Содержание

- 2. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay A Crude Oil Assay There

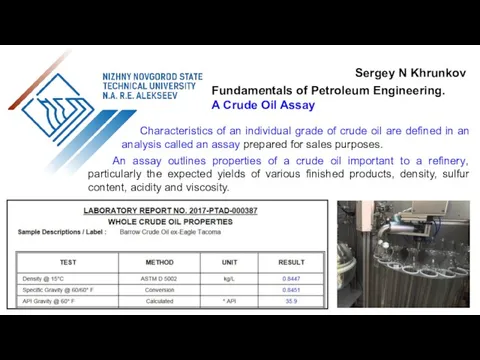

- 3. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Characteristics of an individual grade

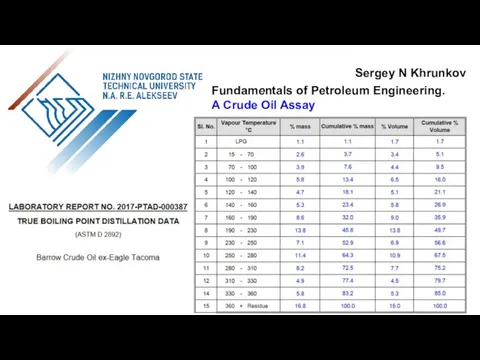

- 4. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay

- 5. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay A crude oil reservoir does

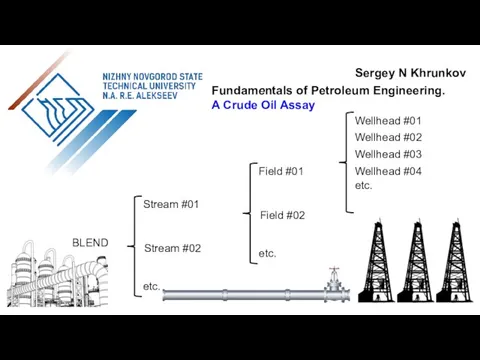

- 6. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Crude oil can come from

- 7. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay

- 8. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay When marketing a crude oil

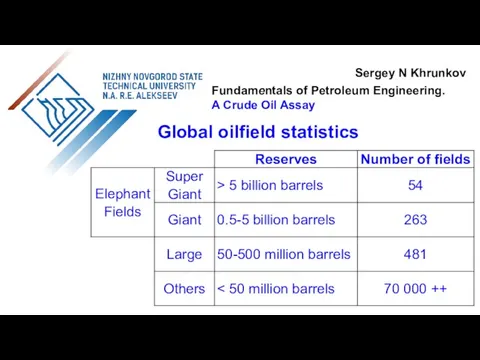

- 9. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Global oilfield statistics

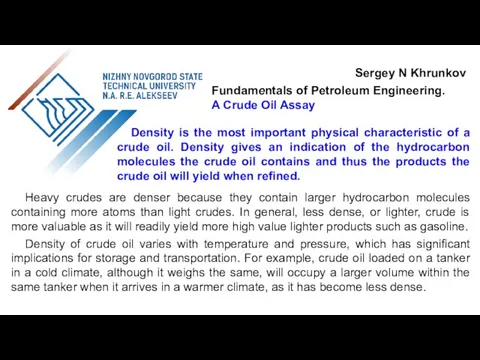

- 10. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Density is the most important

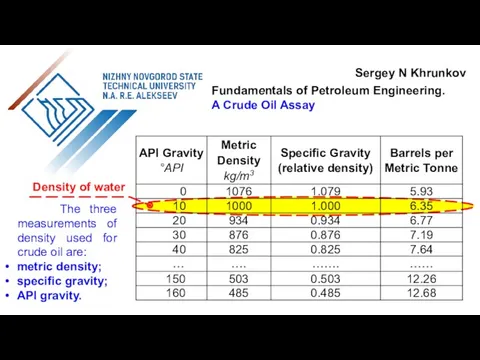

- 11. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay The three measurements of density

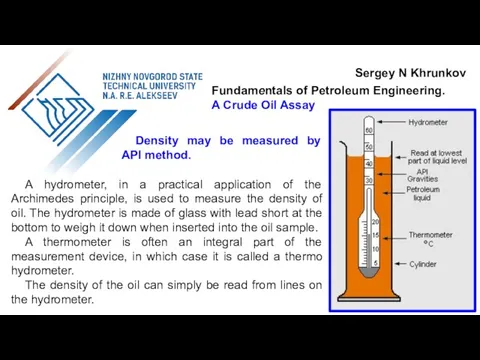

- 12. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Density may be measured by

