Содержание

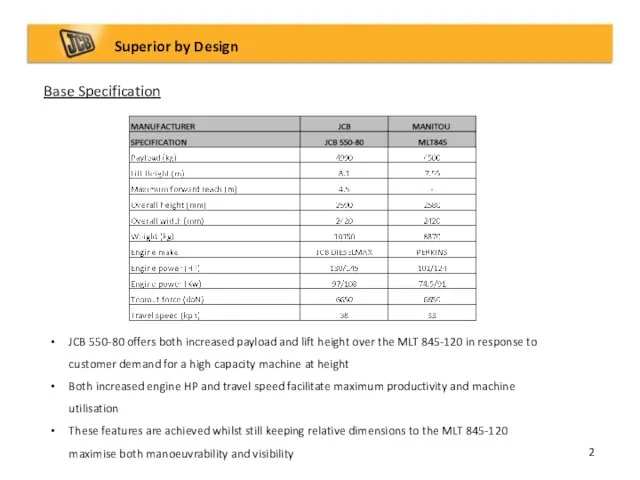

- 2. Base Specification Superior by Design JCB 550-80 offers both increased payload and lift height over the

- 3. Superior by Design Chassis Built to last Strength and weight Attention to detail Built to last

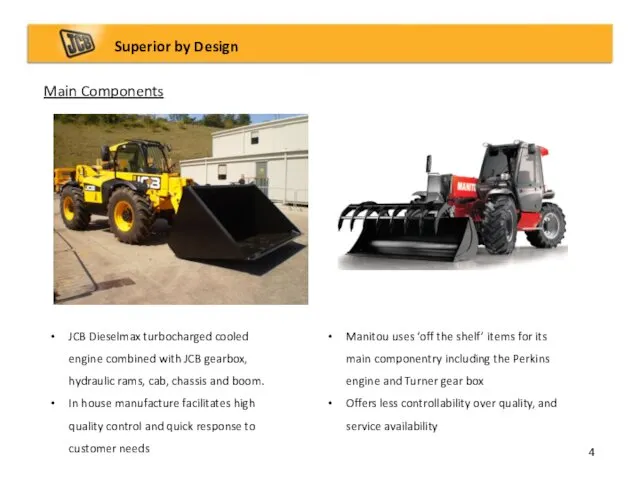

- 4. Main Components Superior by Design JCB Dieselmax turbocharged cooled engine combined with JCB gearbox, hydraulic rams,

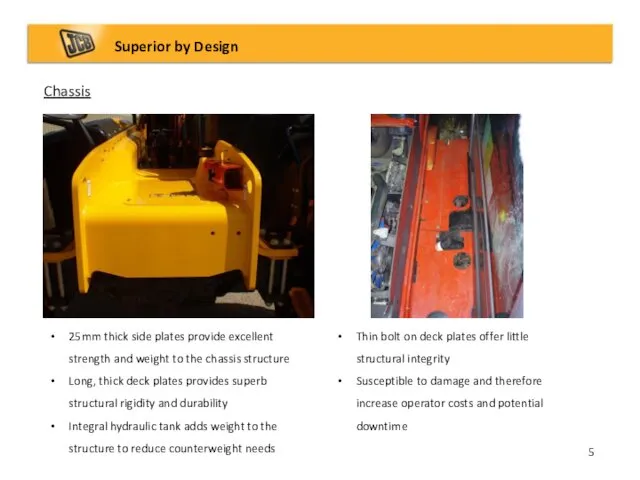

- 5. Chassis Superior by Design 25mm thick side plates provide excellent strength and weight to the chassis

- 6. Chassis Superior by Design Heavy duty axle feet comprehensively absorb stress caused through heavy duty operation

