Содержание

- 2. Casting, as a method of processing metals and their alloys, has been used for a long

- 3. Main stages of production. The metal casting process includes the following steps. Main stages Melting Casting

- 4. Плавка MELTING is the heat treatment of a CHARGE in a MELTING FURNACE to separate metals

- 5. Melting The ore, often with other ingredients, is heated in a melting furnace and melted, resulting

- 6. Melting When melting metals and alloys, the following protective covers are used to protect melts from

- 7. CASTING is a technological process in which molten metal is poured into molds, where it solidifies,

- 8. Casting In modern production, the following types of casting are distinguished. Methods of casting The sand

- 9. The sand casting First, wooden templates are made, and sand forms are based on them. After

- 10. Injection molding The most promising method of casting is considered to be injection molding.The metal is

- 12. Скачать презентацию

Презентация Внеурочная деятельность школьников.

Презентация Внеурочная деятельность школьников. Техники, связанные с использованием бумаги и текстиля

Техники, связанные с использованием бумаги и текстиля Волоконные оптические датчики

Волоконные оптические датчики Брейн-ринг Встреча

Брейн-ринг Встреча Моцарт

Моцарт Измерители барометрической высоты полета. Корректоры высоты. Корректоры-задатчики высоты

Измерители барометрической высоты полета. Корректоры высоты. Корректоры-задатчики высоты Политология, как наука

Политология, как наука Методы контроля качества воздуха. Газоанализаторы

Методы контроля качества воздуха. Газоанализаторы Материаловеденье. Натуральные волокна растительного происхождения. Изготовление ткани

Материаловеденье. Натуральные волокна растительного происхождения. Изготовление ткани Проектирование водопроводной насосной станции II подъема

Проектирование водопроводной насосной станции II подъема Горы. Фото

Горы. Фото интерактивная игра

интерактивная игра Інформаційні технології математичного аналізу систем

Інформаційні технології математичного аналізу систем Объемно-планировочные параметры одноэтажных промышленных зданий

Объемно-планировочные параметры одноэтажных промышленных зданий Убранство избы. Работа с бумагой. Плетение. Изделие Коврик

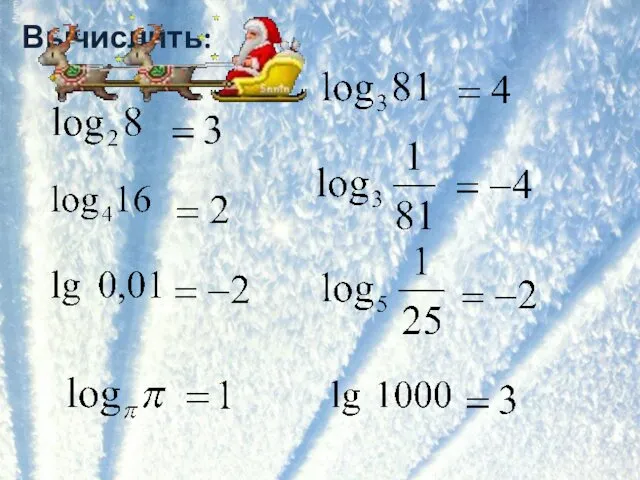

Убранство избы. Работа с бумагой. Плетение. Изделие Коврик Логарифмические уравнения

Логарифмические уравнения Классификация теплового оборудования для предприятий общественного питания

Классификация теплового оборудования для предприятий общественного питания Социальные группы в организации и управление групповым поведением

Социальные группы в организации и управление групповым поведением История служебного собаководства в России

История служебного собаководства в России Способы эффект.орг. личного бюджета

Способы эффект.орг. личного бюджета Europejski Bank Centralny

Europejski Bank Centralny особенности работы с семьями воспитанников в условиях лекотеки

особенности работы с семьями воспитанников в условиях лекотеки Этих лет не смолкнет слава Памяти павших в Великой Отечественной войне

Этих лет не смолкнет слава Памяти павших в Великой Отечественной войне Pedestrian Monitoring

Pedestrian Monitoring Виртуальная выставка: Астафьев В. П

Виртуальная выставка: Астафьев В. П Плойки. Разновидности плоек

Плойки. Разновидности плоек Технология хранения и переработки продукции растениеводства

Технология хранения и переработки продукции растениеводства 20231009_otkrytyy_urok_v_10_klasse

20231009_otkrytyy_urok_v_10_klasse