Содержание

- 2. © ANDRITZ 2011 Table of Contents Process data and applications Layout Process basics of pusher centrifuges

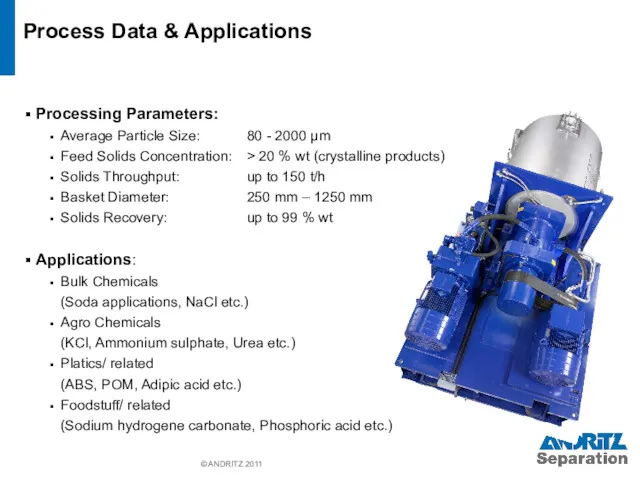

- 3. © ANDRITZ 2011 Process Data & Applications Processing Parameters: Average Particle Size: 80 - 2000 µm

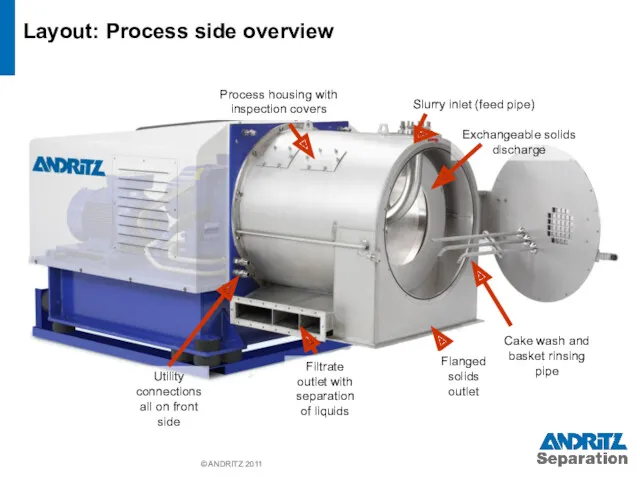

- 4. © ANDRITZ 2011 Exchangeable solids discharge Layout: Process side overview Filtrate outlet with separation of liquids

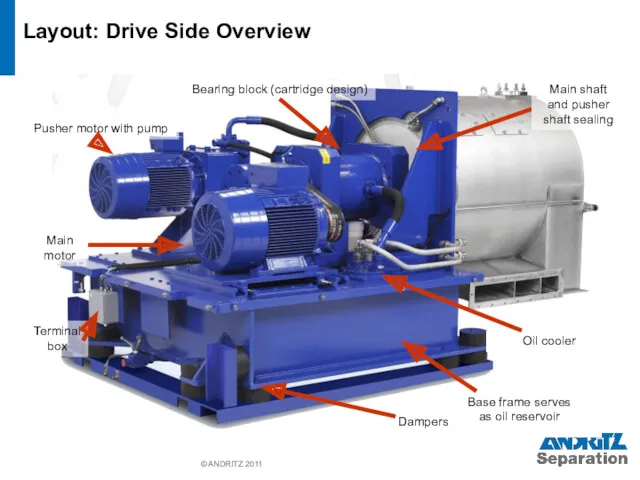

- 5. © ANDRITZ 2011 Layout: Drive Side Overview Pusher motor with pump Main motor Dampers Base frame

