Содержание

- 2. Welcome to the Dialog+ Component Overview. Here you will have the opportunity to look at different

- 3. The Sub-Racks are devided in: Low Level Electronics UF Sub-Rack DF Sub-Rack Water Sub-Rack The hydraulics

- 4. Dialog+ Start Hydraulic Flow Diagram Please choose a part of the flow diagram that you would

- 5. Hydraulic Flow Diagram Please choose a part of the flow diagram that you would like to

- 6. Water Sub-Rack Functions of the Water Sub-Rack Controls incoming water amount Degasses the water Heats the

- 7. Pressure Reduction Valve Functions of the Pressure Reduction Valve Reduces ring-line pressure to 0.9 bar Functions

- 8. Water Block Functions of the Water Block Mounting for valves Contains the upline tank Contains the

- 9. Upline Tank Components in the Upline Tank Heat exchanger Float Switch Heater rod Water Sub-Rack Start

- 10. Degassing Valve VEB Functions of the Degassing Valve Creates a restriction in the water flow The

- 11. Heater Rod Functions of the Heater Rod Heats up incoming water Properties of the Heater Rod

- 12. Float Switch Functions of the Float Switch Regulates the water level in the upline tank Turns

- 13. Heat Exchanger Function of the Heat Exchanger Pre-heats the incoming water to increase energy efficiency The

- 14. Degassing Chamber Functions of the Degassing Chamber Allows water to degas Slow flow of water Contains

- 15. Degassing Pressure Sensor Functions of the Degassing Pressure Sensor Measure the degassing pressure Feedback for the

- 16. Degassing Circuit The Flow Path of the Water Water is taken from the upline tank If

- 17. Functions of the Degassing Pump Degasses the water Creates a negative pressure Degassing Pump, Micropump Vers.

- 18. Degassing Pump Functions of the Degassing Pump Creates a negative degassing pressure Pumps fluid with two

- 19. Degassing Motor Functions of the Degassing Motor Drives the degassing pump Onboard driving circuits Is regulated

- 20. Degassing Motor Cover Functions of the Degassing Motor Cover Protects the moving parts of the motor

- 21. Degassing Adapter Block Function of the Adapter Block Mounting of the degassing pump O-rings to seal

- 22. Degassing Pump Foot Piece Functions of the Foot Piece Holds the degassing pump module Absorbs vibrations

- 23. RVDA Functions of the RVDA Ensures a minimum pressure of 400 mmHg on the balance chamber

- 24. RVDA Rear view of the RVDA Pay attention to the assembly direction Water Sub-Rack Start Back

- 25. DF Sub-Rack Functions of the DF Sub-Rack Contains the pumps that push water in and out

- 26. Inlet Flow Pump Functions of the FPE Pumps fresh dialysate into the balance chamber Pumps used

- 27. Outlet Flow Pump Functions of the FPA Pumps used dialysate from the dialyser to the balance

- 28. DF Block Functions of the DF Block Measures conductivity Measures temperature Mixes the dialysate fluid DF

- 29. DF Block Functions of the DF Block Measures conductivity Measures temperature Mixes the dialysate fluid DF

- 30. DF Block Functions of the DF Block Measures conductivity Measures temperature Mixes the dialysate fluid DF

- 31. RVB & RVK Functions of RVB and RVK Absorbs the shock from the piston pumps This

- 32. Concentrate and Bicarbonate Pumps Pump Functions Pumps concentrate and bicarbonate into the DF block Normal speed

- 33. Working concept of the Piston Pump Fluid is sucked in on the one side of the

- 34. RVFPE Functions of the RVFPE Prevents an over pressure Set to 1.3 bar Prevents tubes from

- 35. UF Pump UF Pump Functions Pumps the UF volume to drain Removes fluid from the patient

- 36. Temperature Sensors Functions of TSD_S Measures the temperature for ENDLF_S Is used to compensate the conductivity

- 37. Turbulance Spacer Functions of the Turbulance Spacer Creates turbulance on the temperature sensor Removes dead spaces

- 38. ENDLF Functions of the Final Conductivity Sensor Measures the final conductivity The conductivity controls the speed

- 39. ENDLF_S Functions of the Final Conductivity Sensor for the Supervisor Measures the final conductivity Is dependent

- 40. BICLF Functions of the Bicarbonate Conductivity Sensor Measures bicarbonate conductivity The conductivity controls the speed of

