Содержание

- 2. Weatherford’s Premium Performance Discover breadth and depth of completion technology custom-engineered systems for your toughest wells

- 3. Weatherford provides completion options with a broad range of products to meet every application Packers Subsurface

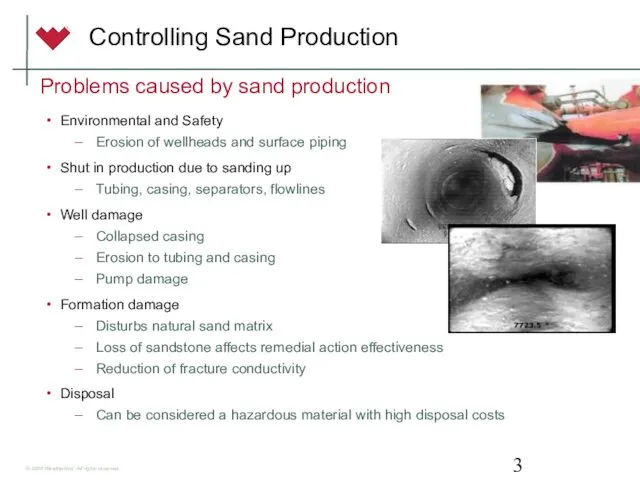

- 4. Controlling Sand Production Environmental and Safety Erosion of wellheads and surface piping Shut in production due

- 5. Controlling Sand Production Common Methods Production rates Oriented perforating Stand alone screens Cased hole and open

- 6. Weatherford’s Fit in the Market Largest worldwide manufacturer of oil and gas well screens Leader in

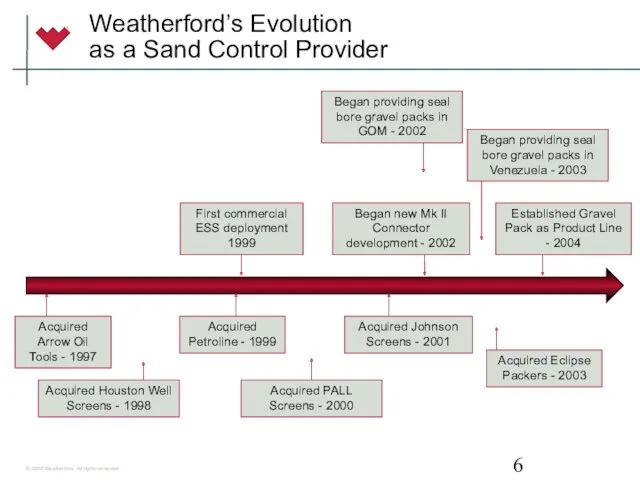

- 7. Weatherford’s Evolution as a Sand Control Provider Began providing seal bore gravel packs in Venezuela -

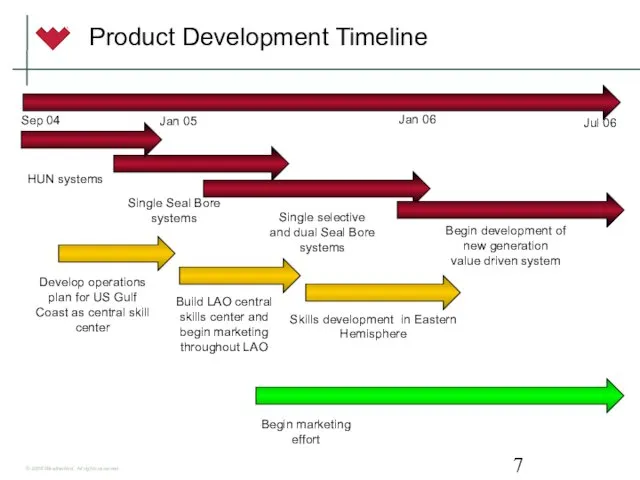

- 8. Product Development Timeline Jul 06 HUN systems Single Seal Bore systems Single selective and dual Seal

- 9. Weatherford’s Strategy Weatherford will establish itself as a provider gravel pack solutions focused on overlooked, neglected,

