Содержание

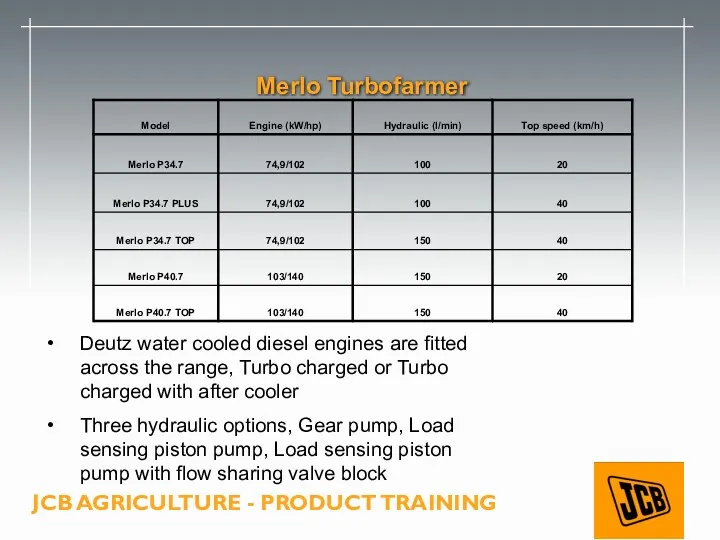

- 2. Merlo Turbofarmer Deutz water cooled diesel engines are fitted across the range, Turbo charged or Turbo

- 3. Merlo Turbofarmer

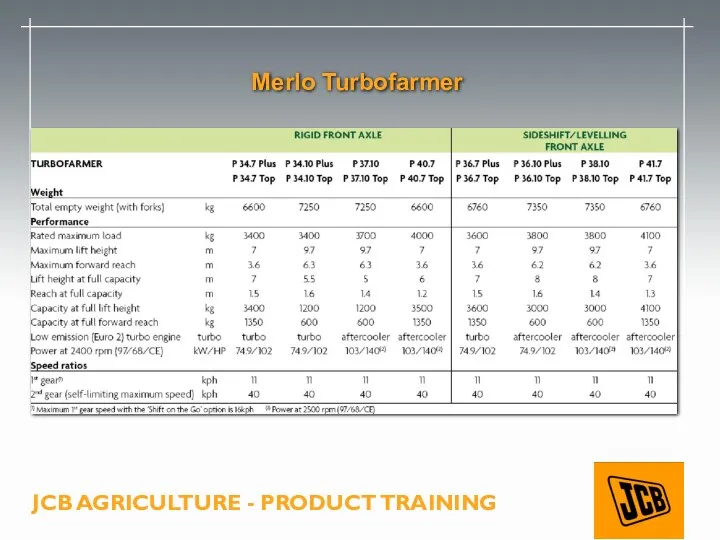

- 4. Merlo Turbofarmer Fixed axle Sideshift/leveling front axle

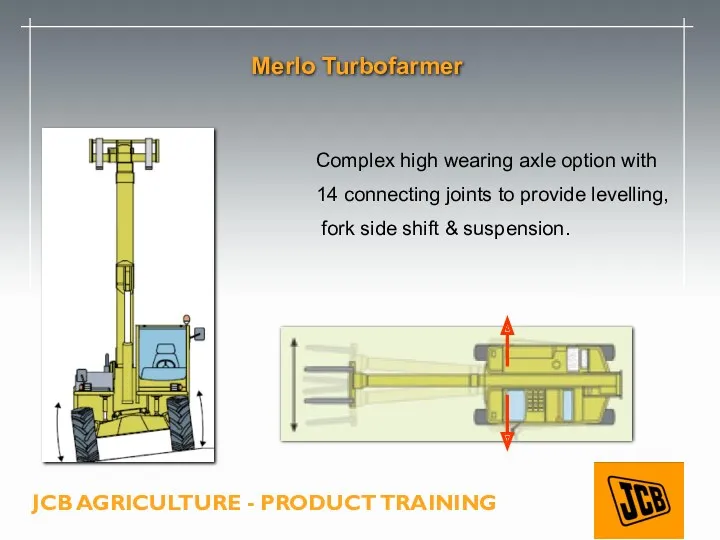

- 5. Merlo Turbofarmer Complex high wearing axle option with 14 connecting joints to provide levelling, fork side

