Содержание

- 2. Programme Brief description of water hardness application Principle of measurement for water hardness Operation of the

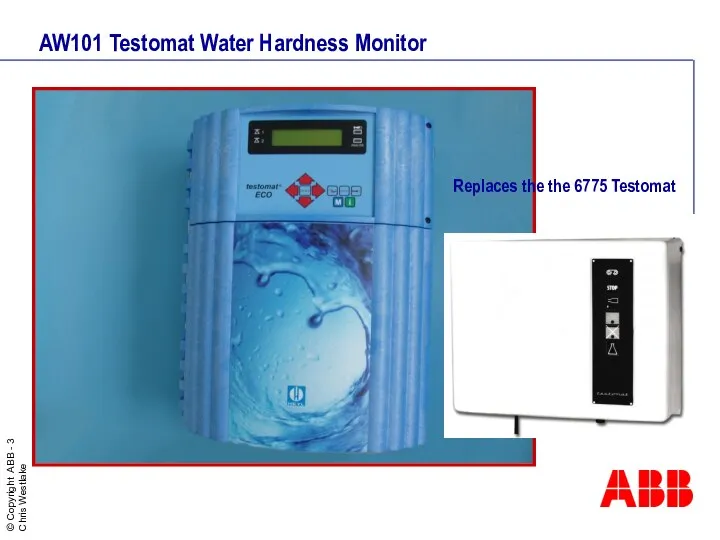

- 3. AW101 Testomat Water Hardness Monitor

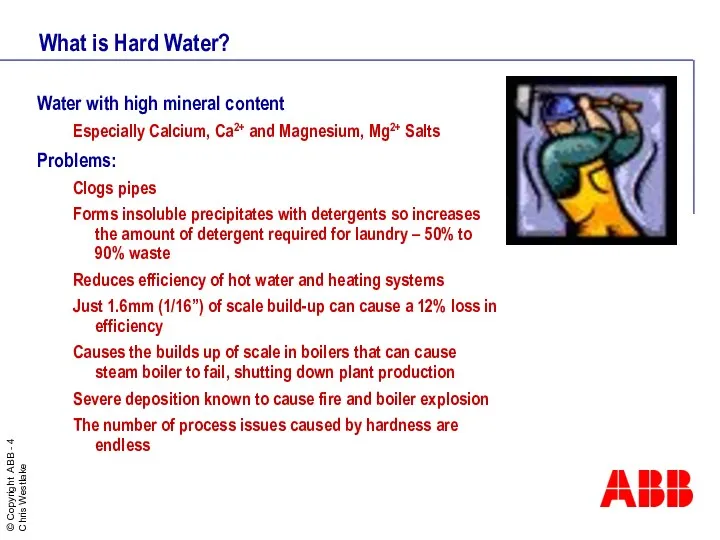

- 4. What is Hard Water? Water with high mineral content Especially Calcium, Ca2+ and Magnesium, Mg2+ Salts

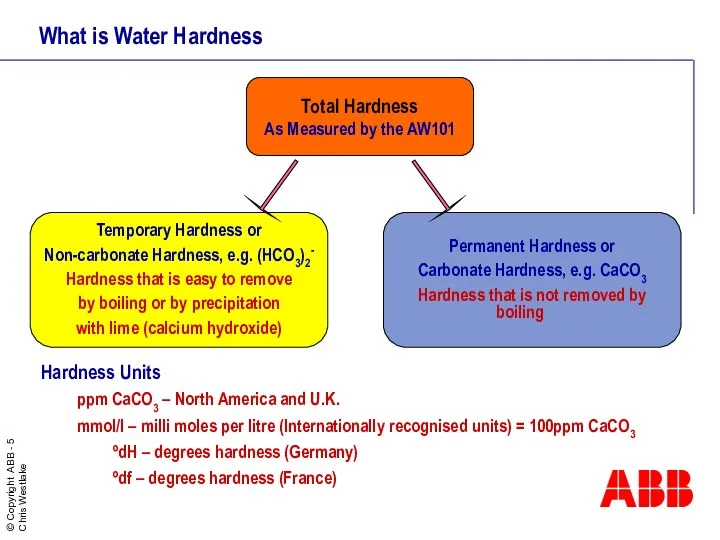

- 5. What is Water Hardness Total Hardness As Measured by the AW101 Hardness Units ppm CaCO3 –