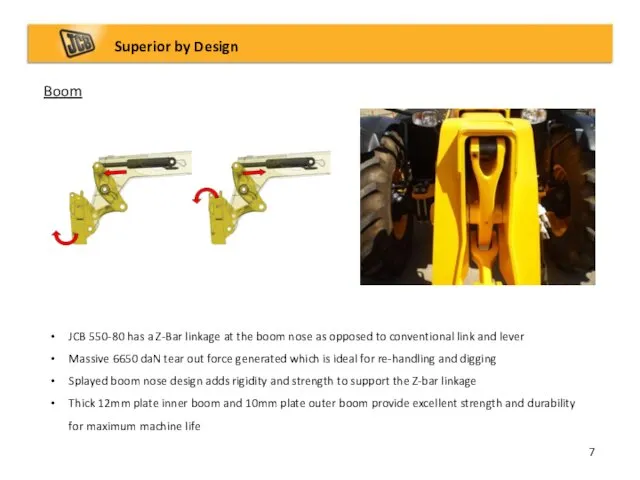

- 7. Boom Superior by Design JCB 550-80 has a Z-Bar linkage at the boom nose as opposed

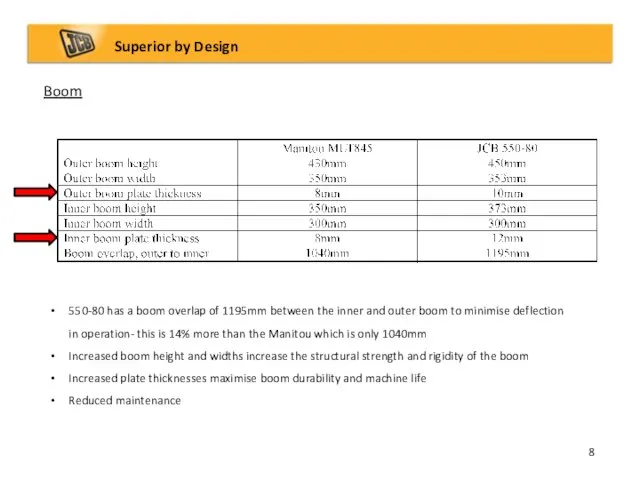

- 8. Boom Superior by Design 550-80 has a boom overlap of 1195mm between the inner and outer

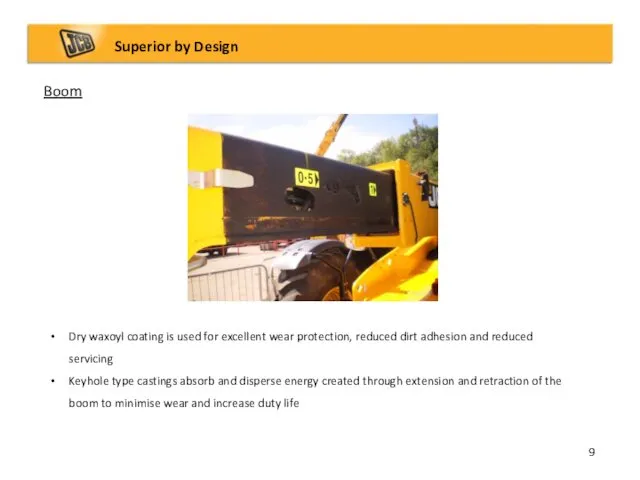

- 9. Boom Superior by Design Dry waxoyl coating is used for excellent wear protection, reduced dirt adhesion

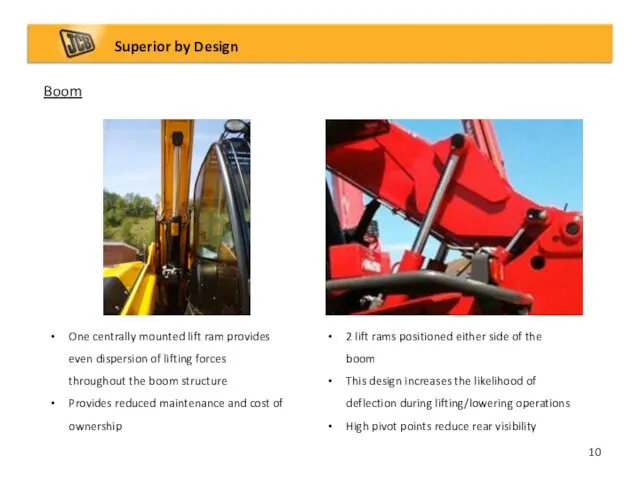

- 10. Boom Superior by Design One centrally mounted lift ram provides even dispersion of lifting forces throughout

