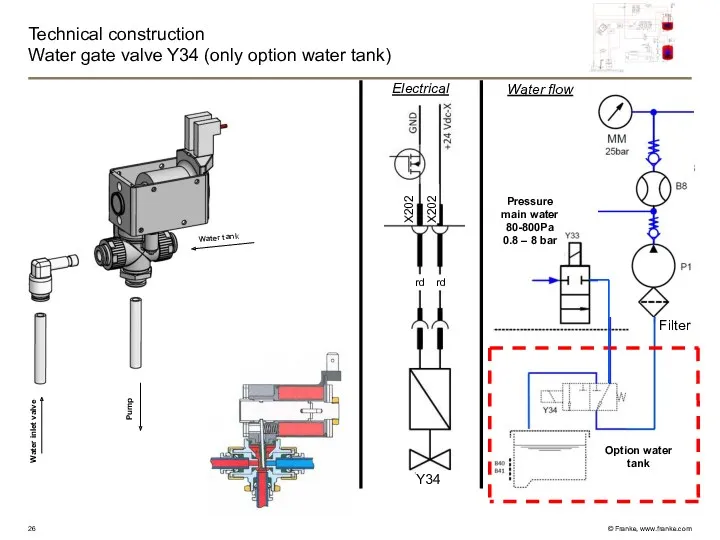

- 26. Technical construction Water gate valve Y34 (only option water tank) Electrical Water flow Filter X202 X202

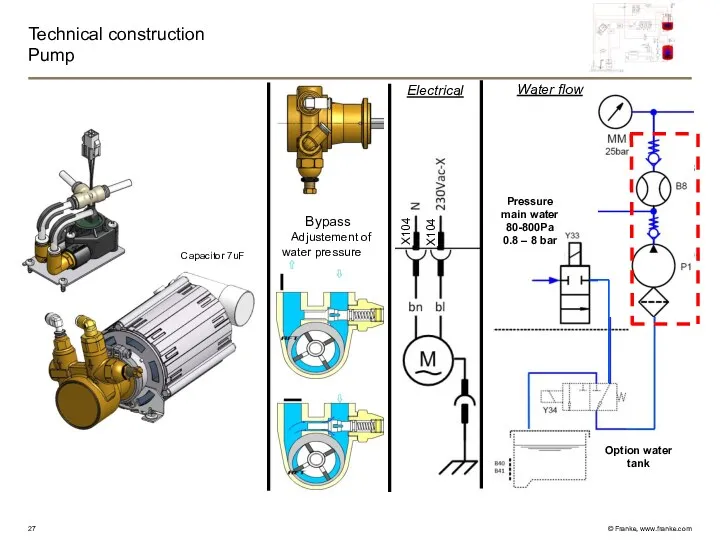

- 27. Technical construction Pump Bypass Adjustement of water pressure Electrical Water flow X104 X104 Capacitor 7uF Pressure

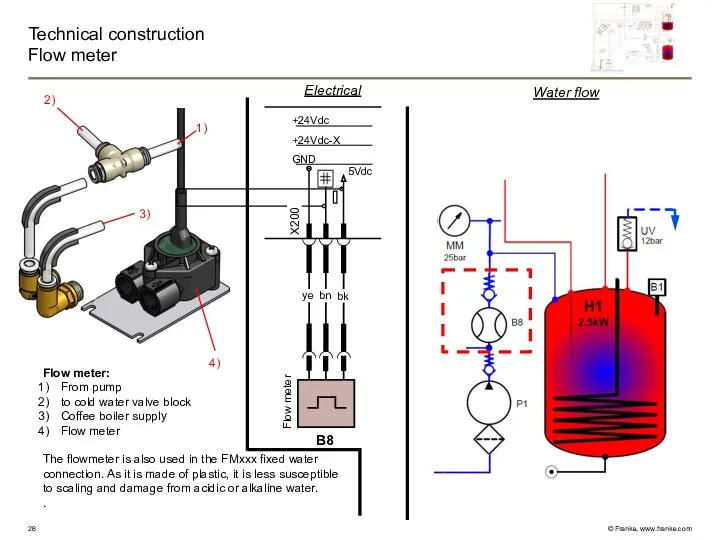

- 28. Technical construction Flow meter Flow meter: From pump to cold water valve block Coffee boiler supply

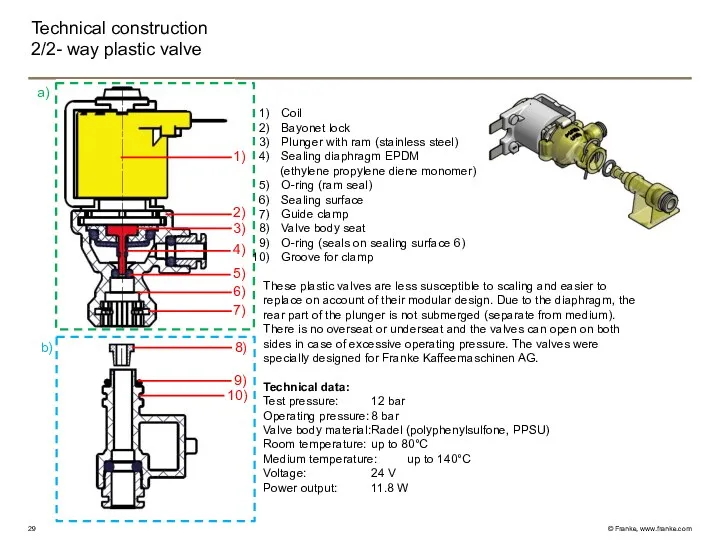

- 29. Technical construction 2/2- way plastic valve 1) 2) 3) 4) 6) 5) 7) 9) 10) a)

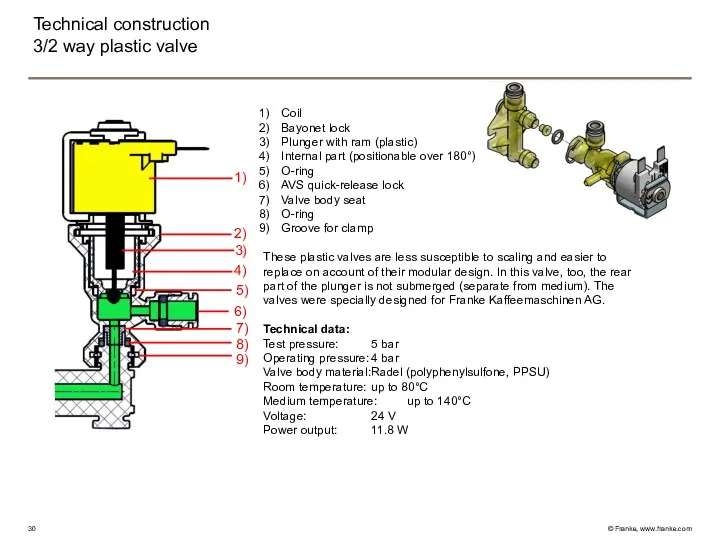

- 30. Technical construction 3/2 way plastic valve 1) 2) 3) 4) 6) 5) 7) 8) 9) Coil

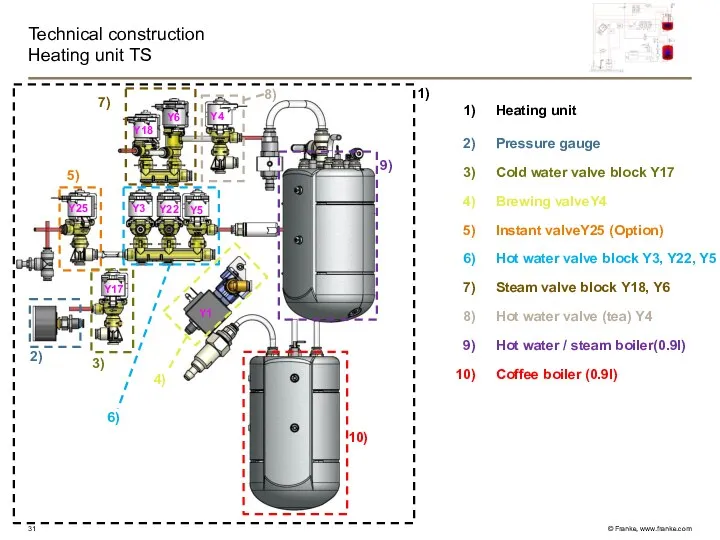

- 31. Technical construction Heating unit TS 6) 9) 10) 2) 7) 8) 3) 1) 4) 5) Y1

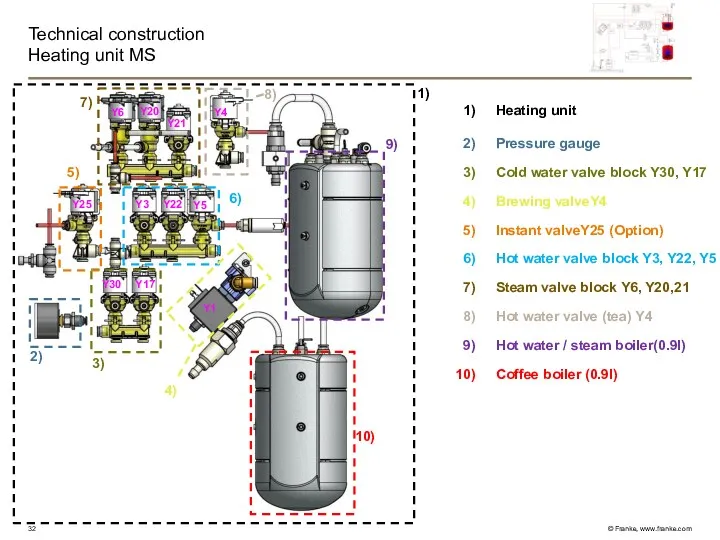

- 32. Technical construction Heating unit MS 6) 9) 10) 2) 7) 8) 3) 1) 4) 5) Y1

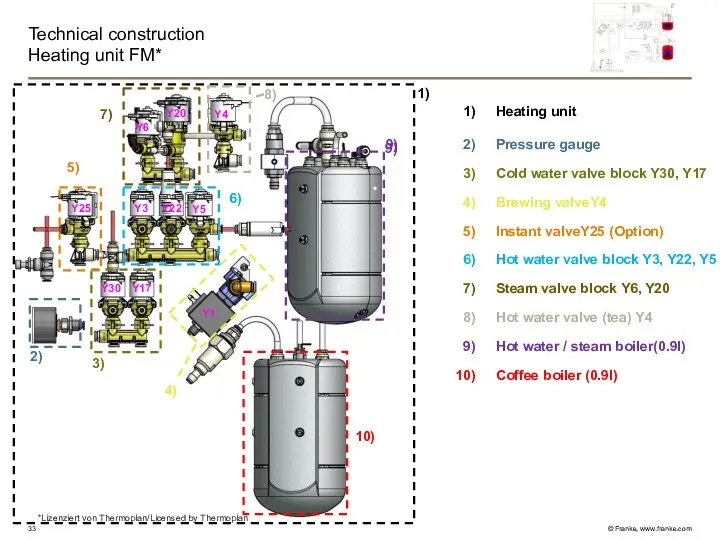

- 33. Technical construction Heating unit FM* Heating unit Pressure gauge Cold water valve block Y30, Y17 Brewing

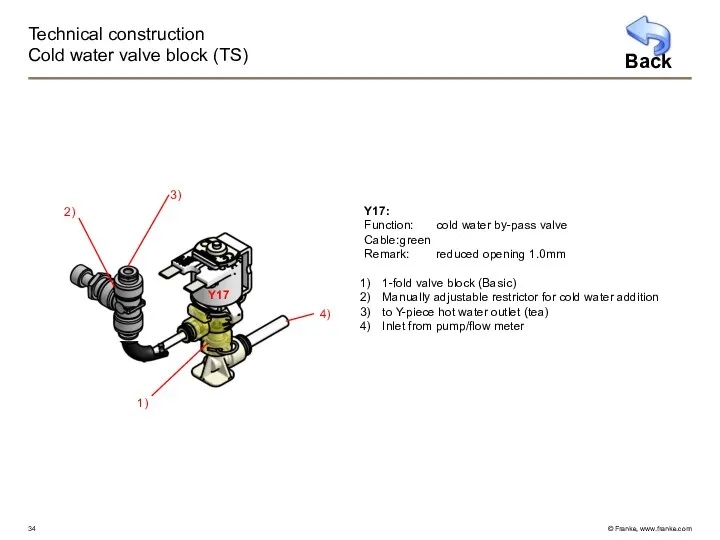

- 34. Technical construction Cold water valve block (TS) Y17: Function: cold water by-pass valve Cable: green Remark:

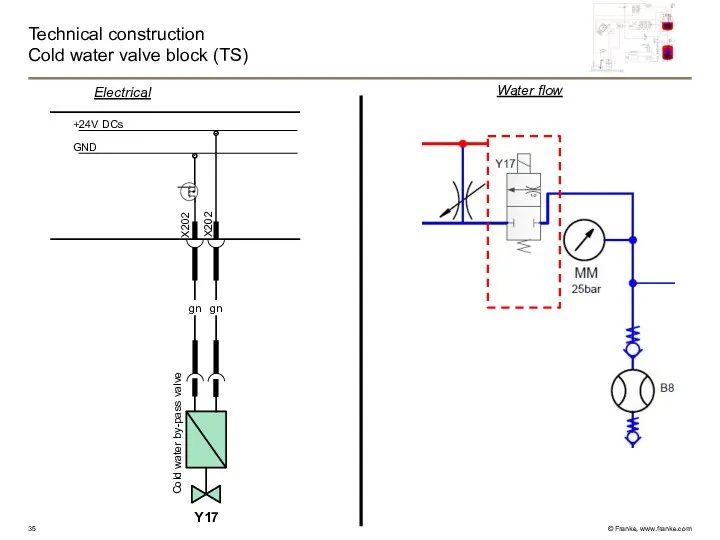

- 35. Technical construction Cold water valve block (TS) GND +24V DCs X202 X202 gn gn Y17 Water