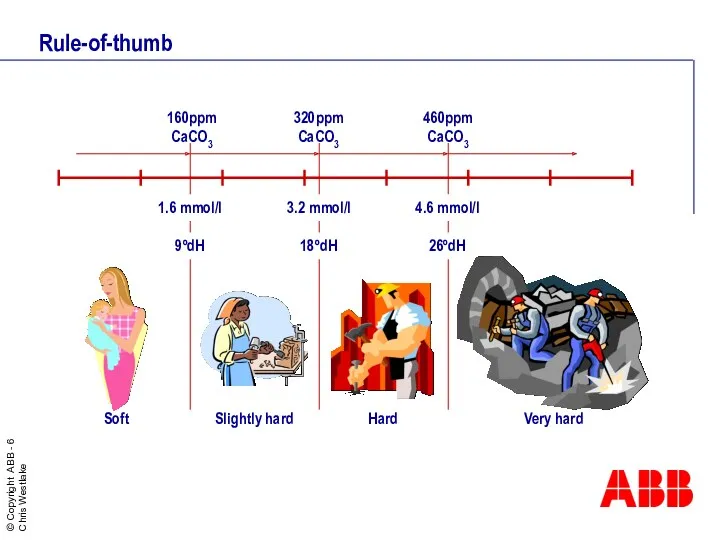

- 6. Rule-of-thumb 160ppm CaCO3 1.6 mmol/l 9ºdH

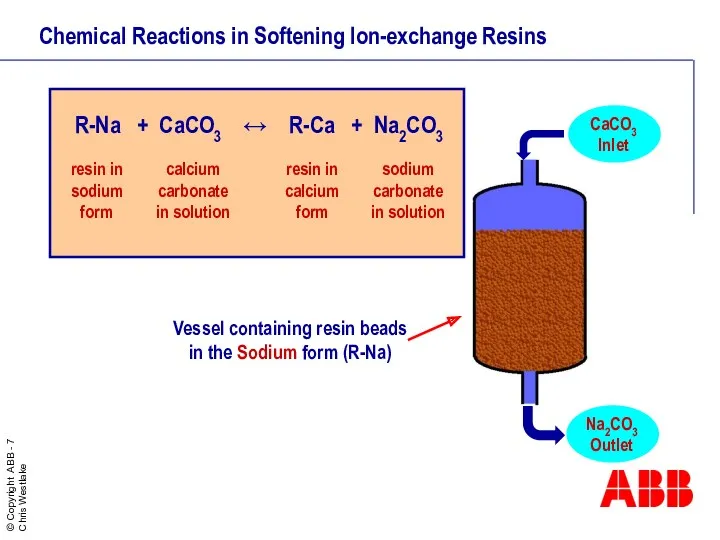

- 7. Chemical Reactions in Softening Ion-exchange Resins Vessel containing resin beads in the Sodium form (R-Na)

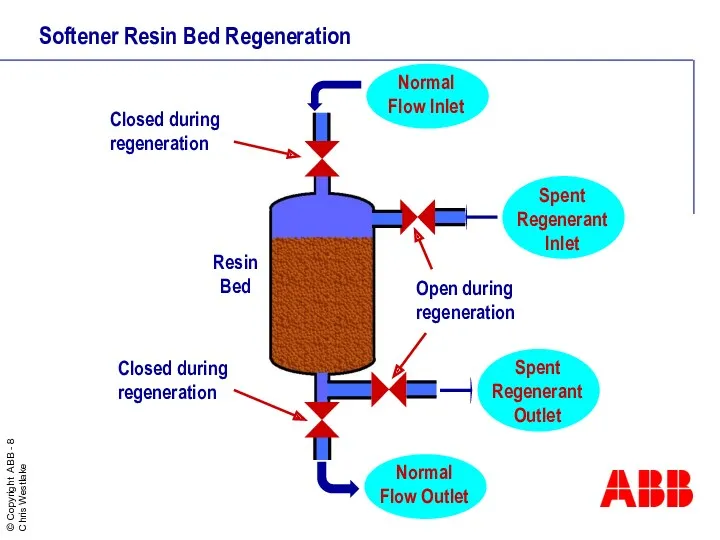

- 8. Softener Resin Bed Regeneration Open during regeneration Resin Bed Closed during regeneration Closed during regeneration

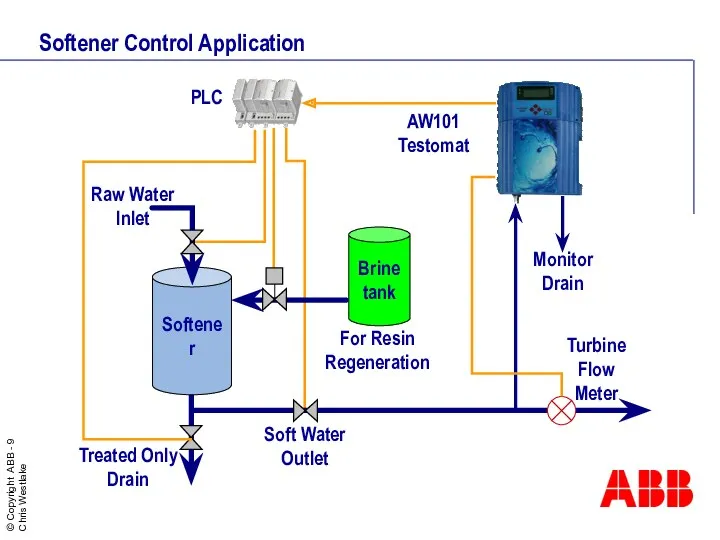

- 9. Softener Control Application Brine tank AW101 Testomat Softener Raw Water Inlet Soft Water Outlet Treated Only

- 10. AW101 Testomat Total Water Hardness Monitor

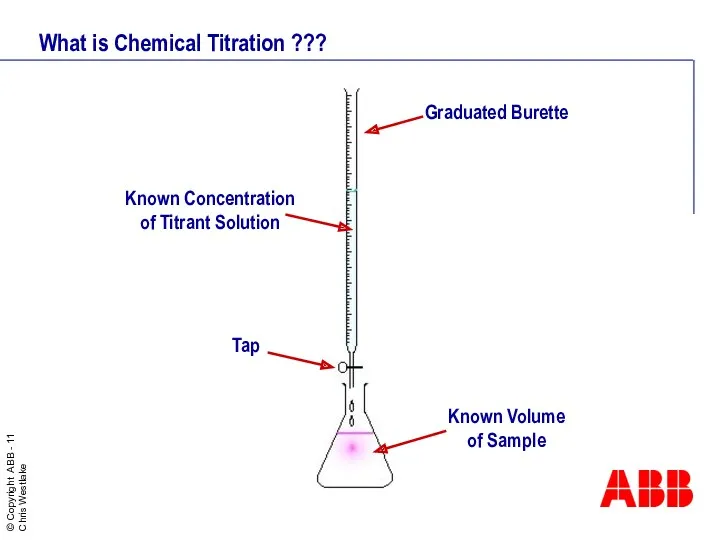

- 11. What is Chemical Titration ??? Graduated Burette Tap Known Volume of Sample

