Содержание

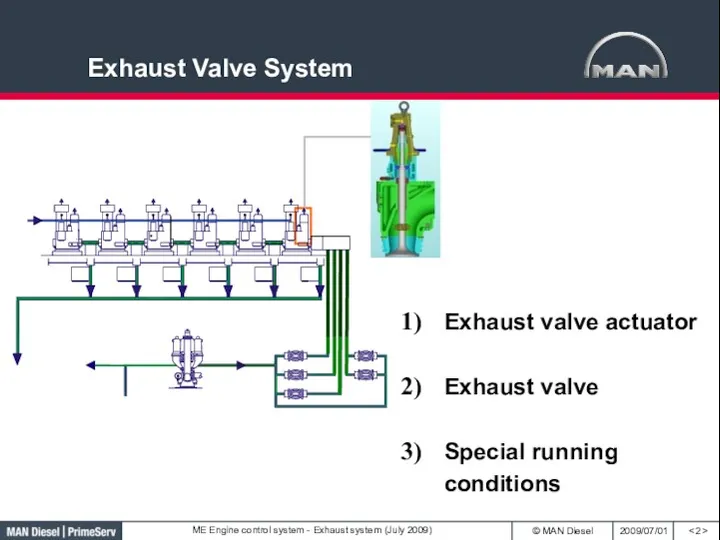

- 2. Exhaust Valve System Exhaust valve actuator Exhaust valve Special running conditions