- 10. Weatherford’s Strategy Initial Focus Mature and overlooked markets Majority of the world’s wells are in mature

- 11. Weatherford’s Strategy Long Term Focus Combine conventional practices with new technology GP systems with greater functionality

- 12. Focused on Economical Gravel Pack Solutions

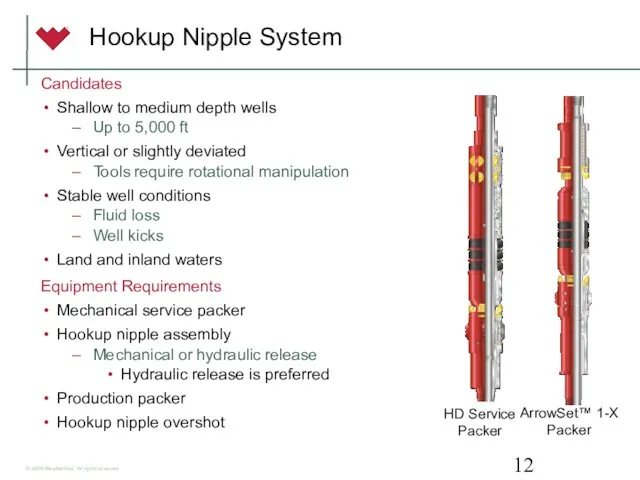

- 13. Hookup Nipple System Candidates Shallow to medium depth wells Up to 5,000 ft Vertical or slightly

- 14. Hookup Nipple System Circulating or squeeze packs Circulating pack is preferred Better for longer intervals Forces

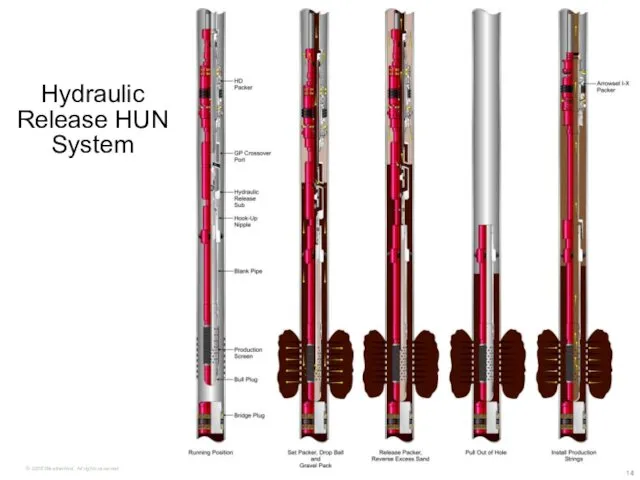

- 15. Hydraulic Release HUN System

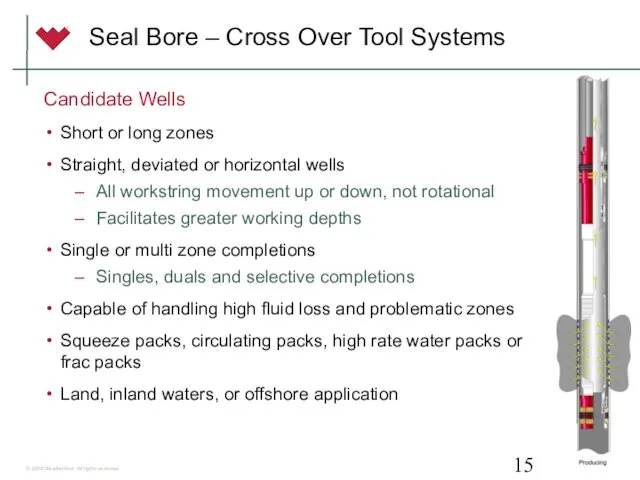

- 16. Seal Bore – Cross Over Tool Systems Candidate Wells Short or long zones Straight, deviated or