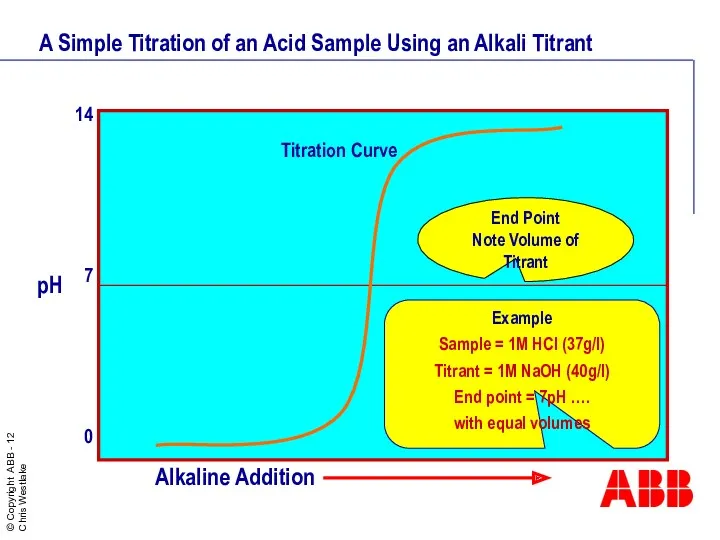

- 12. A Simple Titration of an Acid Sample Using an Alkali Titrant End Point Note Volume of

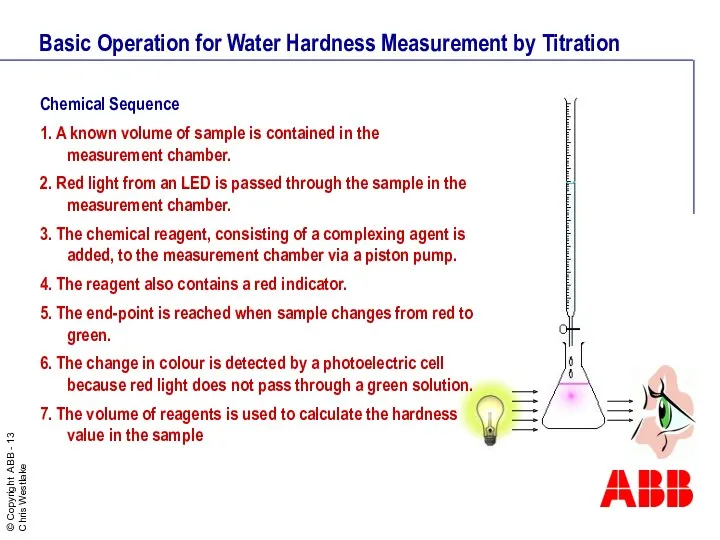

- 13. Basic Operation for Water Hardness Measurement by Titration Chemical Sequence 1. A known volume of sample

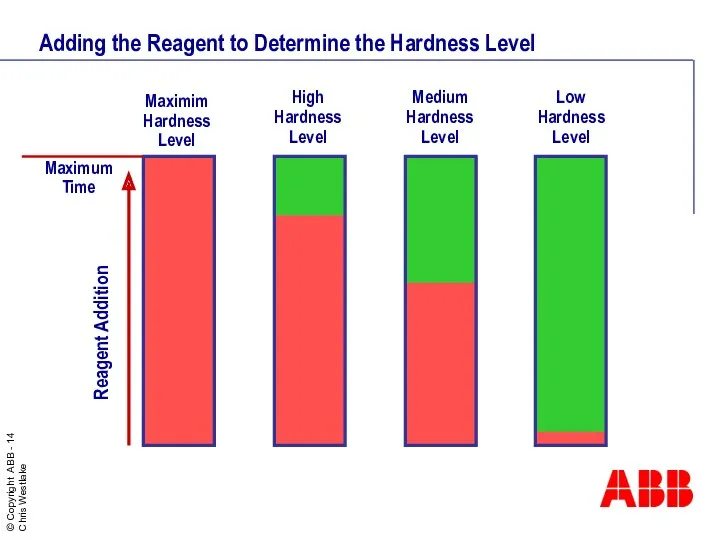

- 14. Adding the Reagent to Determine the Hardness Level Reagent Addition Maximim Hardness Level Maximum Time

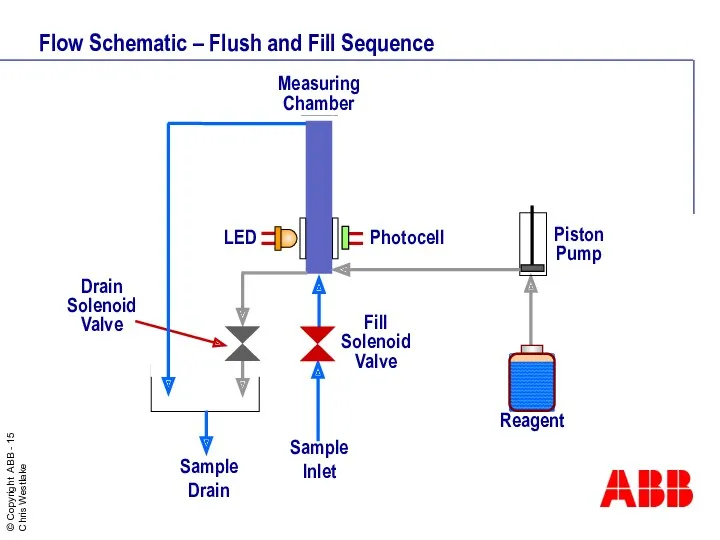

- 15. Flow Schematic – Flush and Fill Sequence Sample Inlet Drain Solenoid Valve Measuring Chamber Photocell LED

