Содержание

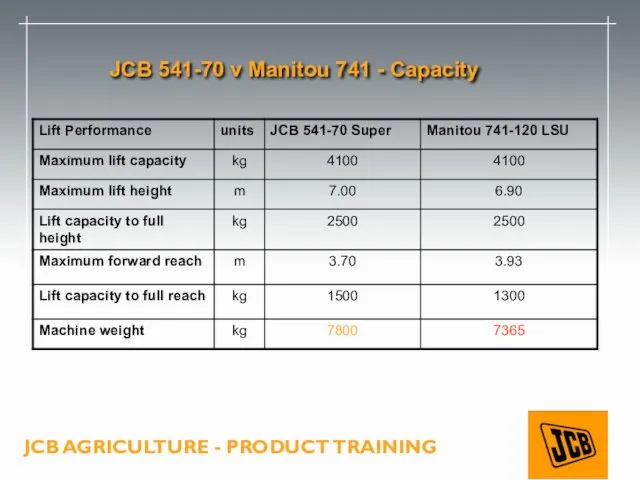

- 2. JCB 541-70 v Manitou 741 - Capacity

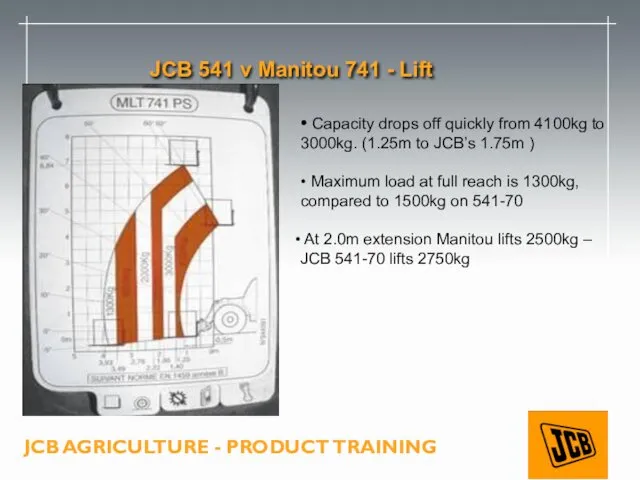

- 3. • Capacity drops off quickly from 4100kg to 3000kg. (1.25m to JCB’s 1.75m ) • Maximum

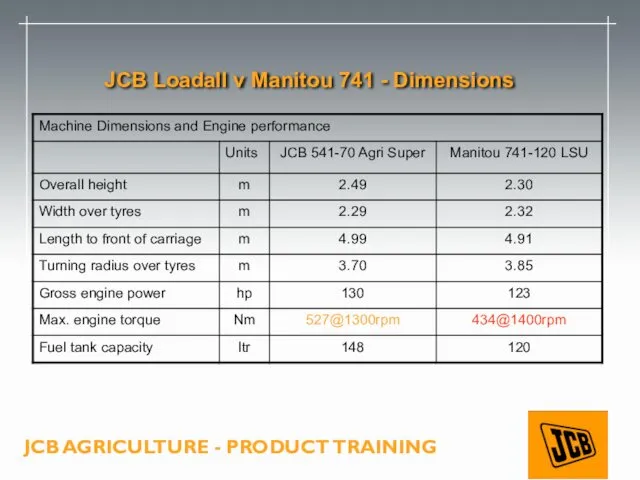

- 4. JCB Loadall v Manitou 741 - Dimensions

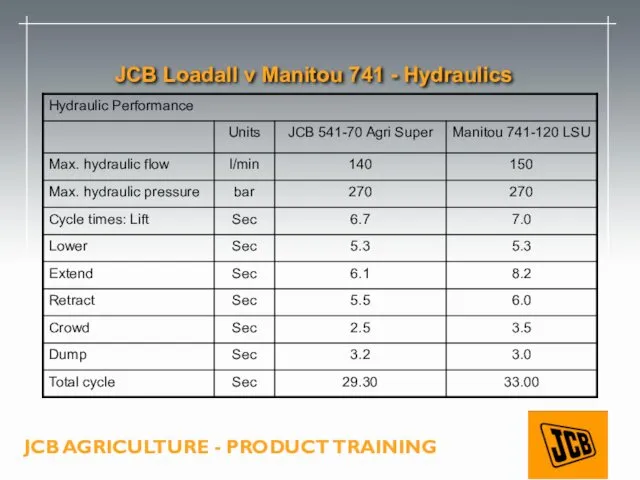

- 5. JCB Loadall v Manitou 741 - Hydraulics

- 6. Fitted with the 4.4-litre Perkins engine. 101/123hp Engine mounted onto bodywork, driving bevel box via a

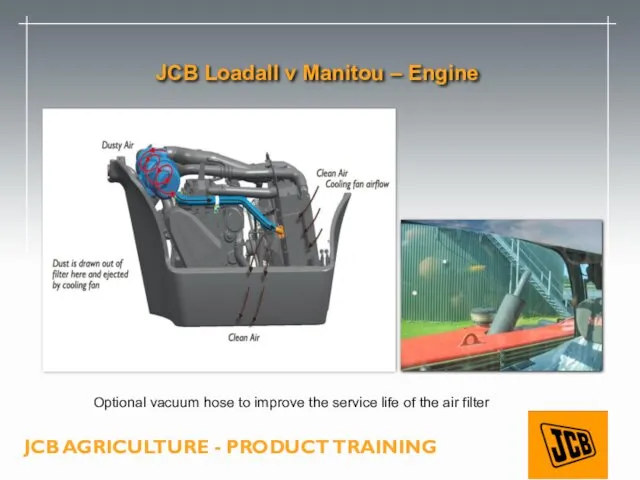

- 7. JCB Loadall v Manitou – Engine Optional vacuum hose to improve the service life of the