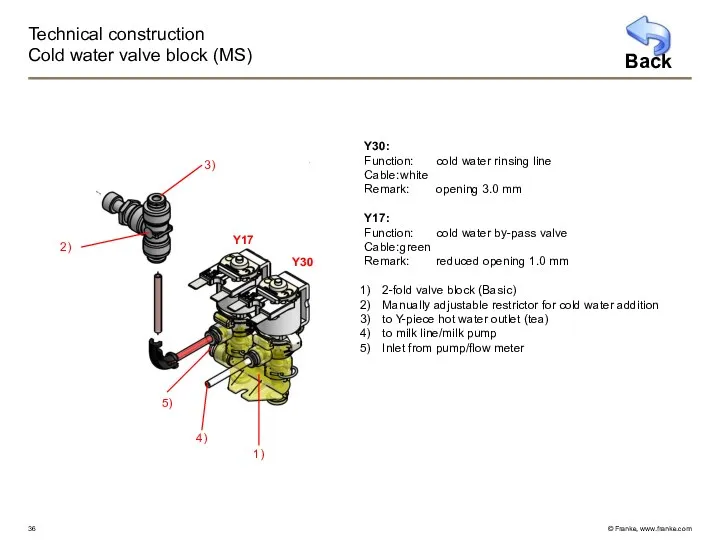

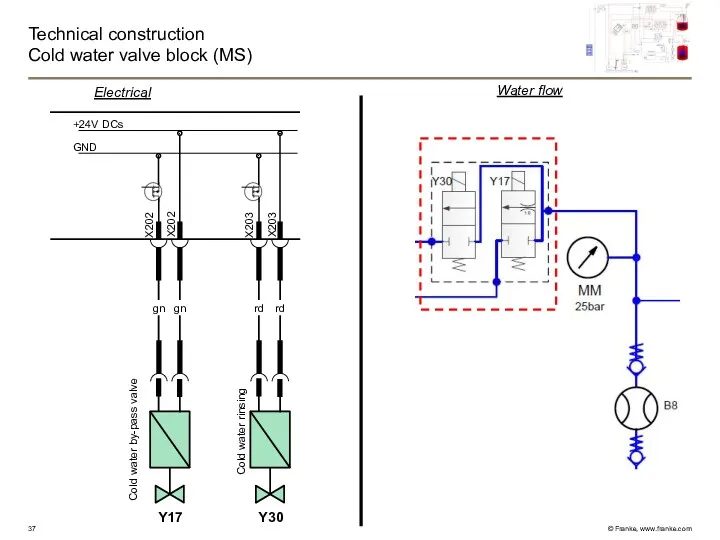

- 36. Technical construction Cold water valve block (MS) Y30: Function: cold water rinsing line Cable: white Remark:

- 37. Technical construction Cold water valve block (MS) GND +24V DCs X202 X202 gn gn Water flow

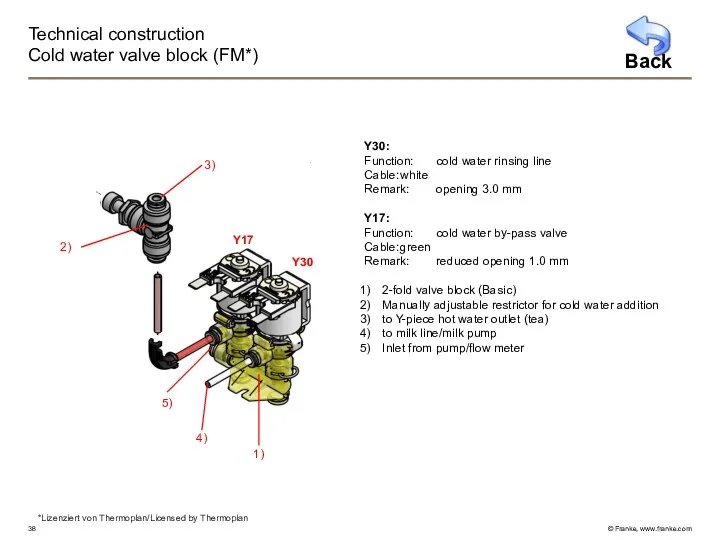

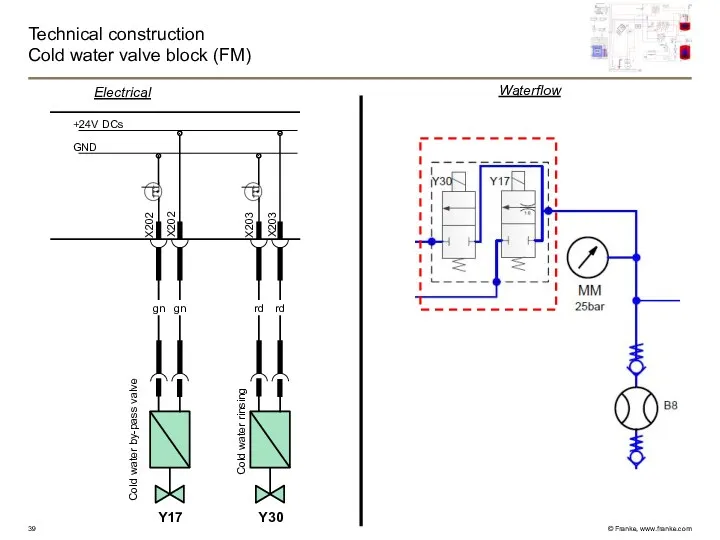

- 38. Technical construction Cold water valve block (FM*) Y17 2) 1) 3) 4) Y30 5) Back *Lizenziert

- 39. Technical construction Cold water valve block (FM) Waterflow GND +24V DCs X202 X202 gn gn Electrical

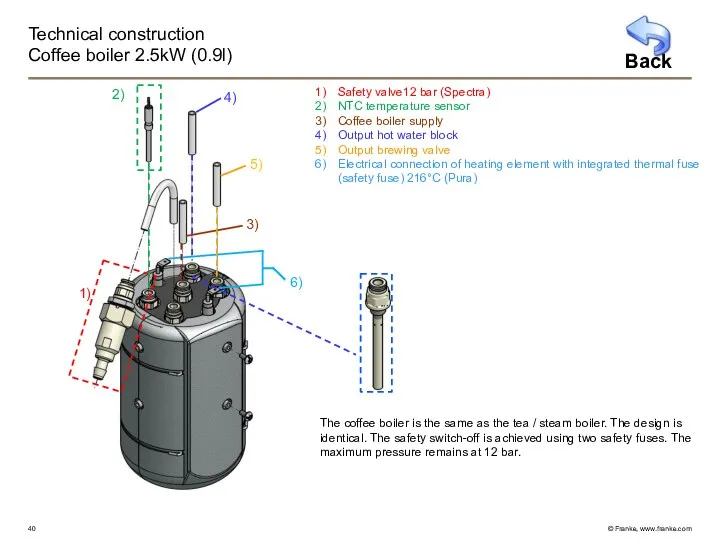

- 40. Technical construction Coffee boiler 2.5kW (0.9l) Safety valve12 bar (Spectra) NTC temperature sensor Coffee boiler supply

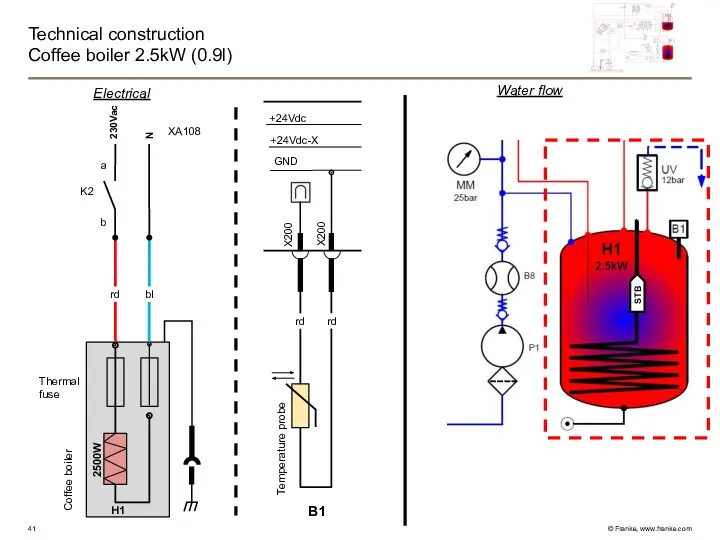

- 41. Technical construction Coffee boiler 2.5kW (0.9l) Electrical N rd H1 bl K2 b a Thermal fuse

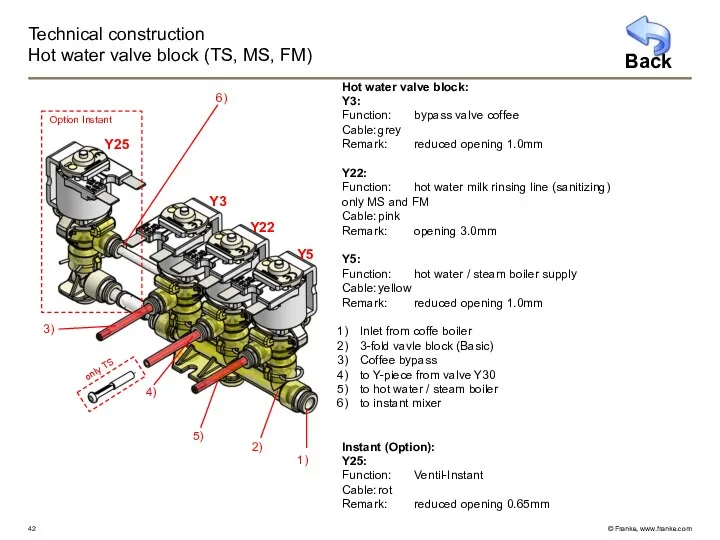

- 42. Technical construction Hot water valve block (TS, MS, FM) Hot water valve block: Y3: Function: bypass

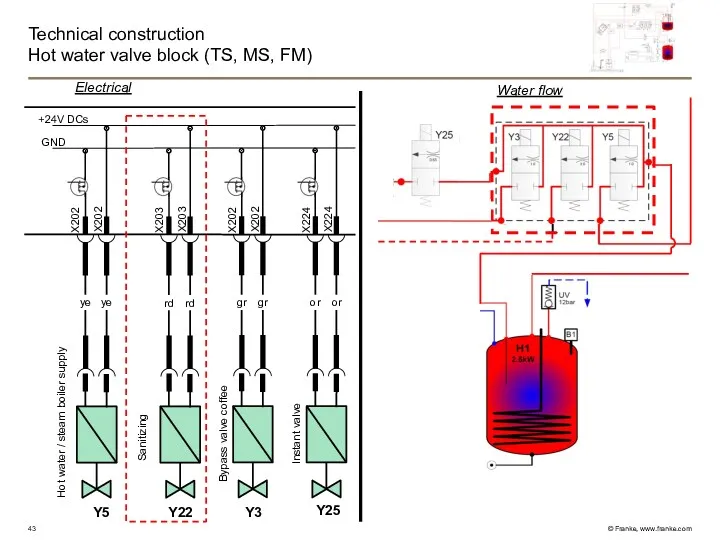

- 43. Technical construction Hot water valve block (TS, MS, FM) GND +24V DCs X202 X202 X203 X203

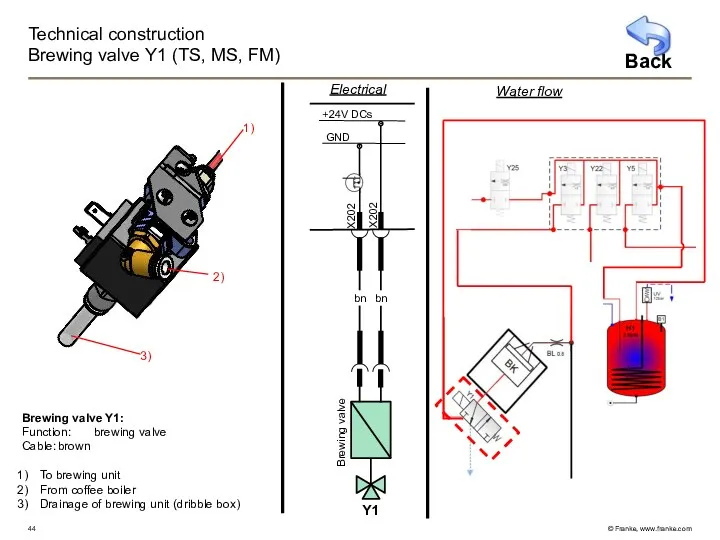

- 44. Technical construction Brewing valve Y1 (TS, MS, FM) GND +24V DCs Electrical X202 X202 bn bn

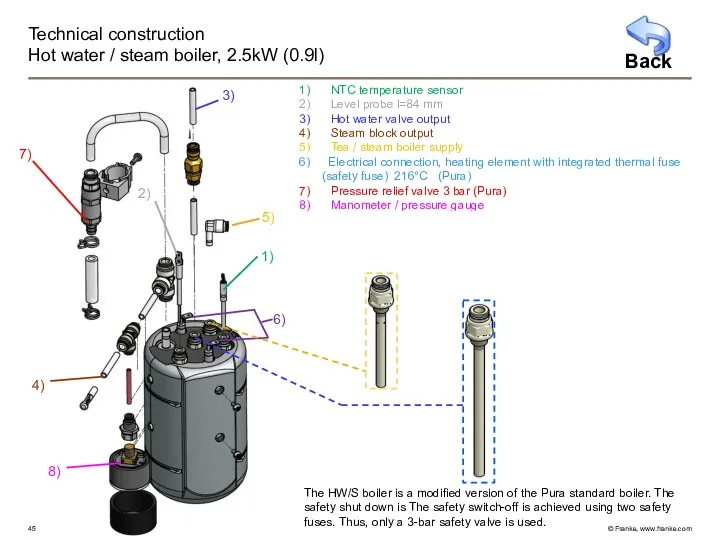

- 45. Technical construction Hot water / steam boiler, 2.5kW (0.9l) NTC temperature sensor Level probe l=84 mm

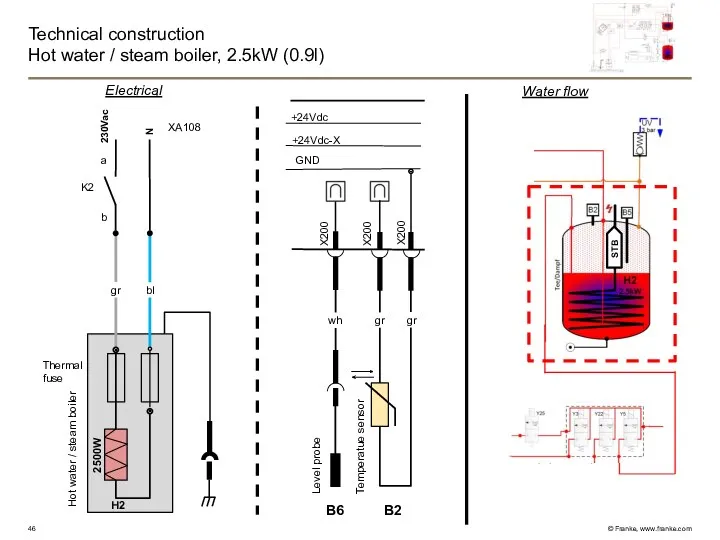

- 46. Technical construction Hot water / steam boiler, 2.5kW (0.9l) STB Water flow Electrical N gr H2