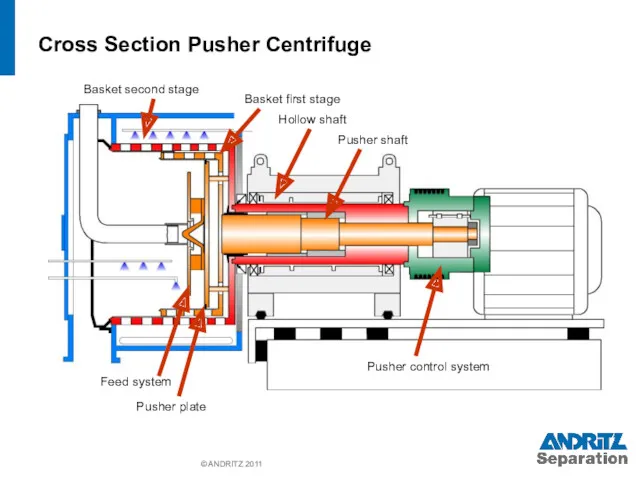

- 6. © ANDRITZ 2011 Cross Section Pusher Centrifuge Basket second stage Basket first stage Pusher plate Feed

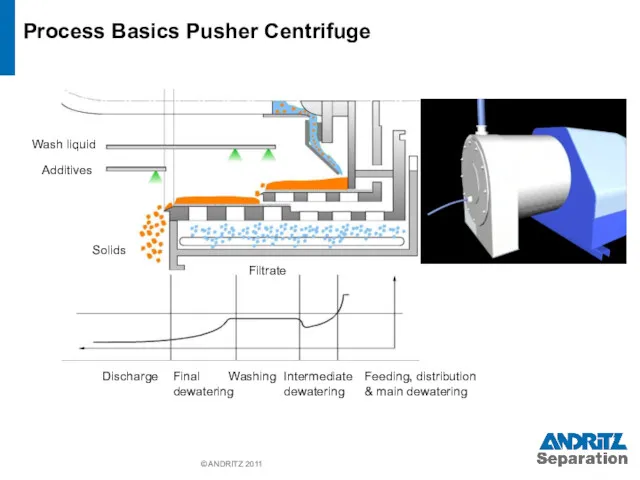

- 7. © ANDRITZ 2011 Process Basics Pusher Centrifuge Feeding, distribution & main dewatering Discharge Washing Intermediate dewatering

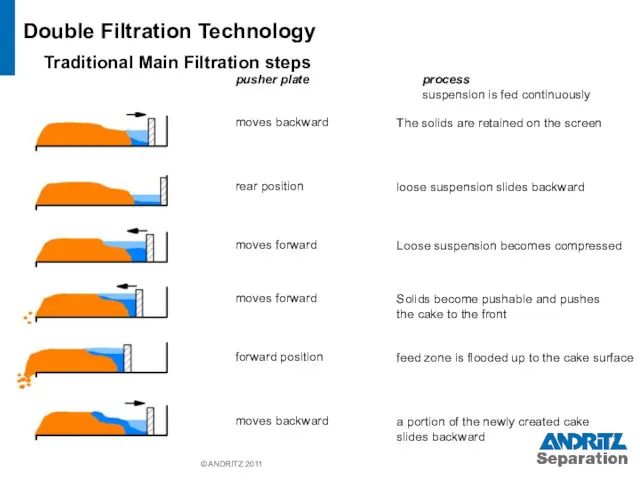

- 8. Double Filtration Technology Traditional Main Filtration steps pusher plate process suspension is fed continuously moves backward

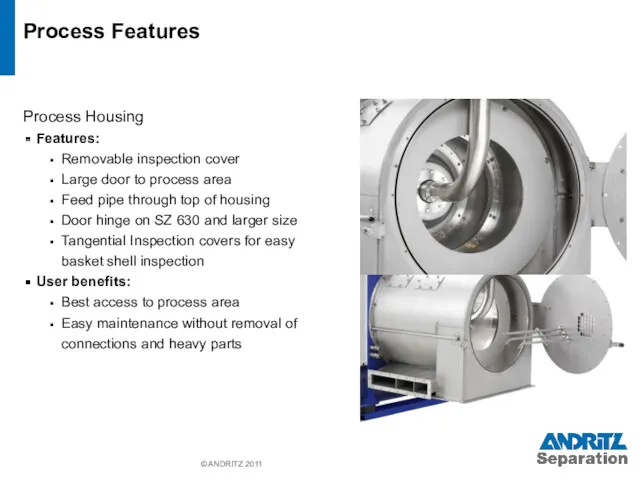

- 9. © ANDRITZ 2011 Process Features Process Housing Features: Removable inspection cover Large door to process area