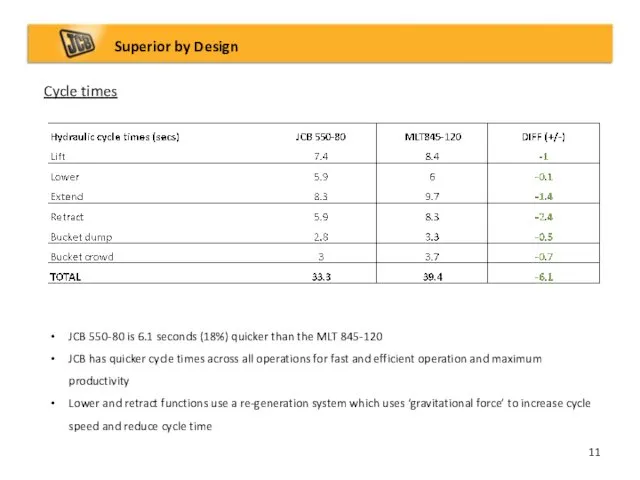

- 11. Cycle times Superior by Design JCB 550-80 is 6.1 seconds (18%) quicker than the MLT 845-120

- 12. Transmission Superior by Design JCB has an overall higher travel speed than the Manitou This facilitates

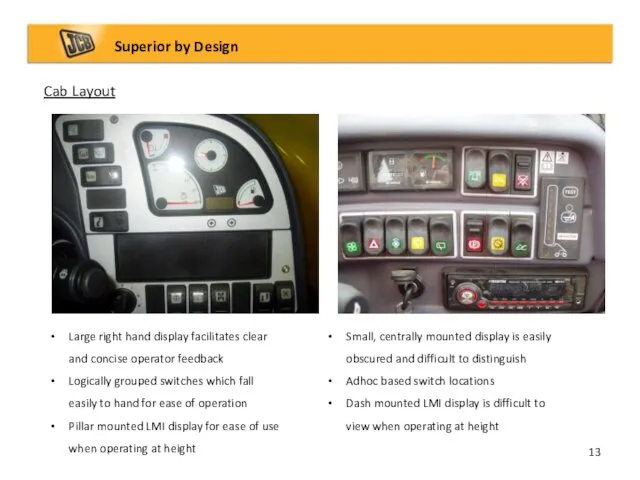

- 13. Cab Layout Superior by Design Large right hand display facilitates clear and concise operator feedback Logically

- 14. Cab Controls Superior by Design Electric servo control offers light and responsive control of the hydraulic

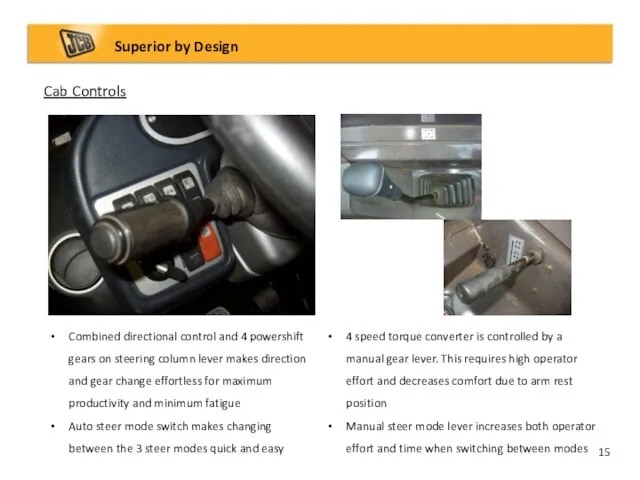

- 15. Cab Controls Superior by Design Combined directional control and 4 powershift gears on steering column lever

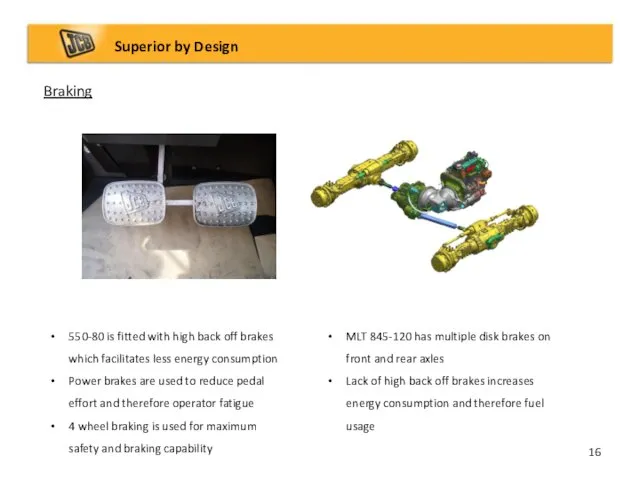

- 16. Braking Superior by Design 550-80 is fitted with high back off brakes which facilitates less energy