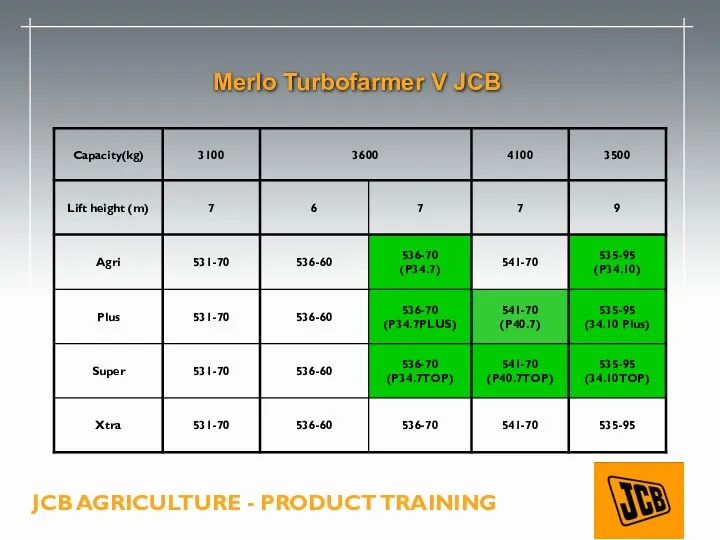

- 6. Merlo Turbofarmer V JCB

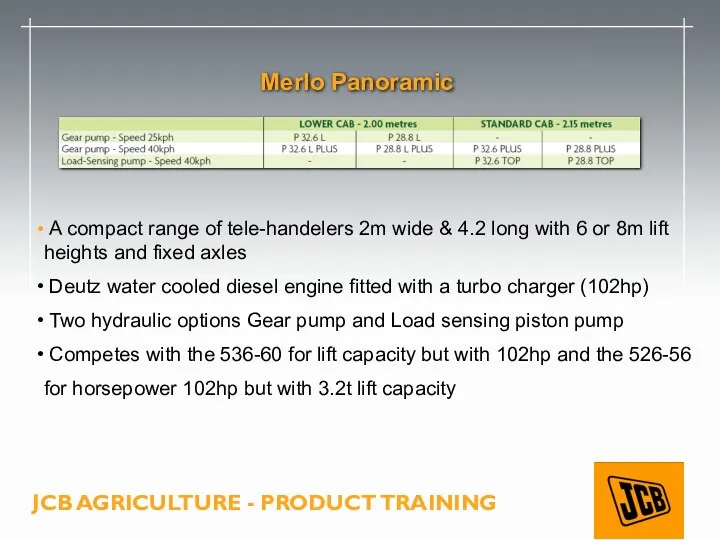

- 7. Merlo Panoramic

- 8. Merlo Panoramic A compact range of tele-handelers 2m wide & 4.2 long with 6 or 8m

