Слайд 2

Master Model

Orientation

Flange

Surface

Draft angle

Release agent

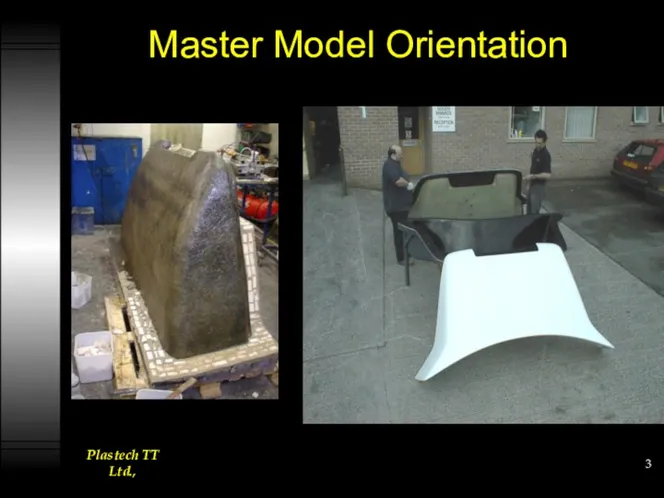

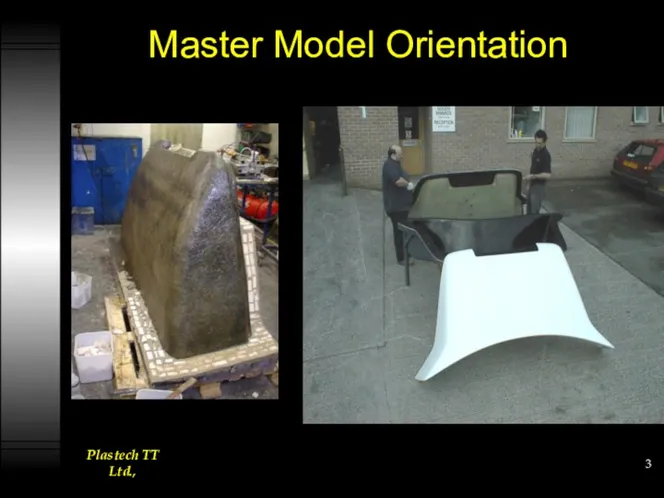

Слайд 3

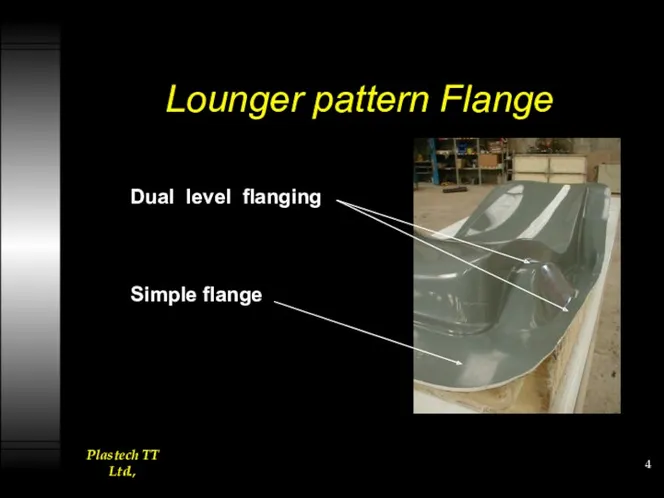

Слайд 4

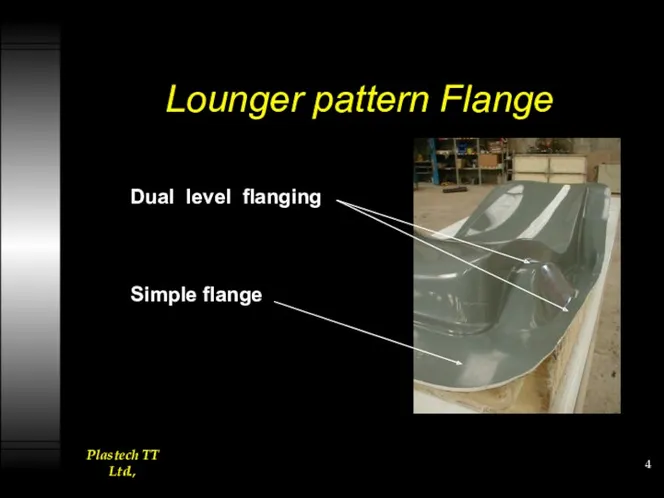

Lounger pattern Flange

Dual level flanging

Simple flange

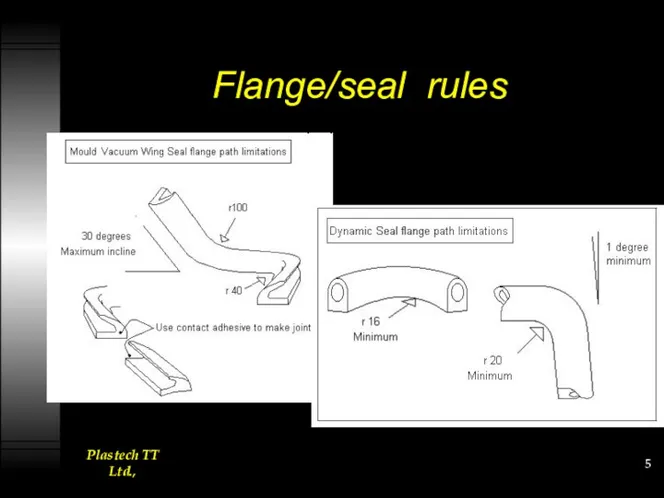

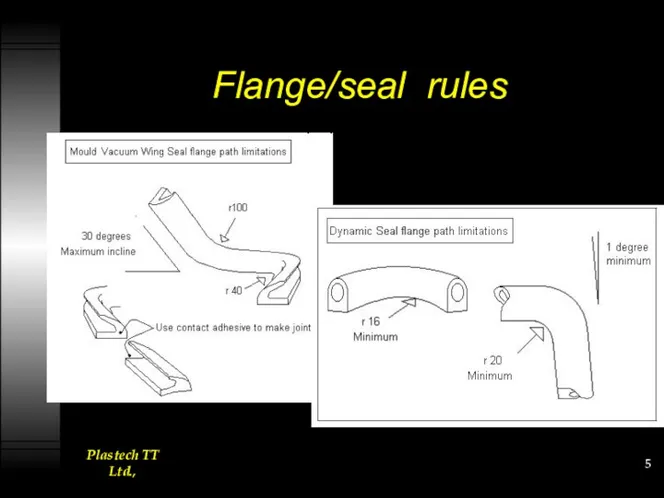

Слайд 5

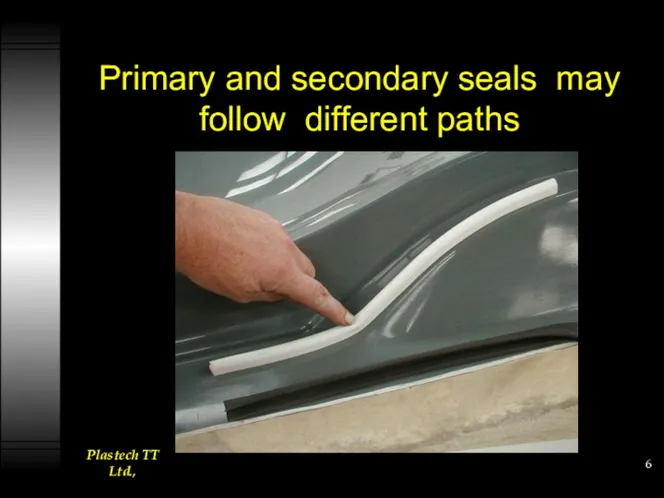

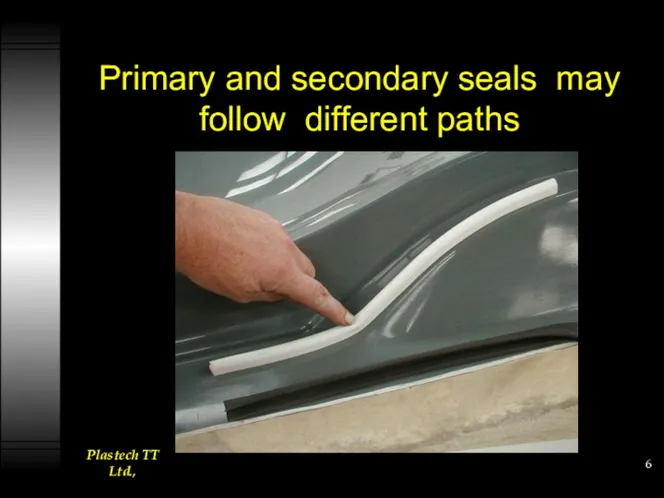

Слайд 6

Primary and secondary seals may follow different paths

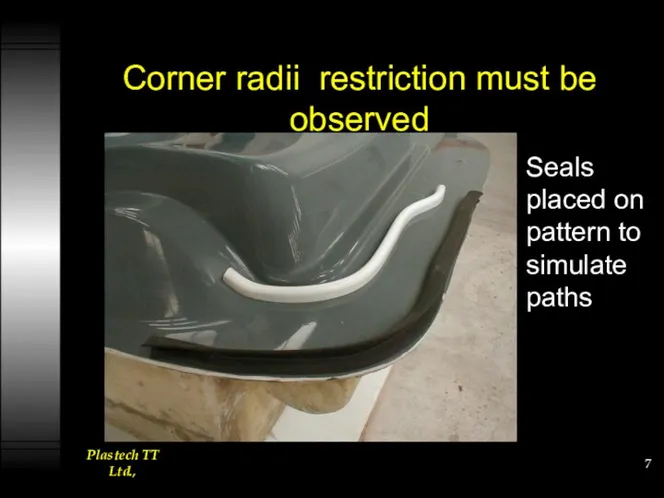

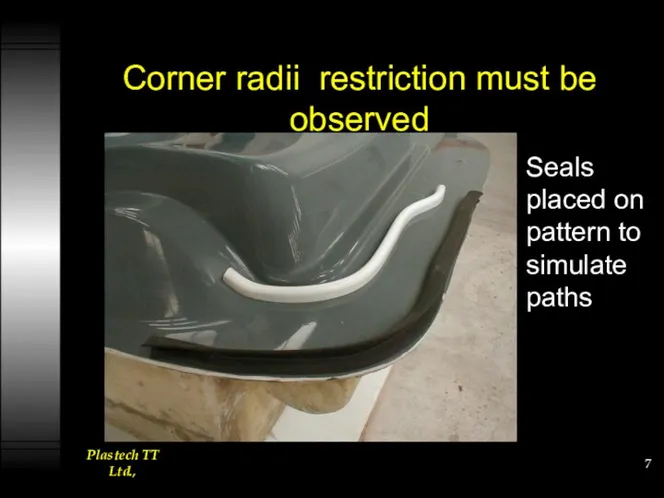

Слайд 7

Corner radii restriction must be observed

Seals placed on pattern to simulate