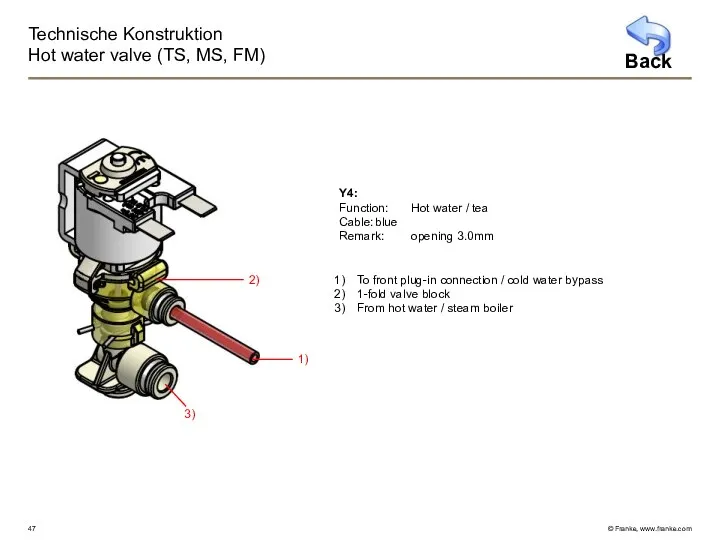

- 47. Technische Konstruktion Hot water valve (TS, MS, FM) 1) 2) 3) Y4: Function: Hot water /

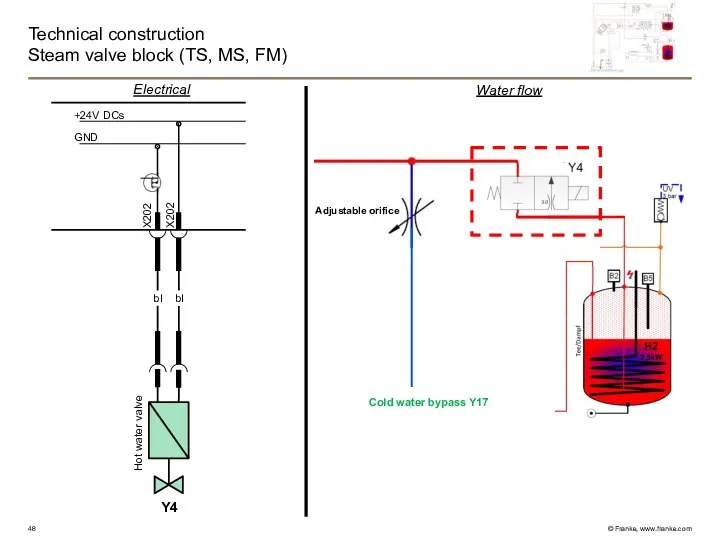

- 48. Technical construction Steam valve block (TS, MS, FM) GND +24V DCs X202 X202 bl bl Y4

- 49. Technical construction Steam valve block TS Y6: Fuction: Autosteam (3/2 way valve) Cable: brown Remark: Opening

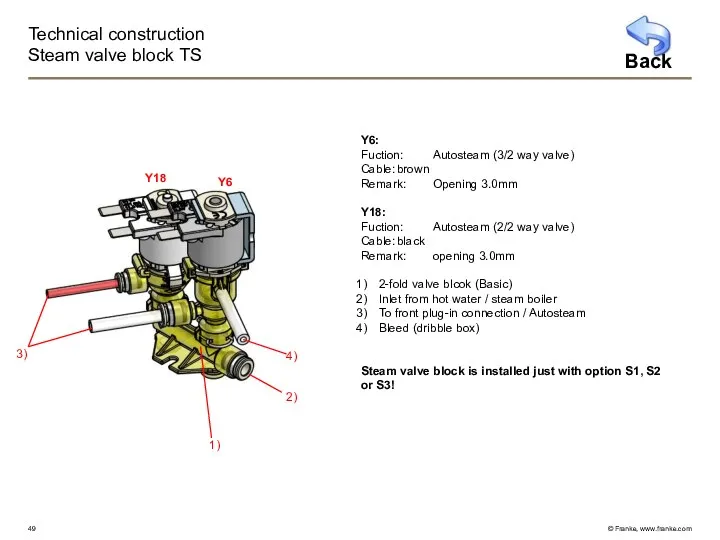

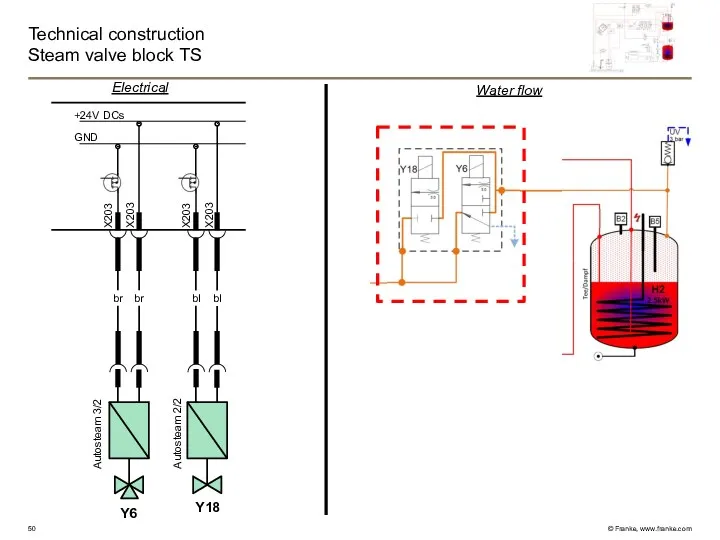

- 50. Technical construction Steam valve block TS GND +24V DCs X203 X203 X203 X203 br br bl

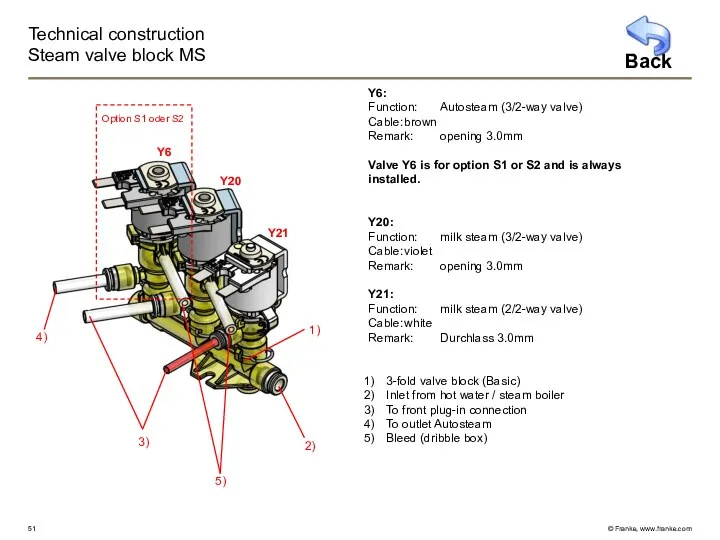

- 51. Technical construction Steam valve block MS Y6: Function: Autosteam (3/2-way valve) Cable: brown Remark: opening 3.0mm

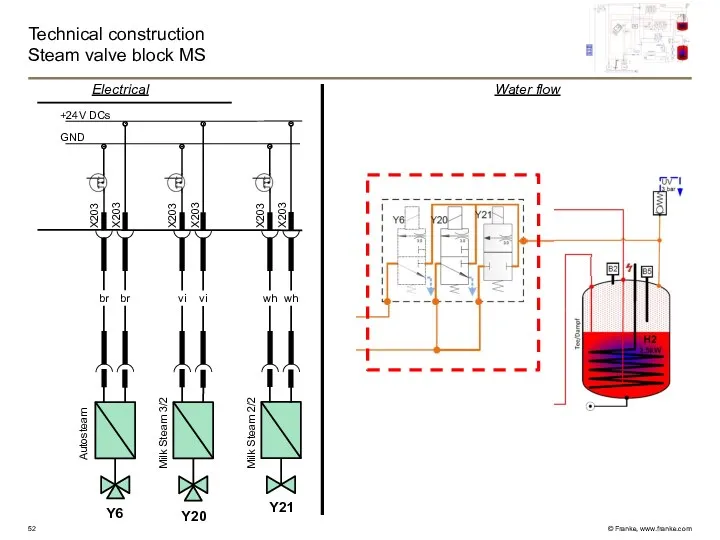

- 52. Technical construction Steam valve block MS GND +24V DCs X203 X203 X203 X203 br br vi

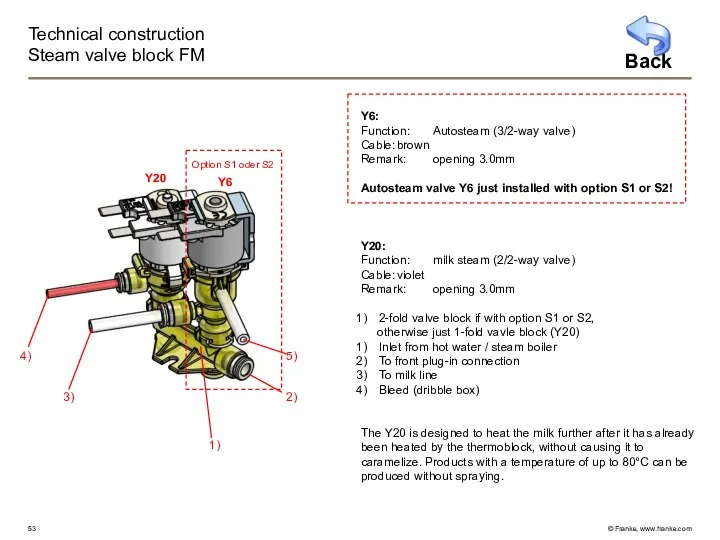

- 53. Technical construction Steam valve block FM Y6: Function: Autosteam (3/2-way valve) Cable: brown Remark: opening 3.0mm

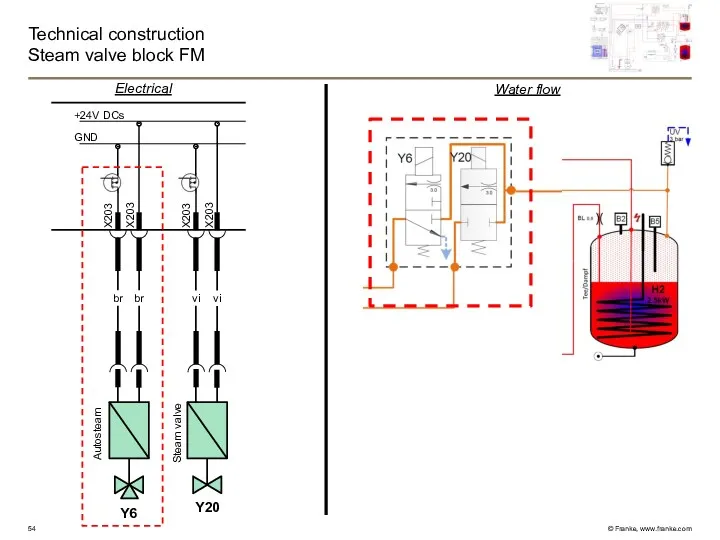

- 54. Technical construction Steam valve block FM GND +24V DCs X203 X203 X203 X203 br br vi

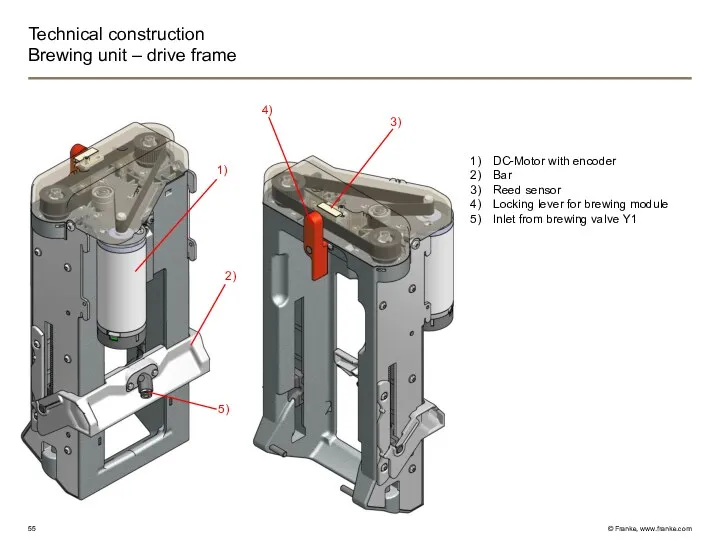

- 55. Technical construction Brewing unit – drive frame DC-Motor with encoder Bar Reed sensor Locking lever for

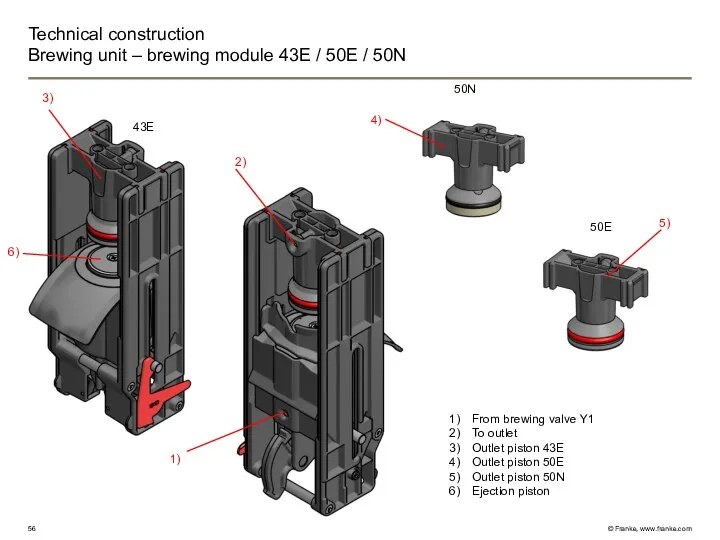

- 56. Technical construction Brewing unit – brewing module 43E / 50E / 50N 43E 50N 50E From

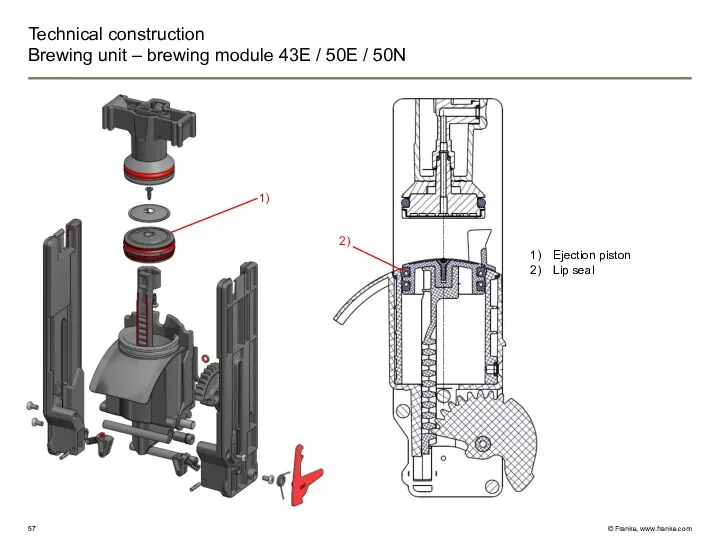

- 57. Technical construction Brewing unit – brewing module 43E / 50E / 50N Ejection piston Lip seal

