Содержание

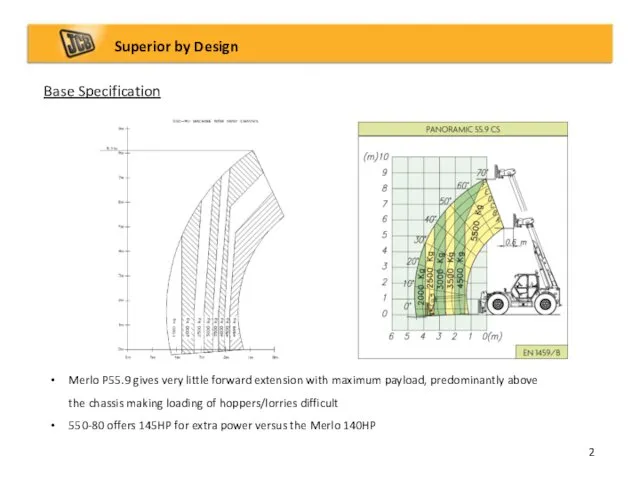

- 2. Base Specification Superior by Design 2 Merlo P55.9 gives very little forward extension with maximum payload,

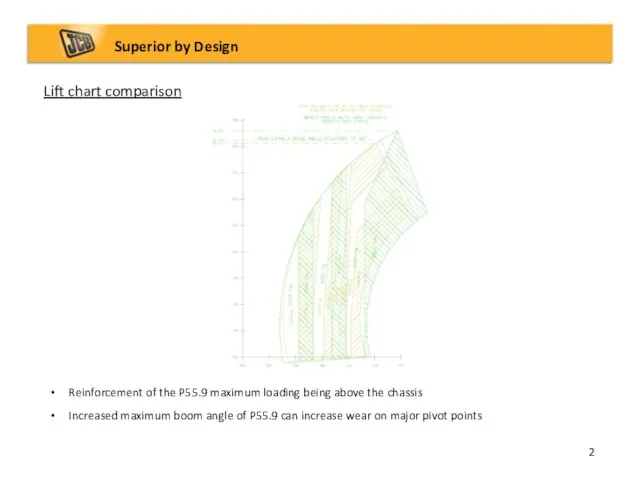

- 3. Lift chart comparison Superior by Design 2 Reinforcement of the P55.9 maximum loading being above the

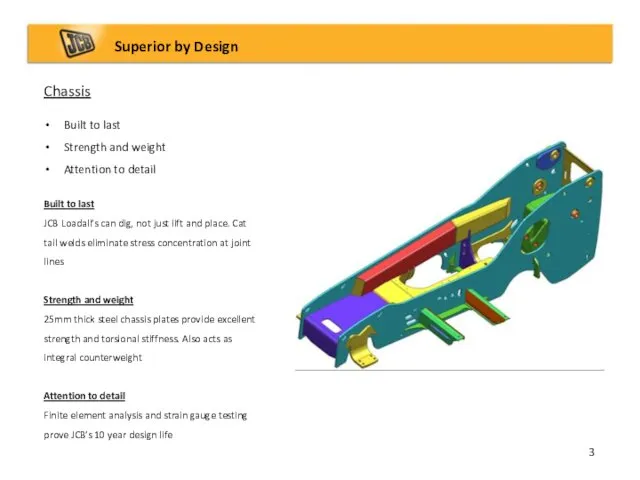

- 4. Superior by Design Chassis Built to last Strength and weight Attention to detail Built to last

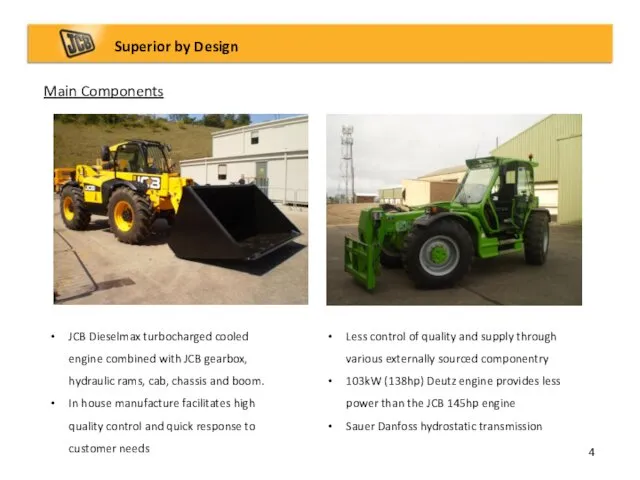

- 5. Main Components Superior by Design JCB Dieselmax turbocharged cooled engine combined with JCB gearbox, hydraulic rams,