paths

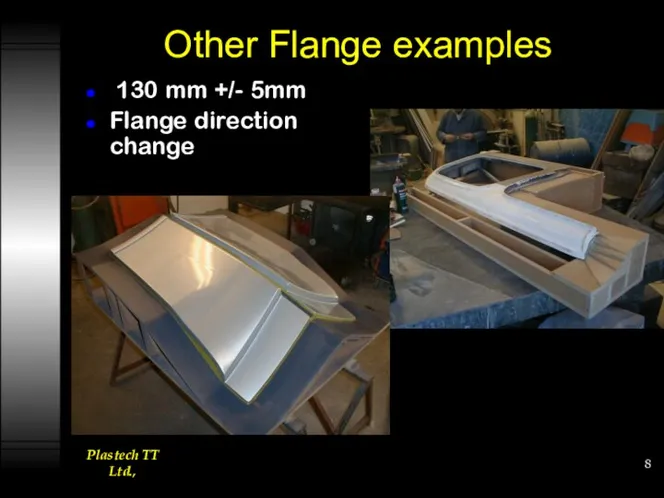

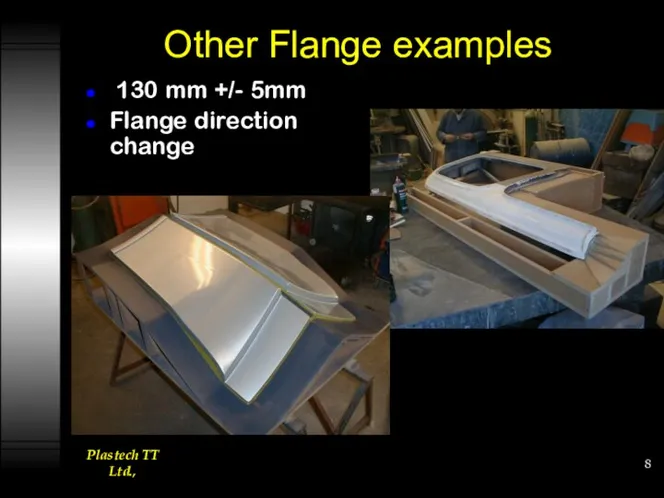

Слайд 8

Other Flange examples

130 mm +/- 5mm

Flange direction change

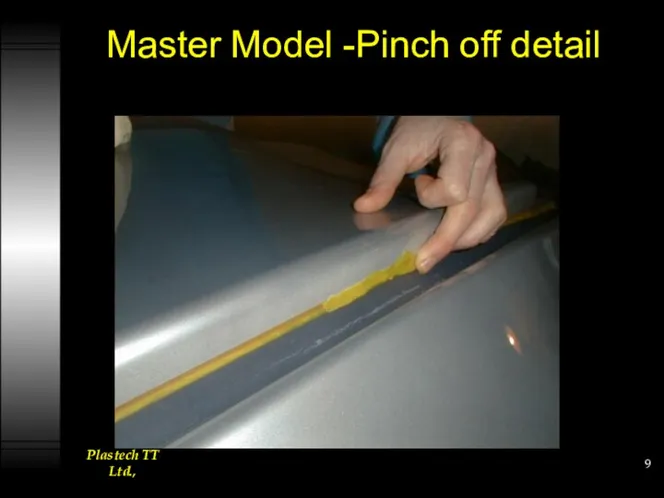

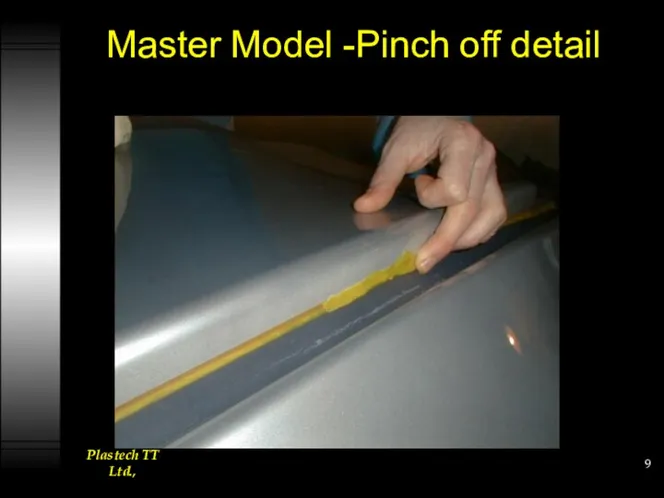

Слайд 9

Master Model -Pinch off detail

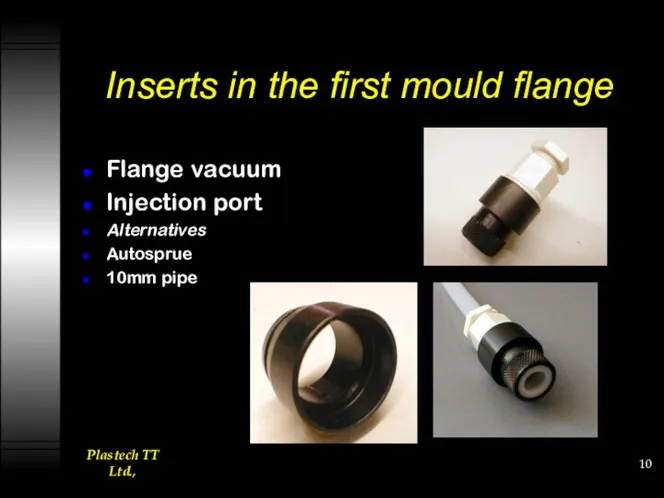

Слайд 10

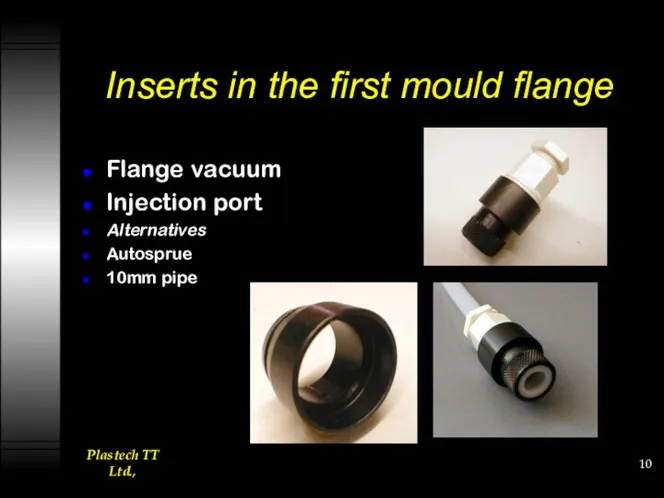

Inserts in the first mould flange

Flange vacuum

Injection port

Alternatives

Autosprue

10mm pipe

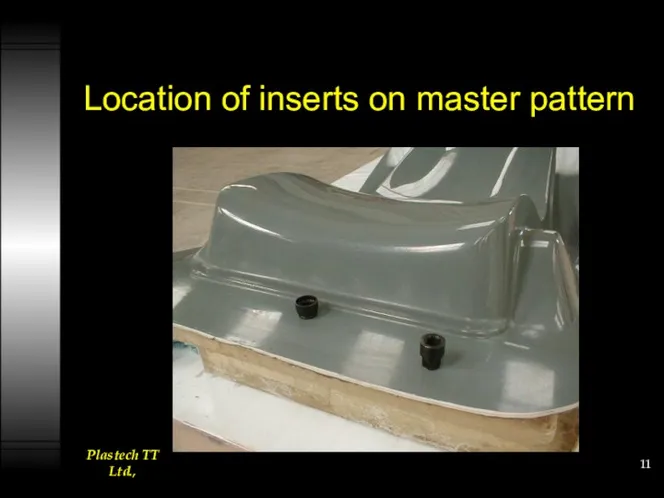

Слайд 11

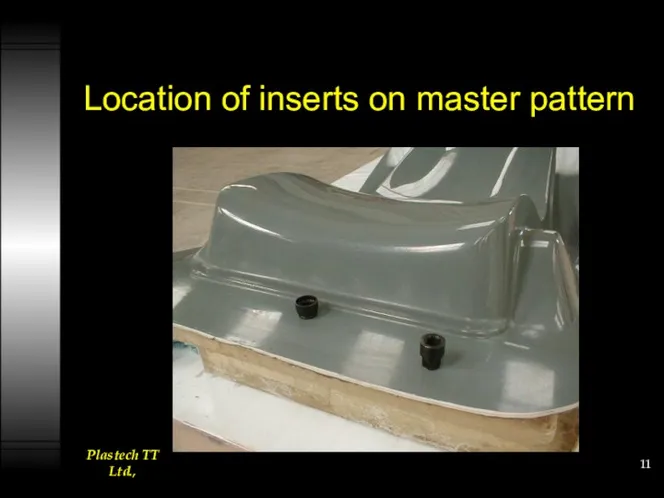

Location of inserts on master pattern

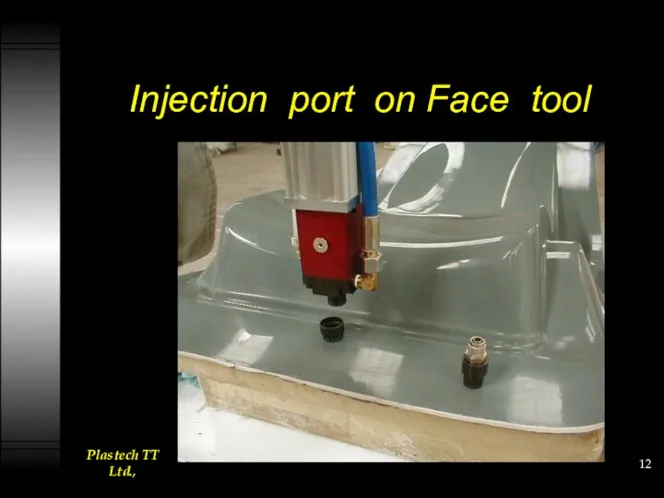

Слайд 12

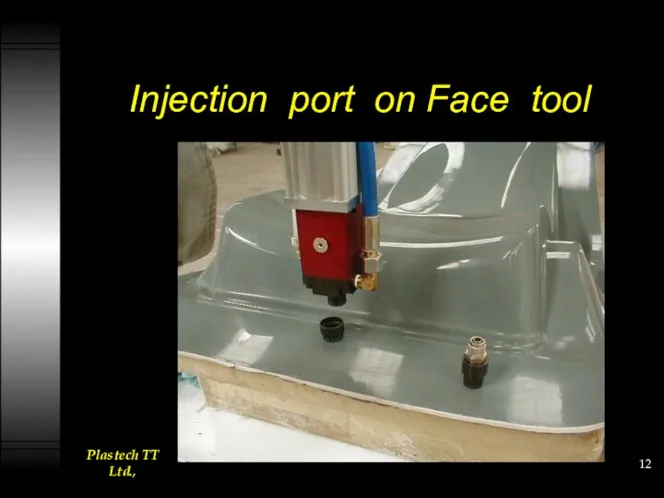

Injection port on Face tool