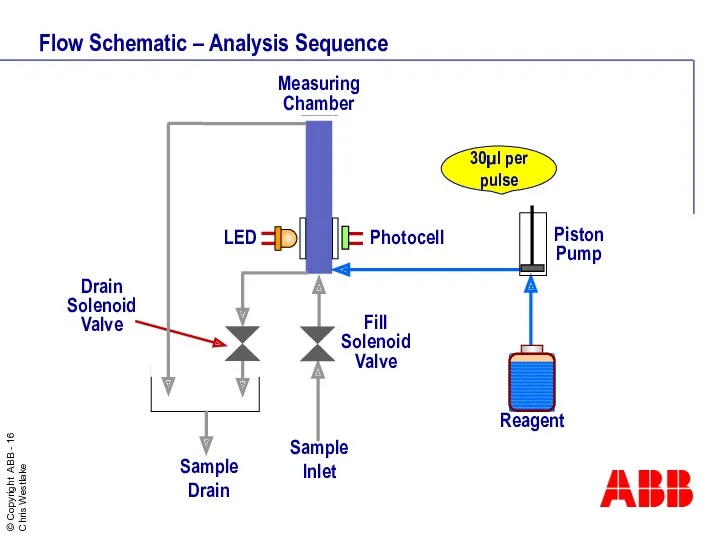

- 16. Flow Schematic – Analysis Sequence Sample Inlet Fill Solenoid Valve Drain Solenoid Valve Photocell LED Sample

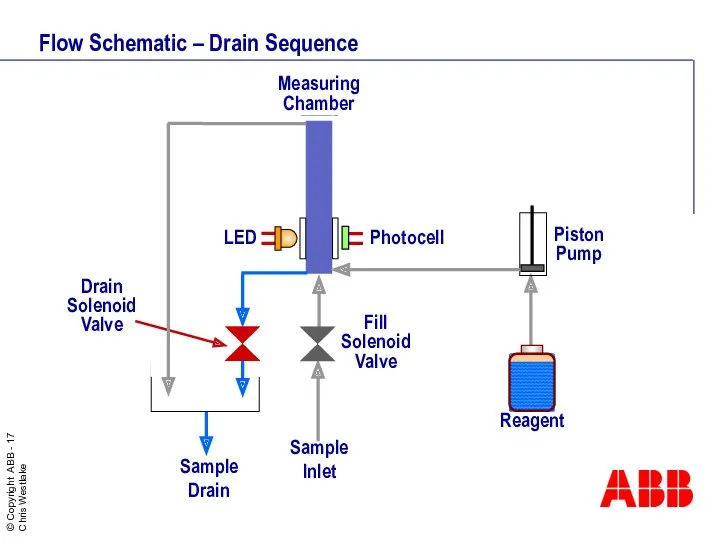

- 17. Flow Schematic – Drain Sequence Sample Inlet Sample Drain Drain Solenoid Valve Photocell LED Fill Solenoid

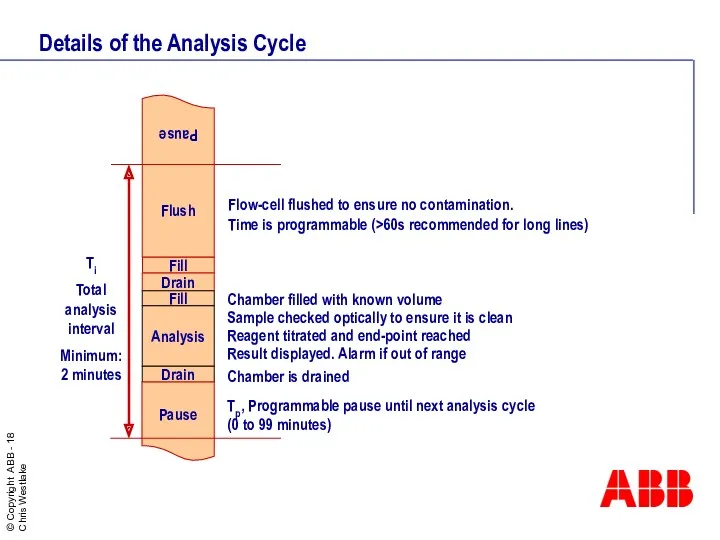

- 18. Details of the Analysis Cycle Fill Drain Pause Reagent titrated and end-point reached Result displayed. Alarm