- 8. JCB Loadall v Manitou – Engine Engine mounted to the chassis not carried on the protection

- 9. Charge-air-cooler pipes made of mild steel, with jubilee clip connections and ‘standard’ black hosing. Dense core

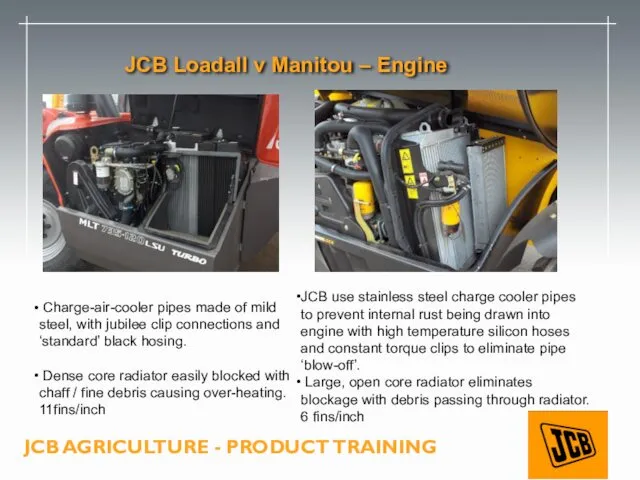

- 10. Fan is belt driven from the engine, ‘Clean fix’ type fan used to reverse fan direction

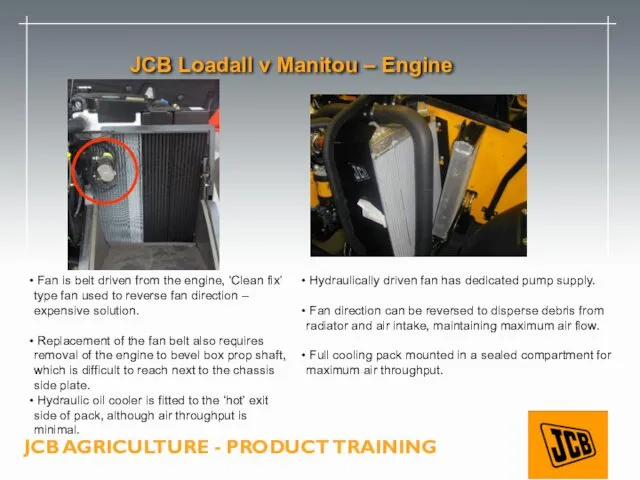

- 11. JCB Loadall v Manitou – Engine Engine to transmission drive shaft which provides a belt drive

- 12. JCB Loadall v Manitou – Engine Larger meshed air panel to increase air flow to the

- 13. Additional engine driven pump is required to push oil through the oil cooler. 123hp models JCB

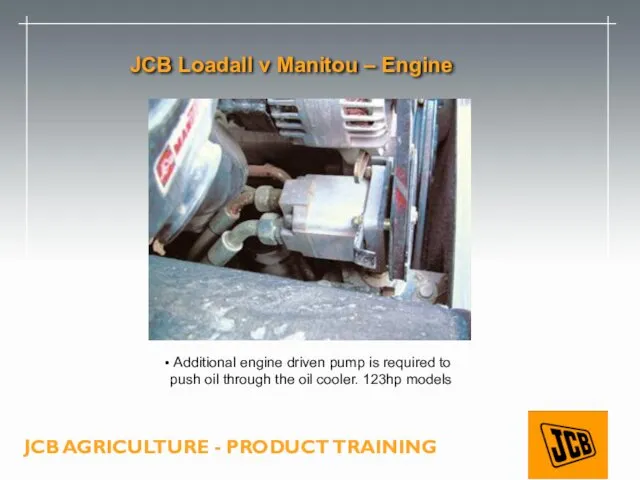

- 14. Transversely mounted engine drives into 90-degree bevel box. Drive shaft with rubber damper prior to transmission.