Слайд 13

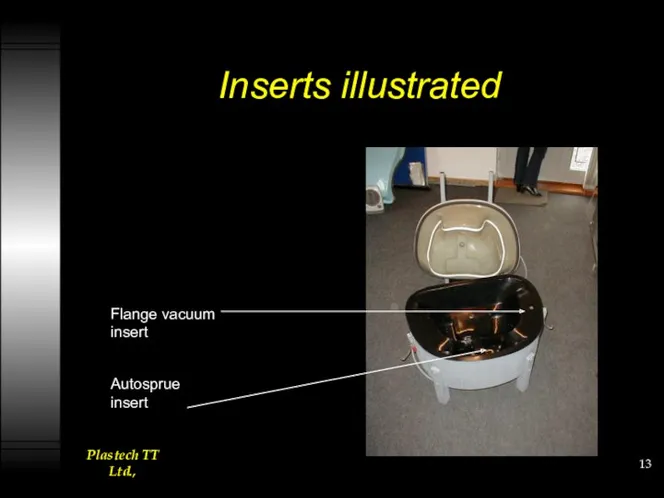

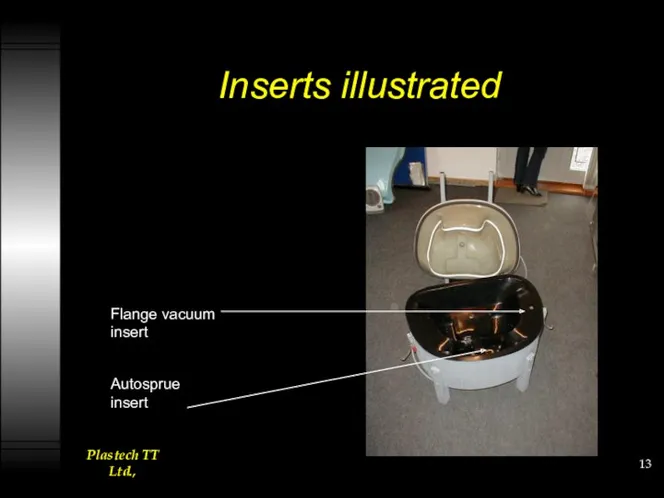

Inserts illustrated

Flange vacuum insert

Autosprue insert

Слайд 14

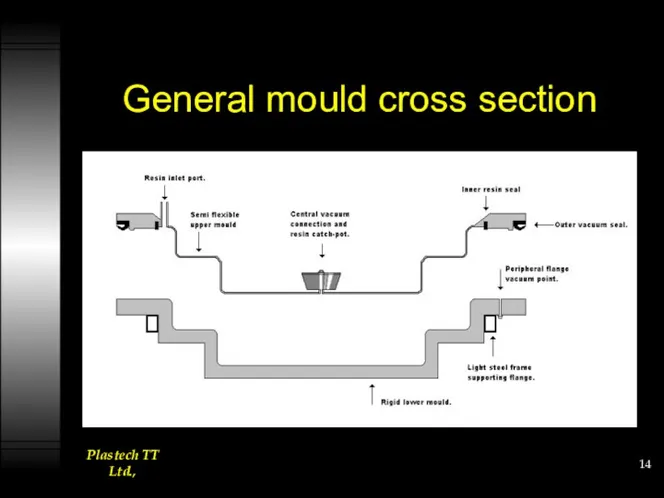

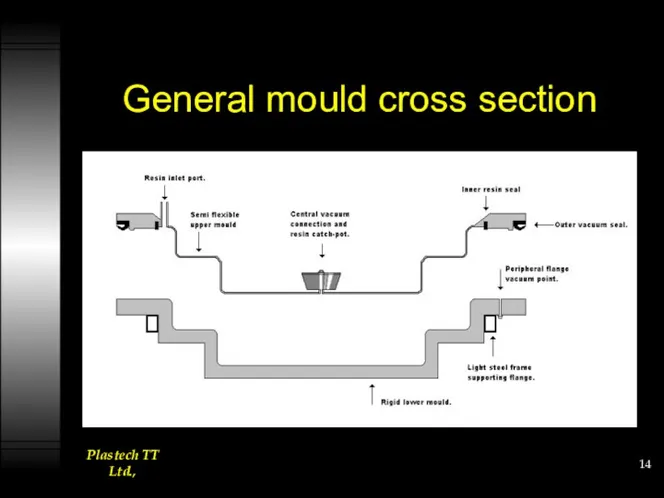

General mould cross section

Слайд 15

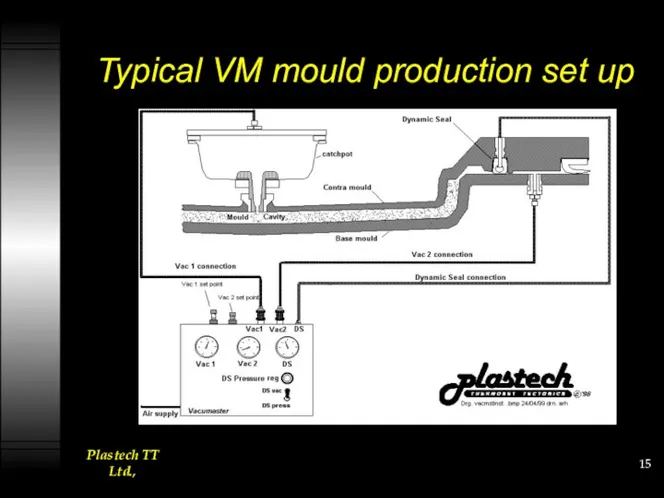

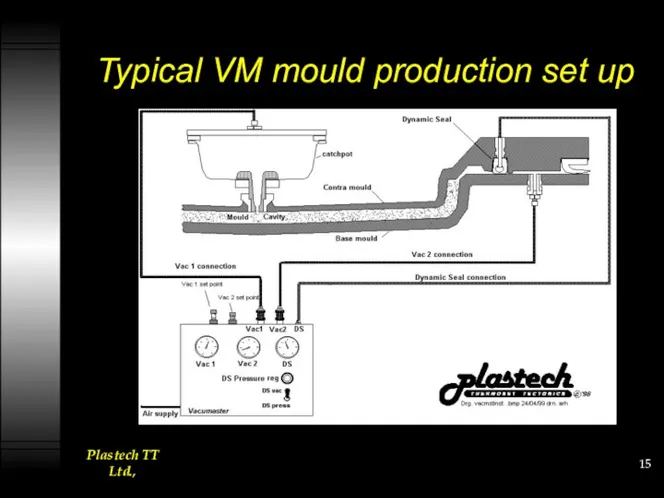

Typical VM mould production set up

Слайд 16

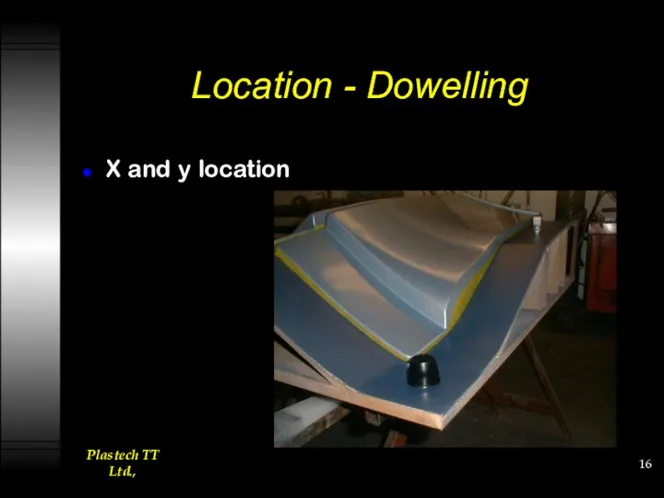

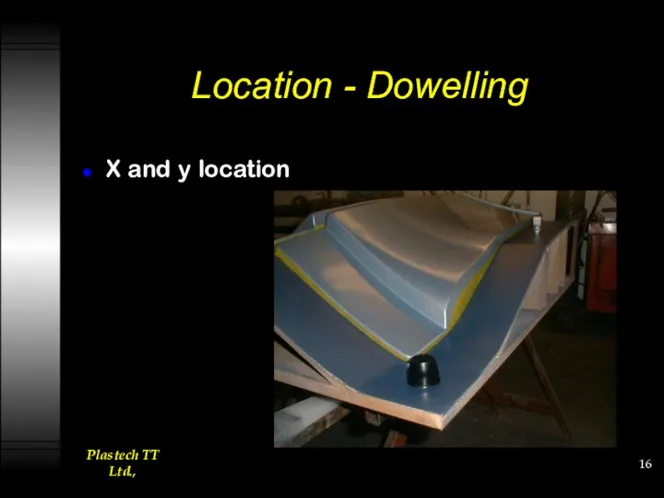

Location - Dowelling

X and y location

Слайд 17

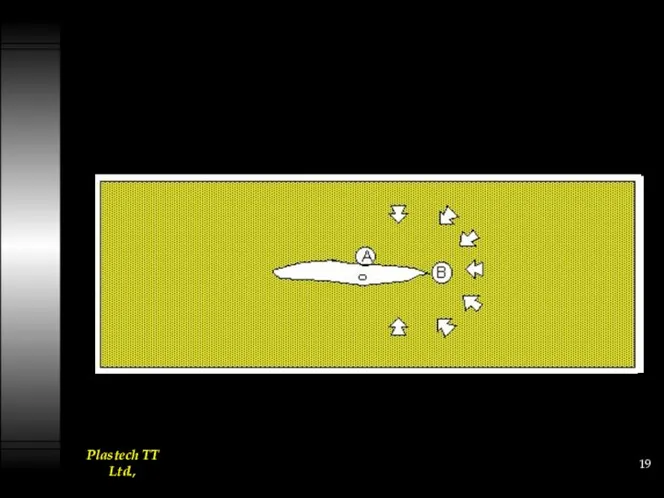

Peripheral Fill

Resin mould flow designed to find initial easy path around

cavity.

Ideal - path fills before cavity starts to fill.