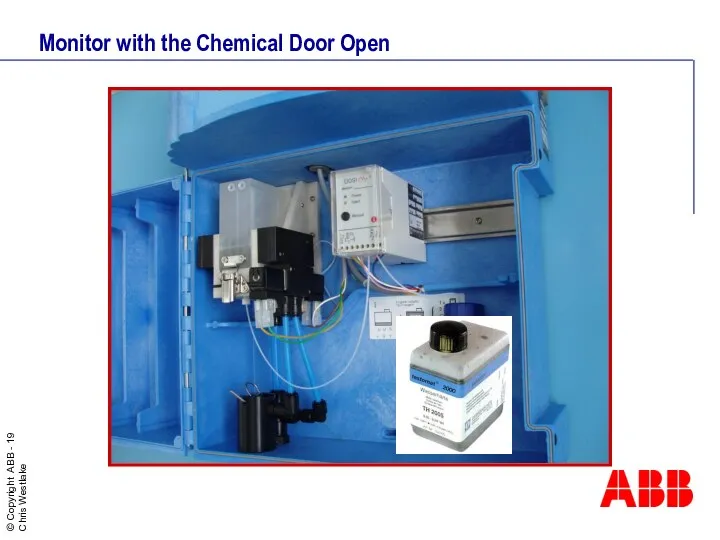

- 19. Monitor with the Chemical Door Open

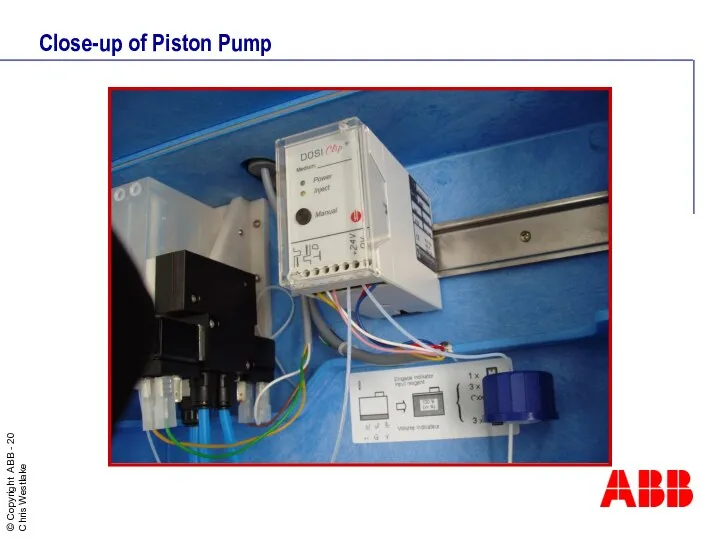

- 20. Close-up of Piston Pump

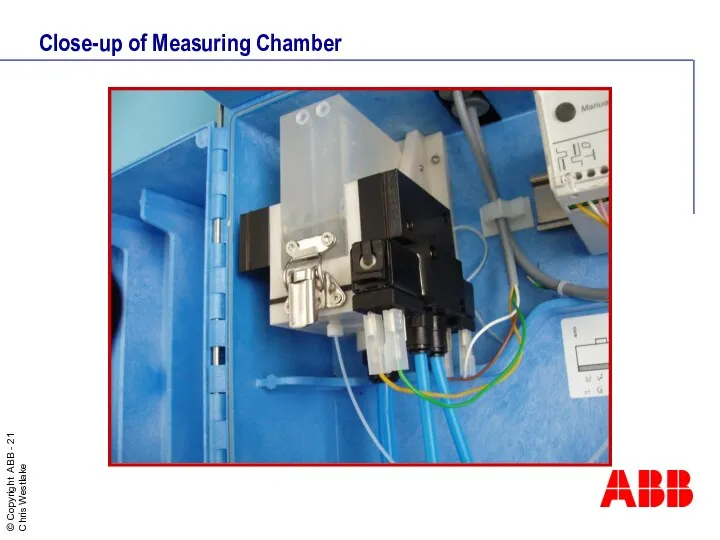

- 21. Close-up of Measuring Chamber

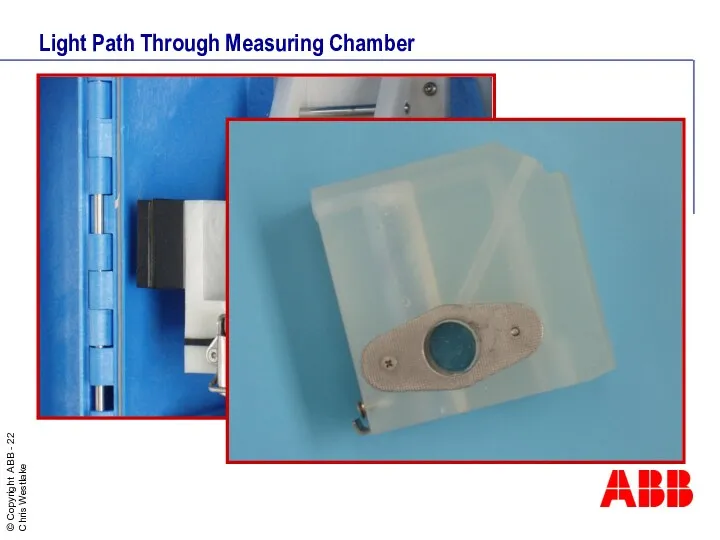

- 22. Light Path Through Measuring Chamber

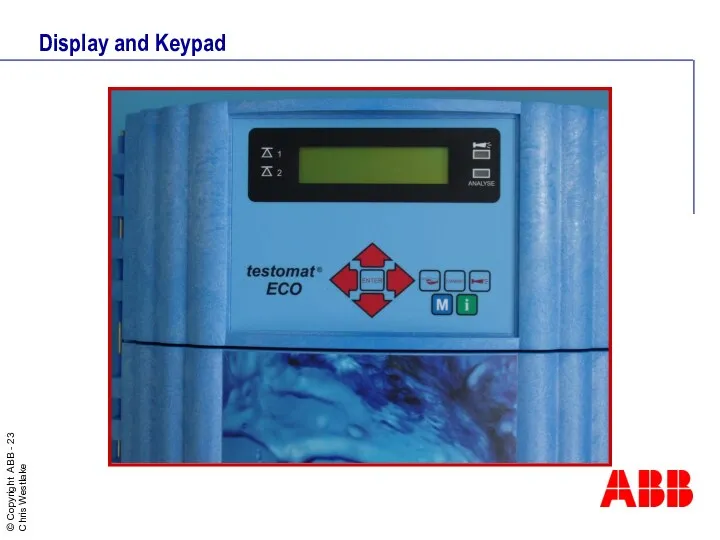

- 23. Display and Keypad

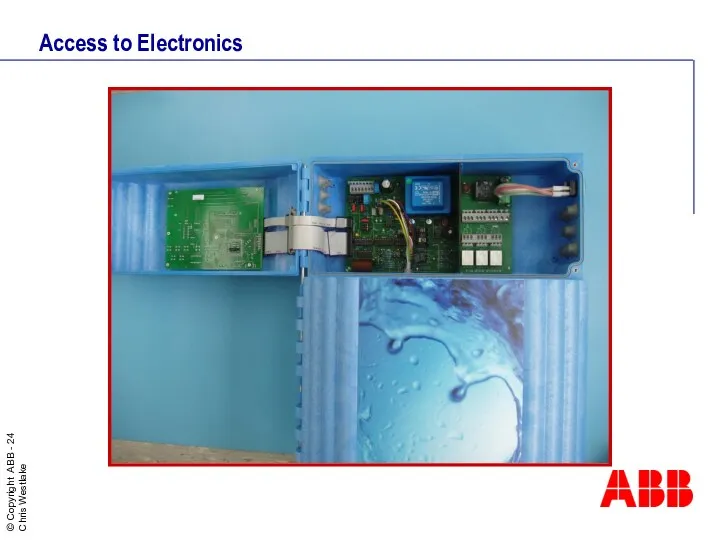

- 24. Access to Electronics

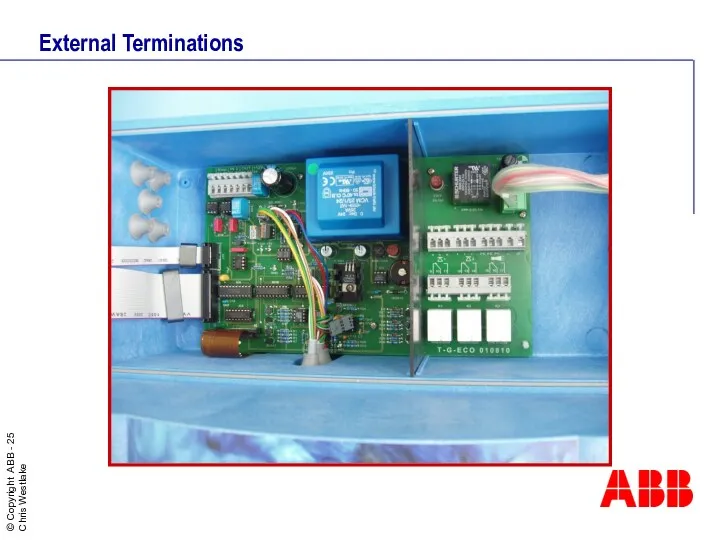