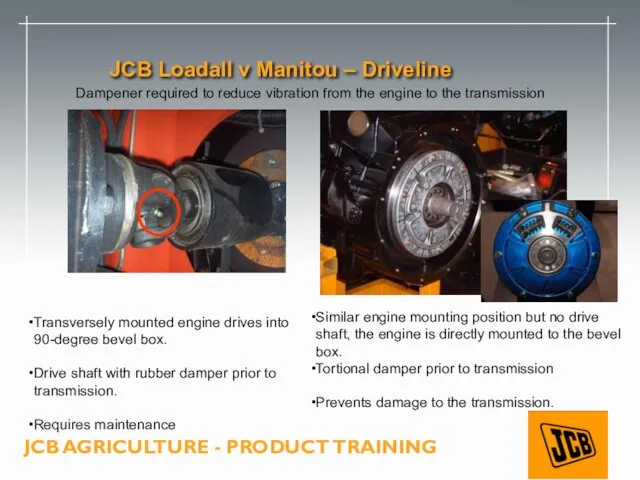

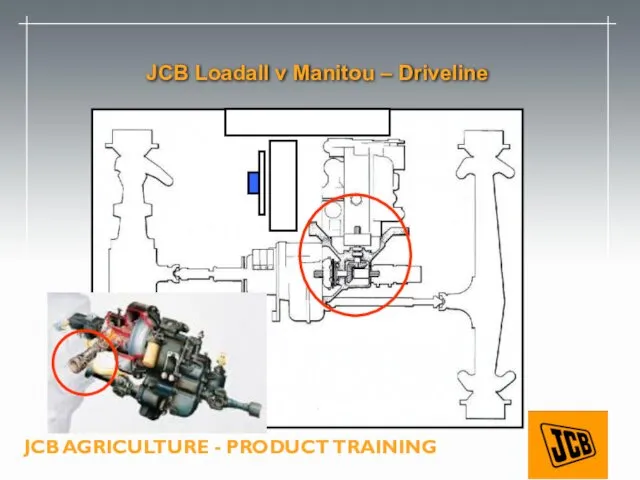

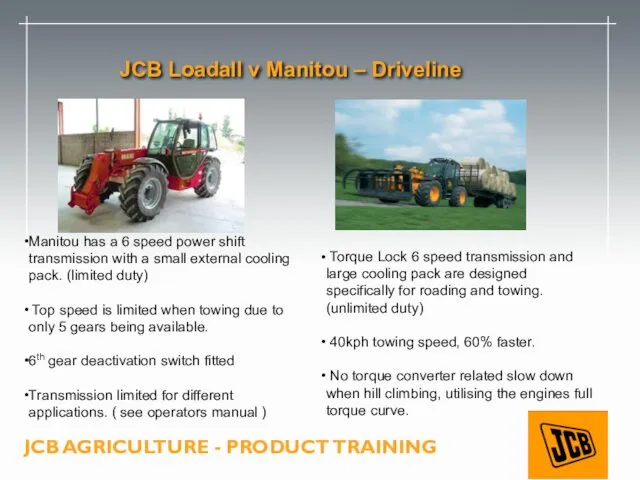

- 15. JCB Loadall v Manitou – Driveline

- 16. 741 has turner 6-speed power shift or 4-speed manual transmission (Power shuttle). Power shift capable of

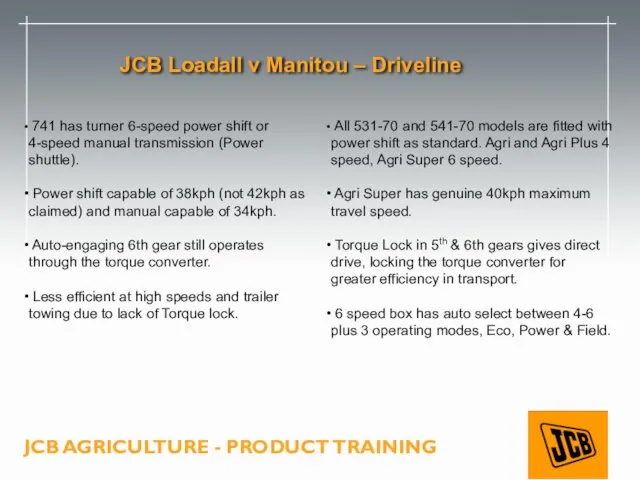

- 17. JCB Loadall v Manitou – Driveline Manitou standard 4 speed manual gear box and power shuttle

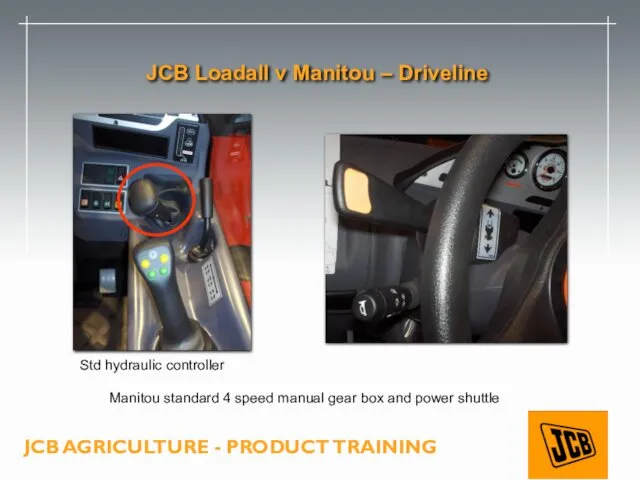

- 18. Manitou has a 6 speed power shift transmission with a small external cooling pack. (limited duty)