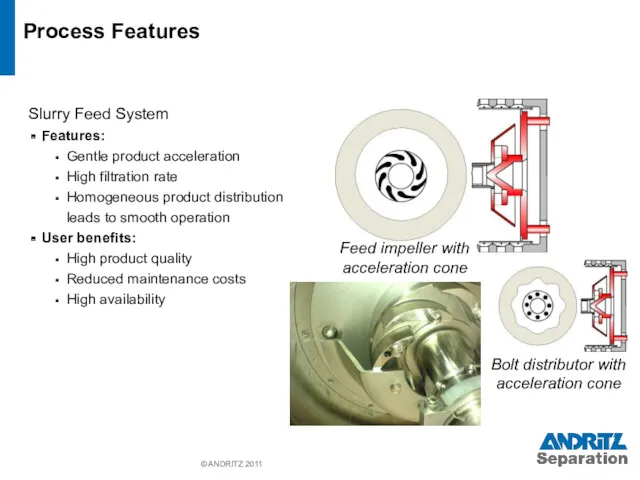

- 10. © ANDRITZ 2011 Process Features Bolt distributor with acceleration cone Feed impeller with acceleration cone Slurry

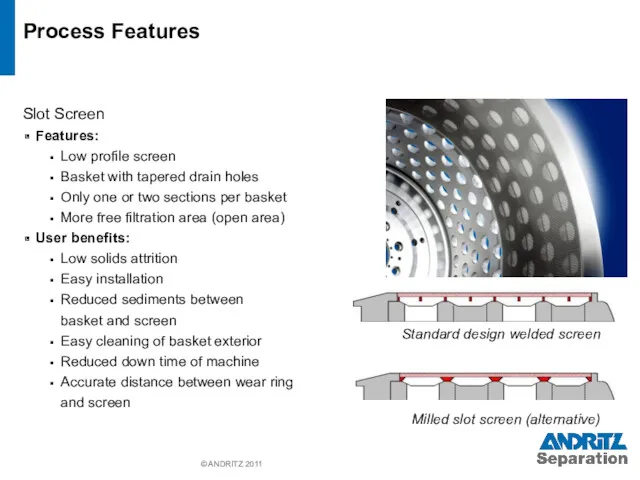

- 11. © ANDRITZ 2011 Process Features Slot Screen Features: Low profile screen Basket with tapered drain holes

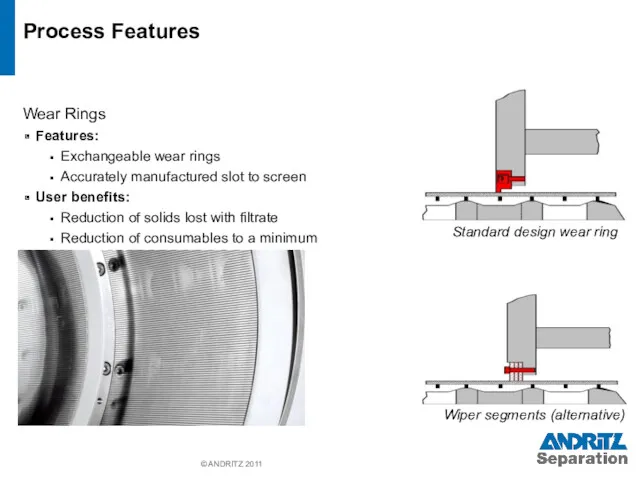

- 12. © ANDRITZ 2011 Process Features Wear Rings Features: Exchangeable wear rings Accurately manufactured slot to screen