- 25. External Terminations

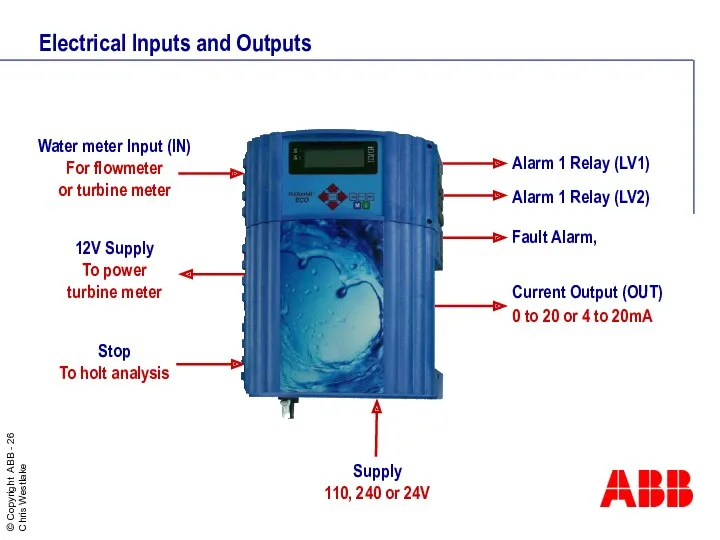

- 26. Electrical Inputs and Outputs Fault Alarm, Alarm 1 Relay (LV1) Water meter Input (IN) For flowmeter

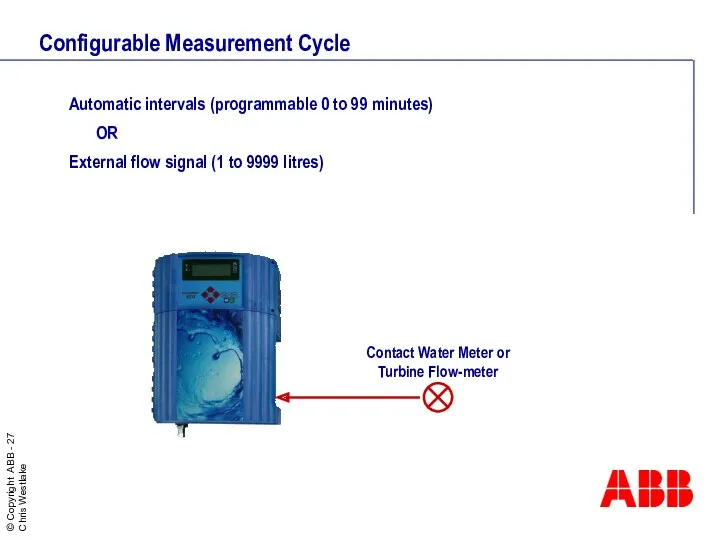

- 27. Configurable Measurement Cycle Automatic intervals (programmable 0 to 99 minutes) OR External flow signal (1 to

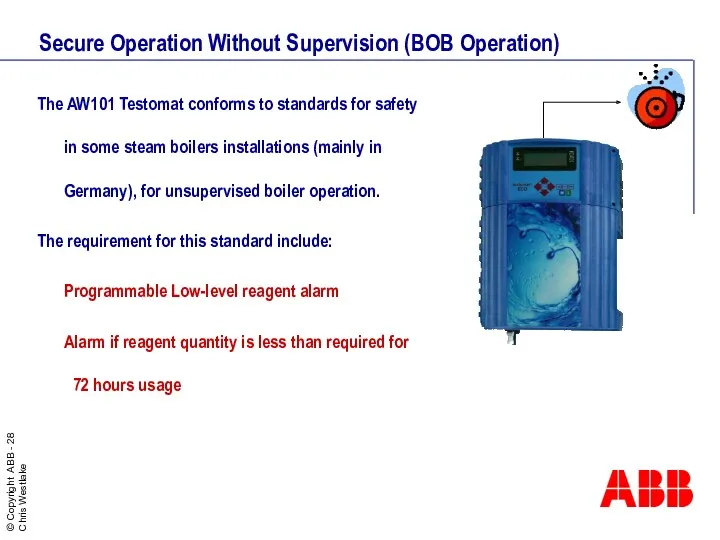

- 28. Secure Operation Without Supervision (BOB Operation) The AW101 Testomat conforms to standards for safety in some

