Содержание

- 2. The insulators or dielectric, is a material that resists the flow of electric current. An insulating

- 3. A composite insulator in one made of at least two insulating parts, namely a core and

- 4. The first electrical systems to make use of insulators were telegraph lines; direct attachment of wires

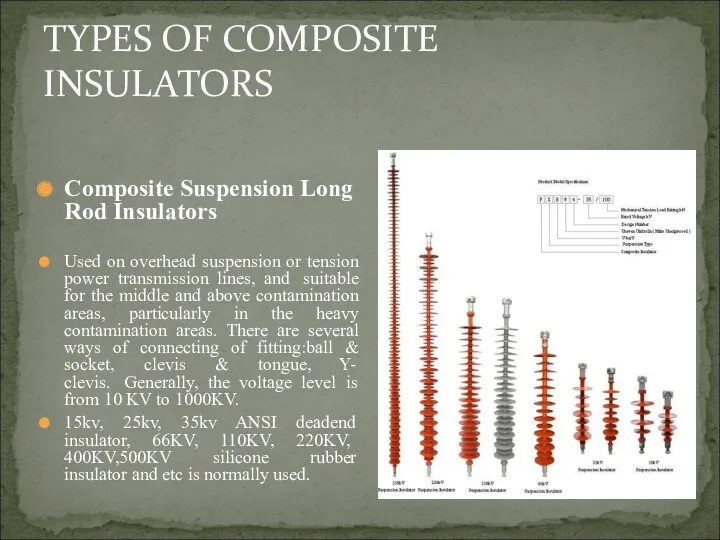

- 5. TYPES OF COMPOSITE INSULATORS Composite Suspension Long Rod Insulators Used on overhead suspension or tension power

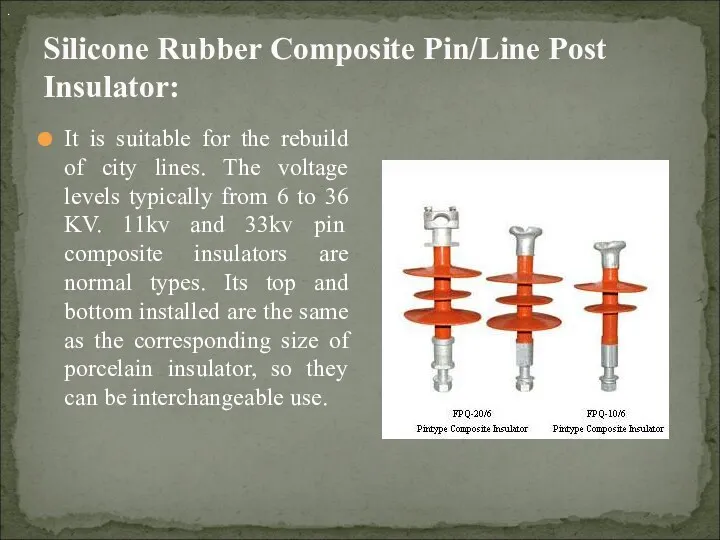

- 6. Silicone Rubber Composite Pin/Line Post Insulator: It is suitable for the rebuild of city lines. The