- 19. MANITOU OPERATORS MANUAL

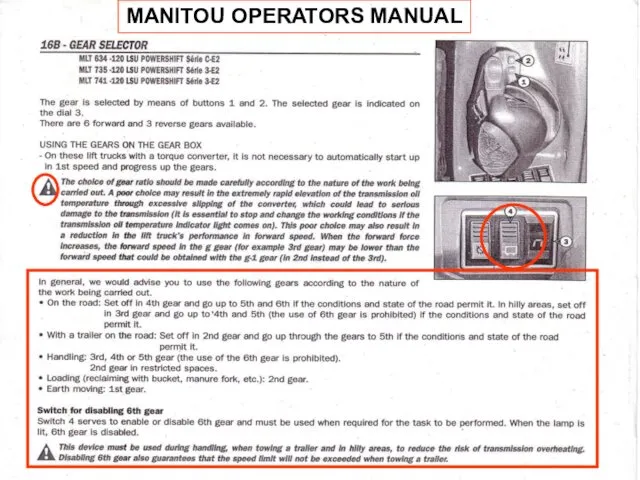

- 20. Manitou – Driveline Small external transmission cooler with limited air flow Cooler is mounted behind the

- 21. Manitou - Transmission Transmission oil dip stick and filler cap located under the boom

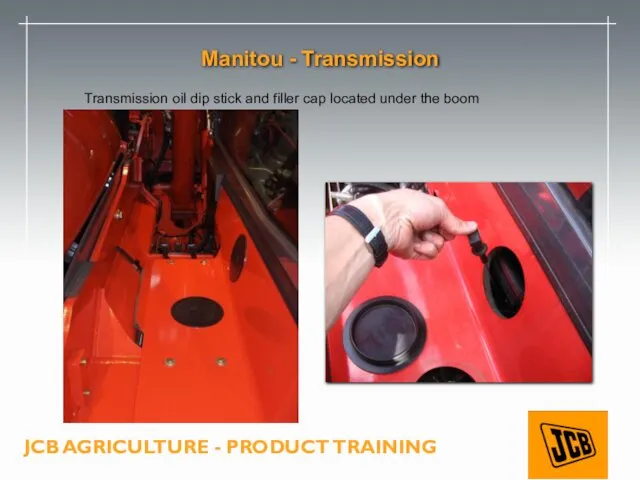

- 22. Hydraulic oil tank mounted directly under the cab. Potential source of heat. Hydraulic oil tank integrated

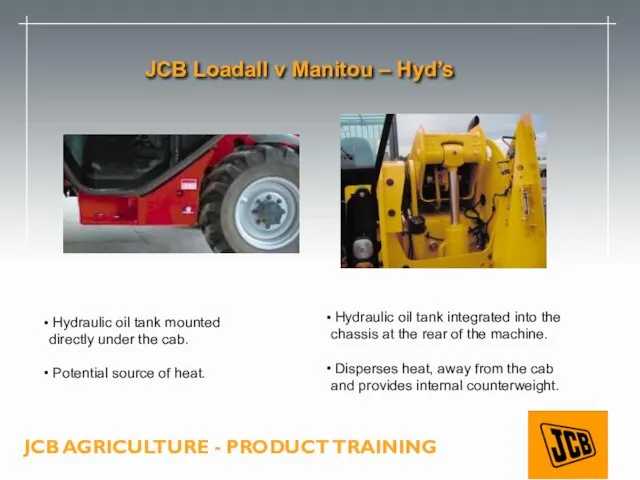

- 23. JCB Loadall v Manitou - Fuel JCB has a low level fuel tank for easy filling

- 24. Spicer axles fitted. Compare size to axles fitted to JCB Loadalls. Heavy duty JCB axles fitted.

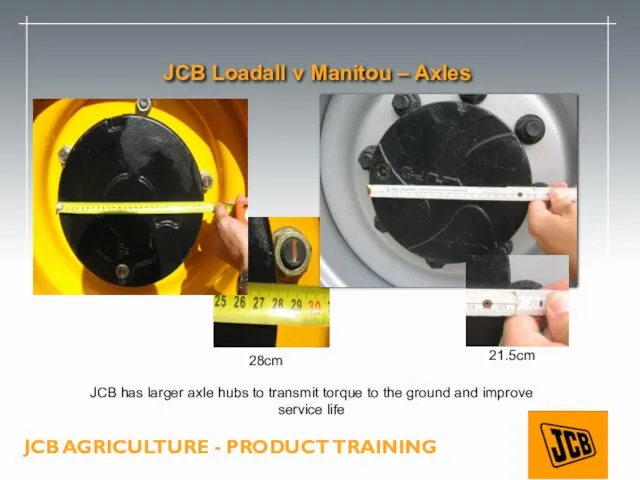

- 25. JCB Loadall v Manitou – Axles JCB has larger axle hubs to transmit torque to the

- 26. MLT741 chassis side plate thickness = 20mm. Stronger chassis or counter weight ? JCB 531-70 chassis

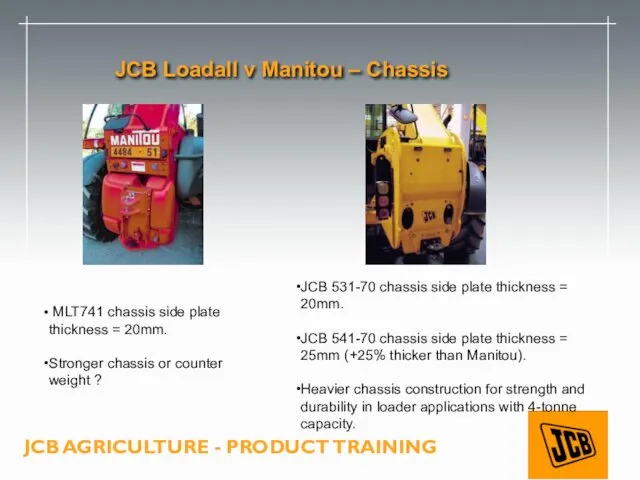

- 27. Manitou use large rear counterweight to achieve lift performance. Counter weight removed to create 735-120 &

- 28. Manitou chassis is offset to centre of machine, potentially creating greater stress in right-hand axle foot.