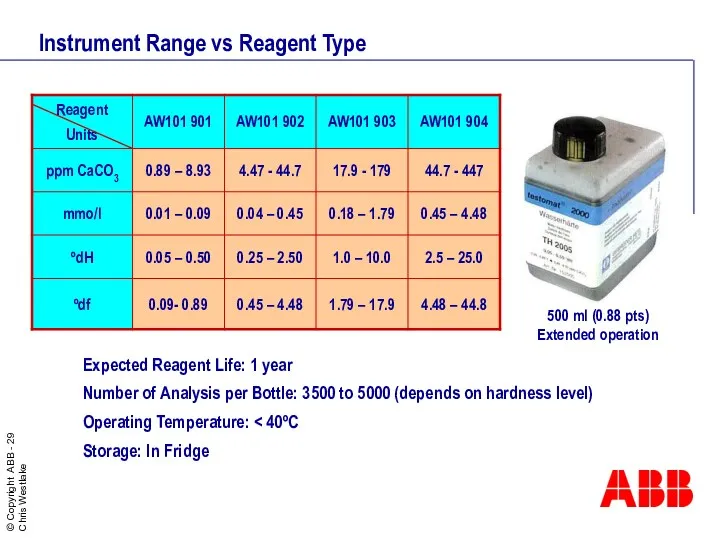

- 29. Instrument Range vs Reagent Type Expected Reagent Life: 1 year Number of Analysis per Bottle: 3500

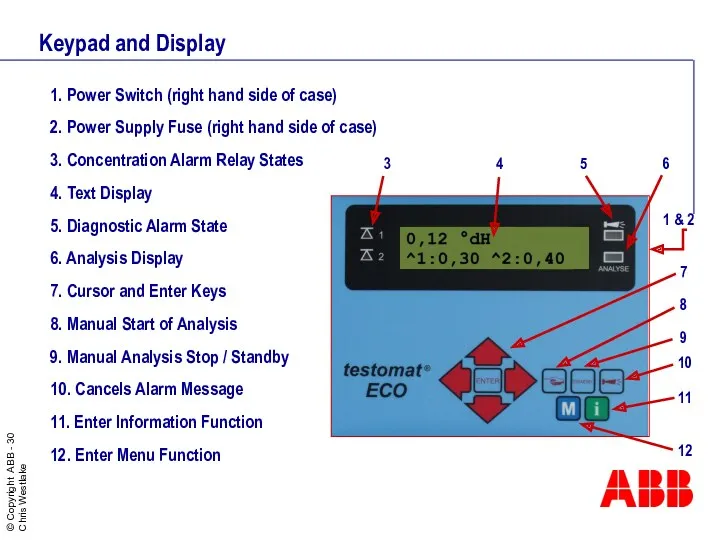

- 30. Keypad and Display 1. Power Switch (right hand side of case) 2. Power Supply Fuse (right

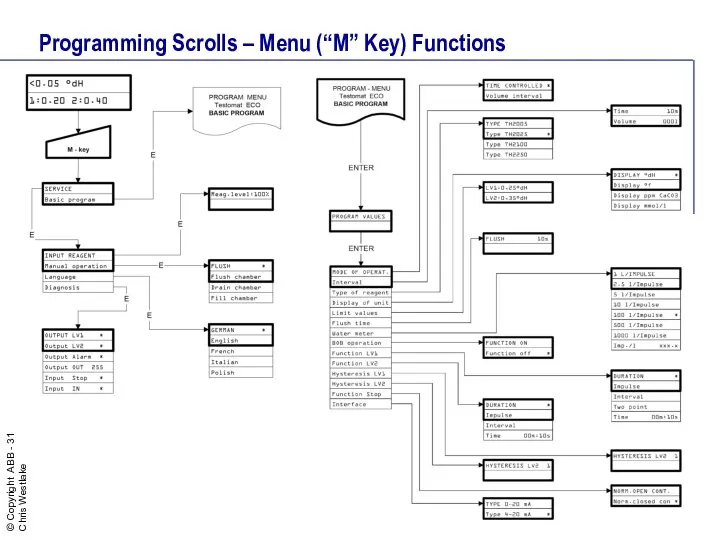

- 31. Programming Scrolls – Menu (“M” Key) Functions

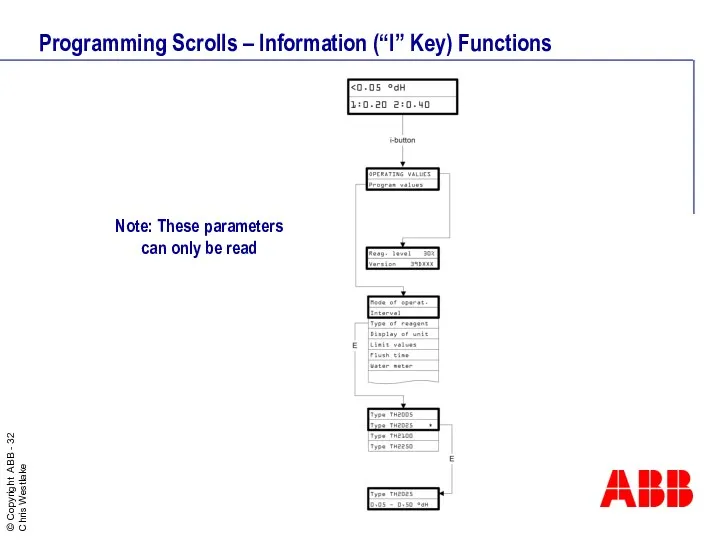

- 32. Programming Scrolls – Information (“I” Key) Functions Note: These parameters can only be read