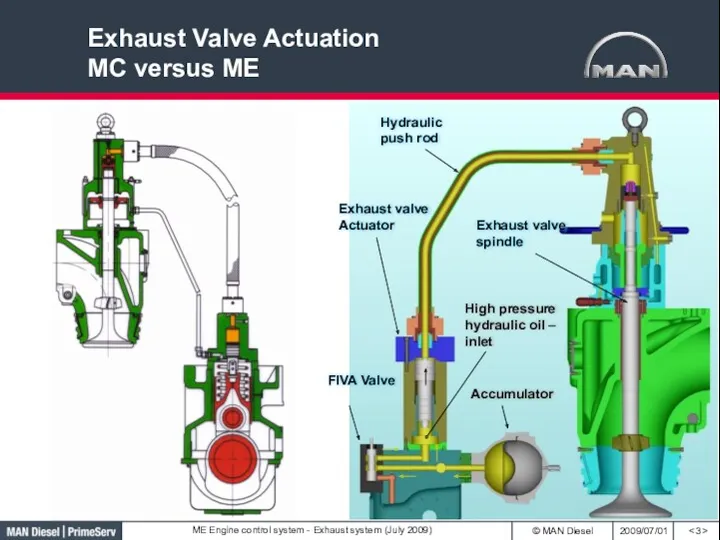

- 3. Exhaust Valve Actuation MC versus ME

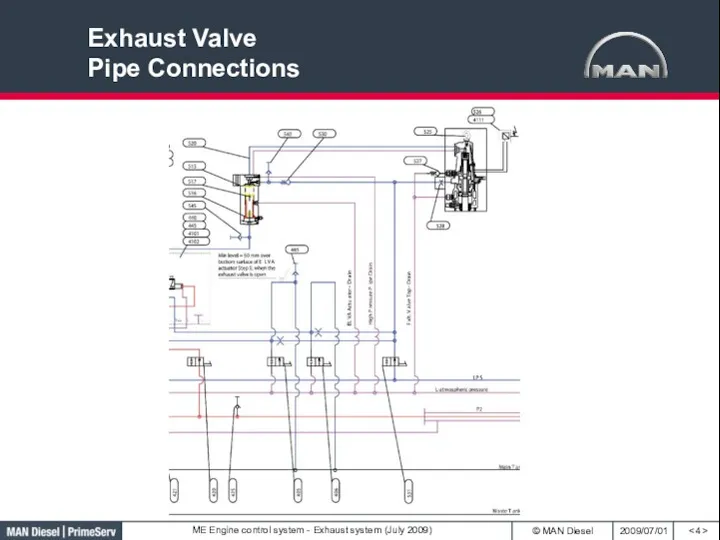

- 4. Exhaust Valve Pipe Connections

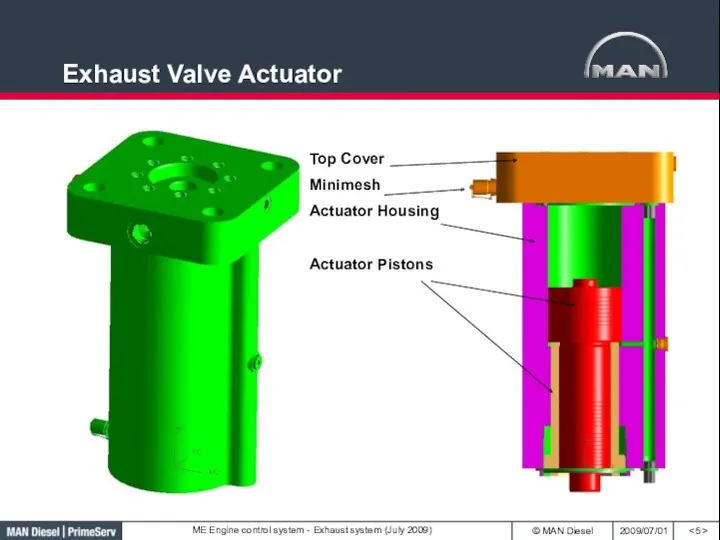

- 5. Exhaust Valve Actuator Top Cover Minimesh Actuator Housing Actuator Pistons

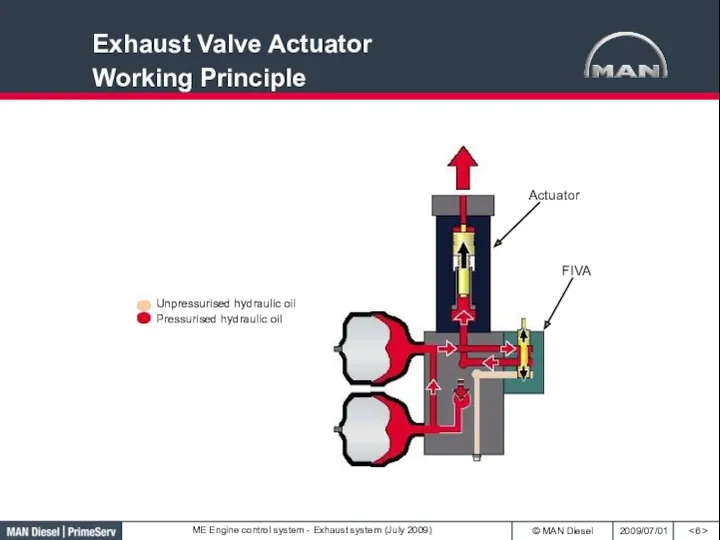

- 6. Exhaust Valve Actuator Working Principle