Theory to practise example………

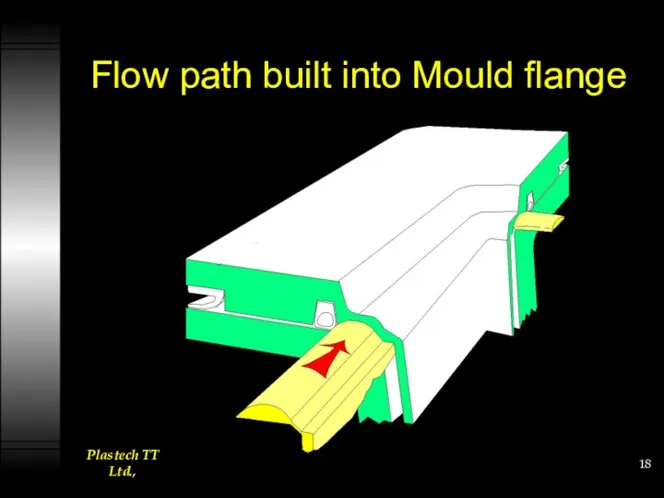

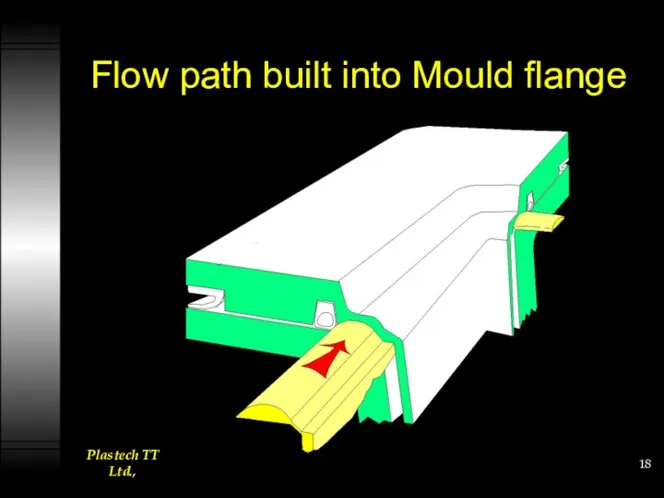

Слайд 18

Flow path built into Mould flange

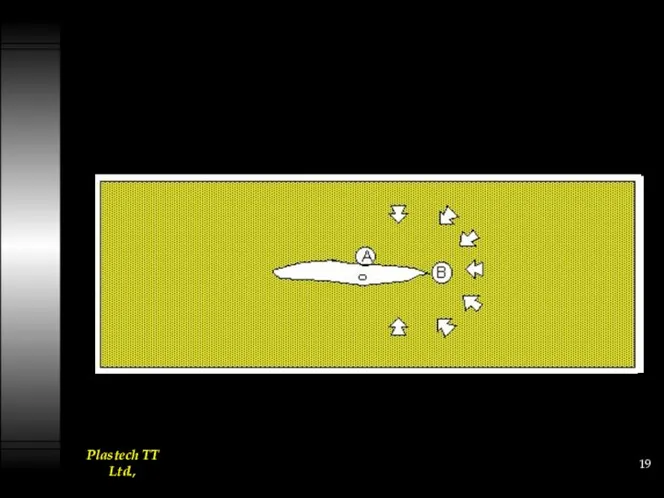

Слайд 19

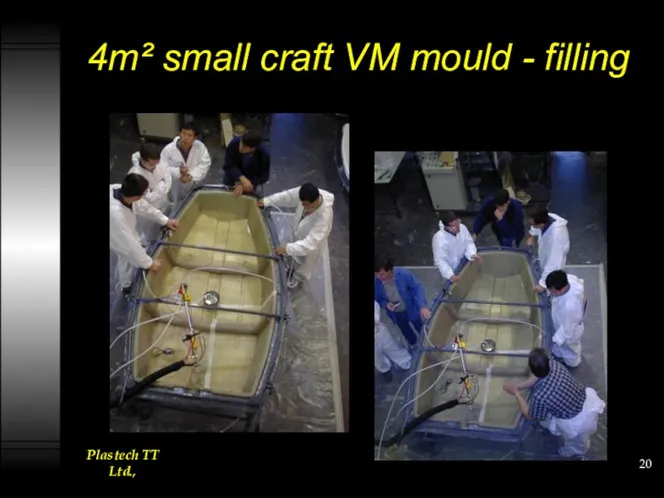

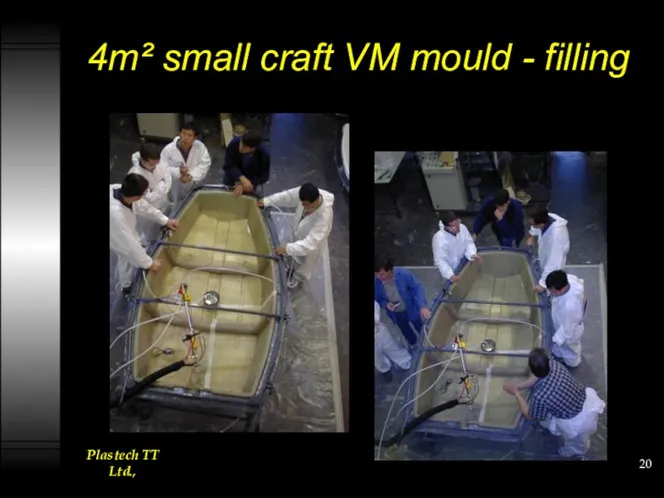

Слайд 20

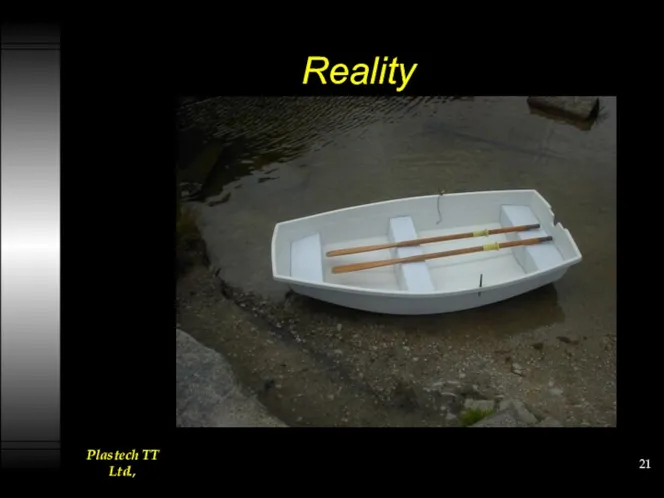

4m² small craft VM mould - filling

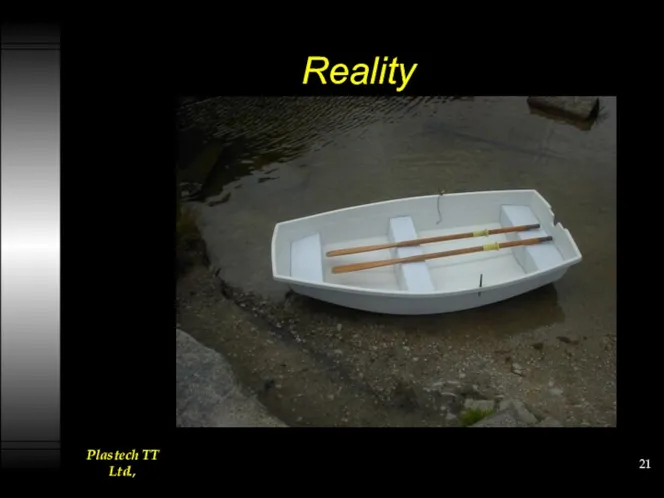

Слайд 21

Слайд 22

Слайд 23

Face tool Lay up

Release agent

Tooling gel coat VE

Tissue + VE

First layer

450 g/m² CSM + VE

Second 3 x 450 g/m² CSM + LP

Frame – wood or light steel

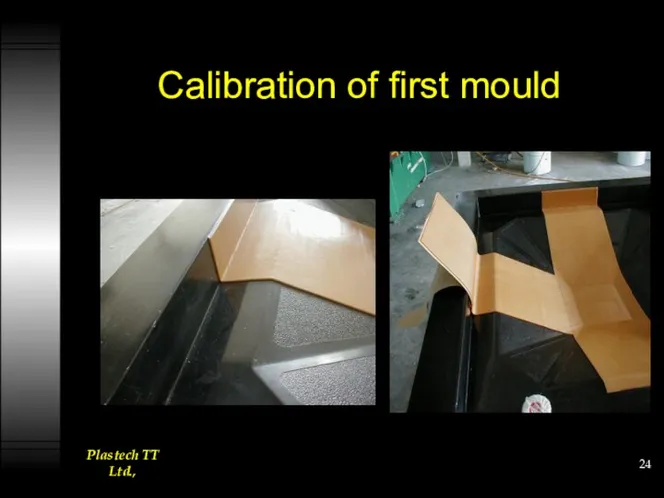

Слайд 24

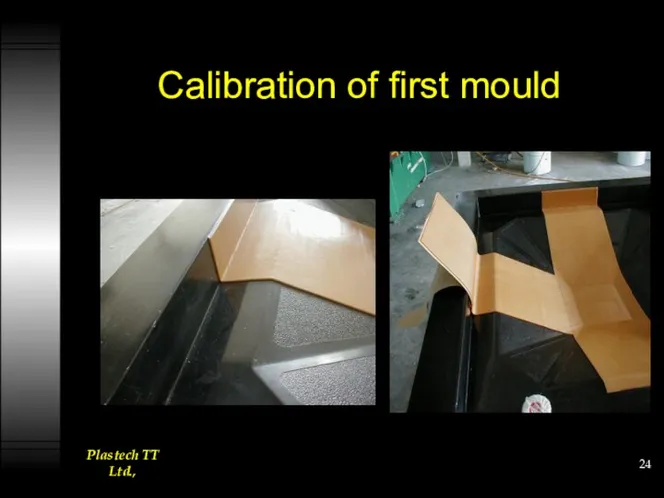