- 41. Conductivity Sensors Functions of the conductivity cells ENDLF measures the final conductivity ENDLF_S supervises the ENDLF

- 42. O-Rings of the Disinfection Valve Function of the O-Rings Lower O-ring: seals off the disinfection port

- 43. Disinfection Valve Functions of the Disinfection Valve Opens when the machine needs to suck in disinfectant

- 44. Sub-Rack Start FPA Adapter Block Functions of the FPA Adapter Block Mounts the FPA Absorbs vibrations

- 45. Rinsing Bridge Start Light Barrier Function of the Light Barrier Senses the position of the disinfection

- 46. Pressure Sensor Dialysate Functions of PDA Measures the dialysate pressure This is used to calculate TMP

- 47. Rinsing Bridge Functions of the Rinsing Bridge Contains the disinfection valve Contains the dialysate pressure sensor

- 48. Rinsing Bridge Sensors Function of the Sensors Detects whether the dialyser couplings are connected to the

- 49. Servo Motor and Controller Board Function of the Servo Motor The motor opens and closes the

- 50. FPE Motor Cover Functions of the FPE Motor Cover Protects the moving parts of the motor

- 51. FPE Motor Functions of the FPE Motor Drives the Flow Pump Inlet pump Onboard driving circuits

- 52. FPA Motor Functions of the FPA Motor Drives the outlet pump Onboard driving circuits Is regulated

- 53. FPA Motor Cover Functions of the FPA Motor Cover Protects the moving parts of the motor

- 54. FPE Adapter Block Functions of the FPE Adapter Block Mounts the FPE Absorbs vibrations for noise

- 55. FPE, Micropump Vers. 1 Functions of the FPE Pump Creates a positive pressure to refill the

- 56. FPA, Micropump Vers. 1 Functions of the FPA Pump Creates a positive pressure to fill the

- 57. UF Sub-Rack Functions of the UF Sub-Rack Contains the balance chamber Is responsible for controlling the

- 58. Air Separator Functions of the Air Separator Prevents air from entering the balance chamber Contains VLA

- 59. Air Separator Functions of the Air Separator Prevents air from entering the balance chamber Contains VLA

- 60. Air Separator Functions of the Air Separator There are 2 pins that sense the level of

- 61. Balance Chamber Functions of the Balance Chamber Consists of 2 chambers, with 8 valves Induction coils

- 62. Balance Chamber Membrane Functions of the Balance Chamber Membrane Separates fresh and used dialysate Controls incoming

- 63. Membrane Position Sensor Functions of the membrane position sensor Measures the position of the membrane Uses

- 64. Bicarbonate Cartridge Holder Please select a part of the catridge holder that you want to look

- 65. Mounting The cartridge holder is fixed to the housing using 2 screws. These screws are accessable

- 66. Swivel Arm Functions of the swivel arm Closes the bicarbonate circuit when no cartride is inserted

- 67. Check Valve The check valve is opened when a cartridge or the swivel arm is inserted.

- 68. Temperature Regulation The temperature regulation is done by the following components TSE TSHE TSD TSDE Start

- 69. Temperature Regulation The first temperature regulation is done with TSE. This sensor is used until the

- 70. Temperature Regulation Once the temperature is stable at TSE, the controller starts to regulate the temperature

- 71. Temperature Regulation Depending on Bypass or Mainflow the machine will use TSDE to regulate the final

- 72. Temperature Regulation If the machine is switched to bypass, TSD will take over regulation of the

- 73. Temperature Regulation At all times during the therapy TSD-S is active to ensure patient safety. The

- 74. Conductivity Regulation Controller Sensors TSBIC & BICLF TSD & ENDLF Start Back Next Supervisor Sensors TSD-S

- 75. The main components of the dialysate preparation are the bicarbonate concentrate pump BICP and the concentrate

- 76. FPE pumps dialysate into the balance chamber Conductivity Regulation DF Sub-Rack Start Back Next Previous

- 77. The BICP adds bicarbonate to the RO water. The pump speed regulated by the conductivity at

- 78. The KP adds concentrate to the Bicarbonate and RO water. The pump speed is regulated by

- 79. RVB and RVK are non-return valves that stablise the concentrate flow. Conductivity Regulation DF Sub-Rack Start