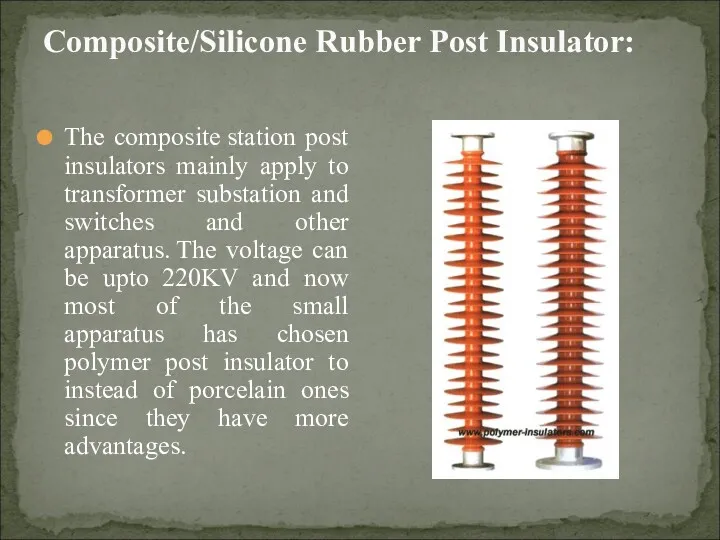

- 7. Composite/Silicone Rubber Post Insulator: The composite station post insulators mainly apply to transformer substation and switches

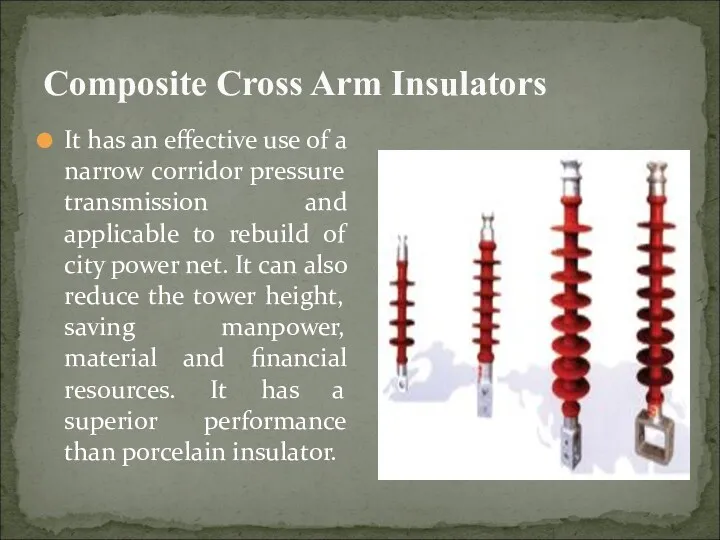

- 8. Composite Cross Arm Insulators It has an effective use of a narrow corridor pressure transmission and

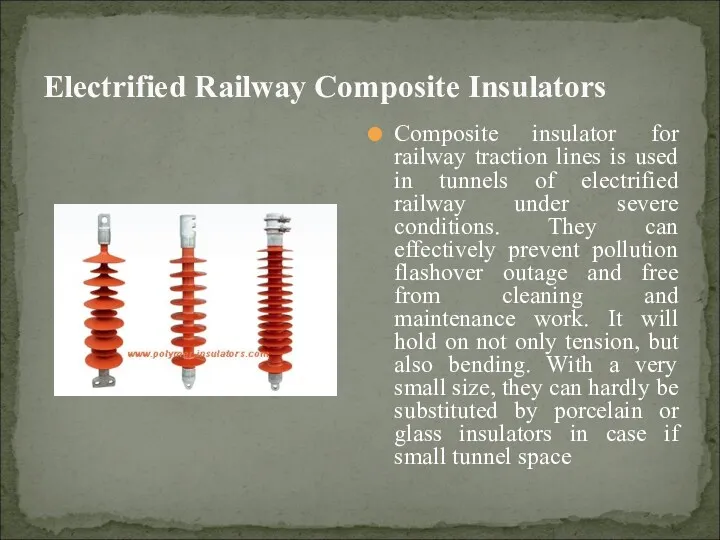

- 9. Electrified Railway Composite Insulators Composite insulator for railway traction lines is used in tunnels of electrified