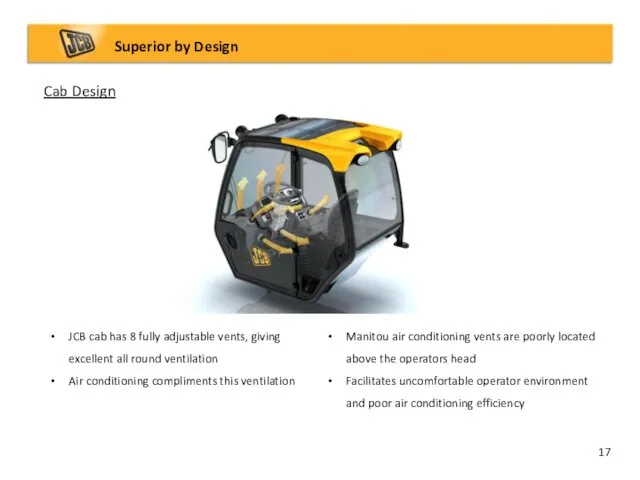

- 17. Cab Design Superior by Design JCB cab has 8 fully adjustable vents, giving excellent all round

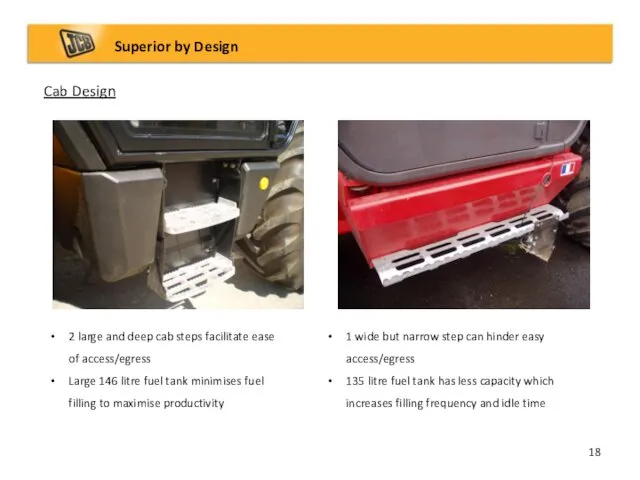

- 18. Cab Design Superior by Design 2 large and deep cab steps facilitate ease of access/egress Large

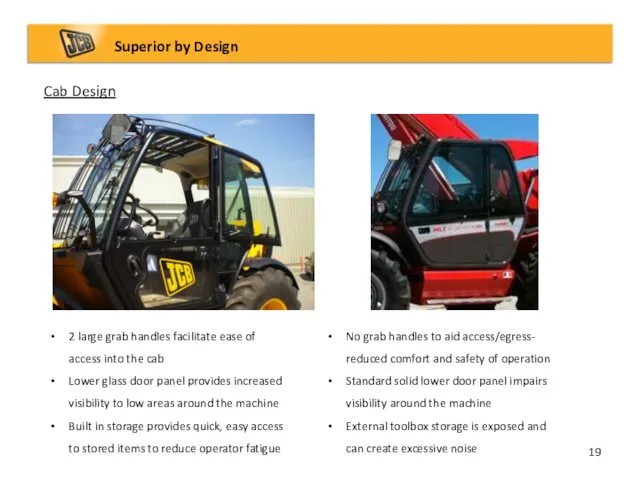

- 19. Cab Design Superior by Design 2 large grab handles facilitate ease of access into the cab

- 20. Service access Superior by Design Wide opening, gas strut assisted bonnet gives extensive access for servicing

- 21. Service access Superior by Design Wide opening for ease of access to hydraulic filler neck Diesel