Calibration of first mould

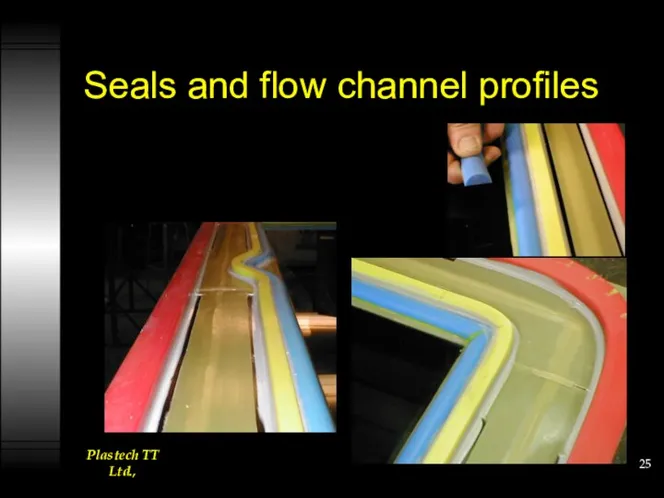

Слайд 25

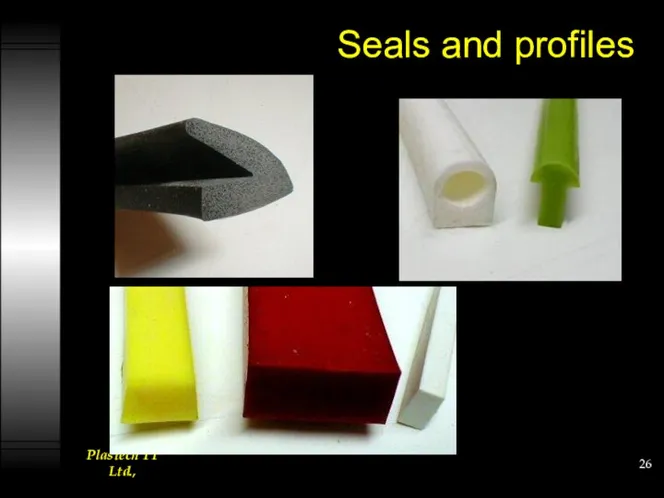

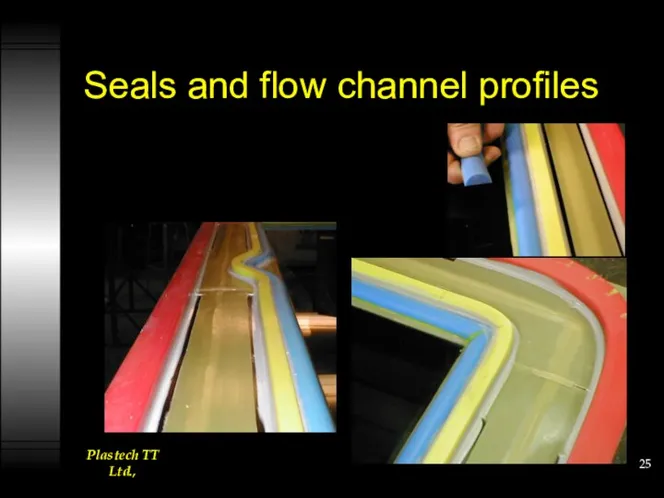

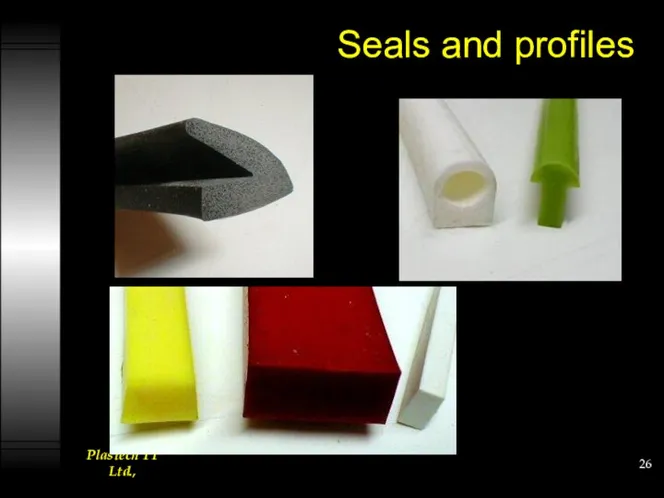

Seals and flow channel profiles

Слайд 26

Слайд 27

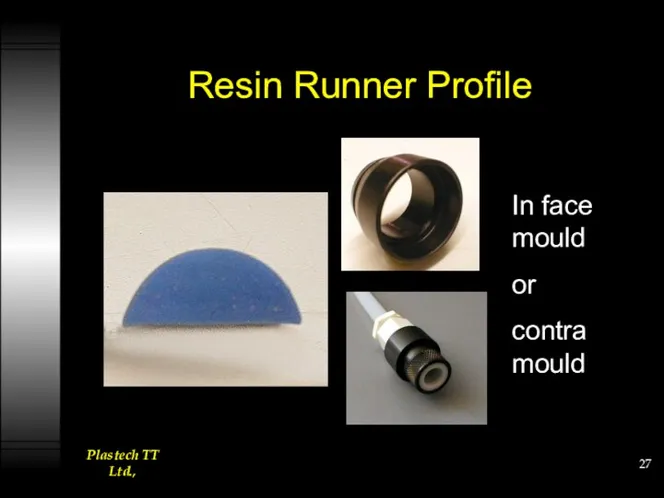

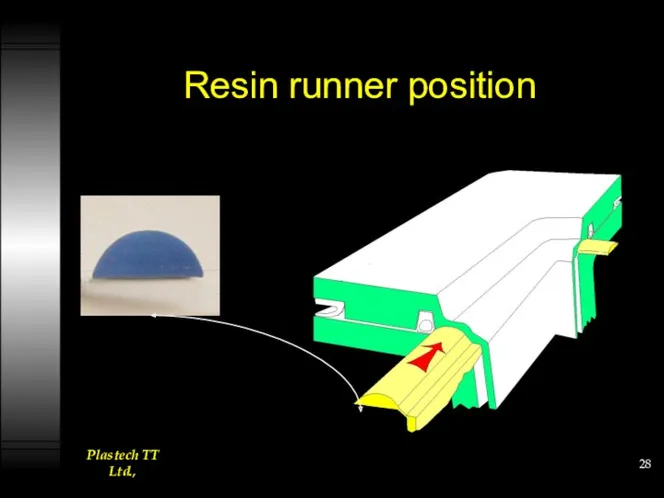

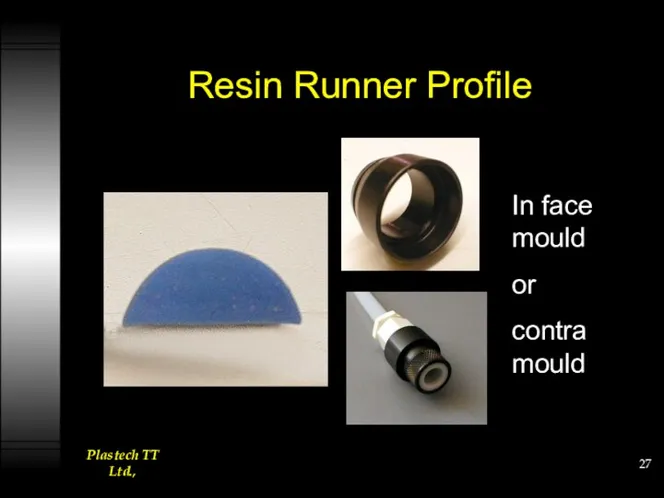

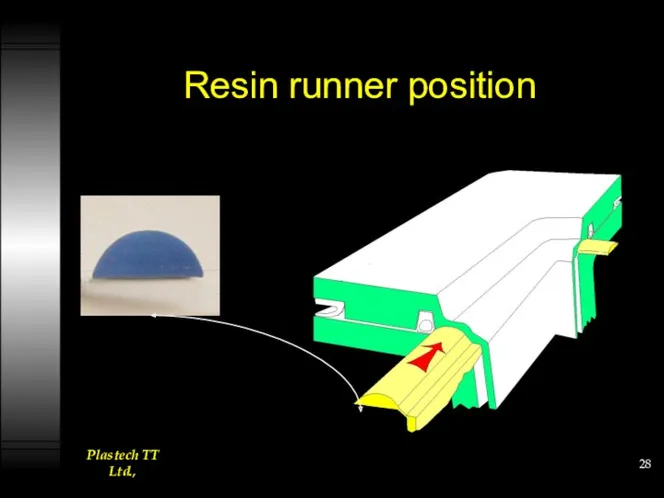

Resin Runner Profile

In face mould

or

contra mould

Слайд 28

Слайд 29

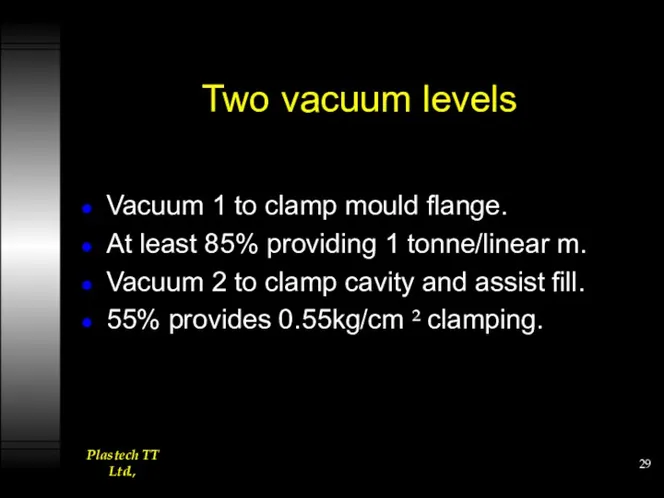

Two vacuum levels

Vacuum 1 to clamp mould flange.

At least 85%

providing 1 tonne/linear m.

Vacuum 2 to clamp cavity and assist fill.

55% provides 0.55kg/cm ² clamping.