- 80. Temperature fluctuations cause a change in the conductivity measurements. Each conductivity sensor has a separate temperature

- 81. TDS-S and ENDLF-S are used by the Supervisor only.They have no influence on the regulation of

- 82. Dialysate Preparation with BIC Cartridge Option Start Back Next

- 83. Dialysate Preparation with BIC Cartridge DF Sub-Rack Start Back Next

- 84. Filling the Cartridge DF Sub-Rack Start Back Next

- 85. Expeling Air from the Cartridge DF Sub-Rack Start Back Next

- 86. Emptying the Cartridge DF Sub-Rack Start Back

- 87. What compenent is not part of the water sub-rack? Welcome to the Dialog+ Component Overview. Here

- 88. Dialog+ Hydraulic Test Question 2 How many temperature sensors are in the machine? 4 5 6

- 89. Dialog+ Hydraulic Test Question 3 What is the status of the degassing valve during disinfection? Closed

- 90. Dialog+ Hydraulic Test Question 4 Which pump is responsible for pumping fresh dialysate fluid into the

- 91. Dialog+ Hydraulic Test Question 5 What is the pressure of RVDA set to on a standard

- 92. Dialog+ Hydraulic Test Question 6 Wat is the approx. speed for EP, FPE, FPA during therapy?

- 93. Dialog+ Hydraulic Test Test Completed All the letters that have turned dark green were answered correctly.

- 94. Chemical Thermal Disinfection All pumps are running 3 min rinsing and heating to 45°C Air Separator

- 95. Chemical Thermal Disinfection All pumps are running Minimum disinfection time, above minimum Temp Dialog+ Next

- 96. Chemical Thermal Disinfection VBICP Test phase 1 PDA stabilizes close to zero VBICP Test phase 2

- 97. Chemical Thermal Disinfection Rinsing out of disinfectant Dialog+ Back

- 98. Phase 1 From FPE to drain The FPE pumps fresh dialysate into the balance chamber Pressure

- 99. Phase 1 Balance Chamber Start From FPE to drain The FPE pumps fresh dialysate into the

- 100. Phase 1 Balance Chamber Start From FPE to drain The FPE pumps fresh dialysate into the

- 101. Phase 1 Balance Chamber Start From FPE to drain The FPE pumps fresh dialysate into the

- 102. Phase 1 Balance Chamber Start From FPE to drain The FPE pumps fresh dialysate into the

- 103. Phase 1 Balance Chamber Start From FPE to drain The FPE pumps fresh dialysate into the

- 104. Phase 1 Balance Chamber Start From FPE to drain The FPE pumps fresh dialysate into the

- 105. Phase 1 Balance Chamber Start From FPE to drain The FPE pumps fresh dialysate into the

- 106. Phase 2 Balance Chamber Start Patient From FPA to patient to FPA The FPE pumps used

- 107. Phase 2 Balance Chamber Start Patient From FPA to patient to FPA The FPE pumps used

- 108. Phase 2 Balance Chamber Start Patient From FPA to patient to FPA The FPE pumps used

- 109. Phase 2 Balance Chamber Start Patient From FPA to patient to FPA The FPE pumps used

- 110. Phase 2 Balance Chamber Start Patient From FPA to patient to FPA The FPE pumps used

- 111. Phase 2 Balance Chamber Start Patient From FPA to patient to FPA The FPE pumps used

- 112. Phase 2 Balance Chamber Start Patient From FPA to patient to FPA The FPE pumps used

- 113. Phase 2 Balance Chamber Start Patient From FPA to patient to FPA The FPE pumps used

- 114. Phase 1 Balance Chamber Start Back Patient

- 115. Phase 1 Balance Chamber Start Back Patient

- 116. Phase 1 Balance Chamber Start Back Patient

- 117. Phase 1 Balance Chamber Start Back Patient

- 118. Phase 1 Balance Chamber Start Back Patient

- 119. Phase 1 Balance Chamber Start Back Patient

- 120. Phase 1 Balance Chamber Start Back Patient

- 121. Phase 1 Balance Chamber Start Back Patient

- 122. Phase 1 Balance Chamber Start Back Patient

- 123. Phase 1 Balance Chamber Start Back Patient

- 124. Phase 1 Balance Chamber Start Back Patient

- 125. Phase 1 Balance Chamber Start Back Patient

- 126. Phase 1 Balance Chamber Start Back Patient

- 127. Phase 1 Balance Chamber Start Back Patient

- 129. Скачать презентацию

Сложные предложения с различными видами связи (вводный урок). 9 класс

Сложные предложения с различными видами связи (вводный урок). 9 класс В гостях у ханты.

