The problem and its solution

Ural Federal district grows a large amount of grain

and thus the market is collapsing, the problem of surplus.

It is difficult to process a large amount of grain, and it is not economically feasible to sell for a song.

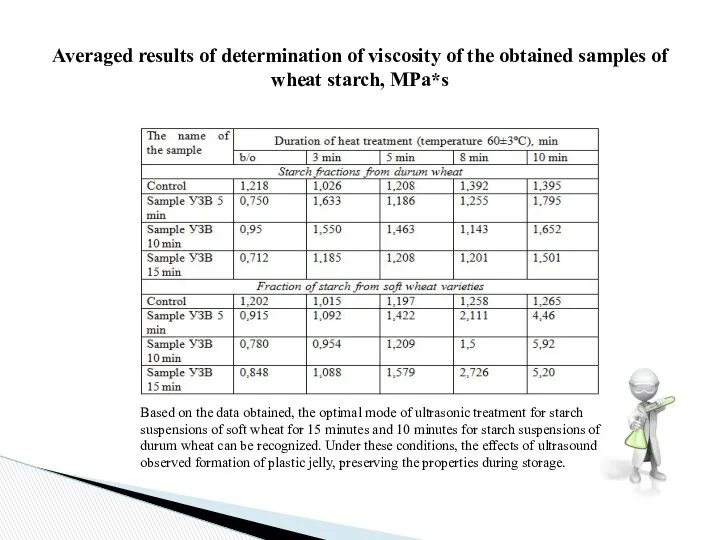

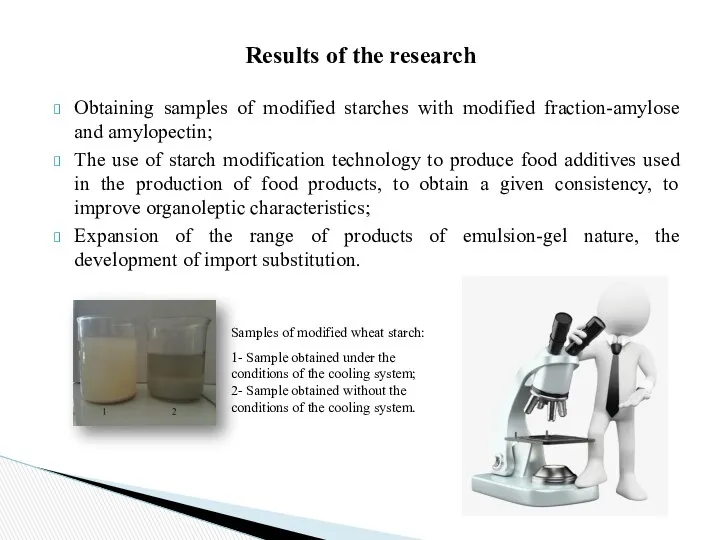

In consequence, it was taken measures for deep processing of grain, in order to isolate and use the components of grain, in particular starch.

The development of deep processing of grain will produce high-tech products, the demand for which is growing on the world market every year.

The most popular are starches and starches, amino acids, glucose, bioplastics.

Production of modified starches is one of the perspective and little developed directions in the Ural Federal district.

Берегите природу.Классный час . 4 класс Презентация

Берегите природу.Классный час . 4 класс Презентация Презентация День Знаний

Презентация День Знаний Таблицы истинности. Логические схемы. 10 класс

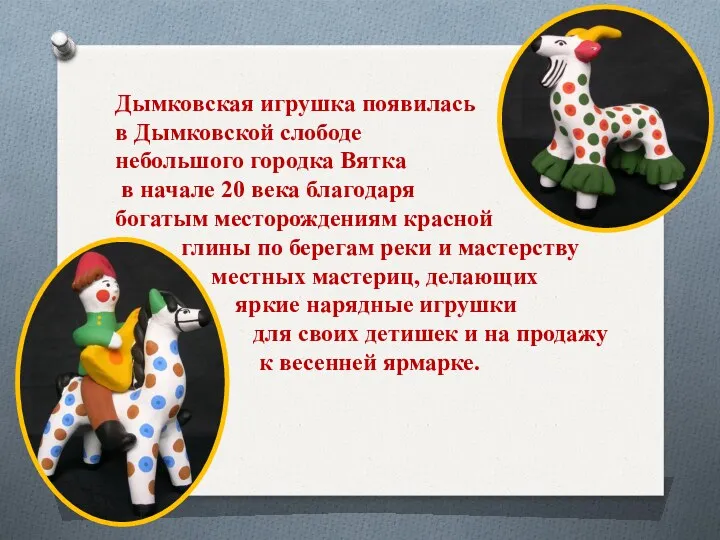

Таблицы истинности. Логические схемы. 10 класс Презентация Дымковская игрушка

Презентация Дымковская игрушка Металлы

Металлы Сенім дегеніміз не? Евр 11:1-2

Сенім дегеніміз не? Евр 11:1-2 Животноводство России

Животноводство России Лекция подготовка к ЕГЭ (профиль 11 класс) Тема Классификация неорганических веществ