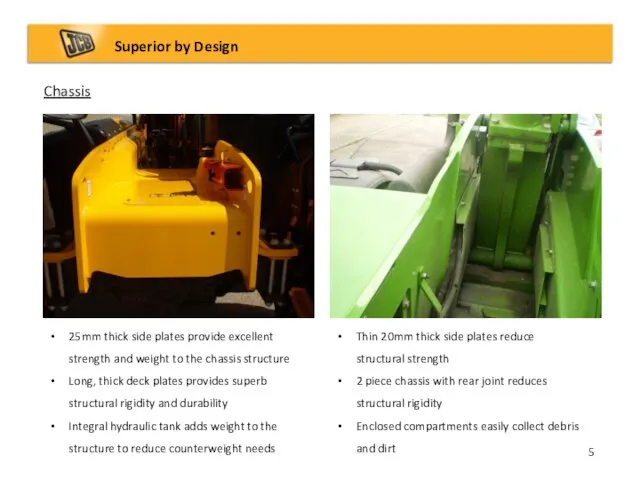

- 6. Chassis Superior by Design 25mm thick side plates provide excellent strength and weight to the chassis

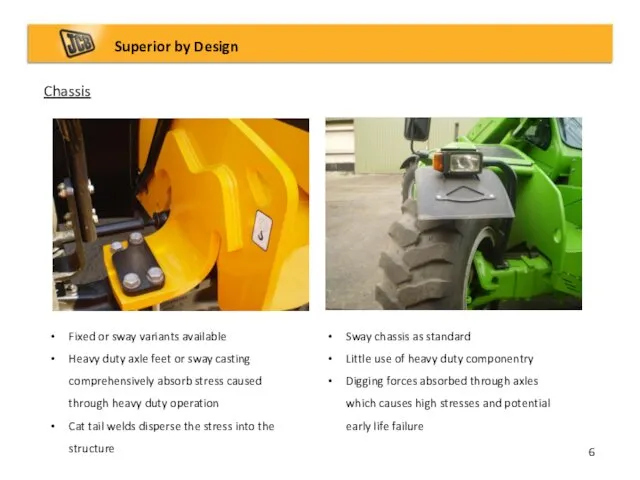

- 7. Chassis Superior by Design Fixed or sway variants available Heavy duty axle feet or sway casting

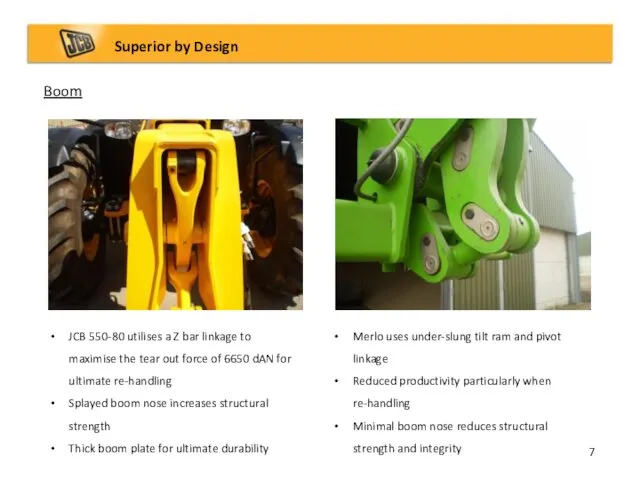

- 8. Boom Superior by Design JCB 550-80 utilises a Z bar linkage to maximise the tear out