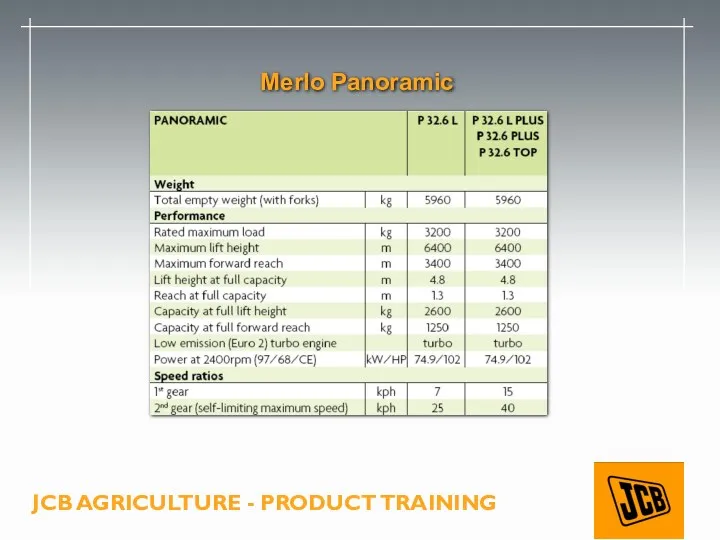

- 9. Merlo Panoramic

- 10. JCB LOADALL ADVANTAGES OVER MERLO

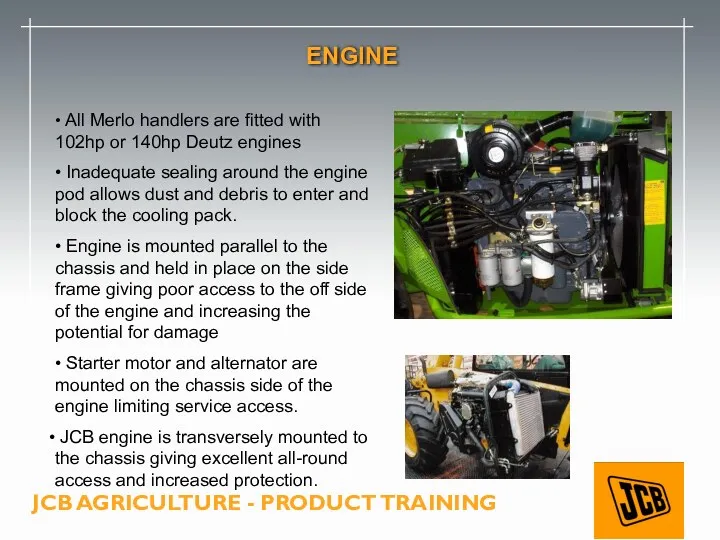

- 11. ENGINE • All Merlo handlers are fitted with 102hp or 140hp Deutz engines • Inadequate sealing

- 12. COOLING Belt driven cooling fans with no factory reverse option V’s hydraulically driven cooling fan

- 13. COOLING Small dense cooling pack protected by fine mesh chaff guard with belt driven fan which

- 14. COOLING Large chaff guarded area for maximum cooling performance Small chaff guarded area limits cooling efficiency

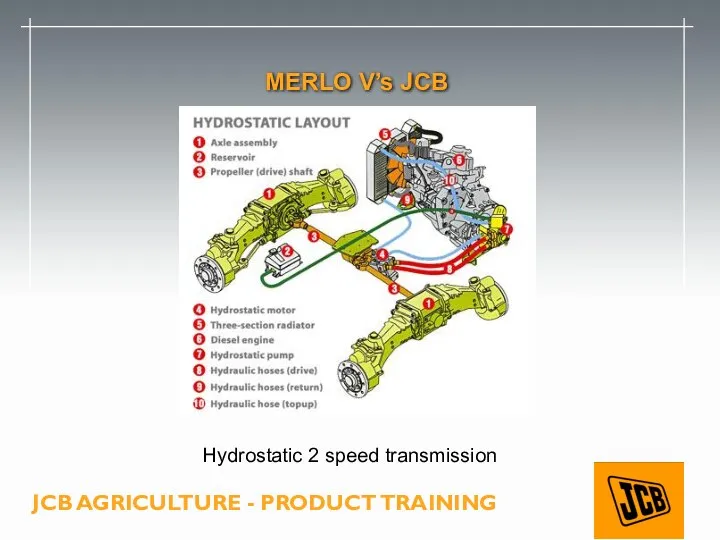

- 15. MERLO V’s JCB Hydrostatic 2 speed transmission

- 16. MERLO V’s JCB Torque converter 6/4 powershift transmission with toque lock

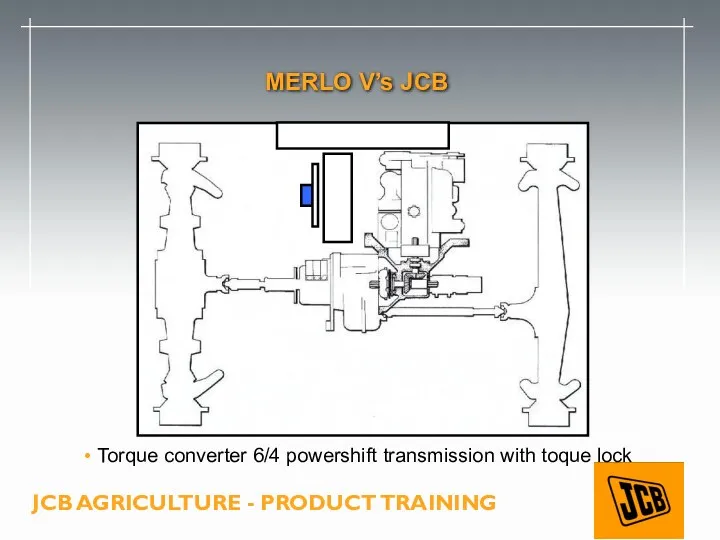

- 17. TRANSMISSION Hydrostatic transmissions are renowned for getting hot, particularly in continuous cycle applications like silage clamping,