- 29. JCB Loadall v Manitou – Chassis Dedicated Heavy duty chassis to each JCB model. 531-70 =

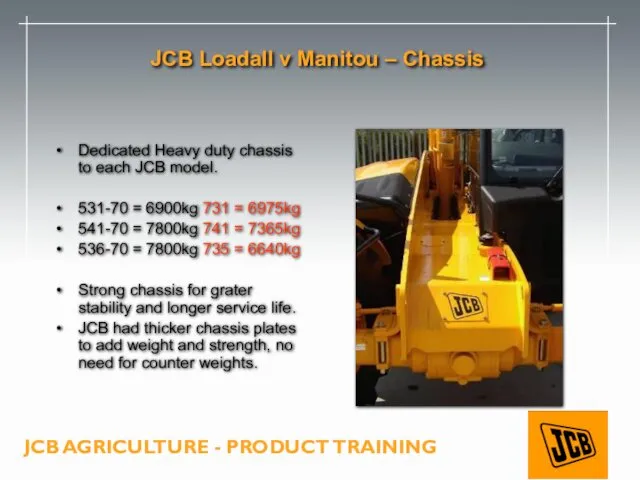

- 30. Maximum download on rear hitch is 1500kg. Maximum hitch download is 2000kg JCB Loadall v Manitou

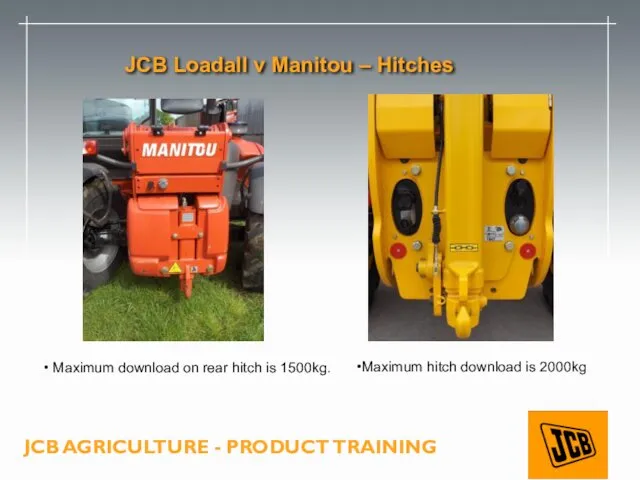

- 31. Boom Sections: Inner = H 280mm x W 250mm x 10mm thick. Outer = H 350mm

- 32. Offset lift and compensation rams. Central lift and compensation rams ensure symmetrical boom loadings, reducing twisting

- 33. JCB Loadall v Manitou – Boom Centrally mounted compensating ram to reduce twisting

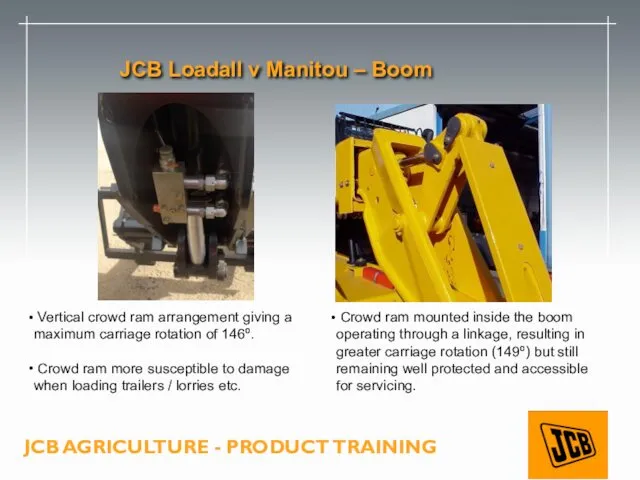

- 34. Greased boom lubrication requires 250-hour servicing. Welded boom nose end – weld at high stress corner

- 35. Crowd ram mounted inside the boom operating through a linkage, resulting in greater carriage rotation (149º)

- 36. Manual locking carriage uses a bar and pin. Manual carriage with locking lever provides mechanical advantage

- 37. SRS is a system proven on thousands of JCB backhoe loaders, Loadalls and wheeled loaders. Reliable

- 38. Oil control block mounted on lift ram, connected by hose to gas accumulator mounted on the