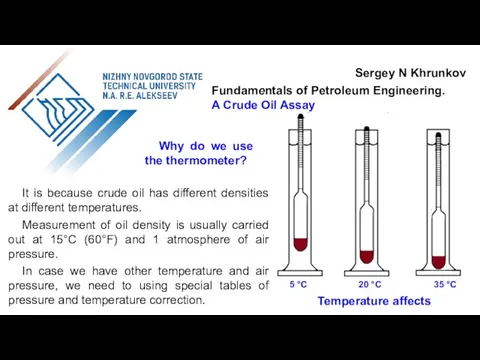

- 13. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Why do we use the

- 14. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay ASTM D 1298-99 (2005) Standard

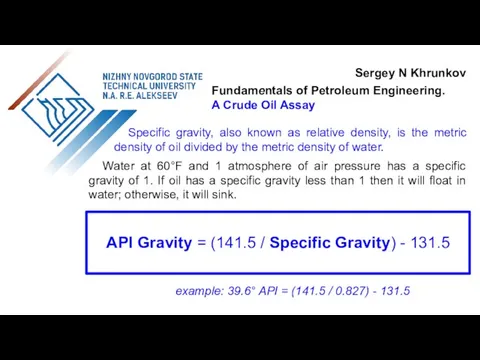

- 15. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Specific gravity, also known as

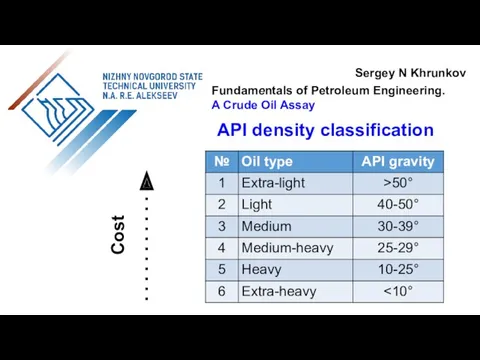

- 16. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay API density classification Cost

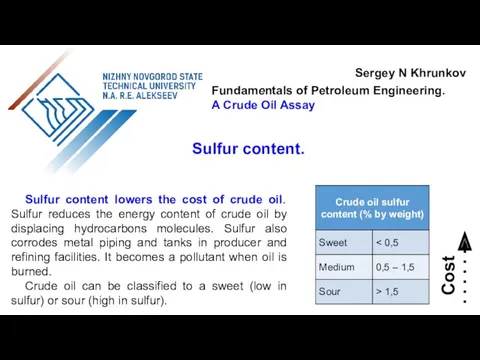

- 17. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Sulfur content. Sulfur content lowers

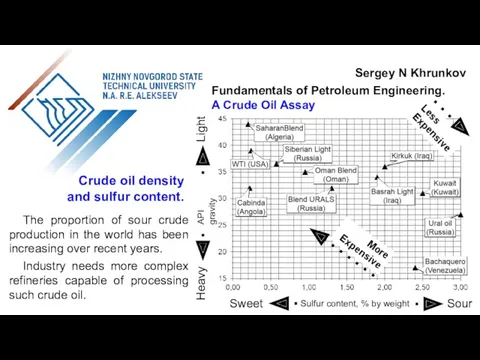

- 18. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay API gravity Sulfur content, %

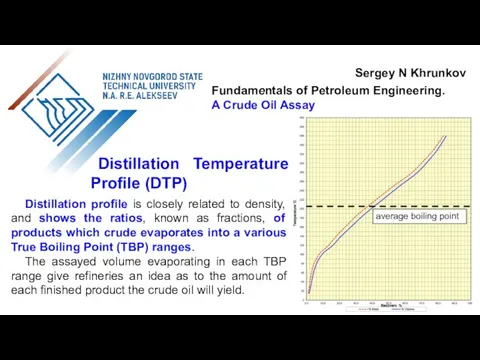

- 19. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Distillation Temperature Profile (DTP) Distillation

- 20. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Acids Acids accumulate as a

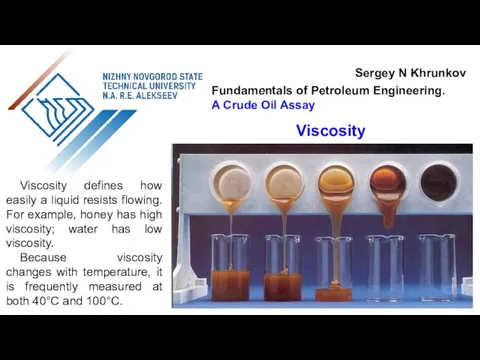

- 21. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Viscosity Viscosity defines how easily