- 17. Seal Bore GP No Tell Tale

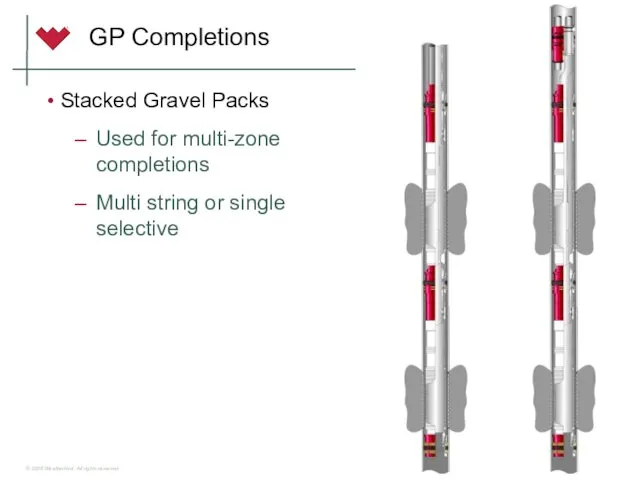

- 18. GP Completions Stacked Gravel Packs Used for multi-zone completions Multi string or single selective

- 19. Seal Bore – Cross Over Tool Systems Equipment Requirements Weatherford BlackCat GP packer GP Extension Choice

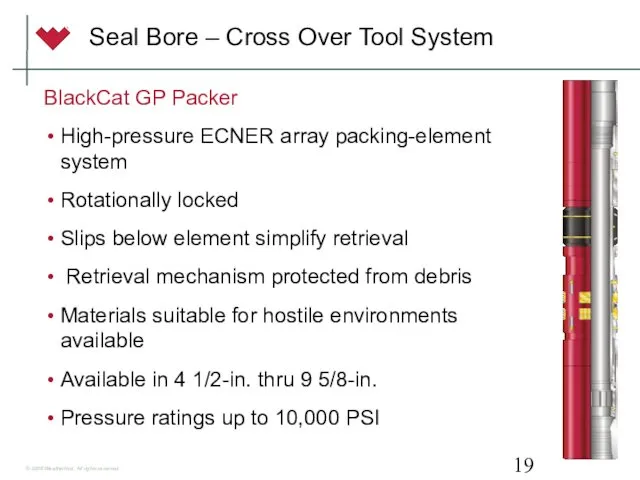

- 20. Seal Bore – Cross Over Tool System BlackCat GP Packer High-pressure ECNER array packing-element system Rotationally

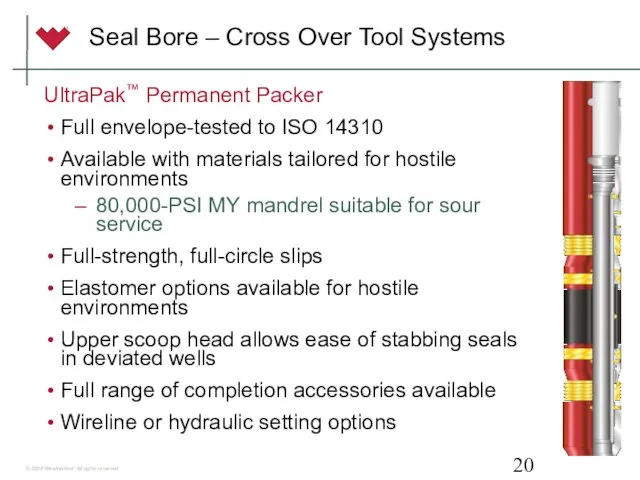

- 21. Seal Bore – Cross Over Tool Systems UltraPak™ Permanent Packer Full envelope-tested to ISO 14310 Available