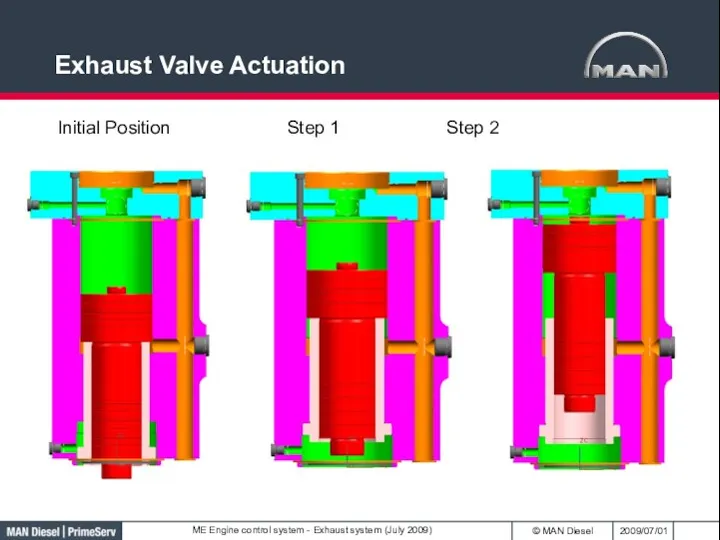

- 7. Exhaust Valve Actuation Initial Position Step 1 Step 2

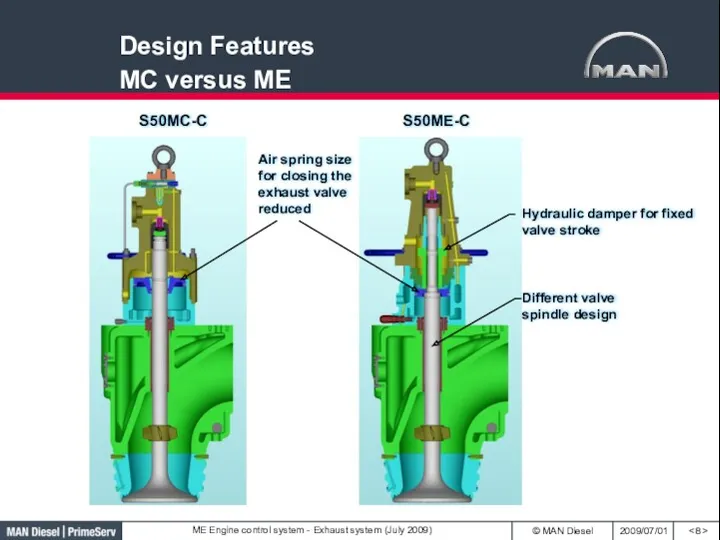

- 8. S50MC-C S50ME-C Hydraulic damper for fixed valve stroke Air spring size for closing the exhaust valve

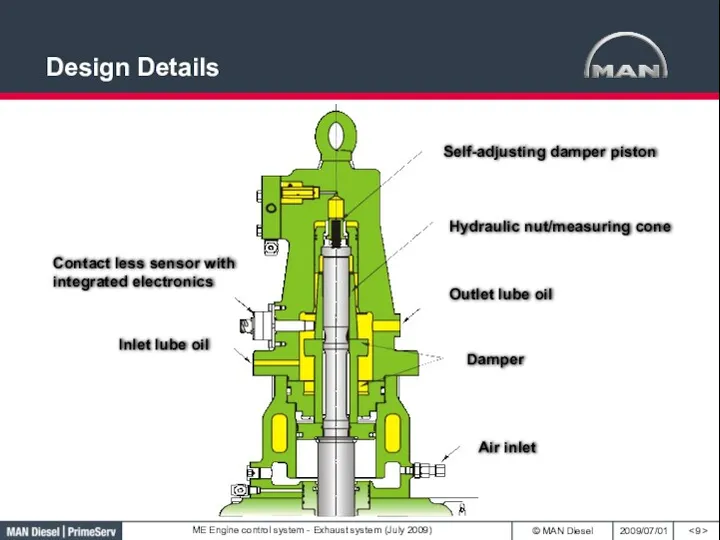

- 9. Self-adjusting damper piston Hydraulic nut/measuring cone Outlet lube oil Damper Air inlet Inlet lube oil Contact