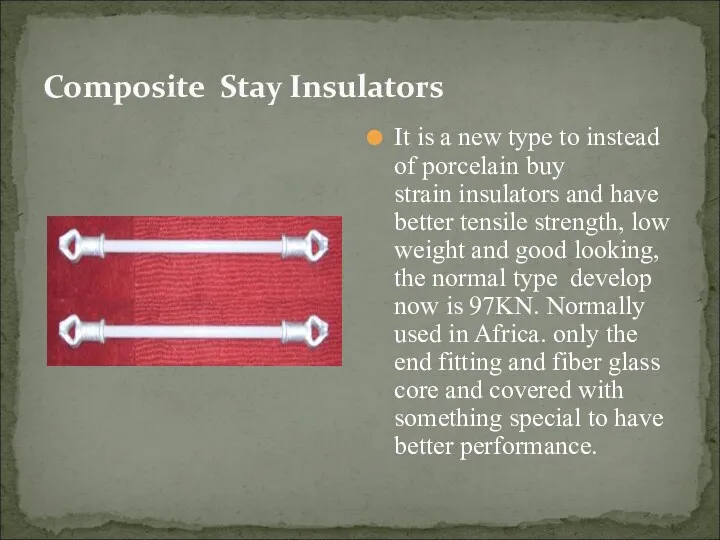

- 11. Composite Stay Insulators It is a new type to instead of porcelain buy strain insulators and

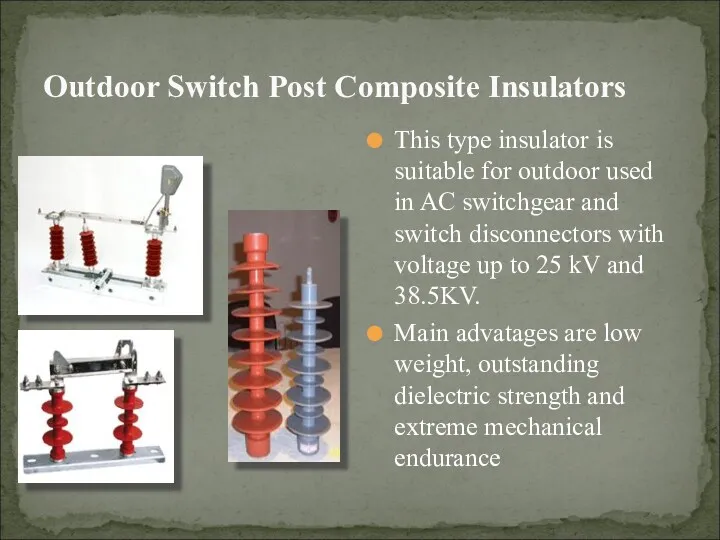

- 12. Outdoor Switch Post Composite Insulators This type insulator is suitable for outdoor used in AC switchgear

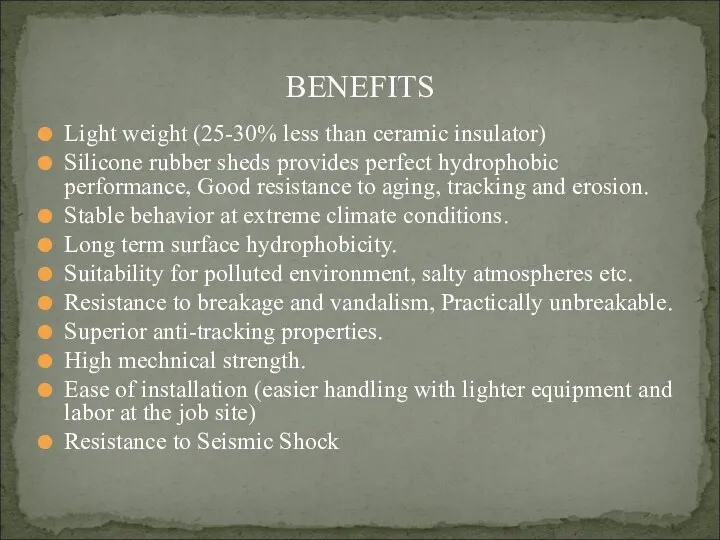

- 13. Light weight (25-30% less than ceramic insulator) Silicone rubber sheds provides perfect hydrophobic performance, Good resistance