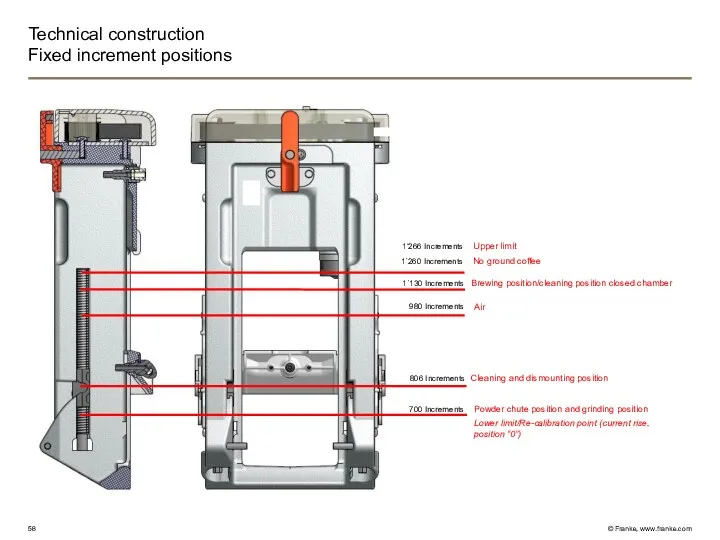

- 58. Lower limit/Re-calibration point (current rise, position “0”) Cleaning and dismounting position Powder chute position and grinding

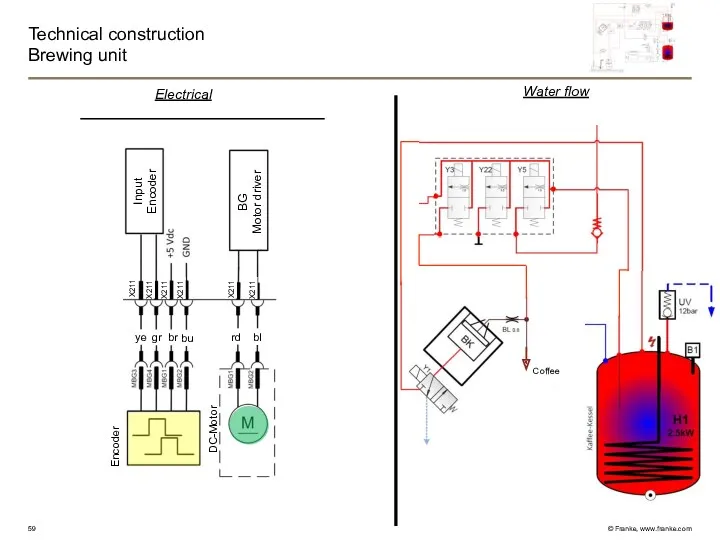

- 59. Technical construction Brewing unit Coffee Water flow Electrical Encoder DC-Motor rd bl ye gr br bu

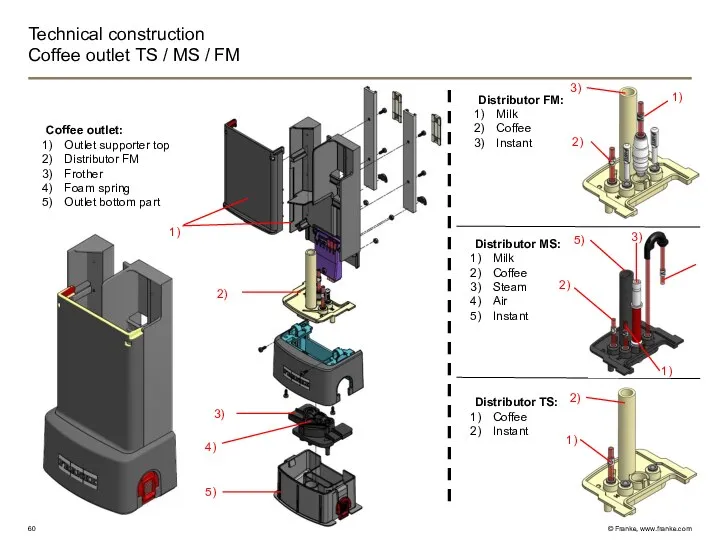

- 60. Technical construction Coffee outlet TS / MS / FM Distributor FM: Milk Coffee Instant Coffee outlet:

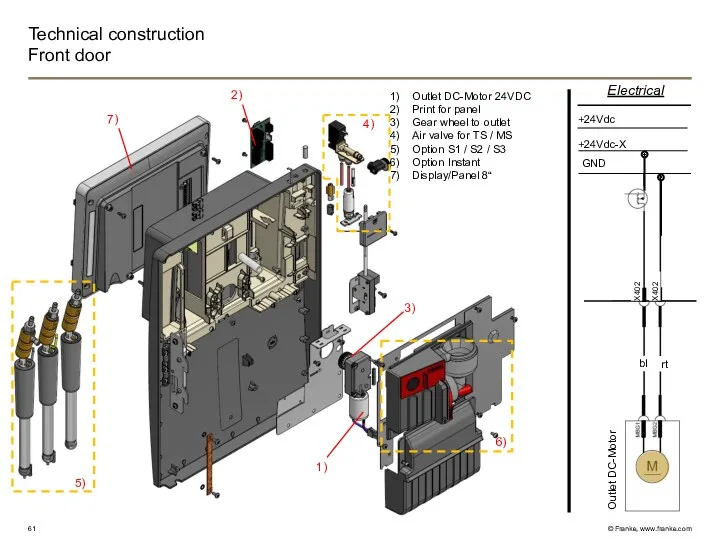

- 61. Technical construction Front door Electrical Outlet Motor GND +24Vdc-X +24Vdc Outlet DC-Motor bl rt Outlet DC-Motor

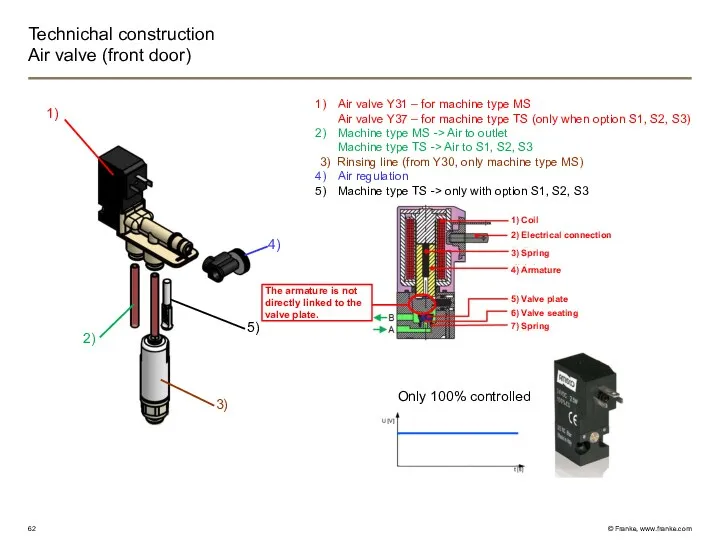

- 62. Technichal construction Air valve (front door) Air valve Y31 – for machine type MS Air valve

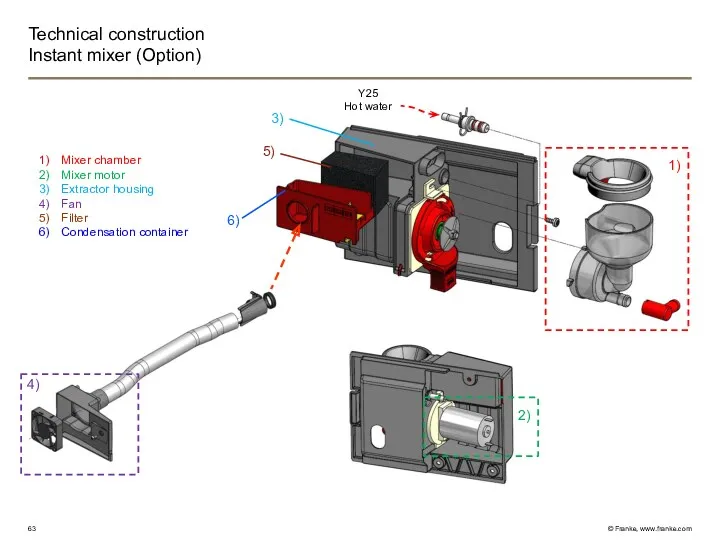

- 63. Technical construction Instant mixer (Option) 1) 2) 3) Mixer chamber Mixer motor Extractor housing Fan Filter

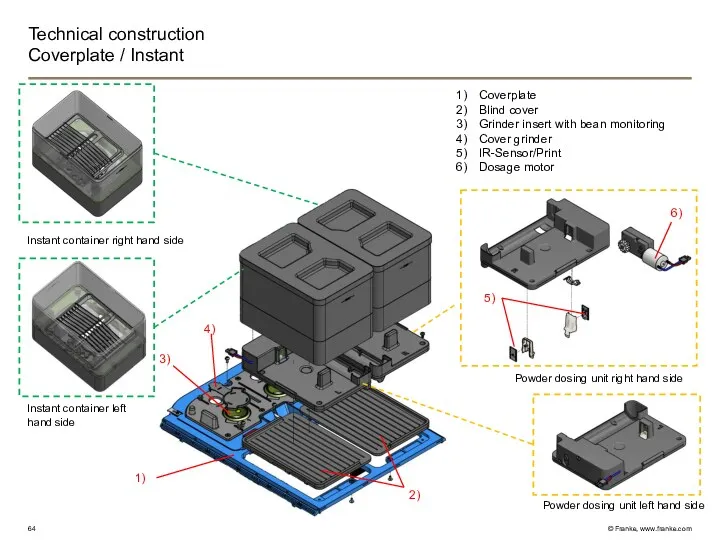

- 64. Pulverdosierer rechts Technical construction Coverplate / Instant Coverplate Blind cover Grinder insert with bean monitoring Cover

- 65. Technical construction Coverplate / layout of containers 1 2 3 4

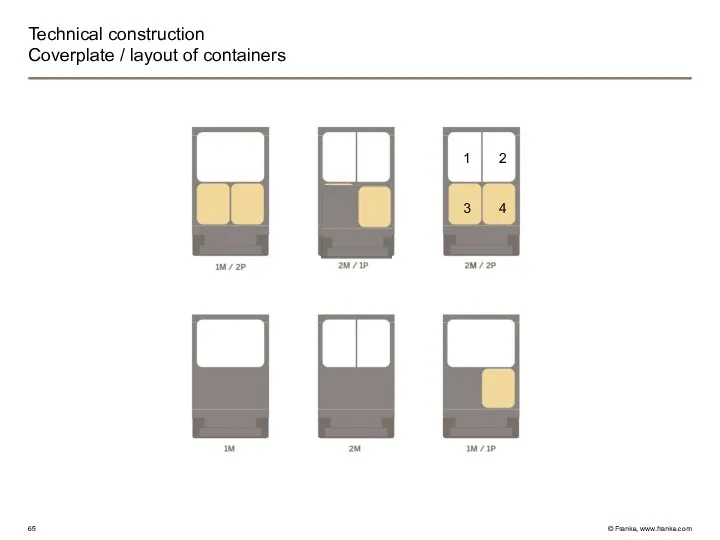

- 66. Technical construction Instant Electrical GND +24Vdc-X +24Vdc Instant fan Instant valve Mixer motor Instant right hand

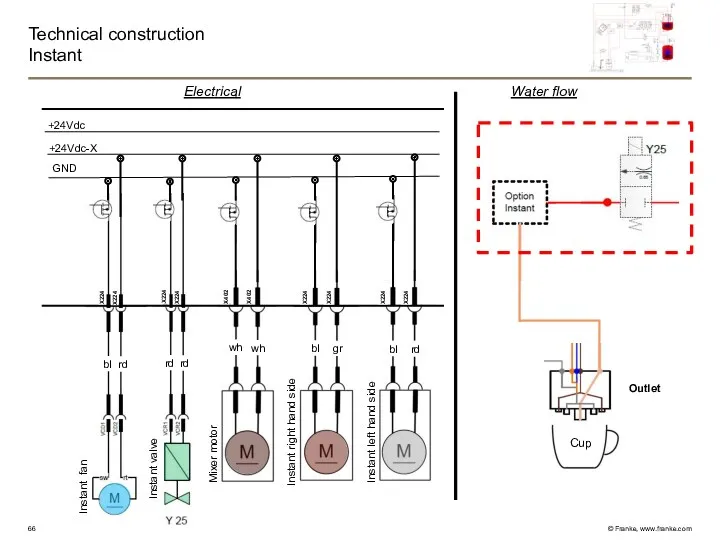

- 67. Technical construction Grinder (Pura) Grinder right Mühle links 1) 2) 3) 4) 6) 5) Specification of

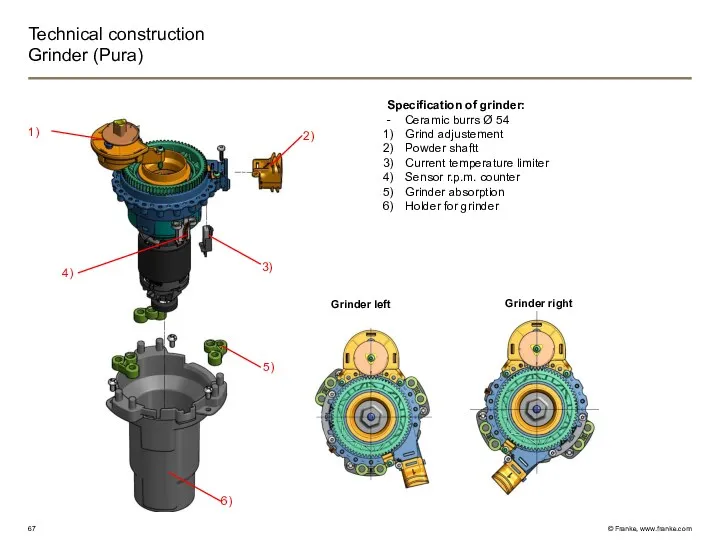

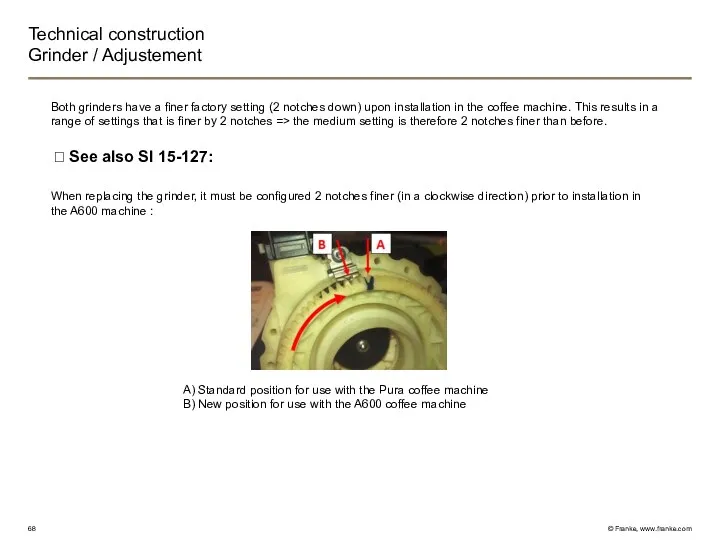

- 68. Technical construction Grinder / Adjustement A) Standard position for use with the Pura coffee machine B)