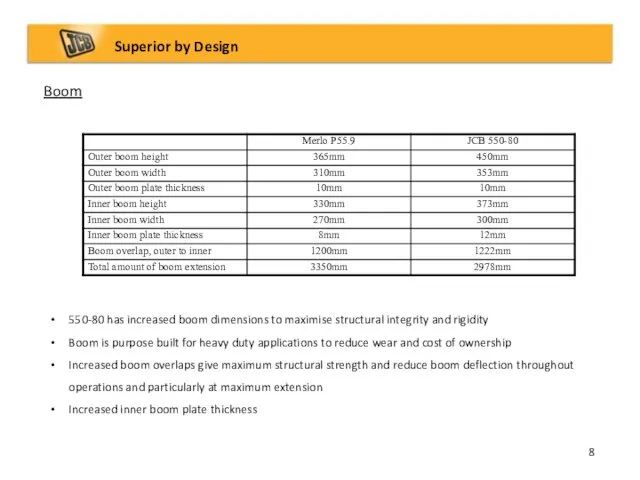

- 9. Boom Superior by Design 550-80 has increased boom dimensions to maximise structural integrity and rigidity Boom

- 10. Boom Superior by Design Dry waxoyl coating is used for excellent wear protection, reduced dirt adhesion

- 11. Boom Superior by Design One centrally mounted lift ram provides even dispersion of lifting forces throughout

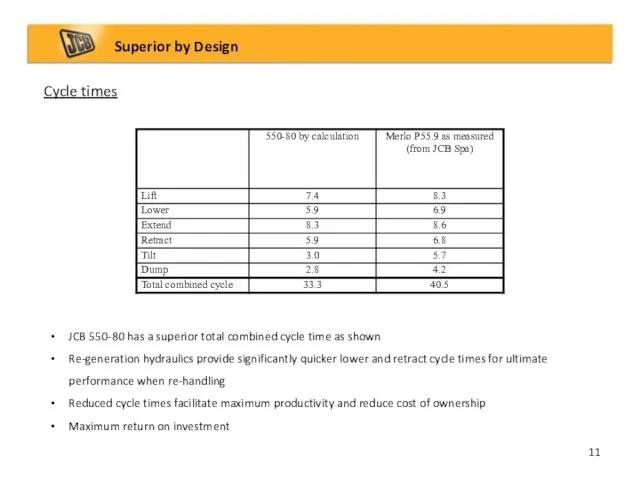

- 12. Cycle times Superior by Design JCB 550-80 has a superior total combined cycle time as shown

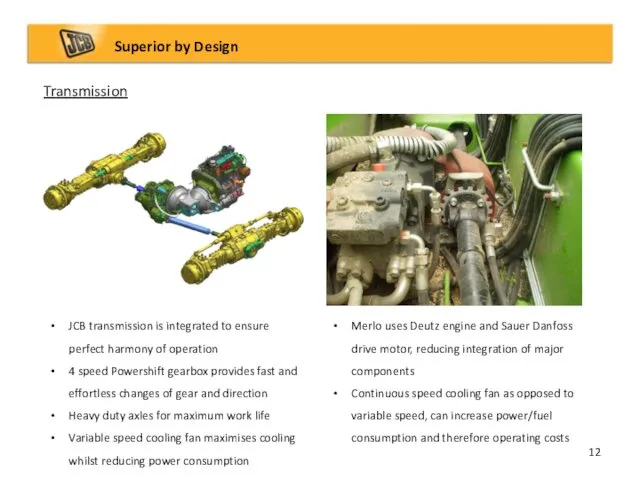

- 13. Transmission Superior by Design JCB transmission is integrated to ensure perfect harmony of operation 4 speed

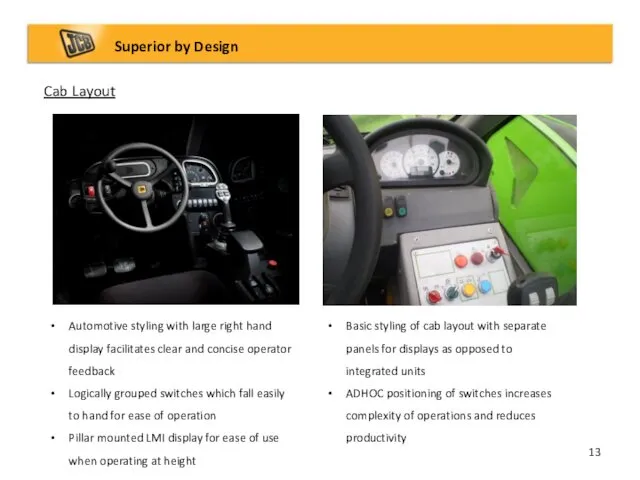

- 14. Cab Layout Superior by Design Automotive styling with large right hand display facilitates clear and concise