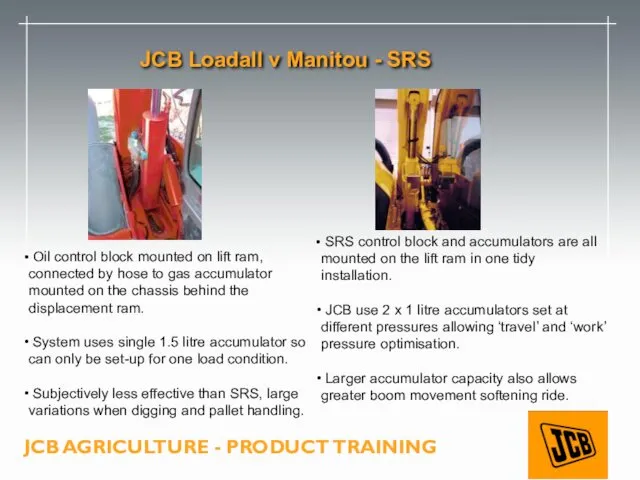

- 39. Overall cab length (140cm) and width (86cm) are less than the JCB, less available space and

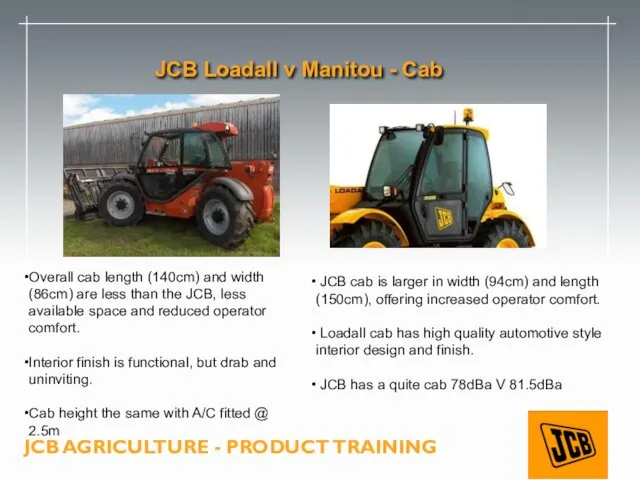

- 40. JCB Loadall v Manitou - Cab JCB has more leg room and floor space

- 41. Steering console is cluttered with information, some switches are hidden making operation difficult. Manual steering alignment

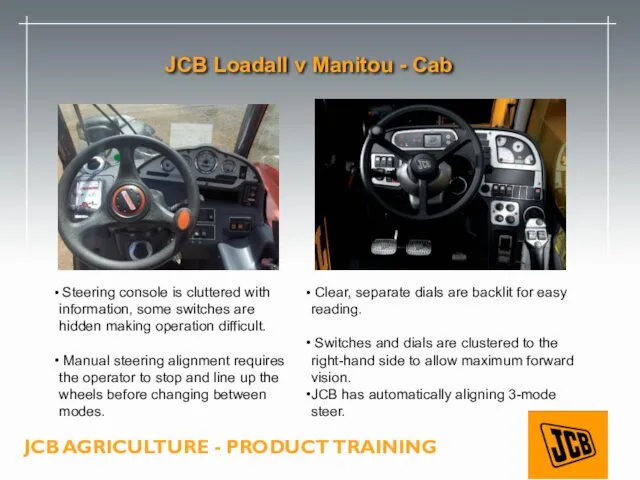

- 42. JCB Loadall v Manitou - Cab Joy stick controls

- 43. JCB Loadall v Manitou - Cab Manual steering controls v automatic

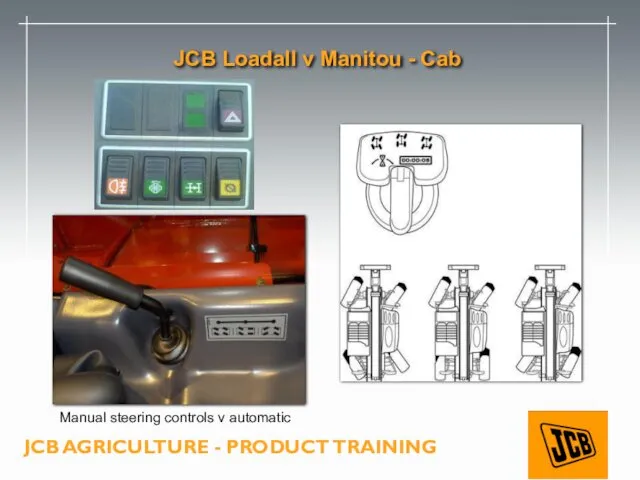

- 44. Screen wash and brake reservoir mounted in the cab. Washer bottle, brake fluid reservoir and storage

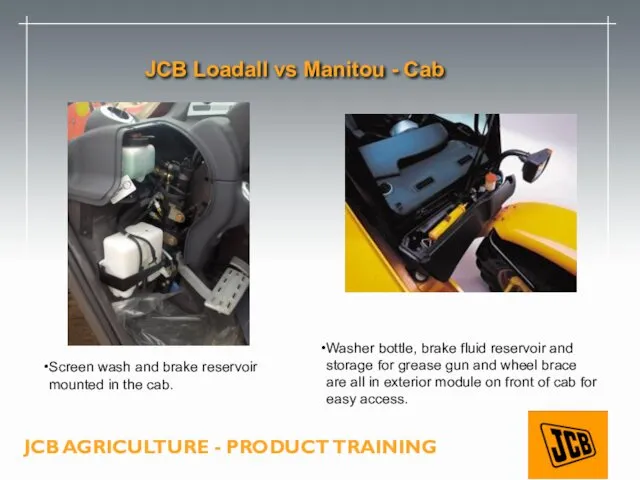

- 45. No telescope option on the steering column, tilt only. Tilt/telescopic steering column available on all 531-70

- 46. Load Moment Indicator is mounted on the front dash. Not easily visible when loading at height.