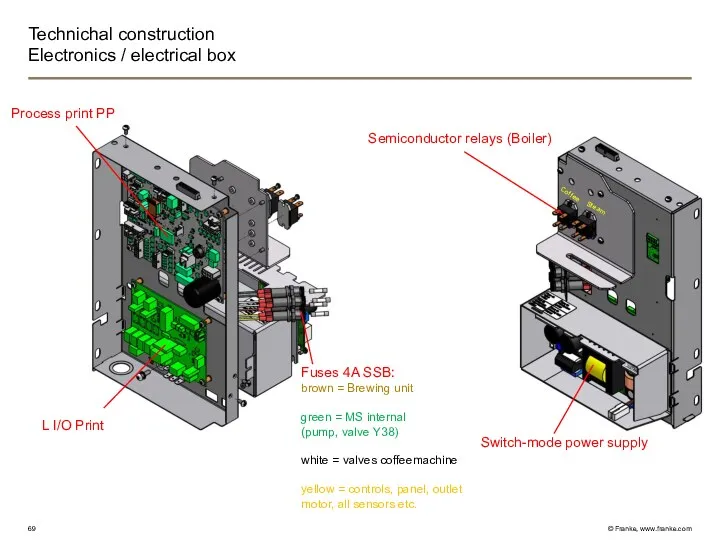

- 69. Technichal construction Electronics / electrical box Switch-mode power supply L I/O Print Semiconductor relays (Boiler) Process

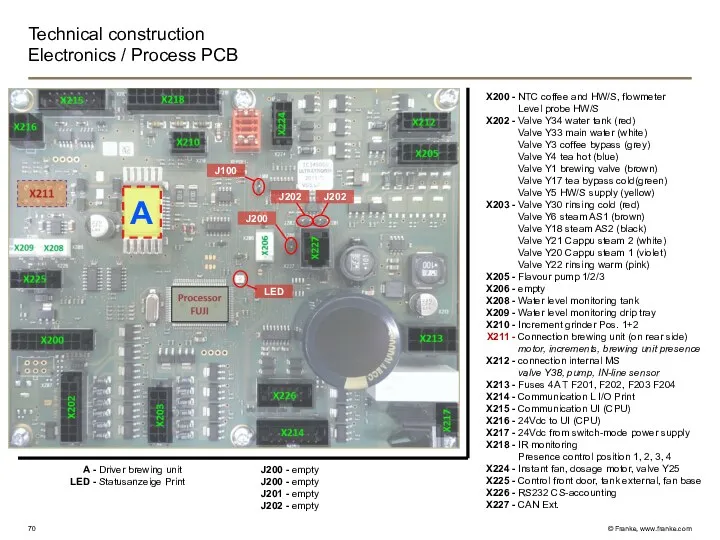

- 70. Technical construction Electronics / Process PCB X200 - X202 - X203 - X205 - X206 -

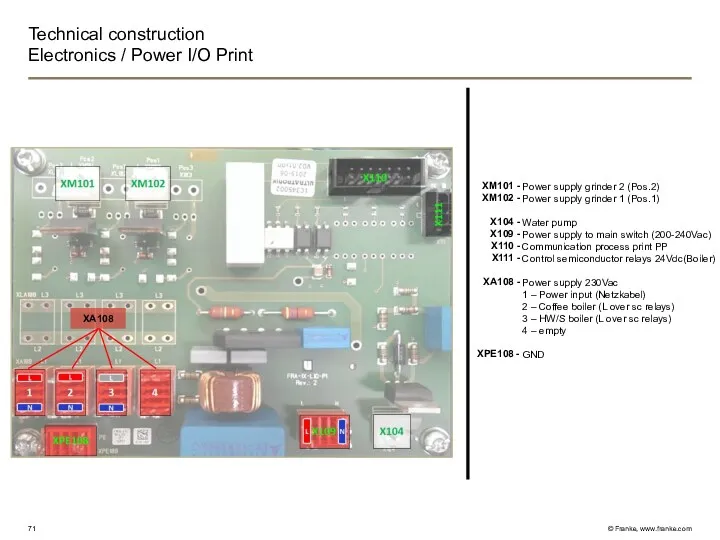

- 71. Technical construction Electronics / Power I/O Print XM101 - XM102 - X104 - X109 - X110

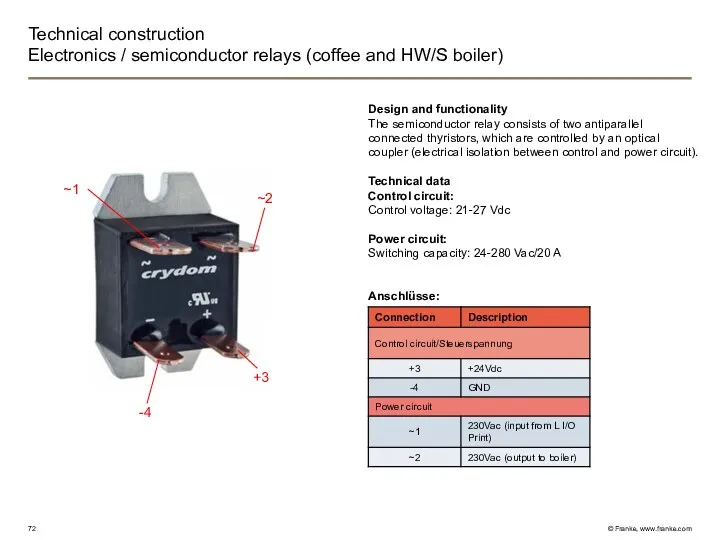

- 72. Technical construction Electronics / semiconductor relays (coffee and HW/S boiler) Design and functionality The semiconductor relay

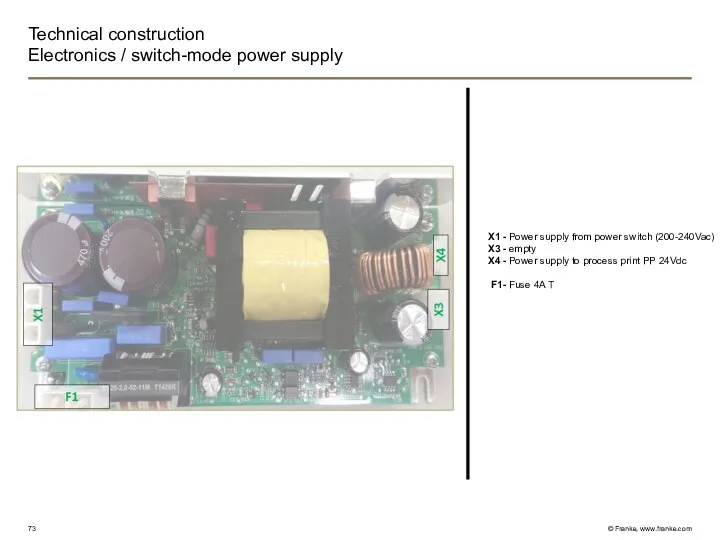

- 73. Technical construction Electronics / switch-mode power supply X1 - X3 - X4 - F1- Power supply

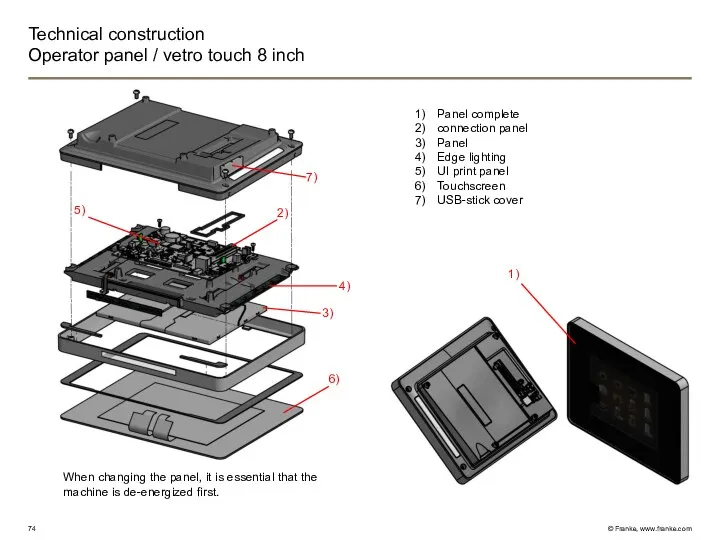

- 74. Technical construction Operator panel / vetro touch 8 inch Panel complete connection panel Panel Edge lighting

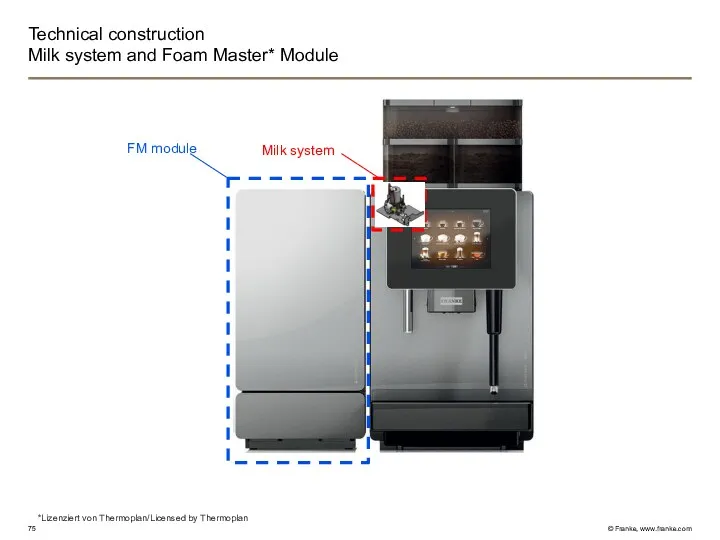

- 75. Technical construction Milk system and Foam Master* Module *Lizenziert von Thermoplan/Licensed by Thermoplan FM module Milk

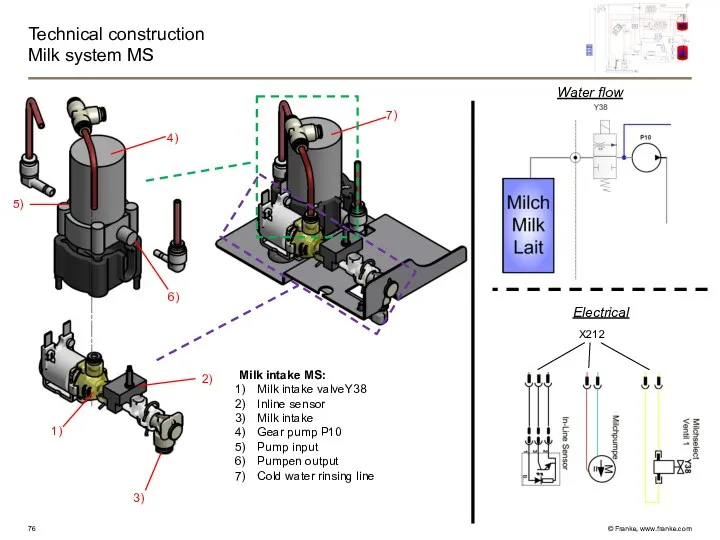

- 76. Technical construction Milk system MS Milk intake MS: Milk intake valveY38 Inline sensor Milk intake Gear

- 77. Technical construction Milk system MS / gear pump Construction and functionality The gear pump is a

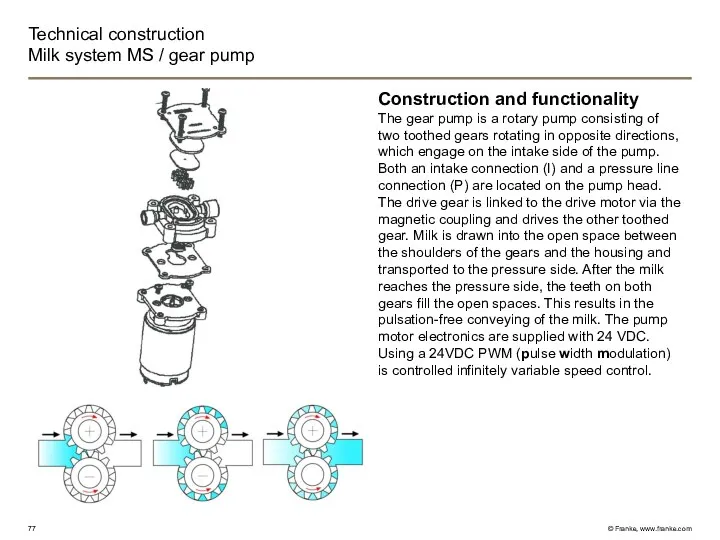

- 78. Technical construction FM* Module *Lizenziert von Thermoplan/Licensed by Thermoplan

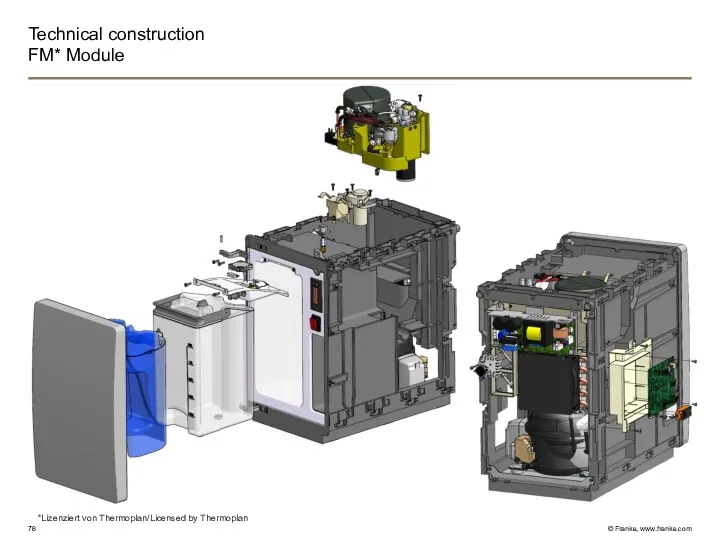

- 79. Technical construction Slide in module FM* Water flow Milk valve Y46 (warm) Gear pump (P10) Milk