- 22. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay: viscosity Highly viscous crude oil

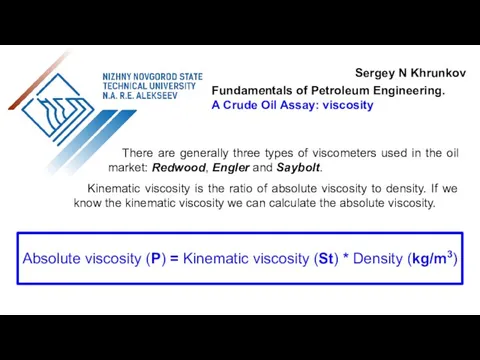

- 23. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay: viscosity Kinematic viscosity is the

- 24. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Pour point The pour point

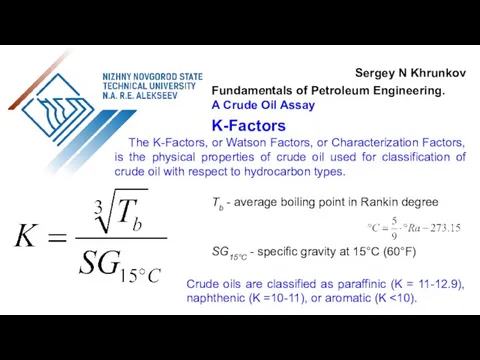

- 25. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay K-Factors The K-Factors, or Watson

- 26. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Vapor pressure indicates how readily

- 27. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Metals and other elements commonly

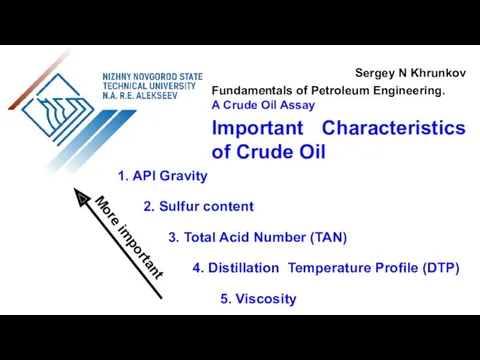

- 28. Sergey N Khrunkov Fundamentals of Petroleum Engineering. A Crude Oil Assay Important Characteristics of Crude Oil