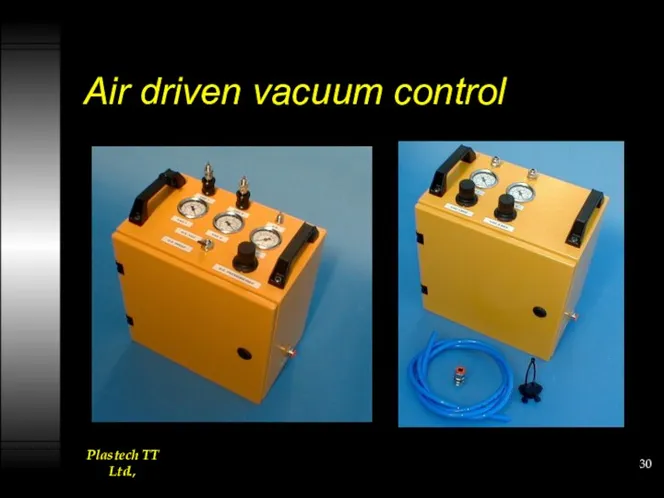

Слайд 30

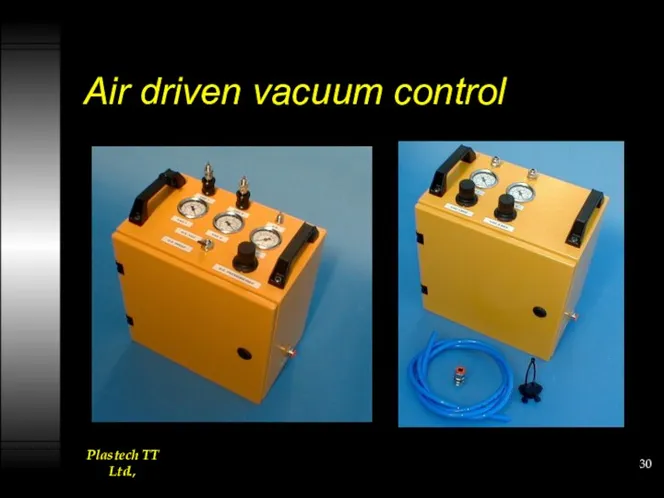

Air driven vacuum control

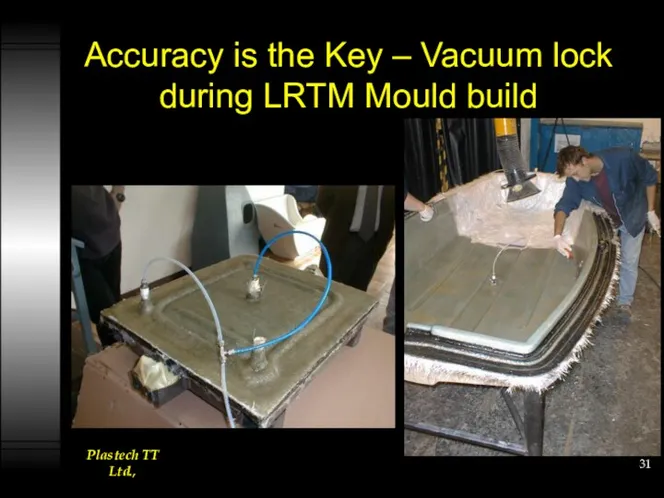

Слайд 31

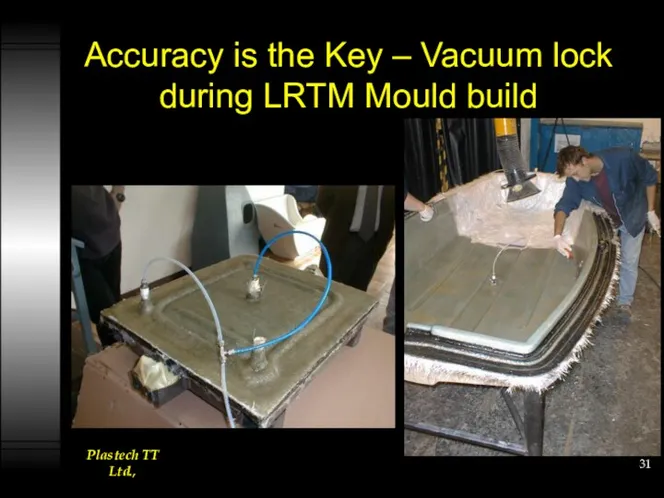

Accuracy is the Key – Vacuum lock during LRTM Mould build

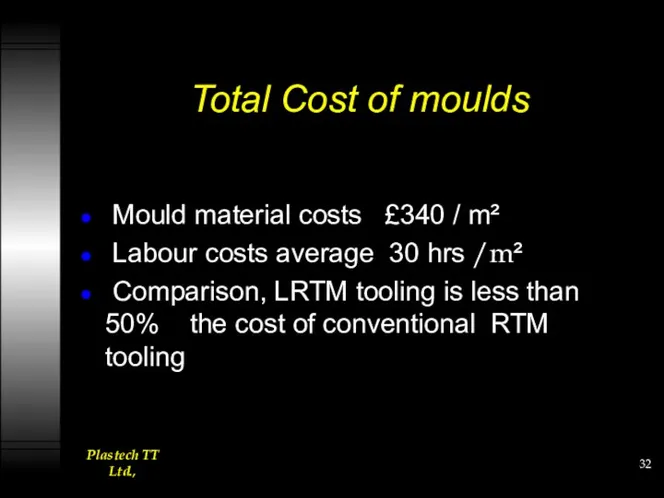

Слайд 32

Total Cost of moulds

Mould material costs £340 / m²

Labour

costs average 30 hrs /m²

Comparison, LRTM tooling is less than 50% the cost of conventional RTM tooling

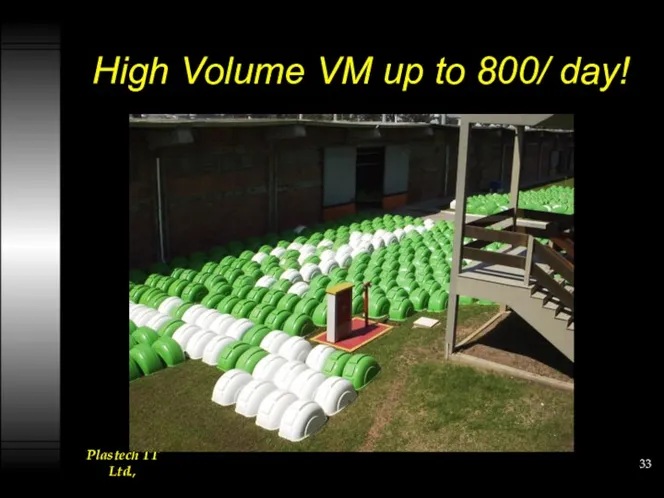

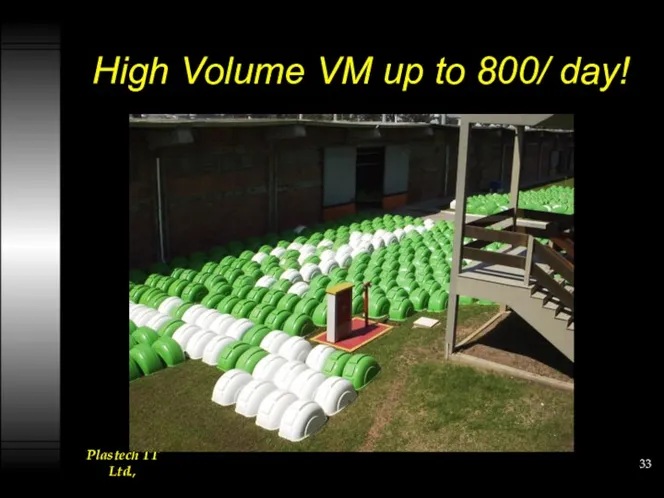

Слайд 33

High Volume VM up to 800/ day!

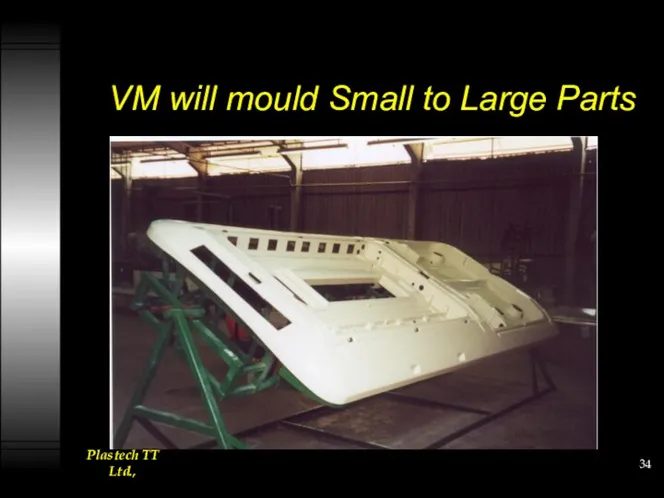

Слайд 34

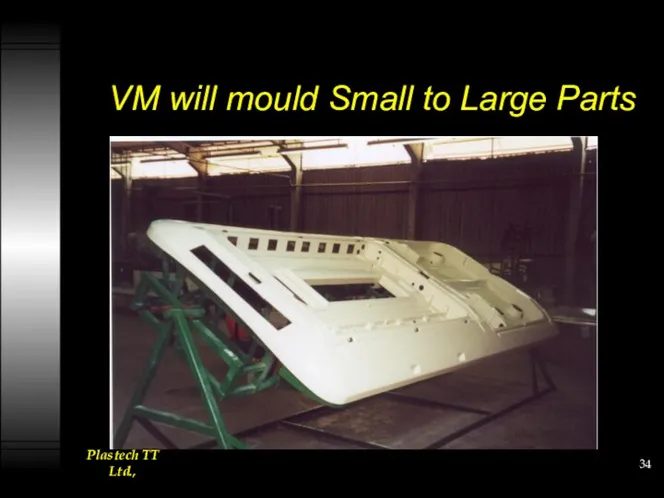

VM will mould Small to Large Parts

Слайд 35

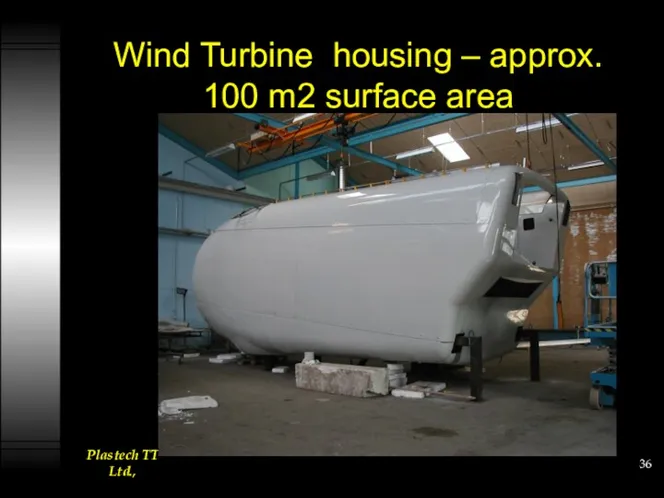

LRTM can go big and complicated

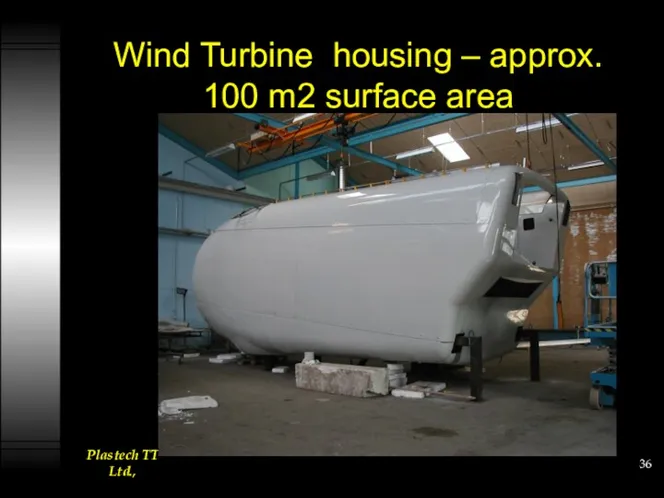

Слайд 36

Wind Turbine housing – approx. 100 m2 surface area

Слайд 37

Слайд 38

Difference between RTM and LRTM

Moulding Speed

Moulding accuracy

Equipment requirements

Слайд 39

“RTM” and complimentary “LRTM” closed moulding for composites

Difference between RTM

and LRTM

Moulding Speed

Слайд 40

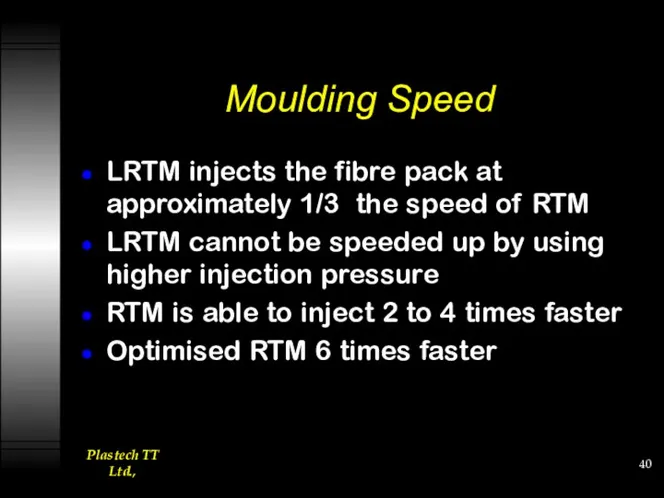

Moulding Speed

LRTM injects the fibre pack at approximately 1/3 the speed

of RTM

LRTM cannot be speeded up by using higher injection pressure

RTM is able to inject 2 to 4 times faster

Optimised RTM 6 times faster

Слайд 41

“RTM” and complimentary “LRTM” closed moulding for composites

Difference between RTM

and LRTM

Moulding Speed

Moulding accuracy

Слайд 42

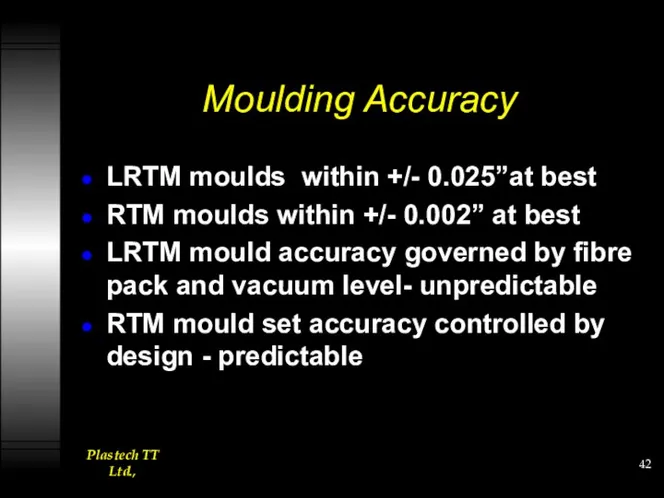

Moulding Accuracy

LRTM moulds within +/- 0.025”at best

RTM moulds within +/- 0.002”

at best

LRTM mould accuracy governed by fibre pack and vacuum level- unpredictable

RTM mould set accuracy controlled by design - predictable

Слайд 43

“RTM” and complimentary “LRTM” closed moulding for composites

Difference between RTM

and LRTM

Moulding Speed

Moulding accuracy

Equipment requirements

Слайд 44

Equipment requirements

RTM needs a low pressure meter mix machine and tool

manipulator.