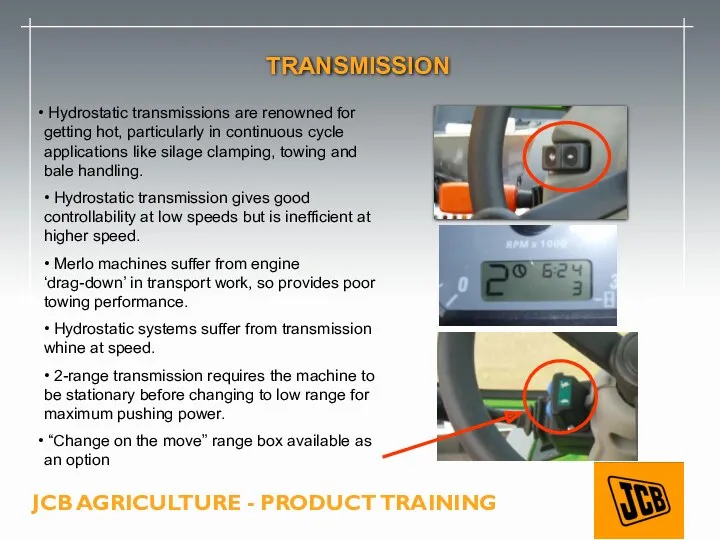

- 18. TRANSMISSION Potentiometer speed adjustment Hand throttle Electric park brake Over load cut out switch

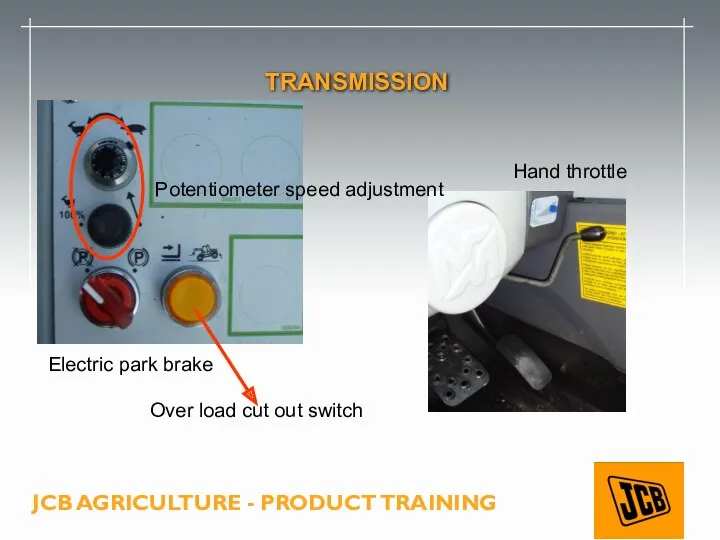

- 19. AXLES 6 & 7 metre machines still use portal hubs with nylon ‘cups’ Exposed axle cavities

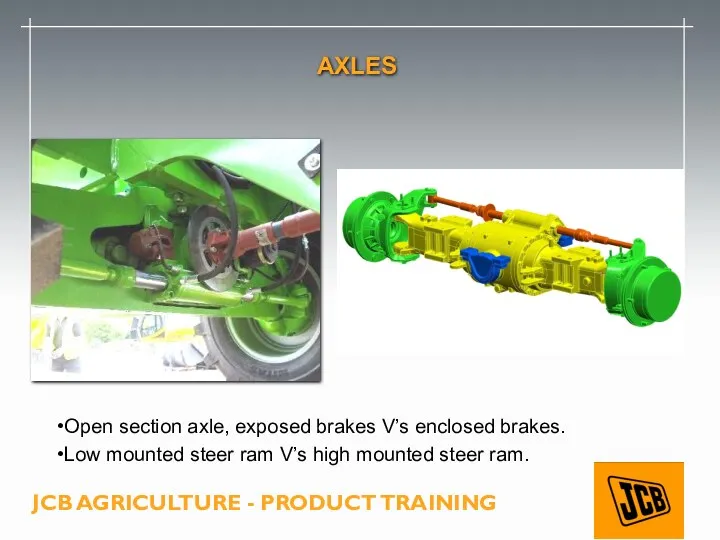

- 20. AXLES Open section axle, exposed brakes V’s enclosed brakes. Low mounted steer ram V’s high mounted

- 21. TYRES JCB: Standard: Michelin 445/70R24 151G Merlo: Standard: Mitas 405/70-24 152B