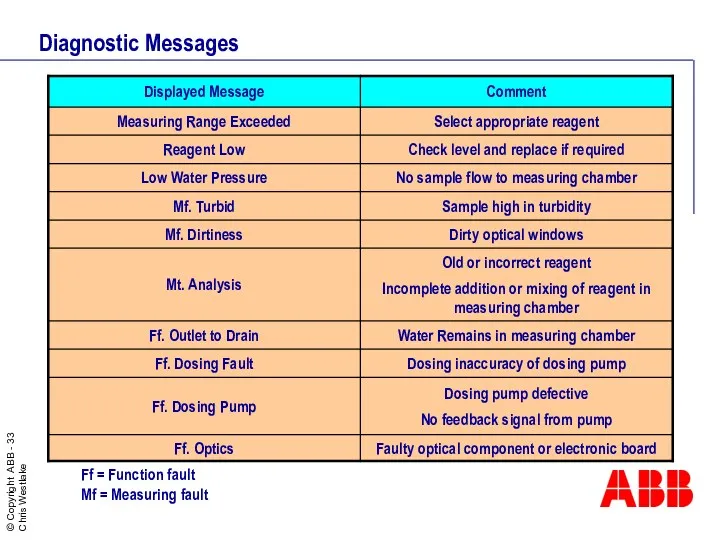

- 33. Diagnostic Messages Ff = Function fault Mf = Measuring fault

- 34. Recommended Maintenance Schedule Twice per year: Filter block: Replace the filter and seal at the base

- 35. Sample Conditions Sample pH in the range 4 – 10.5 pH Sample temperature between 10 &

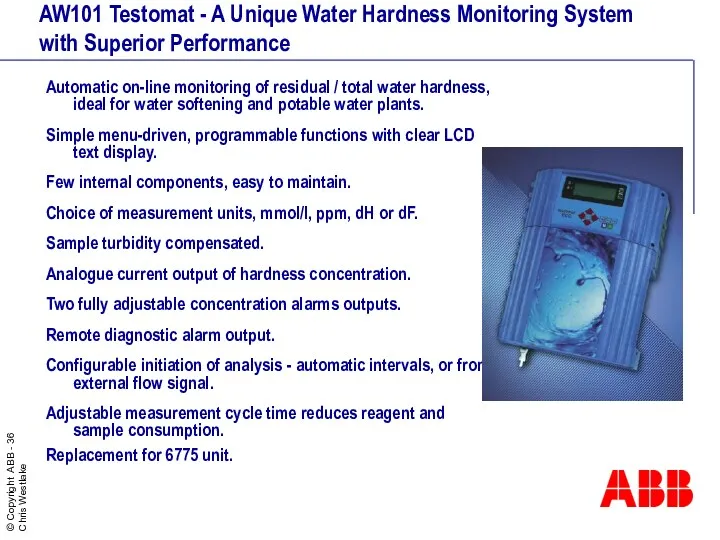

- 36. AW101 Testomat - A Unique Water Hardness Monitoring System with Superior Performance Automatic on-line monitoring of

- 38. Скачать презентацию

20230930_organicheskiy_mir_antarktidy

20230930_organicheskiy_mir_antarktidy Практика. Организация видов работ при эксплуатации и реконструкции строительных объектов

Практика. Организация видов работ при эксплуатации и реконструкции строительных объектов Школа Пифагора

Школа Пифагора Познавательное развитие детей дошкольного возраста

Познавательное развитие детей дошкольного возраста Биологическое действие высокочастотных электромагнитных волн на здоровье человека и защита от них

Биологическое действие высокочастотных электромагнитных волн на здоровье человека и защита от них Презентация к уроку технология. 4 класс

Презентация к уроку технология. 4 класс От совместной деятельности с родителями к совместному управлению

От совместной деятельности с родителями к совместному управлению О холестерине без заблуждений

О холестерине без заблуждений Film program coming up

Film program coming up Облагораживание ТН и ПБ с использованием технологии флюидкокинг

Облагораживание ТН и ПБ с использованием технологии флюидкокинг Назначение, боевые характеристики и устройство ручных осколочных и противотанковых гранат

Назначение, боевые характеристики и устройство ручных осколочных и противотанковых гранат Наши отцы и деды - защитники Родины

Наши отцы и деды - защитники Родины Алкоголизм- это страшная беда современного общества

Алкоголизм- это страшная беда современного общества Презентация проекта Предшкола

Презентация проекта Предшкола игра Ассоциации с зимой

игра Ассоциации с зимой Город Владимир

Город Владимир Тематическая викторина. Растениеводство в фольклоре. Загадки.

Тематическая викторина. Растениеводство в фольклоре. Загадки. Играем и изучаем правила дорожного движения

Играем и изучаем правила дорожного движения Эстетикалық стоматология үшін оптикалық жүйенің маңызы

Эстетикалық стоматология үшін оптикалық жүйенің маңызы Презентация к тематическому занятию, приуроченного к столетнему юбилею со дня рождения Георгия Свиридова для детей подготовительной к школе группы

Презентация к тематическому занятию, приуроченного к столетнему юбилею со дня рождения Георгия Свиридова для детей подготовительной к школе группы Классификация сталей. Термическая обработка сталей

Классификация сталей. Термическая обработка сталей Lukoil company

Lukoil company Технологія друкарських процесів

Технологія друкарських процесів Научные открытия России

Научные открытия России Установление советской власти в Казахстане

Установление советской власти в Казахстане Острая кишечная непроходимость

Острая кишечная непроходимость Постсоветский регион.

Постсоветский регион. Формирование и анализ показателей отчета о финансовых результатах коммерческой организации

Формирование и анализ показателей отчета о финансовых результатах коммерческой организации