LRTM needs a VERY low pressure meter mix machine and two vacuum sources

Слайд 45

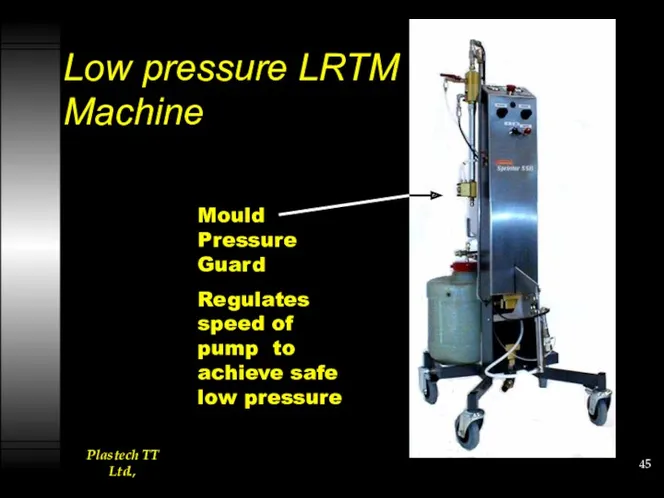

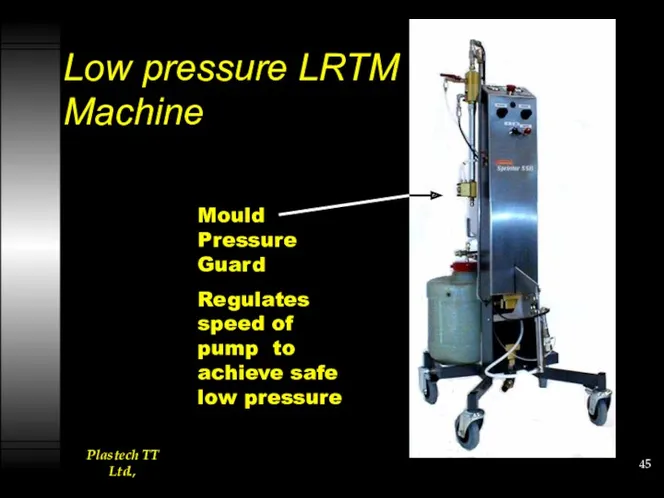

Low pressure LRTM Machine

Mould Pressure Guard

Regulates speed of pump

to achieve safe low pressure

Слайд 46

More Application examples

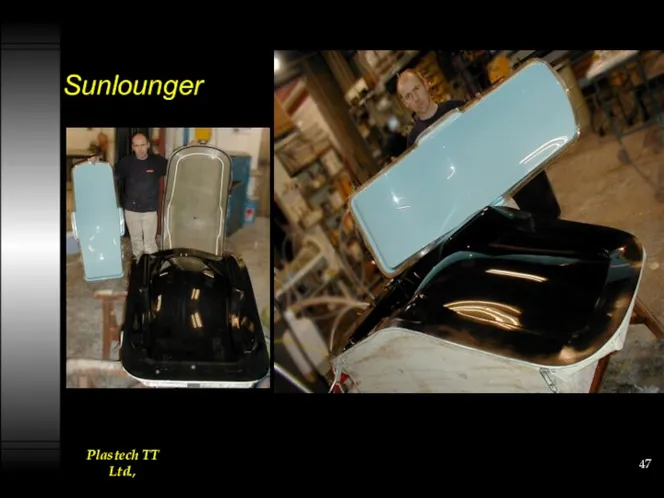

Слайд 47

Слайд 48

Pacific Composites - Australia

Слайд 49

Слайд 50

Слайд 51

Слайд 52

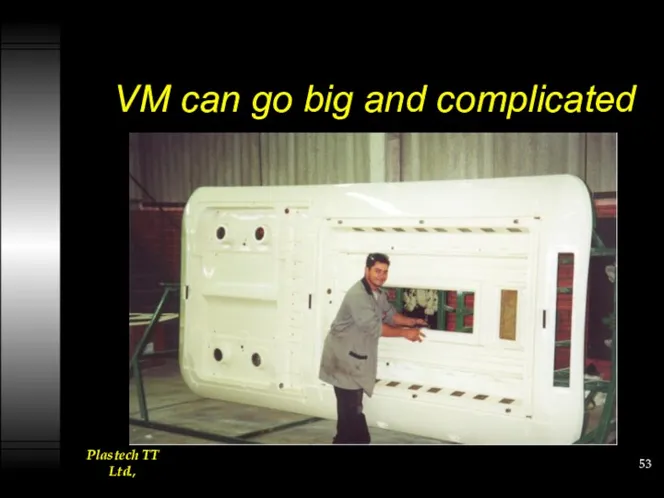

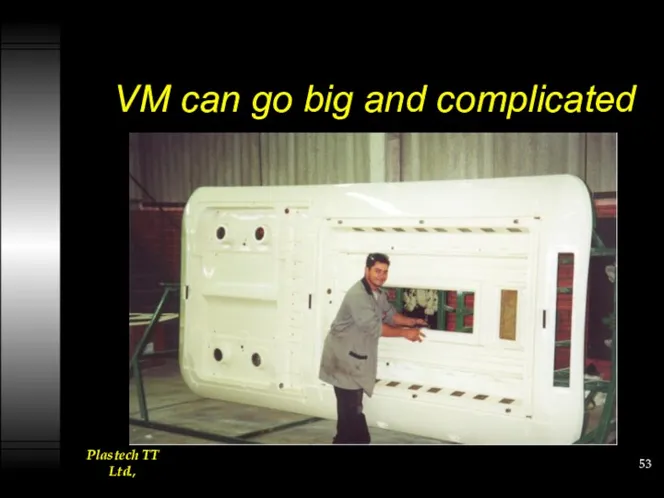

Слайд 53

VM can go big and complicated

Слайд 54

Слайд 55

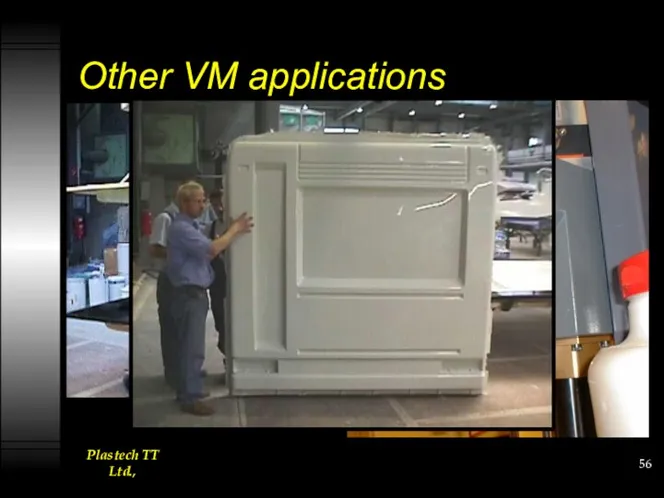

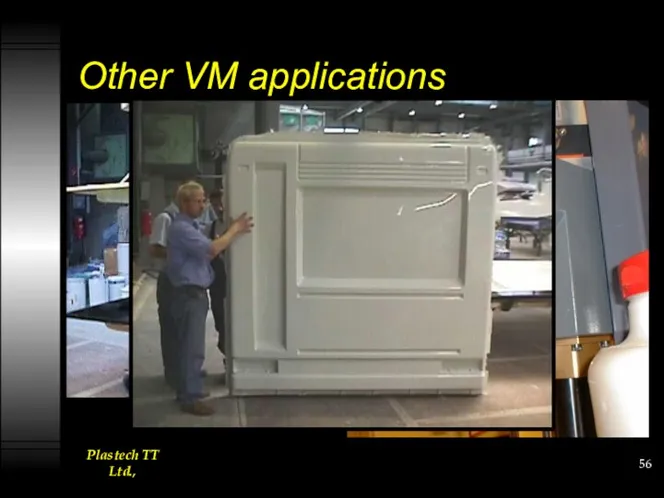

Слайд 56

Слайд 57

Conclusions

LRTM is a viable lower cost system complimentary to RTM.

Tooling manufacture

must be accurate

Material selection, resin, fibre critical.

Operating procedures must be consistent for success.

Слайд 58

Heating /Temperature control

Слайд 59

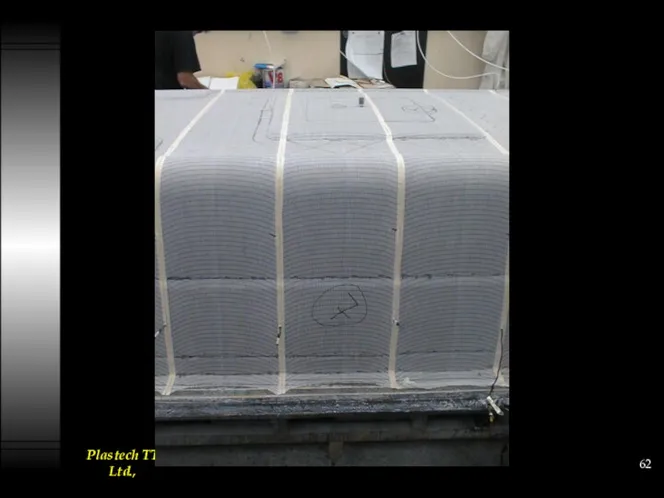

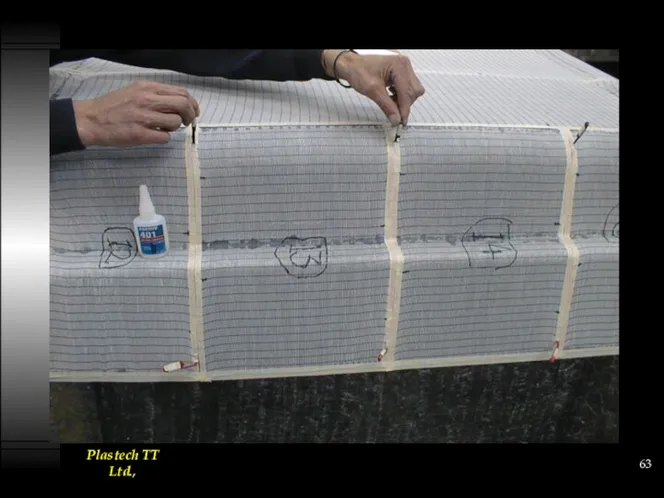

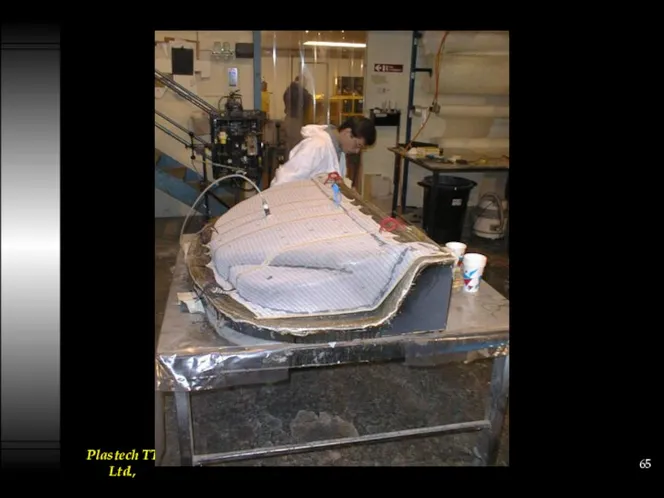

Electrical Heater-Cloth Application.