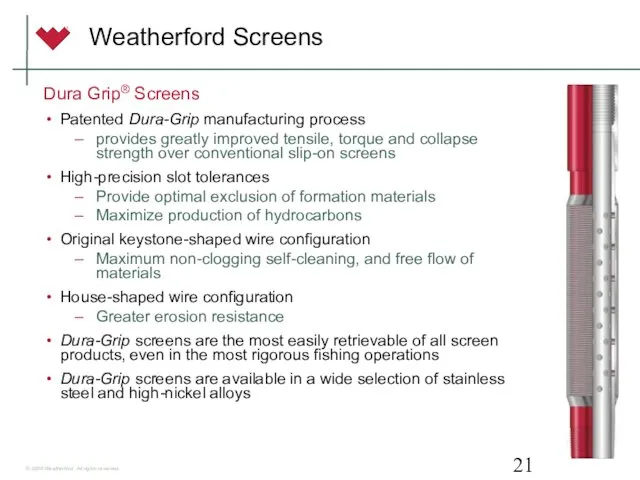

- 22. Weatherford Screens Dura Grip® Screens Patented Dura-Grip manufacturing process provides greatly improved tensile, torque and collapse

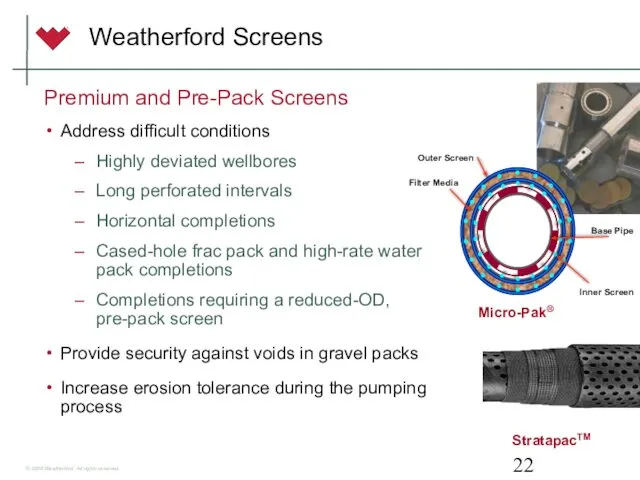

- 23. Weatherford Screens Premium and Pre-Pack Screens Address difficult conditions Highly deviated wellbores Long perforated intervals Horizontal

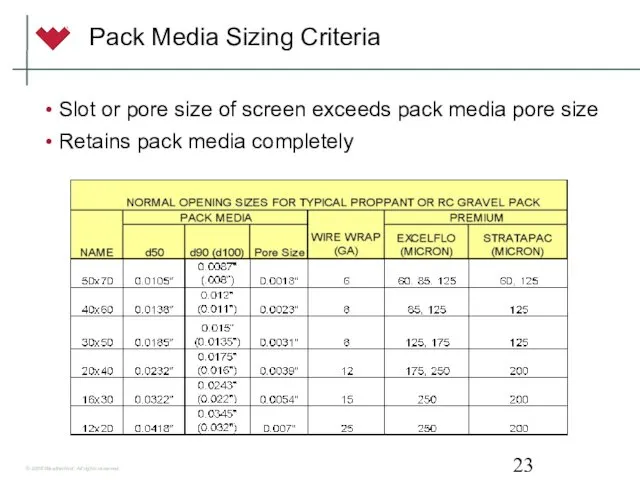

- 24. Pack Media Sizing Criteria Slot or pore size of screen exceeds pack media pore size Retains

- 25. Screen Sizing Guidelines Casing Size 5-in. & 5 1/2-in. to 2 3/8-in. Dura-Grip® or Micro-Pak 7-in.

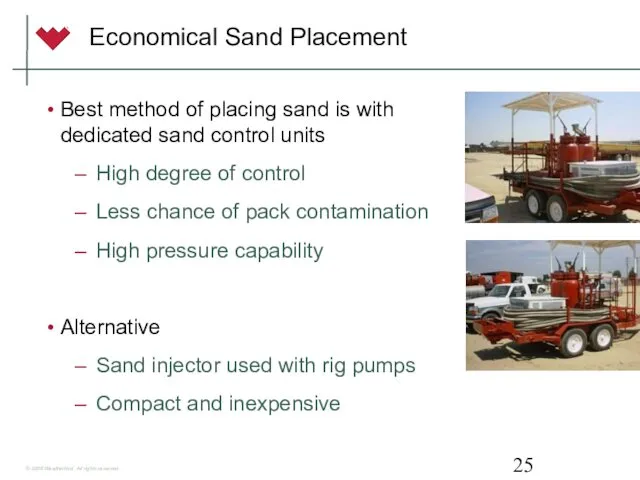

- 26. Economical Sand Placement Best method of placing sand is with dedicated sand control units High degree