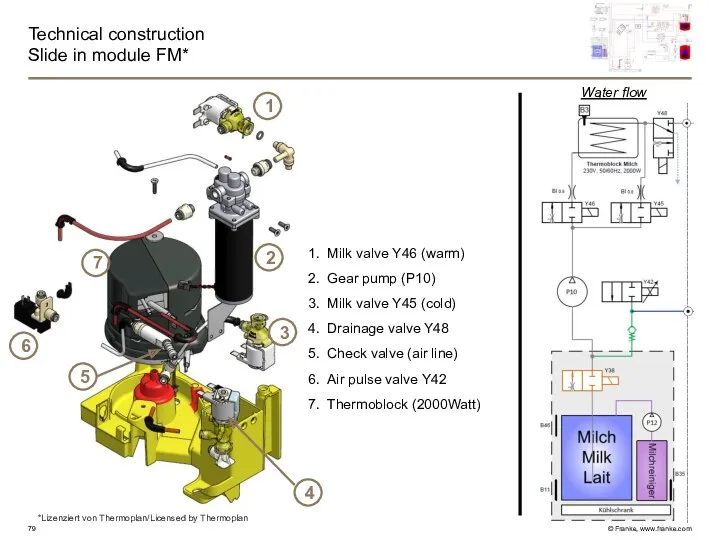

- 80. Technical construction Slide in module FM* / Thermoblock Thermoblock (2000Watt) Isolation Thermoblock R Isolation Thermoblock L

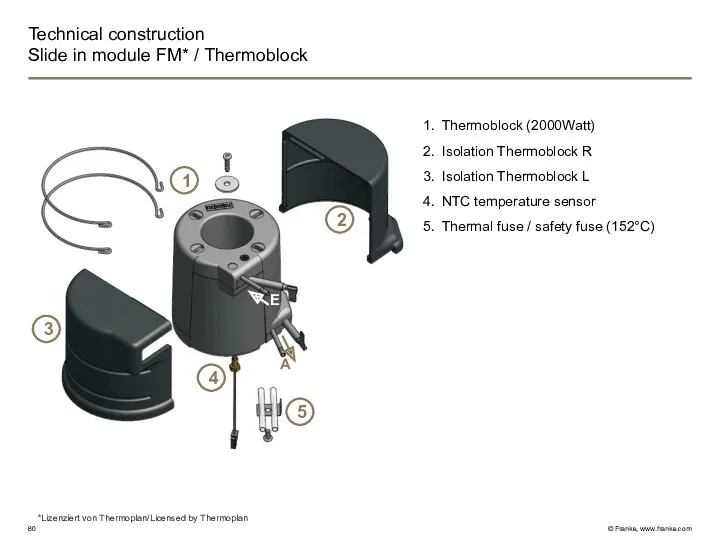

- 81. Technical construction Thermoblock (only FM*) Water flow Electrical 230Vac N sw H3 bl K3 b a

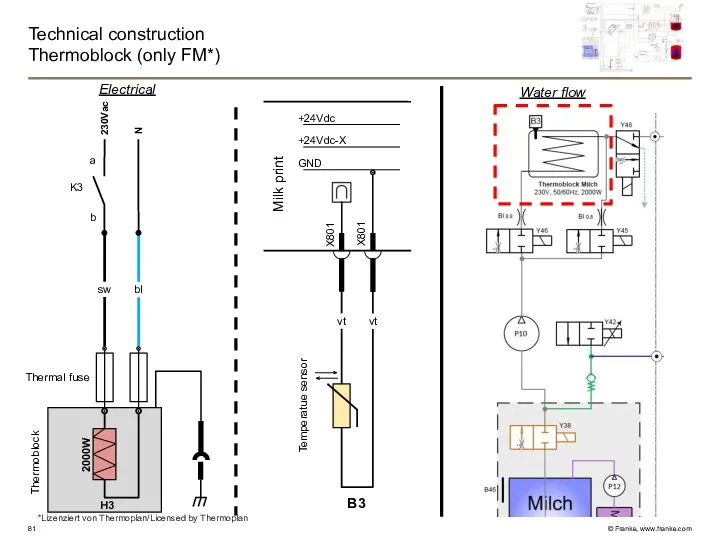

- 82. Technical construction Slide in module FM* / gear pump & air pulse valve 1) Coil 2)

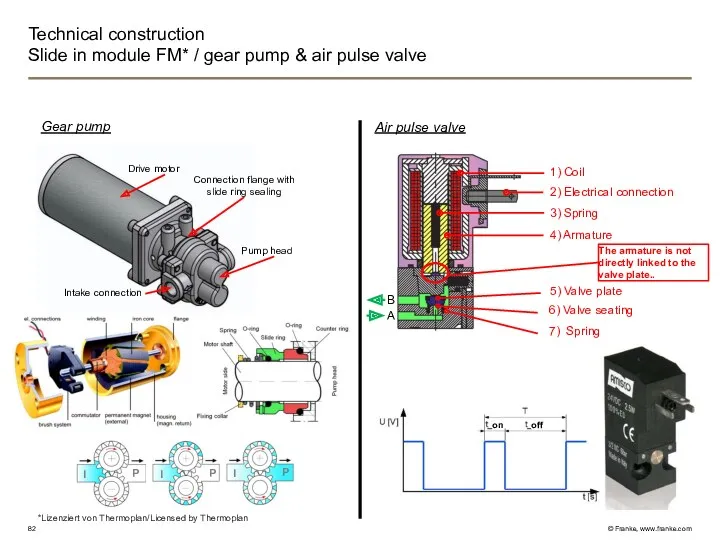

- 83. Technical construction Cleaning agent detection and peristaltic pump FM* Modul Cleaning agent detection (Conductivity) Peristaltic pump

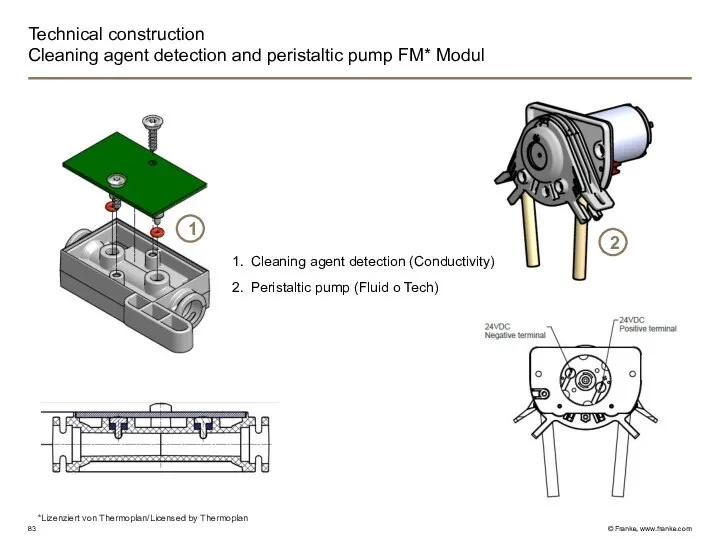

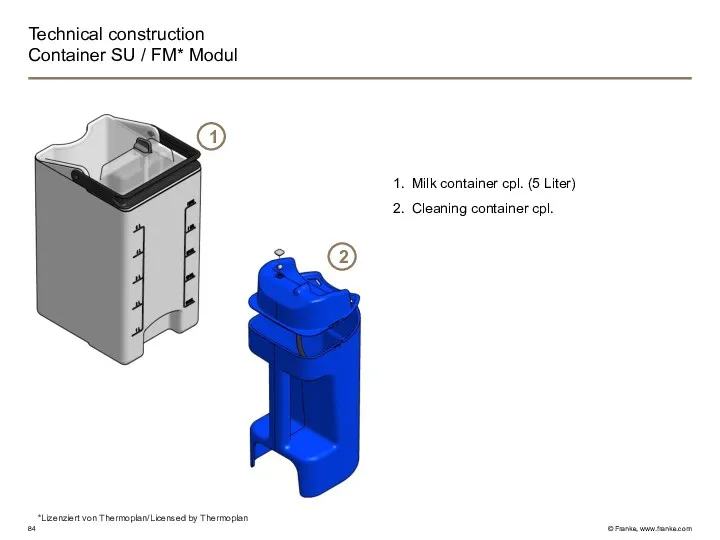

- 84. Technical construction Container SU / FM* Modul Milk container cpl. (5 Liter) Cleaning container cpl. 1

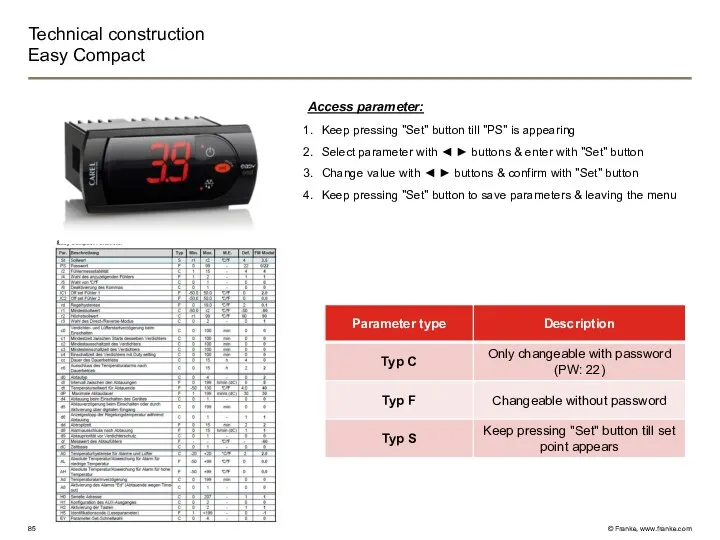

- 85. Technical construction Easy Compact Access parameter: Keep pressing "Set" button till "PS" is appearing Select parameter

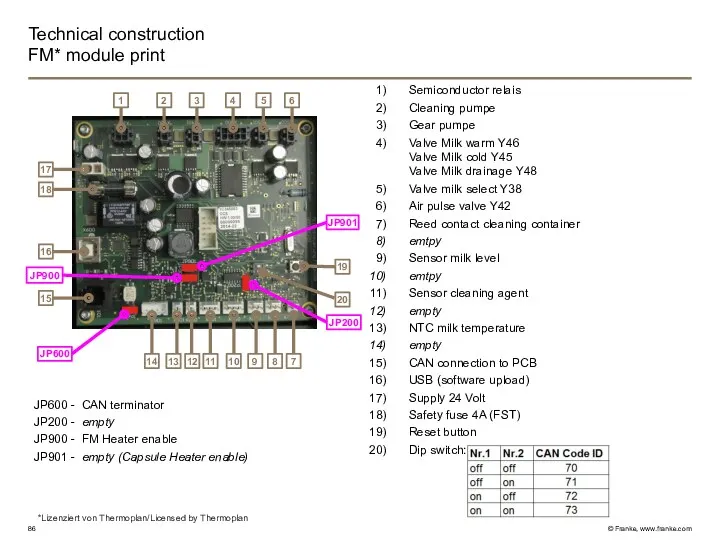

- 86. Technical construction FM* module print Semiconductor relais Cleaning pumpe Gear pumpe Valve Milk warm Y46 Valve

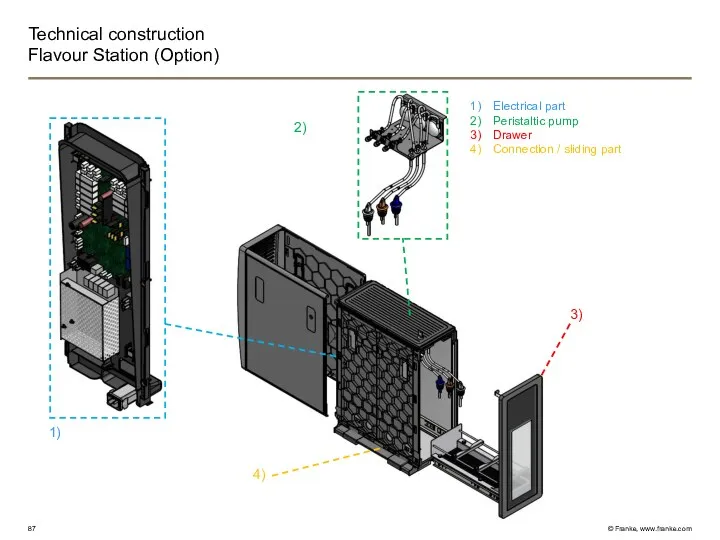

- 87. Technical construction Flavour Station (Option) Electrical part Peristaltic pump Drawer Connection / sliding part 2) 1)

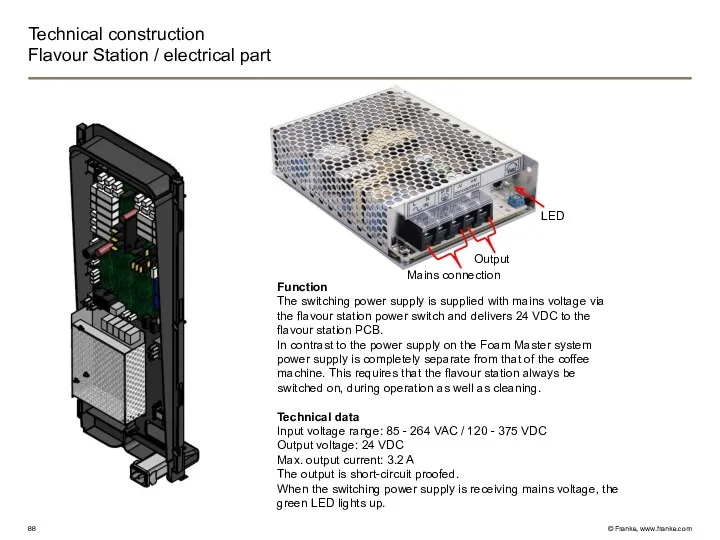

- 88. Technical construction Flavour Station / electrical part Function The switching power supply is supplied with mains

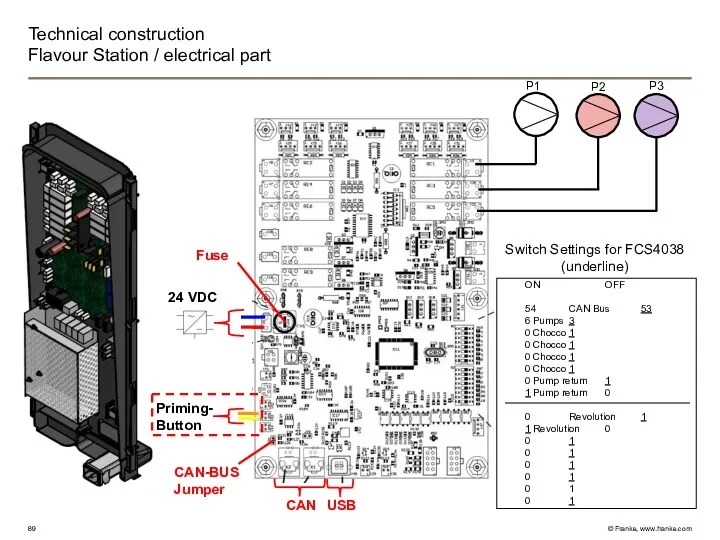

- 89. Technical construction Flavour Station / electrical part P1 P3 P2 24 VDC USB CAN Priming- Button