Лекция подготовка к ЕГЭ (профиль 11 класс) Тема Классификация неорганических веществ Структура психологической службы в учреждениях и органах, исполняющих уголовные наказания и нормативно-правовые документы

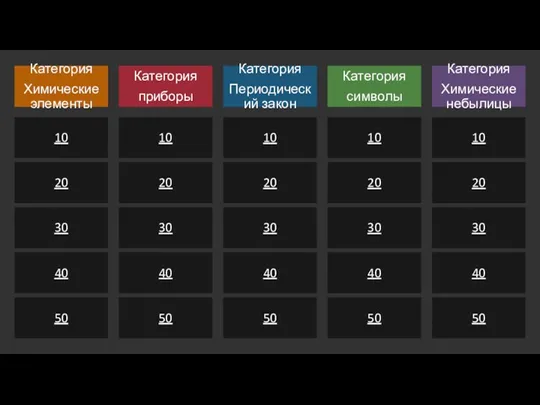

Структура психологической службы в учреждениях и органах, исполняющих уголовные наказания и нормативно-правовые документы викторина по химии

викторина по химии Презентация на свистящие звуки Сказка о гноме

Презентация на свистящие звуки Сказка о гноме Цветы в технике холодного батика

Цветы в технике холодного батика Интерактивный тренажёр по математике. Таблица умножения с маленькими пони

Интерактивный тренажёр по математике. Таблица умножения с маленькими пони ODO. Sprzęt Ochrony Dróg Oddechowych

ODO. Sprzęt Ochrony Dróg Oddechowych Технология обработки продукта убоя для производства мясных изделий

Технология обработки продукта убоя для производства мясных изделий Поект По дороге к олимпийским победам

Поект По дороге к олимпийским победам Информационная система ЖИВУ.РФ

Информационная система ЖИВУ.РФ Аціоналізація конструктивно-технологічних параметрів дільничної станції

Аціоналізація конструктивно-технологічних параметрів дільничної станції Презентация проекта Что такое портрет

Презентация проекта Что такое портрет Процессор и его характеристики

Процессор и его характеристики Презентация лекции 4.2-2021

Презентация лекции 4.2-2021 Проектирование и расчет внутреннего водопровода зданий (Тема 4)

Проектирование и расчет внутреннего водопровода зданий (Тема 4) Графы

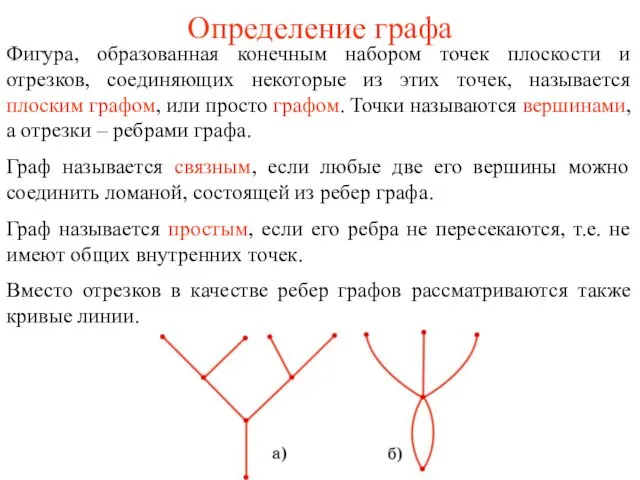

Графы Денежные выплаты (пособия) в связи с материнством, отцовством и детством

Денежные выплаты (пособия) в связи с материнством, отцовством и детством Открытый урок на тему:Спирты

Открытый урок на тему:Спирты Игра-викторина ПДД

Игра-викторина ПДД Рассуждения Рональда Аронсона о конце марксизма

Рассуждения Рональда Аронсона о конце марксизма Урок 20 Заполнение основной надписи и печать в КОМПАС

Урок 20 Заполнение основной надписи и печать в КОМПАС