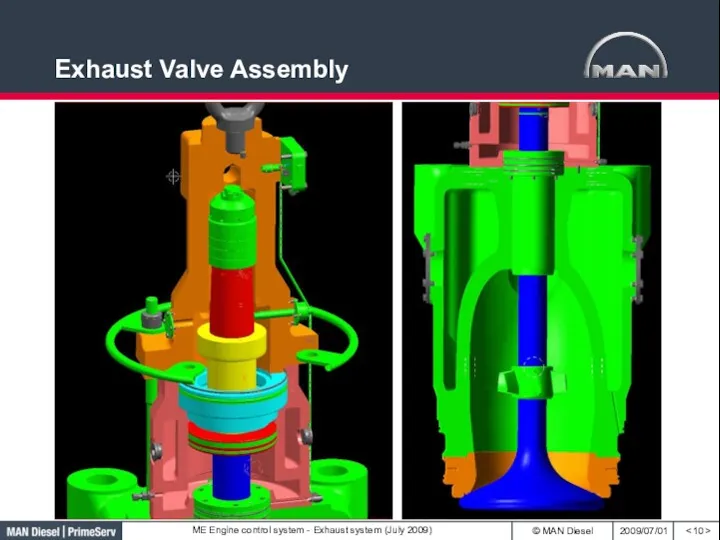

- 10. Exhaust Valve Assembly

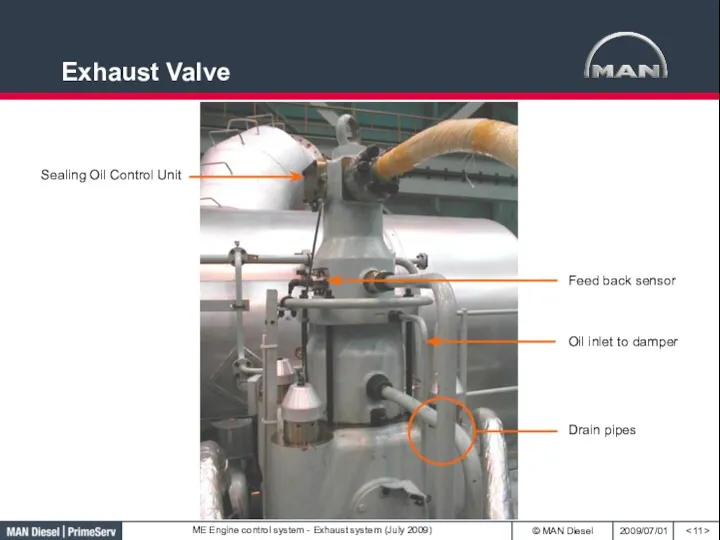

- 11. Oil inlet to damper Drain pipes Feed back sensor Sealing Oil Control Unit Exhaust Valve