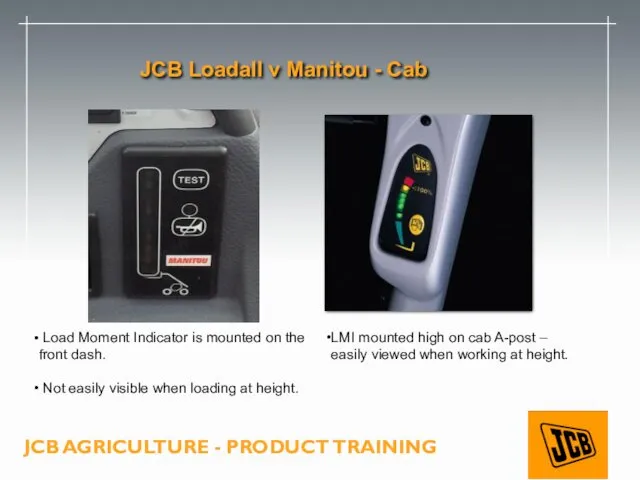

- 47. Spade connectors still used on electrical system. Not IP69 rated. Transmission oil dipstick is accessible in

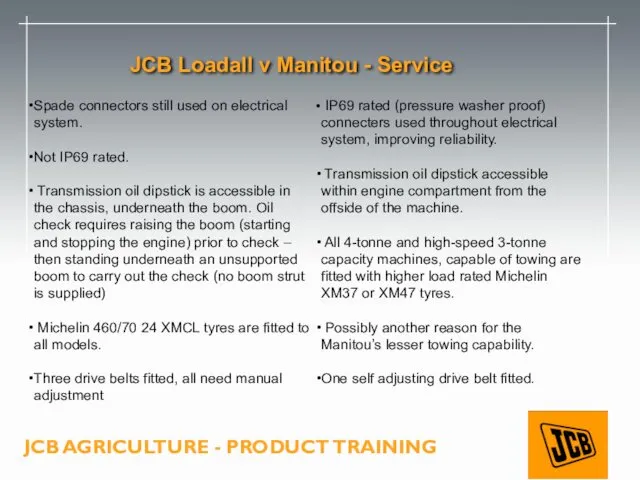

- 48. 741 appears a shortcut to a 4-tonne capacity machine. Chassis and boom structures are not up