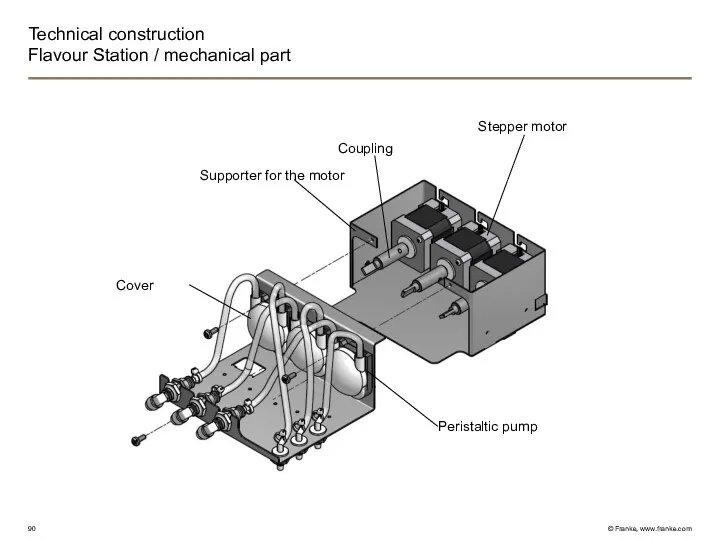

- 90. Technical construction Flavour Station / mechanical part Stepper motor Coupling Supporter for the motor Peristaltic pump

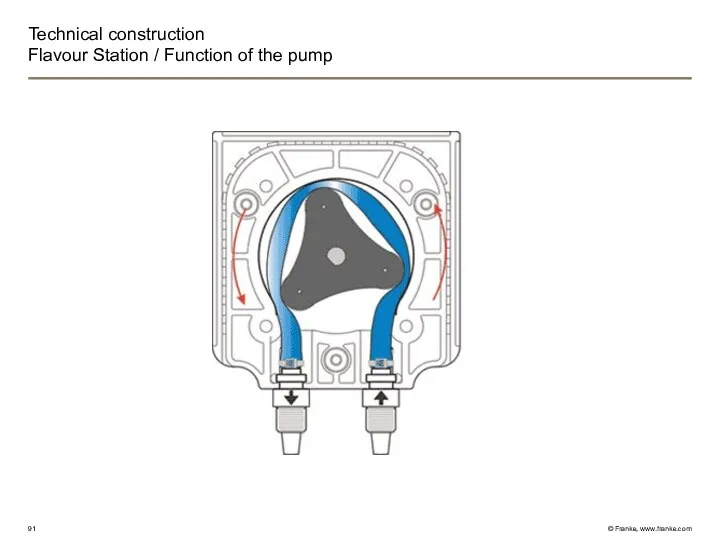

- 91. Technical construction Flavour Station / Function of the pump

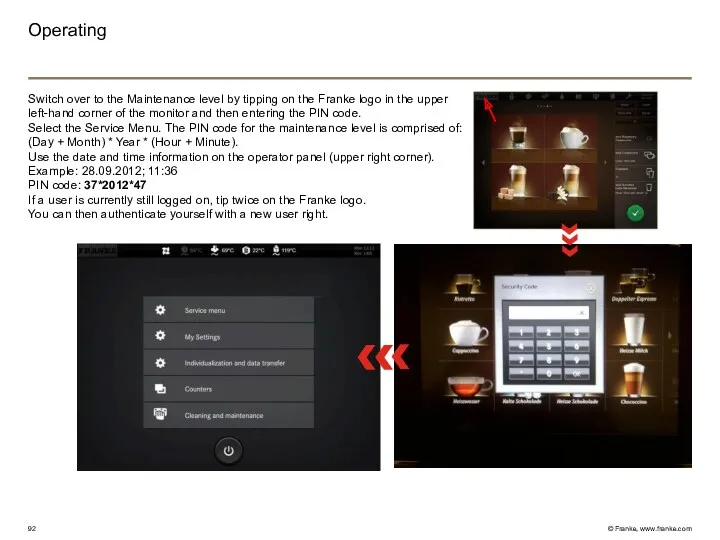

- 92. Operating Switch over to the Maintenance level by tipping on the Franke logo in the upper