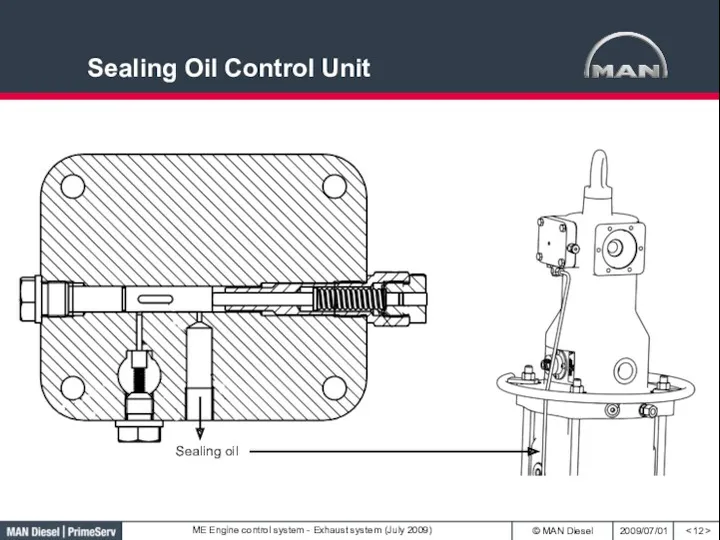

- 12. Sealing Oil Control Unit Sealing oil

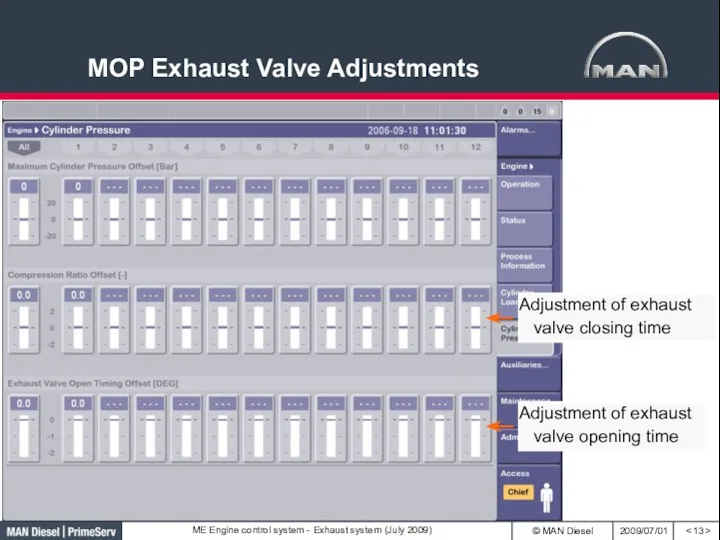

- 13. MOP Exhaust Valve Adjustments

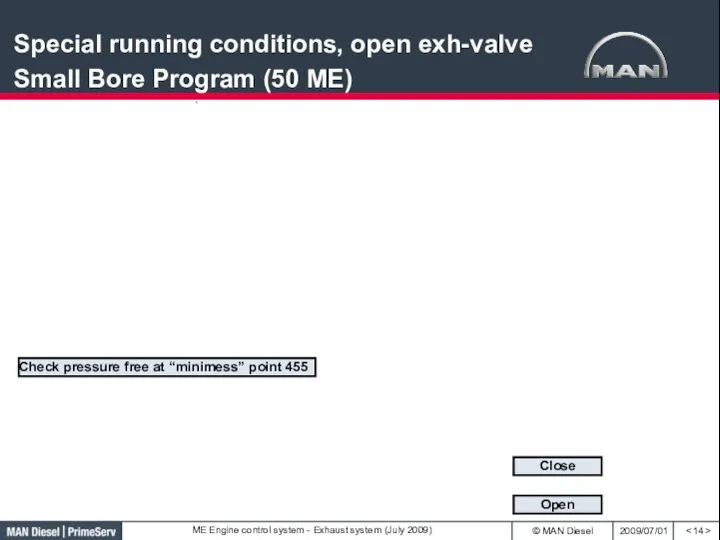

- 14. Check pressure free at “minimess” point 455 Close Open Special running conditions, open exh-valve Small Bore

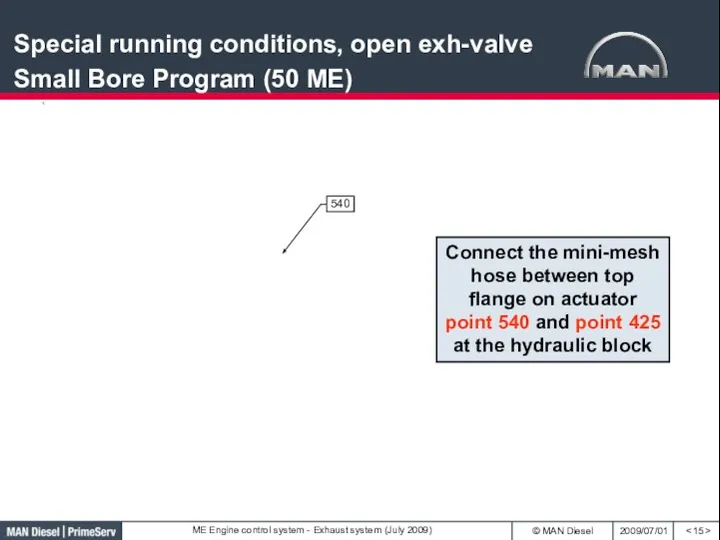

- 15. Connect the mini-mesh hose between top flange on actuator point 540 and point 425 at the

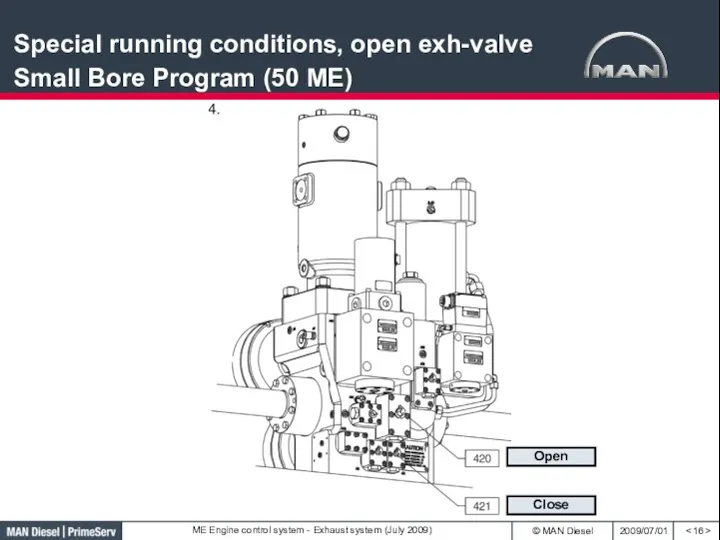

- 16. Close Open Special running conditions, open exh-valve Small Bore Program (50 ME)