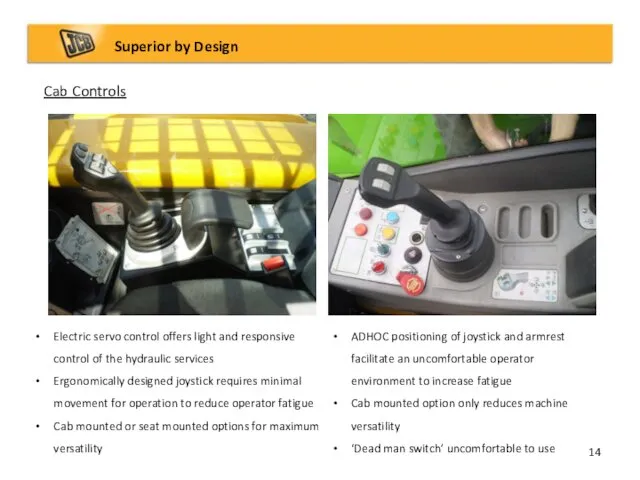

- 15. Cab Controls Superior by Design Electric servo control offers light and responsive control of the hydraulic

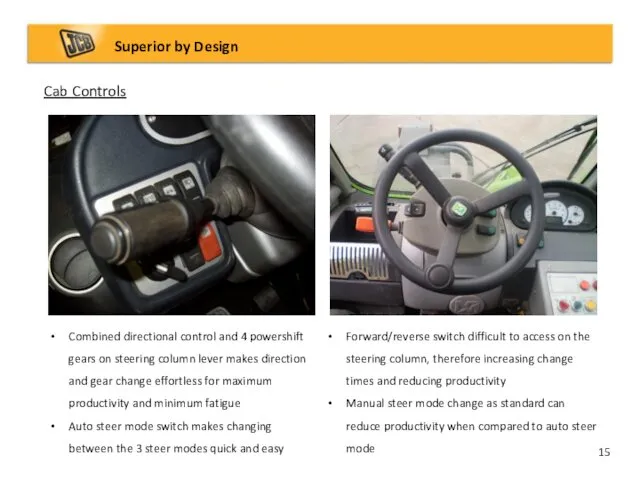

- 16. Cab Controls Superior by Design Combined directional control and 4 powershift gears on steering column lever

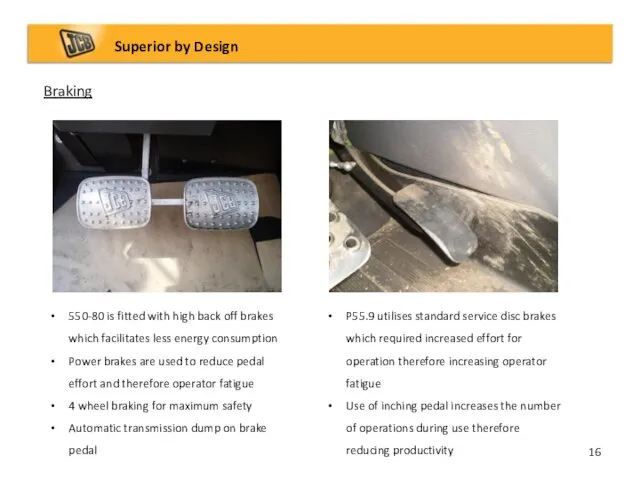

- 17. Braking Superior by Design 550-80 is fitted with high back off brakes which facilitates less energy

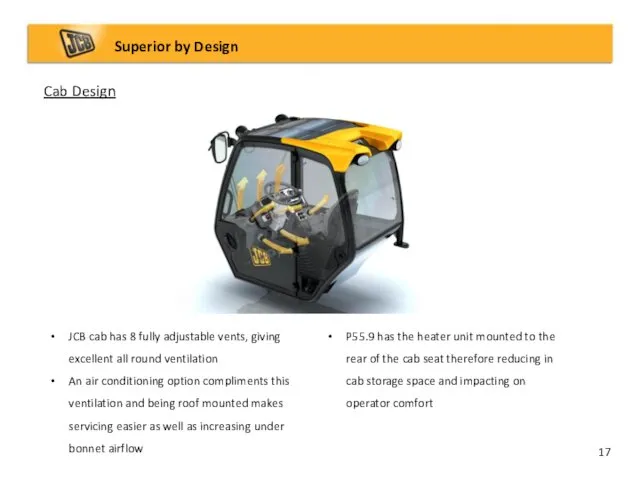

- 18. Cab Design Superior by Design JCB cab has 8 fully adjustable vents, giving excellent all round