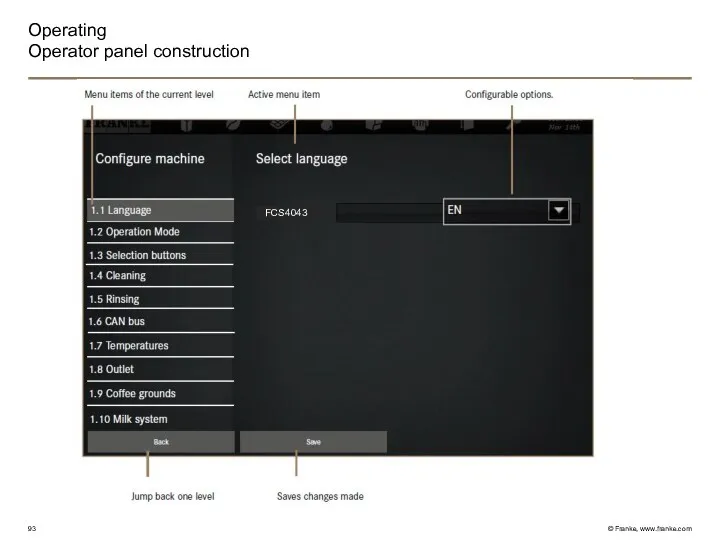

- 93. Operating Operator panel construction FCS4043

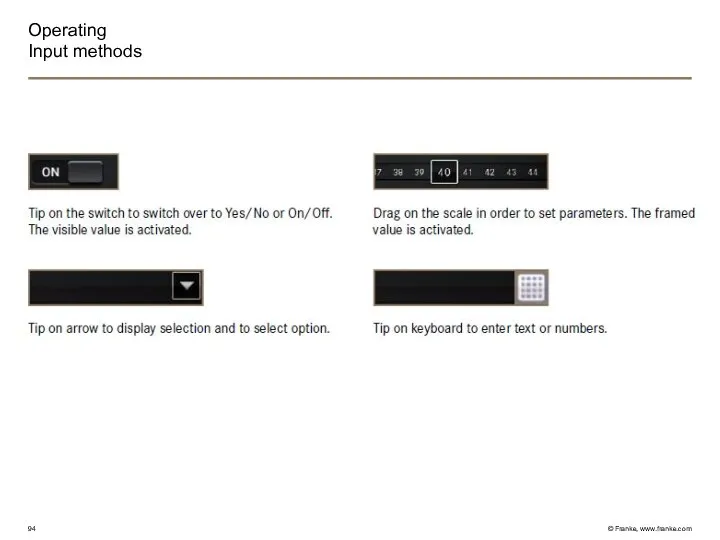

- 94. Operating Input methods

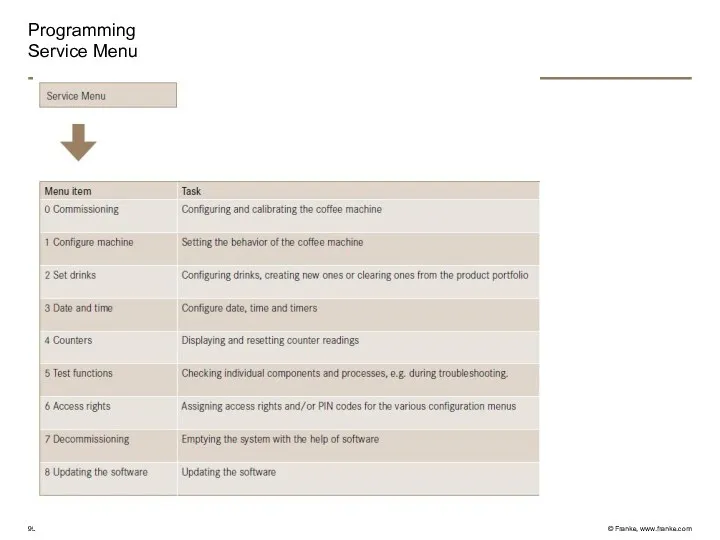

- 95. Programming Service Menu

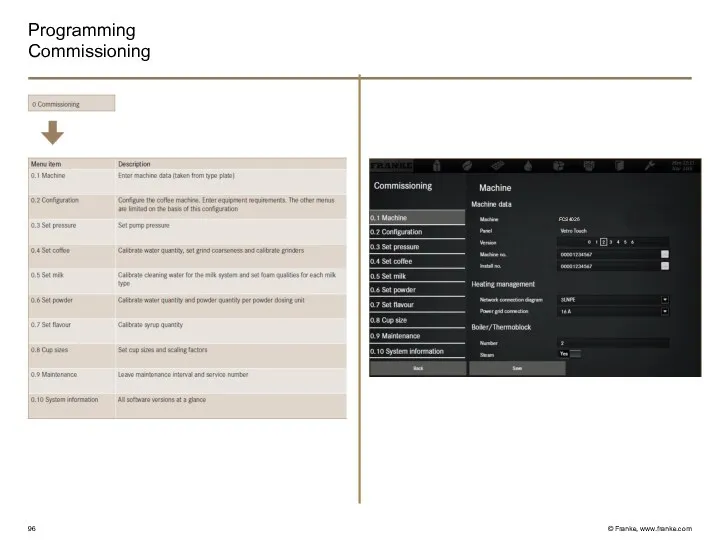

- 96. Programming Commissioning FCS4026

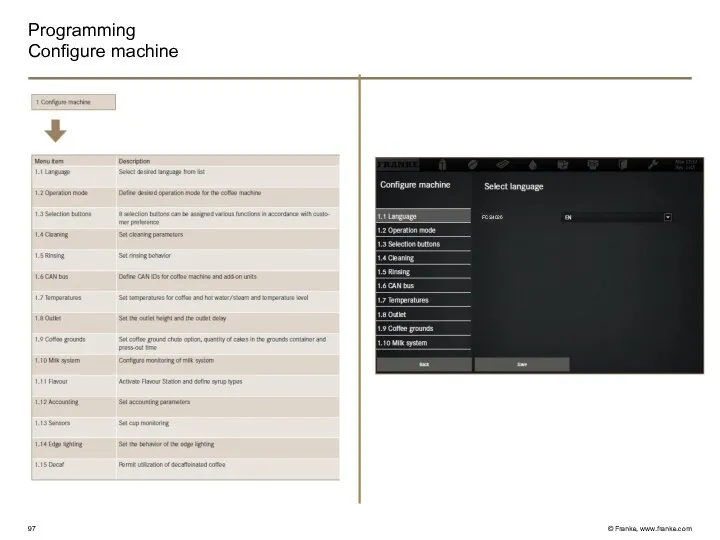

- 97. Programming Configure machine FCS4026

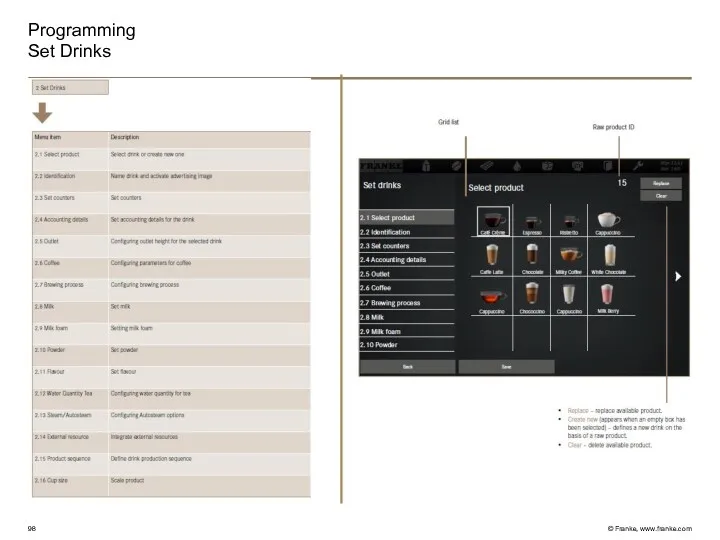

- 98. Programming Set Drinks

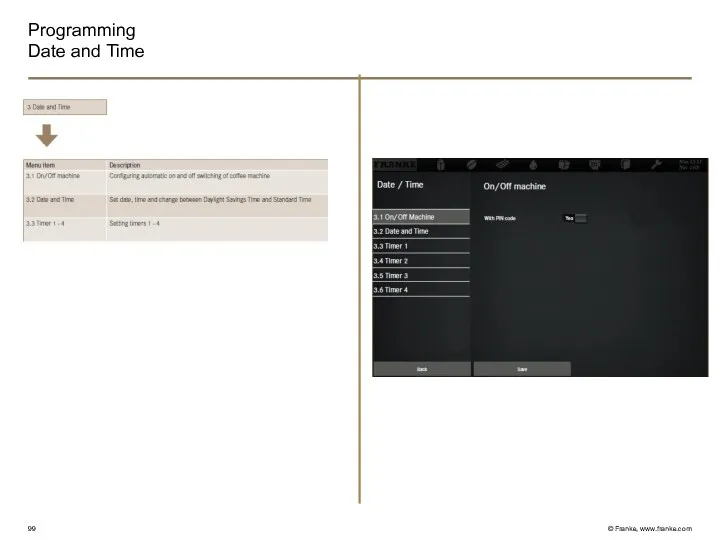

- 99. Programming Date and Time

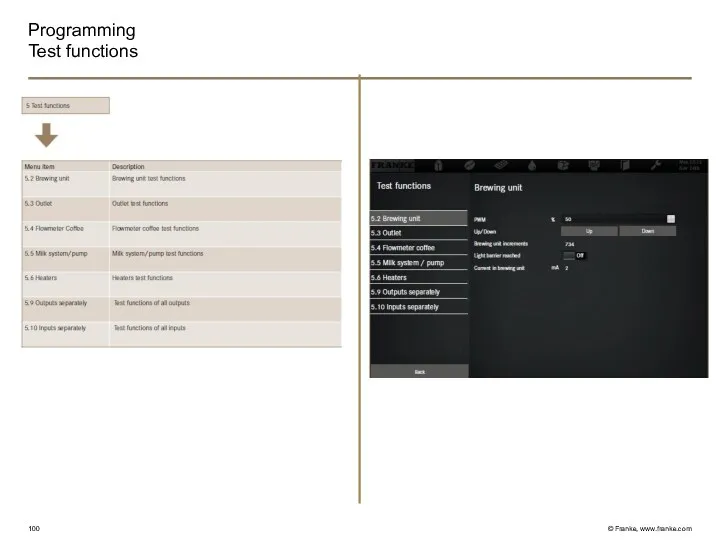

- 100. Programming Test functions

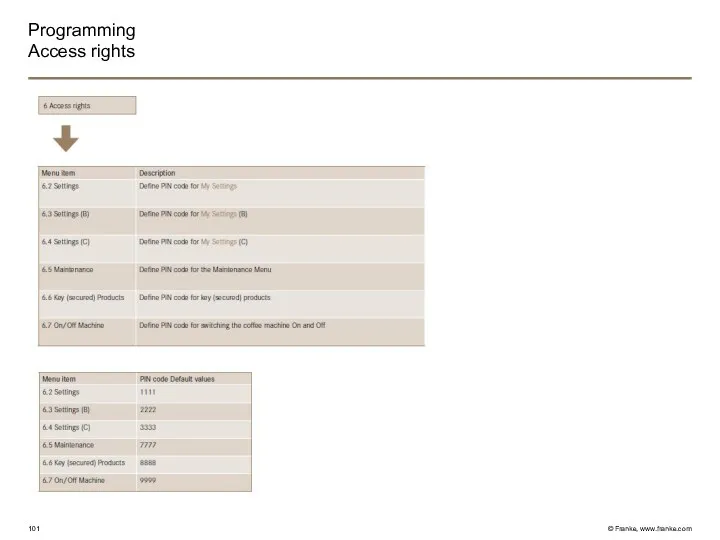

- 101. Programming Access rights

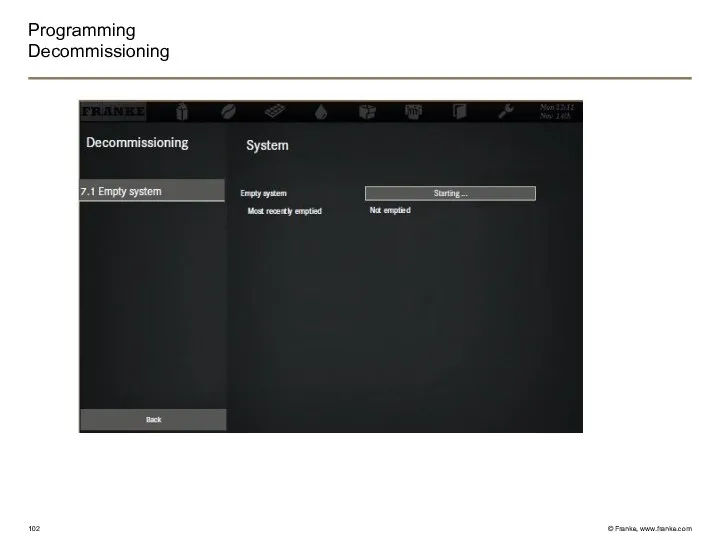

- 102. Programming Decommissioning

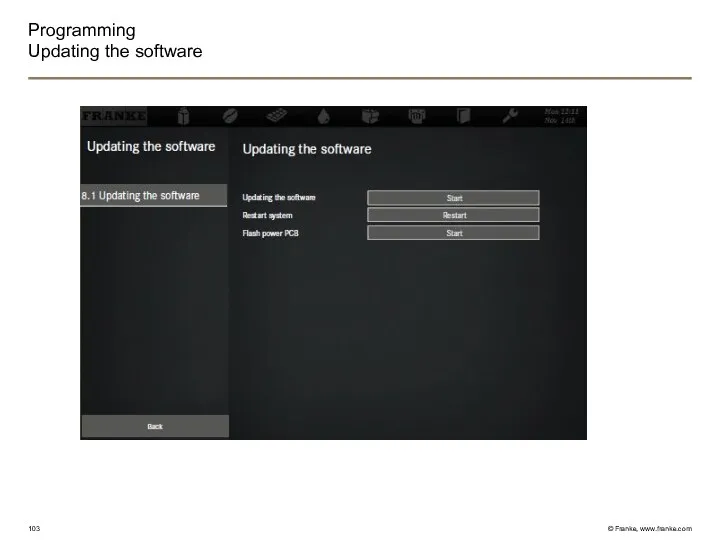

- 103. Programming Updating the software

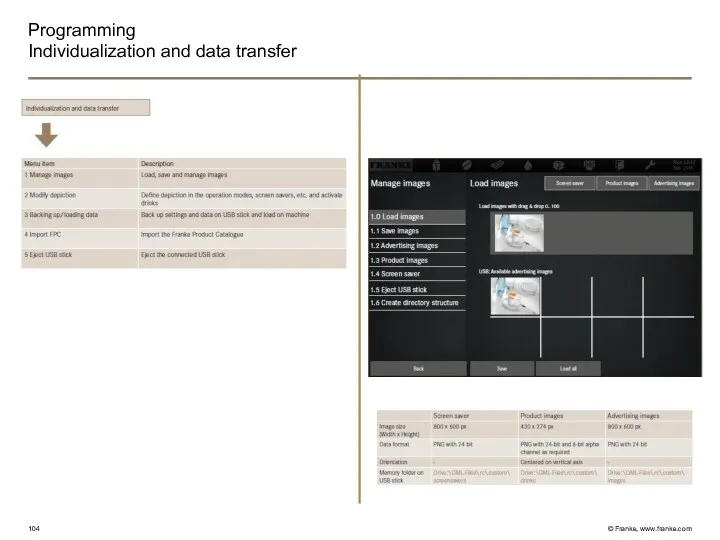

- 104. Programming Individualization and data transfer

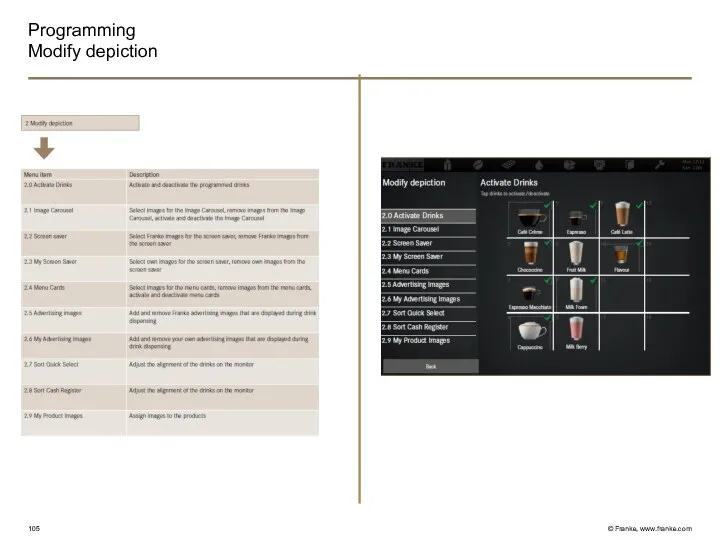

- 105. Programming Modify depiction

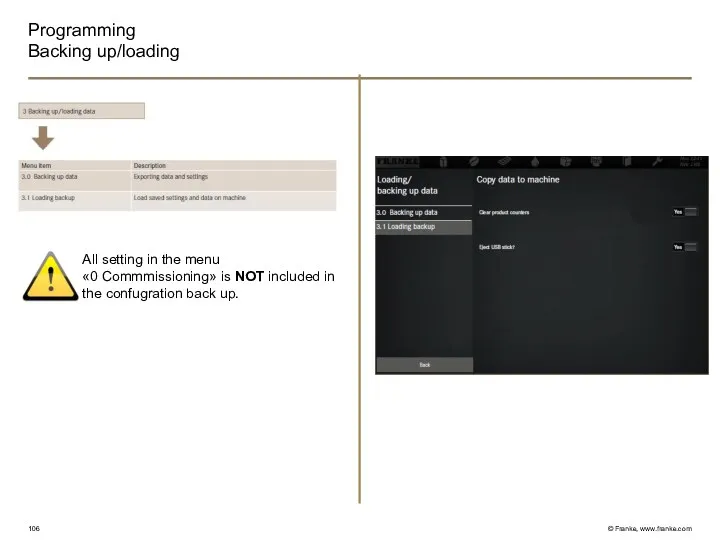

- 106. Programming Backing up/loading All setting in the menu «0 Commmissioning» is NOT included in the confugration

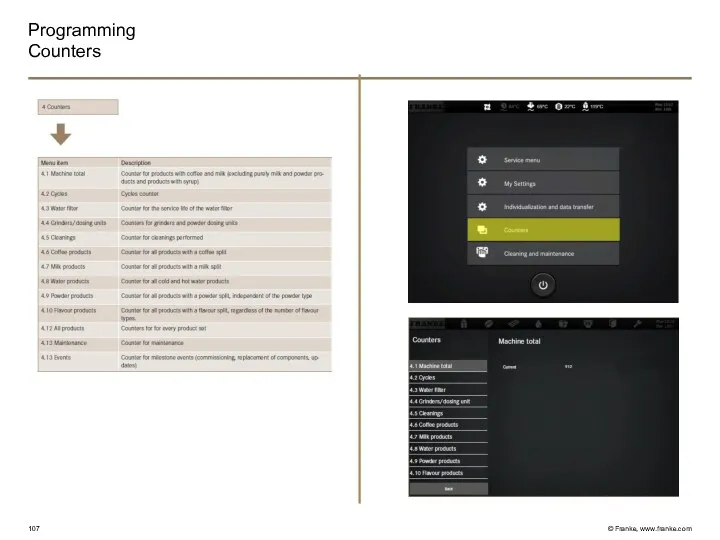

- 107. Programming Counters

- 108. A600 Accessibility components Commissioning Product adjustement Trouble shooting Cleaning

- 109. Questions? QUESTIONS?

- 111. Скачать презентацию

Письмо по электронной почте от микроба Лентяйкина

Письмо по электронной почте от микроба Лентяйкина ГИА. Вопрос А3. Химическая связь

ГИА. Вопрос А3. Химическая связь Открытые переломы, гнойные осложнения переломов, травматический остеомиелит, современные методы лечения открытых переломов

Открытые переломы, гнойные осложнения переломов, травматический остеомиелит, современные методы лечения открытых переломов Тайны яблока

Тайны яблока Анализ ликвидности и платежеспособности организации на основе бухгалтерской отчетности на примере ООО Вертикаль

Анализ ликвидности и платежеспособности организации на основе бухгалтерской отчетности на примере ООО Вертикаль Программа работы с одаренными детьми

Программа работы с одаренными детьми методическая разработка интегрированного урока по предмету Численные методы и Основы алгоритмизации и программирования

методическая разработка интегрированного урока по предмету Численные методы и Основы алгоритмизации и программирования 20240123_izo_5_klass._tema_6._konstruktsiya_i_dekor_predmetov_narodnogo_byta

20240123_izo_5_klass._tema_6._konstruktsiya_i_dekor_predmetov_narodnogo_byta лекция_Растворы

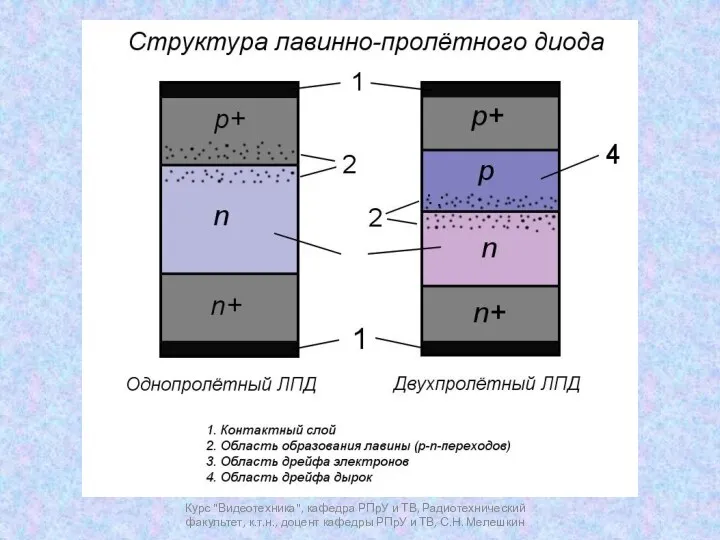

лекция_Растворы Лавинно-пролётный диод. Диод Ганна

Лавинно-пролётный диод. Диод Ганна Кубические и биквадратные уравнения

Кубические и биквадратные уравнения Источники трудового права

Источники трудового права Артикуляционная гимнастика с обезьянкой Соней

Артикуляционная гимнастика с обезьянкой Соней Презентация Покормите птиц зимой

Презентация Покормите птиц зимой Геометрические фигуры (для дошкольников)

Геометрические фигуры (для дошкольников) Химия. Образовательные программы магистратуры

Химия. Образовательные программы магистратуры Тұрақты стенокардия

Тұрақты стенокардия Введение во храм Пресвятой Богородицы

Введение во храм Пресвятой Богородицы Использование нетрадиционной техники на занятиях Юный художник

Использование нетрадиционной техники на занятиях Юный художник Рекламная кампания. Планирование и организация

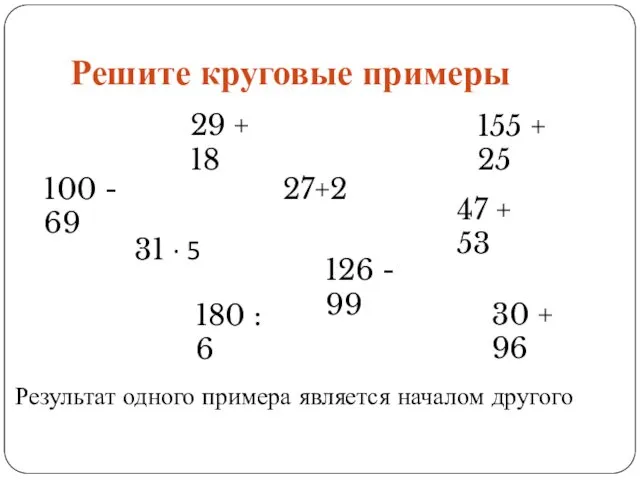

Рекламная кампания. Планирование и организация Буквенная запись свойств сложения и вычитания

Буквенная запись свойств сложения и вычитания Карстовые процессы

Карстовые процессы Девиантное поведение детей и подростков – виды, причины, феноменология

Девиантное поведение детей и подростков – виды, причины, феноменология Инфологическое моделирование

Инфологическое моделирование Недостаточность коры надпочечников

Недостаточность коры надпочечников Потребитель и его права

Потребитель и его права Динамическое проектирование систем стабилизации летательных аппаратов. Исполнительные устройства. Рулевой привод

Динамическое проектирование систем стабилизации летательных аппаратов. Исполнительные устройства. Рулевой привод В здоровом теле - здоровый дух

В здоровом теле - здоровый дух