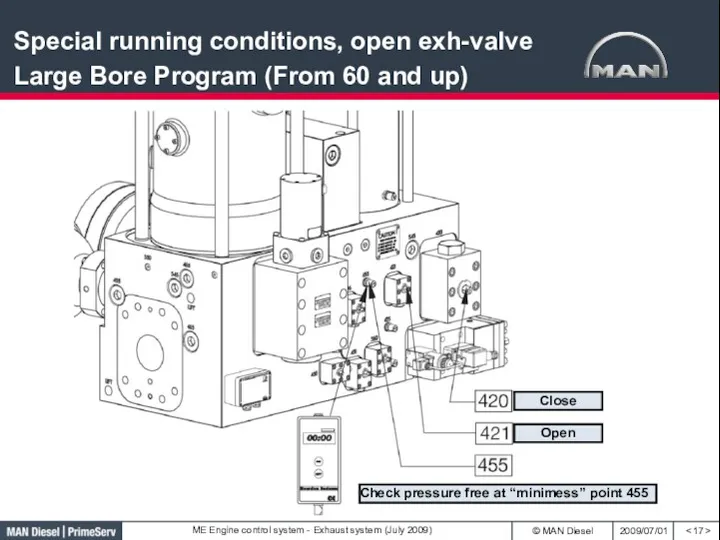

- 17. Check pressure free at “minimess” point 455 Close Open Special running conditions, open exh-valve Large Bore

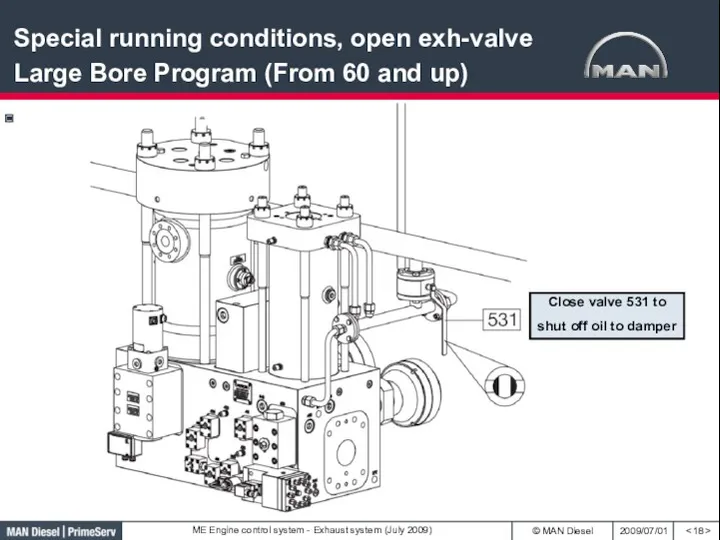

- 18. Close valve 531 to shut off oil to damper Special running conditions, open exh-valve Large Bore

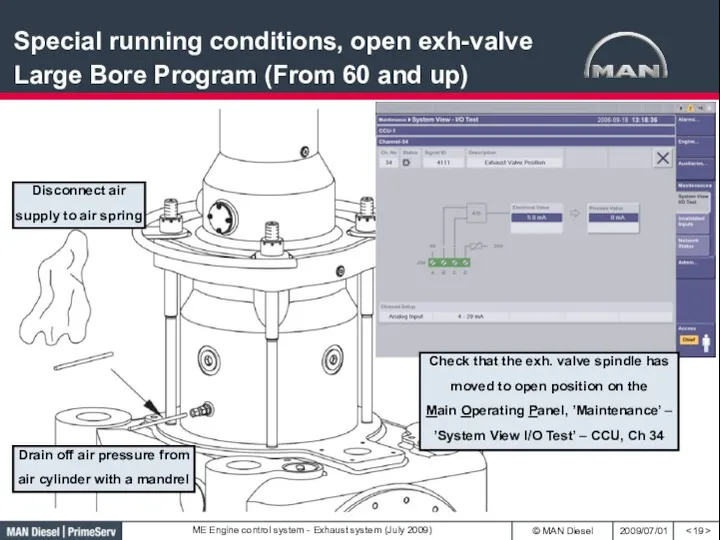

- 19. Drain off air pressure from air cylinder with a mandrel Disconnect air supply to air spring