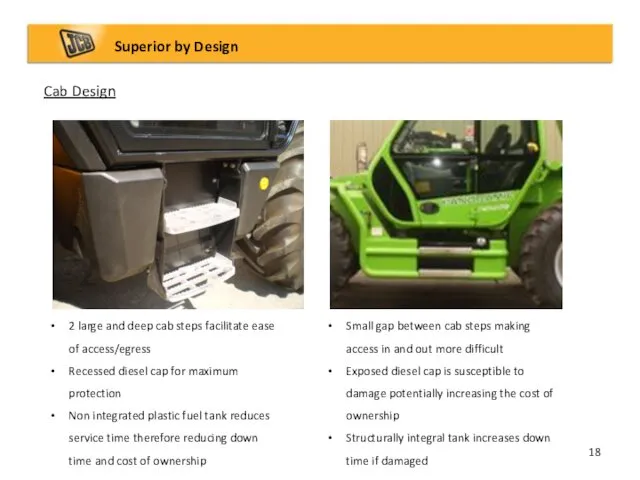

- 19. Cab Design Superior by Design 2 large and deep cab steps facilitate ease of access/egress Recessed

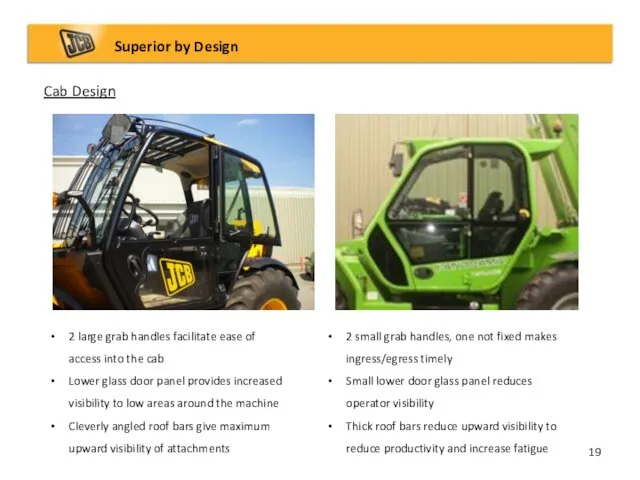

- 20. Cab Design Superior by Design 2 large grab handles facilitate ease of access into the cab

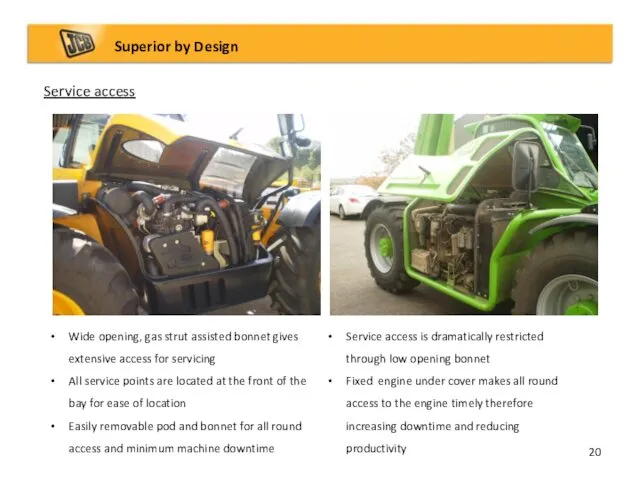

- 21. Service access Superior by Design Wide opening, gas strut assisted bonnet gives extensive access for servicing