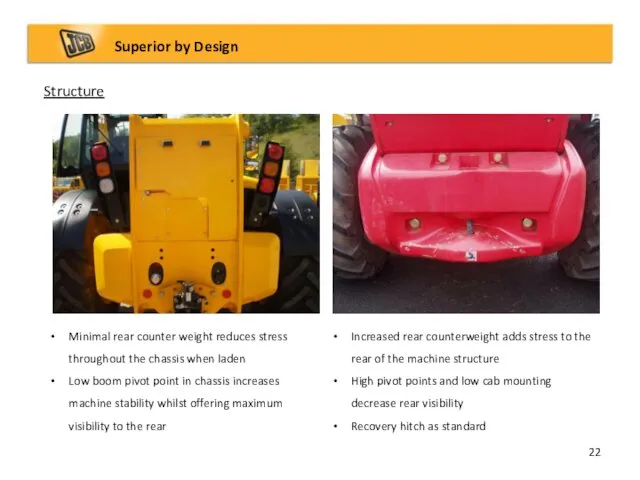

- 22. Structure Superior by Design Minimal rear counter weight reduces stress throughout the chassis when laden Low

- 23. Rear Lights Superior by Design JCB offers 2 positions for the rear lights for roading and

- 24. Superior by Design Why JCB Loadall JCB’s proven 10 year design life In house manufacture of

- 26. Скачать презентацию

Презентация к уроку Резьба по дереву (вводное занятие)

Презентация к уроку Резьба по дереву (вводное занятие) Презентация. Фелтинг. Брошь Мак

Презентация. Фелтинг. Брошь Мак Религия как социокультурный феномен

Религия как социокультурный феномен Електронні та друковані портфоліо

Електронні та друковані портфоліо Александр Трифонович Твардовский 1910-1971

Александр Трифонович Твардовский 1910-1971 Бумажная пластика. Игрушки на елке

Бумажная пластика. Игрушки на елке Самоходные погрузчики

Самоходные погрузчики СПб ГБПОУ Ленинградский машиностроительный техникум им. Ж.Я. Котина

СПб ГБПОУ Ленинградский машиностроительный техникум им. Ж.Я. Котина Кроссворд по правилам дорожного движения (с использованием клавиатуры)

Кроссворд по правилам дорожного движения (с использованием клавиатуры) Цветы в технике квиллинга

Цветы в технике квиллинга Кампания г. Санкт-Петербург: GRP 90.83 OTS 4039.30

Кампания г. Санкт-Петербург: GRP 90.83 OTS 4039.30 Способы решения показательных уравнений

Способы решения показательных уравнений Банк Хоум Кредит

Банк Хоум Кредит Экономика нефтегазовой отрасли

Экономика нефтегазовой отрасли Средиземноморская природная зона, или субтропики: жёстколистные вечнозелёные леса и кустарники, описание, климат, почвы

Средиземноморская природная зона, или субтропики: жёстколистные вечнозелёные леса и кустарники, описание, климат, почвы В бизнесе всё решают связью. Коммерческое предложение ПАО Ростелеком

В бизнесе всё решают связью. Коммерческое предложение ПАО Ростелеком Метод эквивалентного генератора

Метод эквивалентного генератора Мощность конвектора отопления

Мощность конвектора отопления Проект В лесном краю Почитаева

Проект В лесном краю Почитаева КОМПЬЮТЕРНАЯ ПРЕЗЕНТАЦИЯ ПО ГЕОГРАФИИ 11 КЛАСС ФРГ

КОМПЬЮТЕРНАЯ ПРЕЗЕНТАЦИЯ ПО ГЕОГРАФИИ 11 КЛАСС ФРГ Неделя игры и игрушки в подготовительной группе №8

Неделя игры и игрушки в подготовительной группе №8 Структура письма

Структура письма Актуальные проблемы транспортной инфраструктуры в субъектах России

Актуальные проблемы транспортной инфраструктуры в субъектах России Проектирование системы электроснабжения производственного цеха машиностроительного завода

Проектирование системы электроснабжения производственного цеха машиностроительного завода Механические процессы

Механические процессы Замбия Республикасы

Замбия Республикасы Презентация к исследованию

Презентация к исследованию Речной транспорт

Речной транспорт