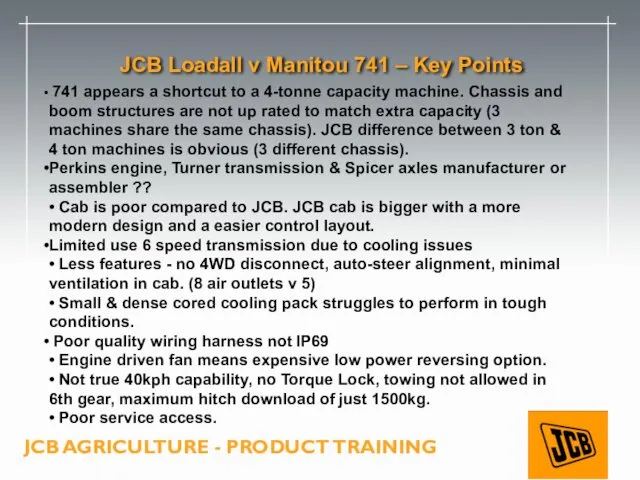

- 49. MANITOU RANGE V JCB

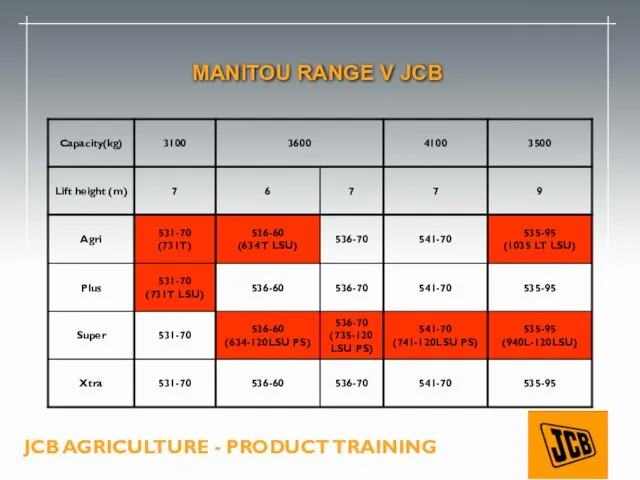

- 50. MANITOU RANGE

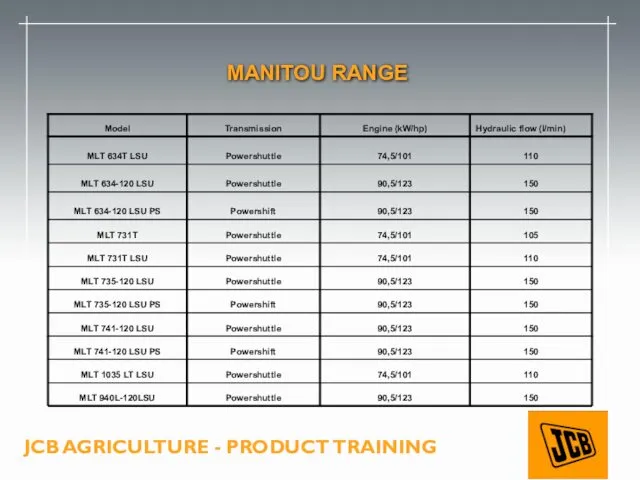

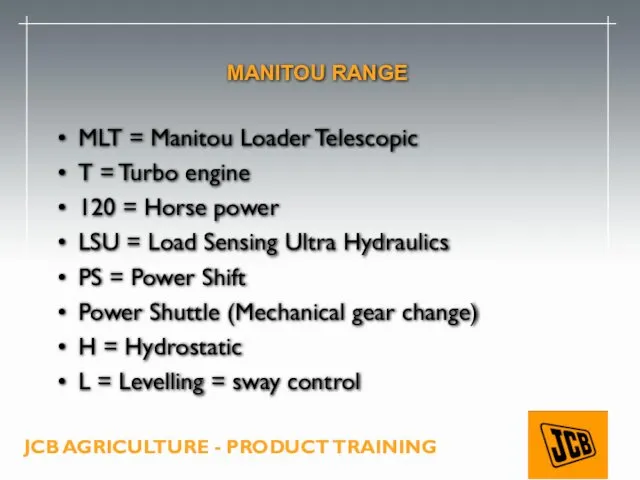

- 51. MANITOU RANGE MLT = Manitou Loader Telescopic T = Turbo engine 120 = Horse power LSU

- 53. Скачать презентацию

Травма позвоночника. Все повреждения спинного мозга и позвоночника

Травма позвоночника. Все повреждения спинного мозга и позвоночника Карбоновые кислоты - презентация

Карбоновые кислоты - презентация Экологическая безопасность акваторий дальневосточных морей Российской Федерации

Экологическая безопасность акваторий дальневосточных морей Российской Федерации ENGLISH

ENGLISH Logistics. Master Data Design. Trade. SAP Best Practices

Logistics. Master Data Design. Trade. SAP Best Practices Дезинфицирующие средства для поверхностей

Дезинфицирующие средства для поверхностей проект Улыбка

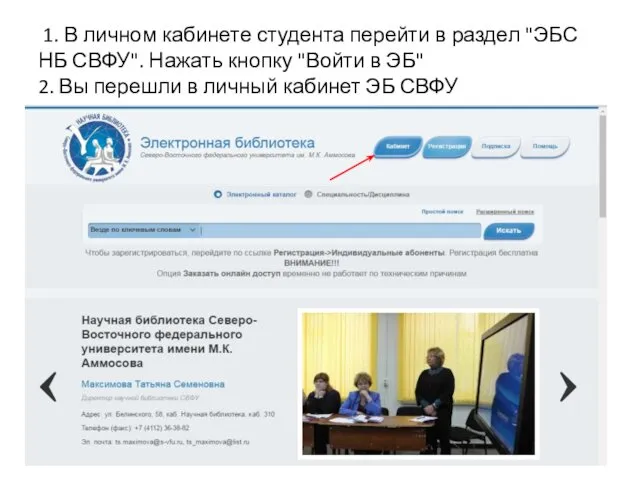

проект Улыбка Загрузка файла в электронную библиотеку

Загрузка файла в электронную библиотеку Карточная система

Карточная система Основные положения и понятия, принятые в строительстве

Основные положения и понятия, принятые в строительстве Скелет нижних конечностей

Скелет нижних конечностей Основные методы поверхностно пластического деформирования

Основные методы поверхностно пластического деформирования Компетентностный подход к определению содержания высшего профессионального образования

Компетентностный подход к определению содержания высшего профессионального образования Вітаміни

Вітаміни Все профессии важны

Все профессии важны Мультфильм это

Мультфильм это Презентация:Театрализованные игры в детском саду для детей младшего дошкольного возраста

Презентация:Театрализованные игры в детском саду для детей младшего дошкольного возраста Презентация-тест Родственные слова

Презентация-тест Родственные слова Природа и сущность лидерства

Природа и сущность лидерства 20240122_28.09.23

20240122_28.09.23 Семинар по проектной деятельности. Научно-исследовательская работа

Семинар по проектной деятельности. Научно-исследовательская работа Бизнес план животноводства

Бизнес план животноводства Дидактические игры для формирования слоговой структуры слова.

Дидактические игры для формирования слоговой структуры слова. Родительское собрание Нравственное воспитание младших школьников

Родительское собрание Нравственное воспитание младших школьников Послідовне з’єднання провідників

Послідовне з’єднання провідників Коррекция зрительной памяти детей младшего школьного возраста с задержкой психического развития на уроках математики

Коррекция зрительной памяти детей младшего школьного возраста с задержкой психического развития на уроках математики Материалы и изделия из древесины. Лекция 14

Материалы и изделия из древесины. Лекция 14 Презентация Странички нашей школьной жизни. 2 класс

Презентация Странички нашей школьной жизни. 2 класс