- 27. Weatherford’s Game Plan Weatherford will be the next major worldwide gravel pack provider Currently providing GP

- 29. Скачать презентацию

20231115_lyzhi_1-4_klass

20231115_lyzhi_1-4_klass Роль домашнего задания в самообразовании школьника

Роль домашнего задания в самообразовании школьника Самые необычные дома мира

Самые необычные дома мира Деструктивное поведение детей. Стратегии и тактики эффективного взаимодействия

Деструктивное поведение детей. Стратегии и тактики эффективного взаимодействия Использование датчиков в RobotC

Использование датчиков в RobotC Мировая религия пастафарианство

Мировая религия пастафарианство Состав штукатурных работ

Состав штукатурных работ Дозиметри

Дозиметри Установочная конференция (преддипломная)

Установочная конференция (преддипломная) Радиоактивность. Модели атомов

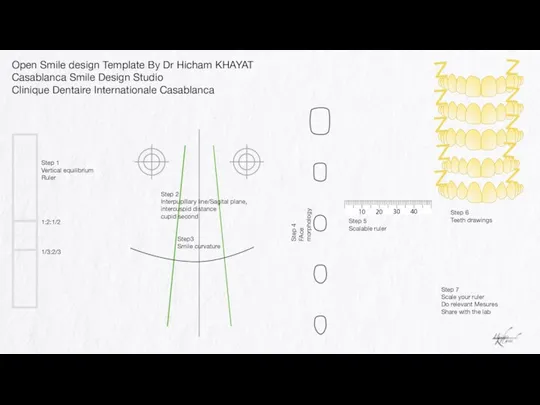

Радиоактивность. Модели атомов Open Smile Design template

Open Smile Design template Бекеттің блокты-түймелі жоспары. БМРО жүйесінің негізгі атқарушы және жинақтаушы блоктары. (Дәріс 14)

Бекеттің блокты-түймелі жоспары. БМРО жүйесінің негізгі атқарушы және жинақтаушы блоктары. (Дәріс 14) Особенности работы с детьми коррекционного класса

Особенности работы с детьми коррекционного класса Портфолио воспитателя Полеевой Веры Алексеевны

Портфолио воспитателя Полеевой Веры Алексеевны Декаплінг. Ядерний ефект оверхаузера. Динамічні ефекти в ямр

Декаплінг. Ядерний ефект оверхаузера. Динамічні ефекти в ямр Приемы работы с гофрополосками. Объемные композиции, животные. Презентация Мастер-класс Гофро-кот

Приемы работы с гофрополосками. Объемные композиции, животные. Презентация Мастер-класс Гофро-кот Оборона Воронежа в годы Великой Отечественной войны

Оборона Воронежа в годы Великой Отечественной войны С 8 марта

С 8 марта Разработка занятия по технике изонить. Первые шаги - угол.

Разработка занятия по технике изонить. Первые шаги - угол. Поворот

Поворот Qu’est-ce que c’est la Cote d’Ivoire

Qu’est-ce que c’est la Cote d’Ivoire Делать Жизнь с Кого?

Делать Жизнь с Кого? Рефінансування банків

Рефінансування банків Гетьманські столиці України

Гетьманські столиці України Аллергия. Отличие иммунитета и аллергии

Аллергия. Отличие иммунитета и аллергии Невидимі ланцюги в осінньому лісі

Невидимі ланцюги в осінньому лісі Чередующиеся гласные в корне

Чередующиеся гласные в корне Поделка оригами Зайчик

Поделка оригами Зайчик