Слайд 60

Слайд 61

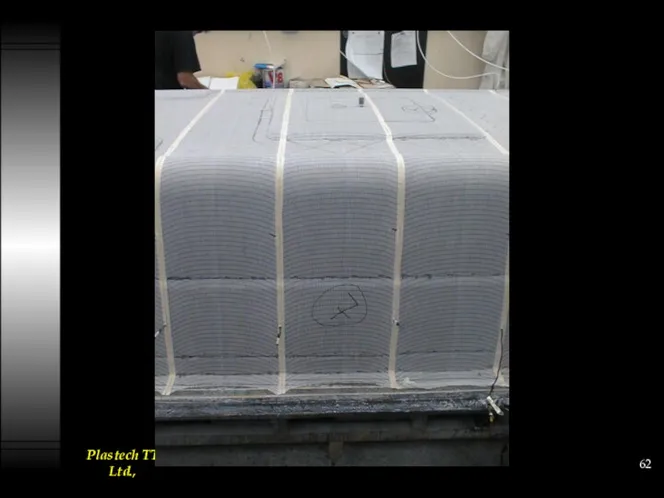

Слайд 62

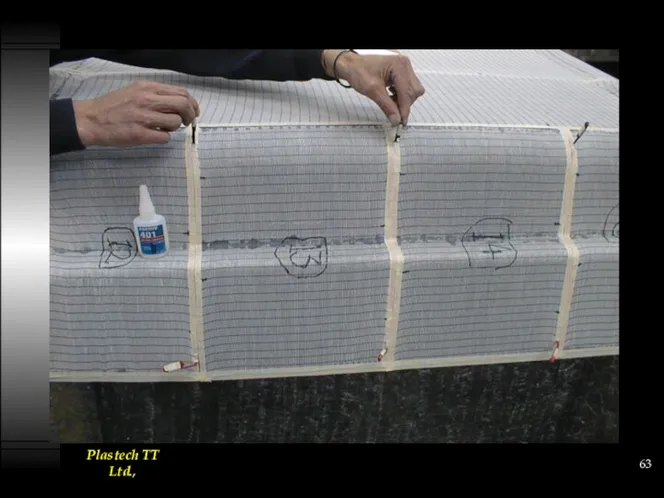

Слайд 63

Слайд 64

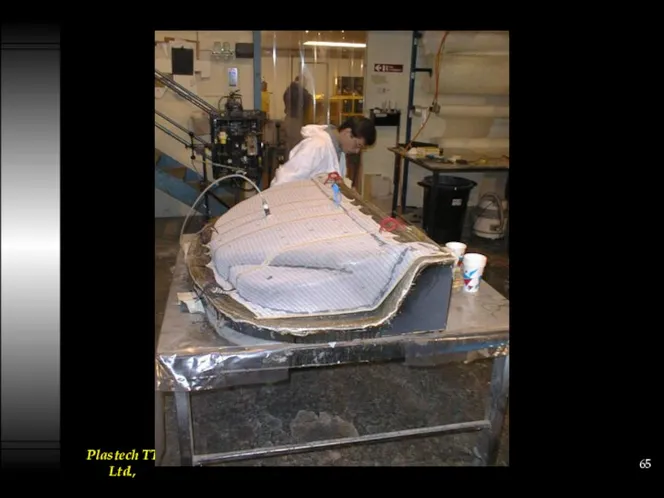

Слайд 65

Слайд 66

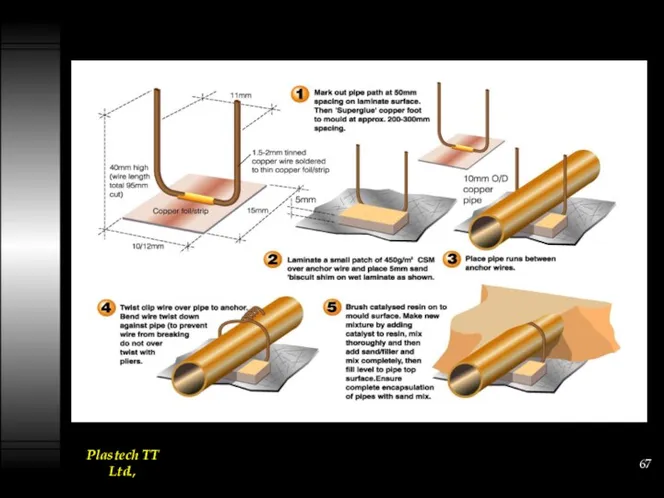

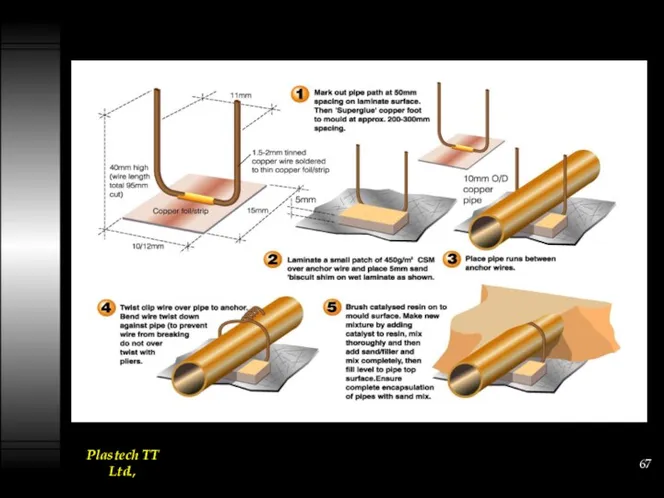

Слайд 67

Слайд 68

Слайд 69

Слайд 70

Слайд 71

Слайд 72

Слайд 73

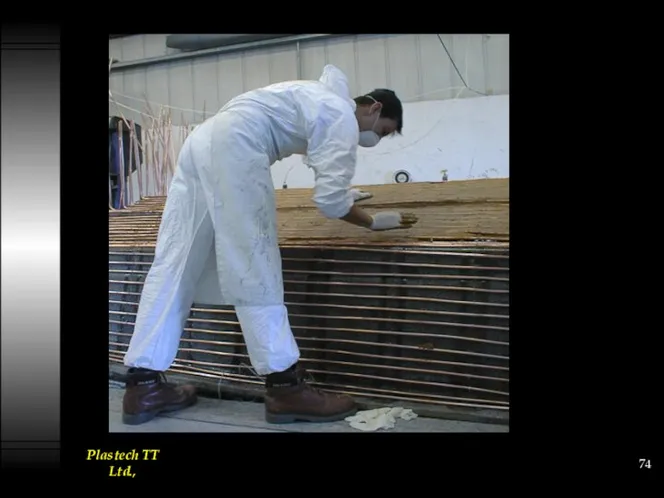

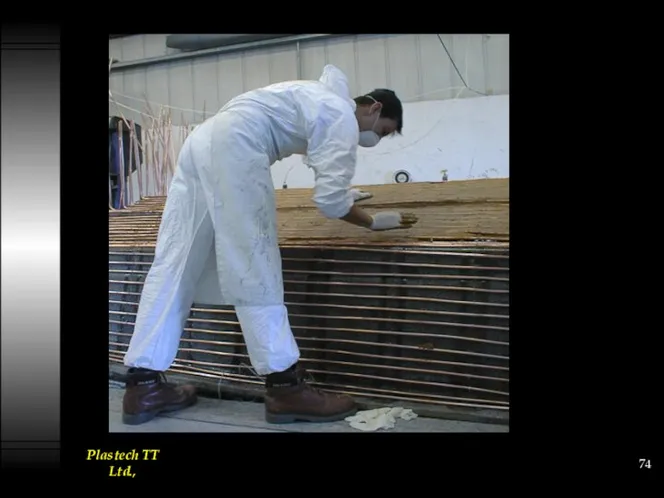

Слайд 74

Вибрационная болезнь (0)

Вибрационная болезнь (0) Сравнительный анализ и методика повышения эффективности дистанционных бросков у баскетболистов разной квалификации

Сравнительный анализ и методика повышения эффективности дистанционных бросков у баскетболистов разной квалификации Границы аэробноанаэробного перехода: АП-1, АнП-2

Границы аэробноанаэробного перехода: АП-1, АнП-2 Флотационные реагенты, применяемые при флотации руд редких и благородных металлов

Флотационные реагенты, применяемые при флотации руд редких и благородных металлов Организации в экономике

Организации в экономике Бизнес – проект по развитию садоводства

Бизнес – проект по развитию садоводства Западная геополитика после II Мировой войны (часть 2)

Западная геополитика после II Мировой войны (часть 2) Бауыр және өт жолдары, ұйқы безі ауруларын тағаммен емдеу және емдік дене шынықтыру

Бауыр және өт жолдары, ұйқы безі ауруларын тағаммен емдеу және емдік дене шынықтыру Интегральные характеристики светового поля. Средние освещенности по поверхности

Интегральные характеристики светового поля. Средние освещенности по поверхности Осуществление образовательной деятельности в игре

Осуществление образовательной деятельности в игре Презентация Проблемы молодежи

Презентация Проблемы молодежи Презентация внекласного мероприятия Моя Кызылорда

Презентация внекласного мероприятия Моя Кызылорда презентация портфолио ученика

презентация портфолио ученика Введение в химию. 8 класс

Введение в химию. 8 класс Овцеводство и свиноводство

Овцеводство и свиноводство Обеспечение предприятий автосервиса материально-техническими ресурсами. Материальные ресурсы. (Тема 9.15)

Обеспечение предприятий автосервиса материально-техническими ресурсами. Материальные ресурсы. (Тема 9.15) Методы вторичного вскрытия пласта

Методы вторичного вскрытия пласта Электрические аппараты электровозов. Классификация

Электрические аппараты электровозов. Классификация Розширена колегія Державного агентства лісових ресурсів України за 1 півріччя 2019 року

Розширена колегія Державного агентства лісових ресурсів України за 1 півріччя 2019 року Классный час СНГ-Содружество Независимых Государств

Классный час СНГ-Содружество Независимых Государств Презентация Лягушка - зелёное брюшко (сказочная история для язычка)

Презентация Лягушка - зелёное брюшко (сказочная история для язычка) Безопасность в сети интернет

Безопасность в сети интернет Лукьянова О. СОШ 30Scientists and their discoveries that changed the world

Лукьянова О. СОШ 30Scientists and their discoveries that changed the world Определение кадастровой стоимости

Определение кадастровой стоимости Презентация по технологии 1 класс на тему Кораблик

Презентация по технологии 1 класс на тему Кораблик Заготовка древесины, ее пороки и выбор для изготовления изделий

Заготовка древесины, ее пороки и выбор для изготовления изделий Основы светской этики. Урок-презентация Свобода и моральный выбор человека

Основы светской этики. Урок-презентация Свобода и моральный выбор человека New technologies

New technologies