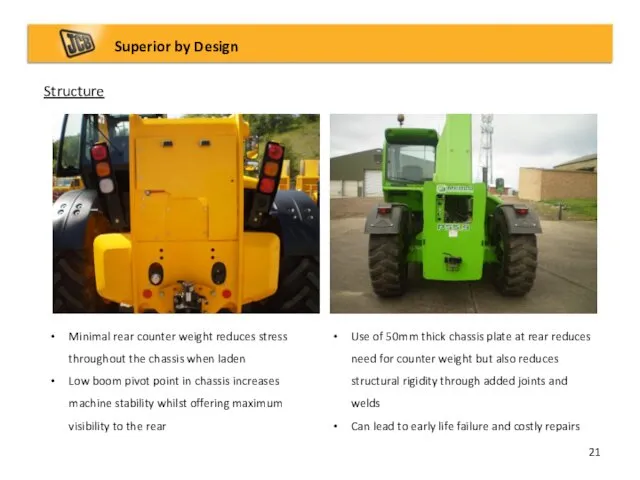

- 22. Structure Superior by Design Minimal rear counter weight reduces stress throughout the chassis when laden Low

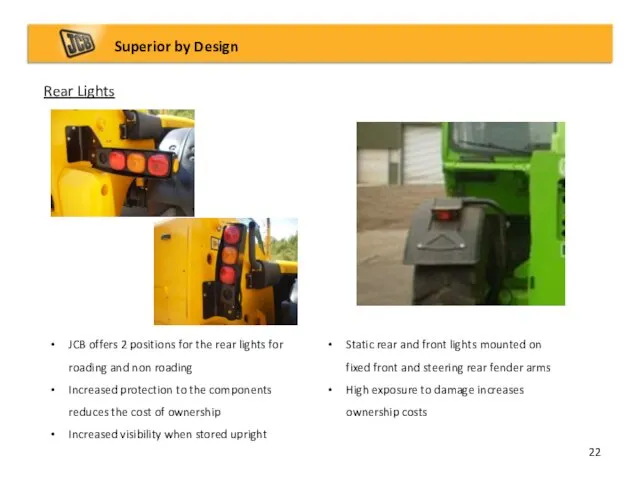

- 23. Rear Lights Superior by Design JCB offers 2 positions for the rear lights for roading and

- 24. Superior by Design Why JCB Loadall JCB’s proven 10 year design life In house manufacture of

- 26. Скачать презентацию

Педагогическое общение

Педагогическое общение освоение человеком космоса

освоение человеком космоса Психологические основы отбора в спорте

Психологические основы отбора в спорте Эксплуатация тракторов МТЗ-80/82

Эксплуатация тракторов МТЗ-80/82 Собор Святого Петра

Собор Святого Петра Презентация Ребусы

Презентация Ребусы Презентация к уроку 23 февраля Диск

Презентация к уроку 23 февраля Диск Система работи з обдарованими дітьми

Система работи з обдарованими дітьми Темперамент. Сангвинистический темперамент

Темперамент. Сангвинистический темперамент Здоровьесберегающие технологии в педагогическом процессе ДОУ-презентация

Здоровьесберегающие технологии в педагогическом процессе ДОУ-презентация Как относиться к отметкам ребенка?

Как относиться к отметкам ребенка? Урок-зачет

Урок-зачет Искусственная ёлочка

Искусственная ёлочка Построение геологического профильного разреза по данным бурения скважин. Прогноз ловушек нефти и газа

Построение геологического профильного разреза по данным бурения скважин. Прогноз ловушек нефти и газа Формы глагола “to be” в настоящем времени

Формы глагола “to be” в настоящем времени Травмы органов и тканей челюстно-лицевой области у детей

Травмы органов и тканей челюстно-лицевой области у детей Часы в технике квиллинг. История возникновения квиллинга

Часы в технике квиллинг. История возникновения квиллинга Общество и государство. Социальное назначение права

Общество и государство. Социальное назначение права Сварочное производство (тема 1.3)

Сварочное производство (тема 1.3) Роман-эпопея Война и мир

Роман-эпопея Война и мир Российские мыслители XIX-XX вв. Виртуальная книжная выставка

Российские мыслители XIX-XX вв. Виртуальная книжная выставка Проектно-исследовательская деятельность моих учеников

Проектно-исследовательская деятельность моих учеников Гражданское право

Гражданское право Презентация Знакомство с пожарной охраной

Презентация Знакомство с пожарной охраной Лента Мёбиуса

Лента Мёбиуса Курс Порядок в голове. Порядок в доме и гаджетах

Курс Порядок в голове. Порядок в доме и гаджетах Моделирование развивающей предметно-пространственнойсреды в старшем дошкольном возрасте

Моделирование развивающей предметно-пространственнойсреды в старшем дошкольном возрасте Лечебно-профилактическое питание

Лечебно-профилактическое питание