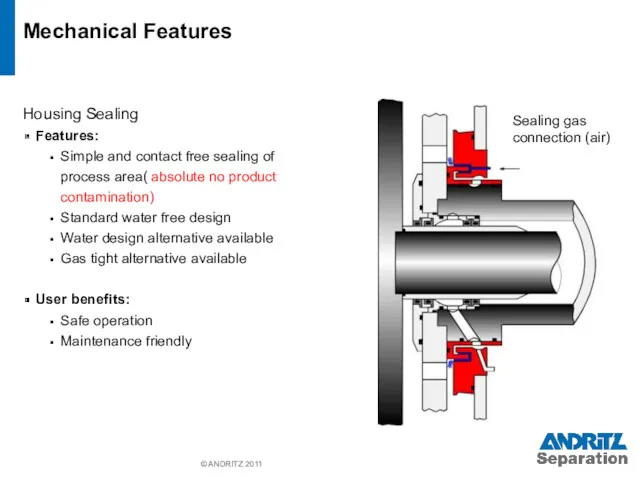

- 13. © ANDRITZ 2011 Mechanical Features Housing Sealing Features: Simple and contact free sealing of process area(

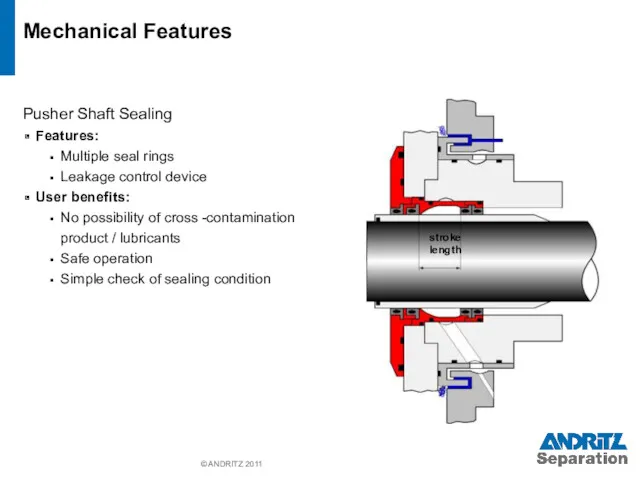

- 14. © ANDRITZ 2011 Mechanical Features Pusher Shaft Sealing Features: Multiple seal rings Leakage control device User

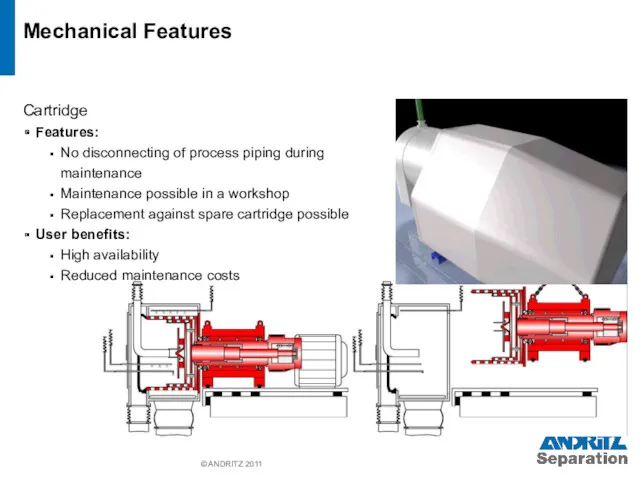

- 15. © ANDRITZ 2011 Mechanical Features Cartridge Features: No disconnecting of process piping during maintenance Maintenance possible

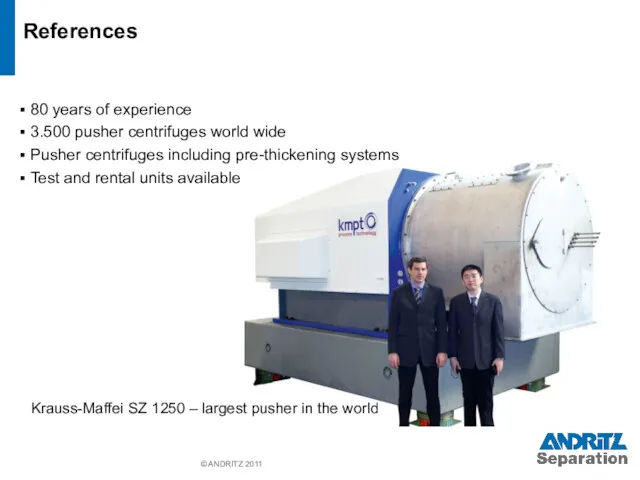

- 16. © ANDRITZ 2011 References 80 years of experience 3.500 pusher centrifuges world wide Pusher centrifuges including