В гостях у ханты. What is Engineering?

What is Engineering? Мировое хозяйство

Мировое хозяйство Виртуалдық машиналар

Виртуалдық машиналар Контрольно-кассовая техника

Контрольно-кассовая техника Оборудование для производства молочной продукции

Оборудование для производства молочной продукции Александр Сергеевич Пушкин

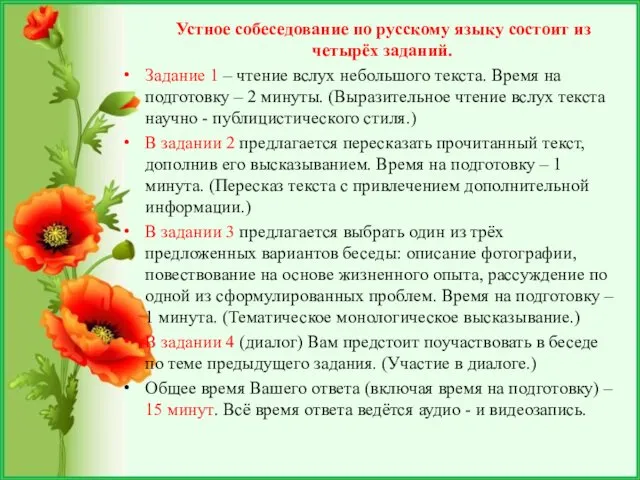

Александр Сергеевич Пушкин Устное собеседование по русскому языку

Устное собеседование по русскому языку Подъемно-транспортное оборудование

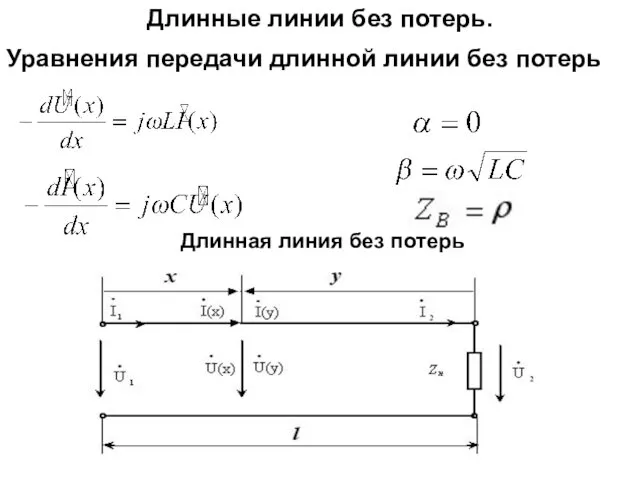

Подъемно-транспортное оборудование Длинные линии без потерь. Уравнения передачи длинной линии без потерь

Длинные линии без потерь. Уравнения передачи длинной линии без потерь Республика Аргентина

Республика Аргентина Презентация по географии в 10 классе по теме Научно-техническая революция и Мировое хозяйство

Презентация по географии в 10 классе по теме Научно-техническая революция и Мировое хозяйство Флегмона орбиты

Флегмона орбиты Социальные взаимодействия

Социальные взаимодействия Классный час, посвященный 70-летию Великой Победы

Классный час, посвященный 70-летию Великой Победы Литературное краеведение Оренбургской области. ЗапискиАксакова

Литературное краеведение Оренбургской области. ЗапискиАксакова Примеры автономного существования человека в природной среде

Примеры автономного существования человека в природной среде Производственный план

Производственный план Презентация к клубному часу Мир, в котором мы живем

Презентация к клубному часу Мир, в котором мы живем Дидактические игры в 1 классе

Дидактические игры в 1 классе МК ATmel

МК ATmel Анатомо-физиологические особенности системы крови

Анатомо-физиологические особенности системы крови Осенины. Викторина.

Осенины. Викторина. День Победы

День Победы Учет поголовья животных в субъекте

Учет поголовья животных в субъекте Зарубежное искусство XX века

Зарубежное искусство XX века Тема: Культура и быт народов Кубани

Тема: Культура и быт народов Кубани