- 14. The paper discusses selected advantages of composite insulators and structures for lines with compact requirements. Beside

- 16. Скачать презентацию

Новогодняя Снежинка-пушинка. Мастер-класс

Новогодняя Снежинка-пушинка. Мастер-класс Саркоидоз легких

Саркоидоз легких Производственный менеджмент

Производственный менеджмент Сложение и вычитание смешанных чисел

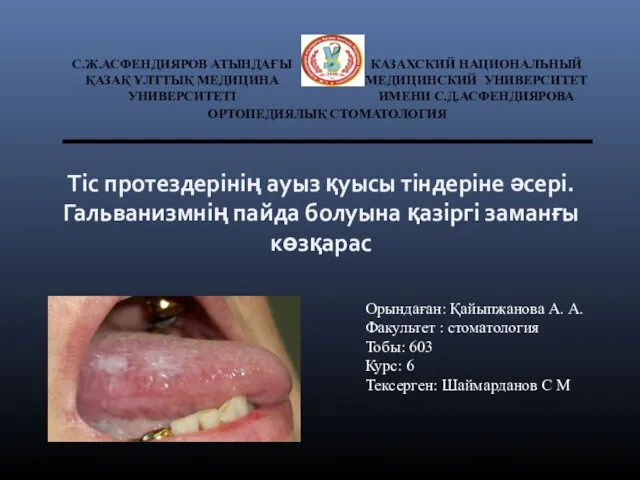

Сложение и вычитание смешанных чисел Тіс протездерін көтере алмау себептері

Тіс протездерін көтере алмау себептері Металлические конструкции, включая сварку. Элементы и соединения

Металлические конструкции, включая сварку. Элементы и соединения Алтайский край. Бренд региона

Алтайский край. Бренд региона Викторина Моя малая Родина, город Отрадный

Викторина Моя малая Родина, город Отрадный Усиление каменных конструкций

Усиление каменных конструкций Особенности памяти у детей с ОНР, ФФНР и заиканием

Особенности памяти у детей с ОНР, ФФНР и заиканием Трёхобмоточные трансформаторы. Лекция 10

Трёхобмоточные трансформаторы. Лекция 10 Бет қаңқасының қатерсіз ісіктері мен ісік тәрізді түзілістері

Бет қаңқасының қатерсіз ісіктері мен ісік тәрізді түзілістері Урок Бабочки

Урок Бабочки Дипломный проект для технических специальностей

Дипломный проект для технических специальностей Проектирование корпуса Лукояновского молочного завода,

Проектирование корпуса Лукояновского молочного завода, Рабочее место для ручной обработки древесины

Рабочее место для ручной обработки древесины 16 ноября – Международный день толерантности

16 ноября – Международный день толерантности Здоровье человека как индивидуальная, так и общественная ценность

Здоровье человека как индивидуальная, так и общественная ценность Мастер-класс Плетение из фольги

Мастер-класс Плетение из фольги Керамические материалы и изделия

Керамические материалы и изделия формирование успеха учащихся на уроках физики

формирование успеха учащихся на уроках физики Возведение высотных зданий со стальным, железобетонным и смешанным каркасом

Возведение высотных зданий со стальным, железобетонным и смешанным каркасом 2016 Brussels bombings

2016 Brussels bombings Функциональные системы автоматизации технологических процессов. Автоматизация добычи промыслового сбора нефти и нефтяного газа

Функциональные системы автоматизации технологических процессов. Автоматизация добычи промыслового сбора нефти и нефтяного газа Этика отношений в системе управляющий, подчиненный

Этика отношений в системе управляющий, подчиненный Дружная семья

Дружная семья Методы и сооружения водоподготовки в системах водоснабжения

Методы и сооружения водоподготовки в системах водоснабжения Приводы приспособлений

Приводы приспособлений