- 17. ANDRITZ KMPT GmbH Industriestrasse 1-3 D-85256 Vierkirchen Phone: +49 8139 80 299 0 kmpt@andritz.com www.kmpt.com

- 19. Скачать презентацию

Микроконтроллеры

Микроконтроллеры Презентация к уроку по теме Углерод ( 9 класс,программа О.С. Габриеляна)

Презентация к уроку по теме Углерод ( 9 класс,программа О.С. Габриеляна) Методологические основы психологии

Методологические основы психологии Компьютерные технологии и их роль в воспитательном процессе

Компьютерные технологии и их роль в воспитательном процессе Любимому отряду

Любимому отряду Elon Musk Loses Record $16.3 Billion

Elon Musk Loses Record $16.3 Billion Презентация История одной песни Смуглянка

Презентация История одной песни Смуглянка Roof and cornice

Roof and cornice ОПЫТ РАБОТЫ ПО ЛОГОРИТМИКЕ С ДЕТЬМИ МЛАДШИХ И СРЕДНИХ ГРУПП.

ОПЫТ РАБОТЫ ПО ЛОГОРИТМИКЕ С ДЕТЬМИ МЛАДШИХ И СРЕДНИХ ГРУПП. Основы расчета по предельным состояниям. Расчет элементов конструкций цельного сечения

Основы расчета по предельным состояниям. Расчет элементов конструкций цельного сечения Понятие об иммунитете

Понятие об иммунитете Башлангыч сыйныфта татар теле һәм әдәби уку дәресләренең кызыксындыру этабы

Башлангыч сыйныфта татар теле һәм әдәби уку дәресләренең кызыксындыру этабы Обыкновенные дроби. 5 класс

Обыкновенные дроби. 5 класс Выявление одарённости ребёнка

Выявление одарённости ребёнка Боевой листок Бронетехника- боевая машина для пехоты

Боевой листок Бронетехника- боевая машина для пехоты Изменения звуков в потоке речи

Изменения звуков в потоке речи Русская матрёшка.

Русская матрёшка. Дифференциация С - Ц.

Дифференциация С - Ц. Системы координат станков с ЧПУ

Системы координат станков с ЧПУ МЭМС-акселерометры

МЭМС-акселерометры День Государственного флага Российской Федерации

День Государственного флага Российской Федерации Технология - кейс

Технология - кейс Английская республика и протекторат Кромвеля

Английская республика и протекторат Кромвеля Швейная промышленность. Системный анализ процессов проектирования и производства изделий легкой промышленности

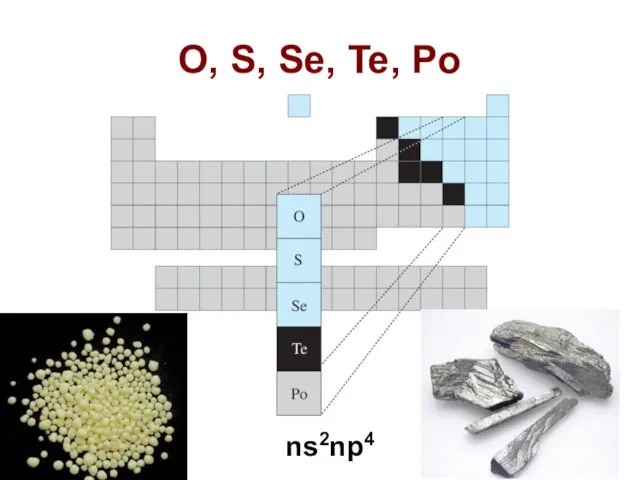

Швейная промышленность. Системный анализ процессов проектирования и производства изделий легкой промышленности Химические элементы O, S, Se, Te_Feb

Химические элементы O, S, Se, Te_Feb Строки, опаленные войной С.П. Гудзенко

Строки, опаленные войной С.П. Гудзенко Международный день Красного Креста и Красного полумесяца

Международный день Красного Креста и Красного полумесяца Портфолио музыкального руководителя

Портфолио музыкального руководителя