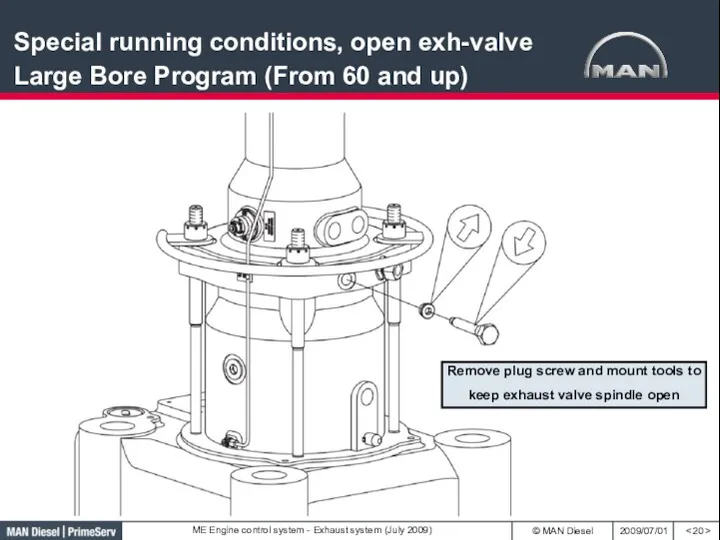

- 20. Remove plug screw and mount tools to keep exhaust valve spindle open Special running conditions, open

- 22. Скачать презентацию

Сложноподчинённое предложение. Типы придаточных предложений

Сложноподчинённое предложение. Типы придаточных предложений Инновационные технологии и технические средства для реализации проекта ВСЖМ 1

Инновационные технологии и технические средства для реализации проекта ВСЖМ 1 Презентация.Знакомство детей с элементами национальной культуры народов, проживающих на территории Крутинского района

Презентация.Знакомство детей с элементами национальной культуры народов, проживающих на территории Крутинского района Александр II: начало правления. Крестьянская реформа 1861 г

Александр II: начало правления. Крестьянская реформа 1861 г Презентация к уроку ПДД Сигналы светофора и регулировщика№

Презентация к уроку ПДД Сигналы светофора и регулировщика№ Аква - фитнес. Плавание и другие формы доходов в бассейне

Аква - фитнес. Плавание и другие формы доходов в бассейне Доклад на педагогическом совете от 25.03.2015

Доклад на педагогическом совете от 25.03.2015 Обучение детей чтению.

Обучение детей чтению. Пишем сочинение на ОГЭ

Пишем сочинение на ОГЭ Фольклор Колыбельные песни

Фольклор Колыбельные песни Альдегиды и кетоны

Альдегиды и кетоны Поздравляю с 23 февраля

Поздравляю с 23 февраля Элементы математической логики

Элементы математической логики Духовная сфера в жизни общества

Духовная сфера в жизни общества Результат усвоения систематизированных знаний, умений и навыков

Результат усвоения систематизированных знаний, умений и навыков Я люблю собак

Я люблю собак Ақсу аудандандық ветеринариялық зертханасы

Ақсу аудандандық ветеринариялық зертханасы Зима

Зима Работа телеметриста

Работа телеметриста Гуманизм педагогической системы Яна Амоса Коменского (1592-1670)

Гуманизм педагогической системы Яна Амоса Коменского (1592-1670) Технология производства аминокислот кормового назначения

Технология производства аминокислот кормового назначения Медицинская паразитология. Экологические связи в подцарстве Простейшие

Медицинская паразитология. Экологические связи в подцарстве Простейшие Презентация Загадки об осени

Презентация Загадки об осени Меры нетарифного регулирования, как составная часть системы внешнеторговых запретов и ограничений

Меры нетарифного регулирования, как составная часть системы внешнеторговых запретов и ограничений Информация и информационные процессы. Представление информации

Информация и информационные процессы. Представление информации СССР в годы перестройки. Л.17

СССР в годы перестройки. Л.17 Edukacja Zdrowotna Dr Hanka Delbani

Edukacja Zdrowotna Dr Hanka Delbani Невротикалық бұзылулардың психогигенасы мен психопрофилактикасы

Невротикалық бұзылулардың психогигенасы мен психопрофилактикасы