- 30. Скачать презентацию

Причины возникновения экстремизма и терроризма

Причины возникновения экстремизма и терроризма Чтение топографических карт

Чтение топографических карт Христиан діні. Тарихы және мәдениеті

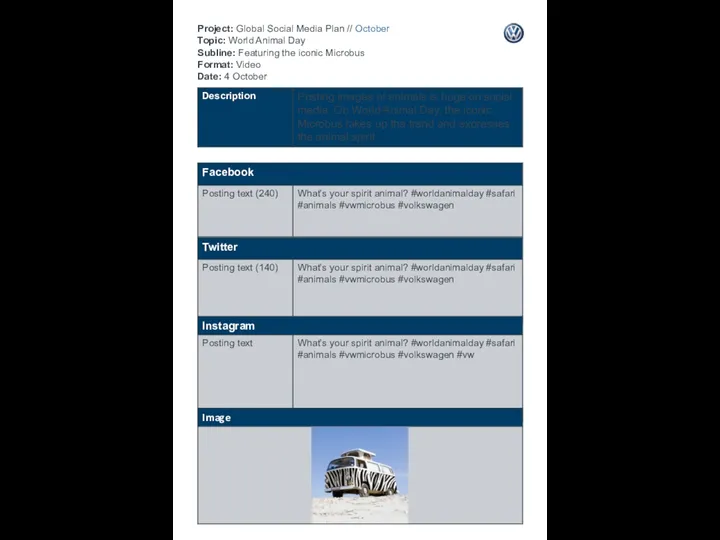

Христиан діні. Тарихы және мәдениеті World Animal Day

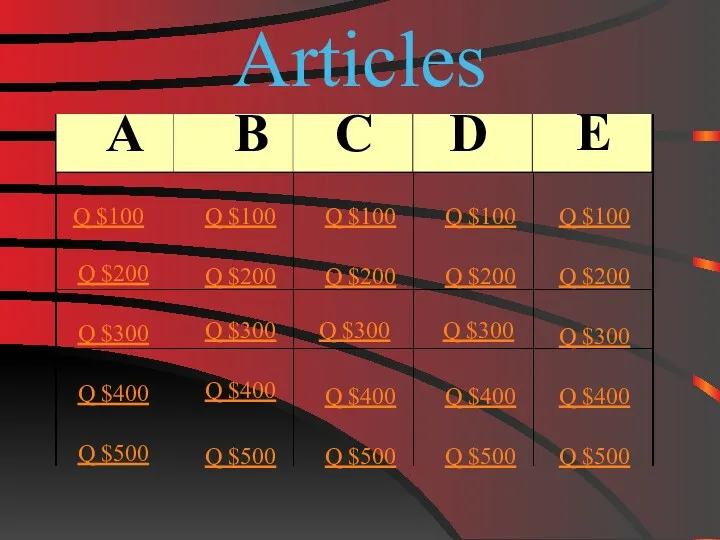

World Animal Day Articles jeopardy game

Articles jeopardy game Презентация Береги здоровье с молоду

Презентация Береги здоровье с молоду Информационное сообщество в Арабских странах

Информационное сообщество в Арабских странах Praktikumsbericht zum 8-wöchigen Praktikum an der Deutschen Schule - Colegio Alemán in Medellín, Kolumbien

Praktikumsbericht zum 8-wöchigen Praktikum an der Deutschen Schule - Colegio Alemán in Medellín, Kolumbien Эпидемический паротит (свинка, заушница)

Эпидемический паротит (свинка, заушница) 20 способов провалить интервью в Google

20 способов провалить интервью в Google Corporate environmental management

Corporate environmental management Электронное приложение для логоритмического урока на развитие двигательных функций

Электронное приложение для логоритмического урока на развитие двигательных функций Итоговое занятие кружка Умелые ручки

Итоговое занятие кружка Умелые ручки Информационно-поисковая система

Информационно-поисковая система Всероссийский конкурс издательства Просвещение УЧИТЕЛЬ ПРОСВЕЩЕНИЯ

Всероссийский конкурс издательства Просвещение УЧИТЕЛЬ ПРОСВЕЩЕНИЯ Сестринский уход при бронхиальной астме

Сестринский уход при бронхиальной астме Странички из истории родного города

Странички из истории родного города Презентация Жизнь нашего класса

Презентация Жизнь нашего класса Составляющие и показатели надежности аппаратного обеспечения невосстанавливаемых АС

Составляющие и показатели надежности аппаратного обеспечения невосстанавливаемых АС Если друг оказался вдруг (1). Крах банка Barings

Если друг оказался вдруг (1). Крах банка Barings Наглядно-дидактическое пособие для развития языкового анализа-синтеза на материале пословиц и предложений

Наглядно-дидактическое пособие для развития языкового анализа-синтеза на материале пословиц и предложений Организация и планирование ремонтного обслуживания в энергетике

Организация и планирование ремонтного обслуживания в энергетике Программа профильного интеллектуально-оздоровительного лагеря для одаренных детей. Умные каникулы

Программа профильного интеллектуально-оздоровительного лагеря для одаренных детей. Умные каникулы 6. Уроки, извлеченные из происшествия - падение фланца ВЛС СМУ 06.01.2024_BL

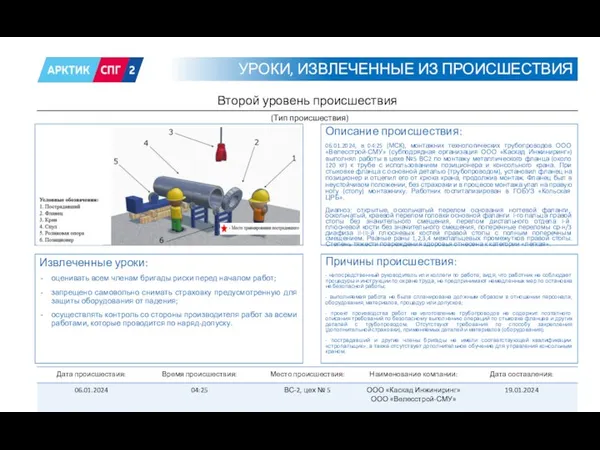

6. Уроки, извлеченные из происшествия - падение фланца ВЛС СМУ 06.01.2024_BL Как подобрать ноутбук?

Как подобрать ноутбук? День животных

День животных Способы преобразования ортогональных проекций

Способы преобразования ортогональных проекций Проектная неделя. Образование будущего

Проектная неделя. Образование будущего