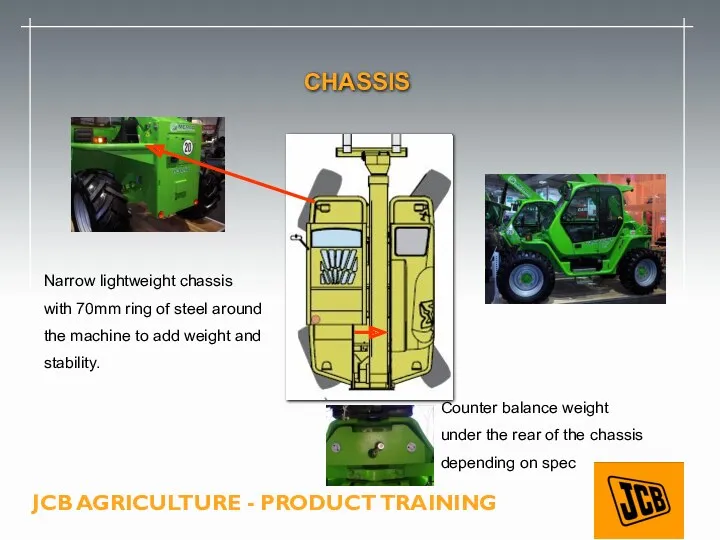

- 22. CHASSIS Narrow lightweight chassis with 70mm ring of steel around the machine to add weight and

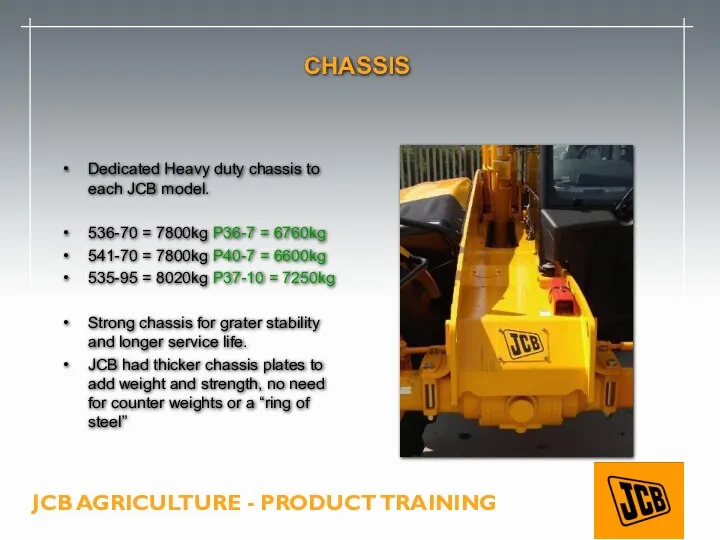

- 23. CHASSIS Dedicated Heavy duty chassis to each JCB model. 536-70 = 7800kg P36-7 = 6760kg 541-70

- 24. CHASSIS JCB hitch is better protected and gives greater ground clearance

- 25. BOOM Offset mounted rams V’s centrally mounted to reduce twisting and stress.

- 26. BOOM Wet grease on boom V’s JCB Waxoyl dry lubricant. 50 hours grease intervals V’s 500

- 27. BOOM Welded boom nose in high stress area V’s continuous side and base plate.

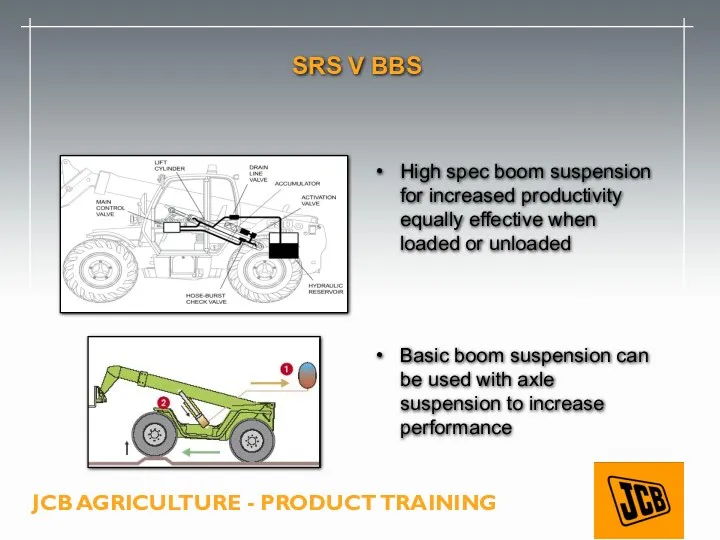

- 28. SRS V BBS High spec boom suspension for increased productivity equally effective when loaded or unloaded

- 29. CARRIAGE Lift, crowd and compensation rams are all offset, imposing twisting forces on the boom and

- 30. CARRIAGE

- 31. CARRIAGE Offset carriage & ram mounting increases stress V’s centrally mounted carriage and ram.

- 32. HYDRAULICS Behind cab hydraulic tank increases cab temperature V’s mounted tank integrally within chassis which improves

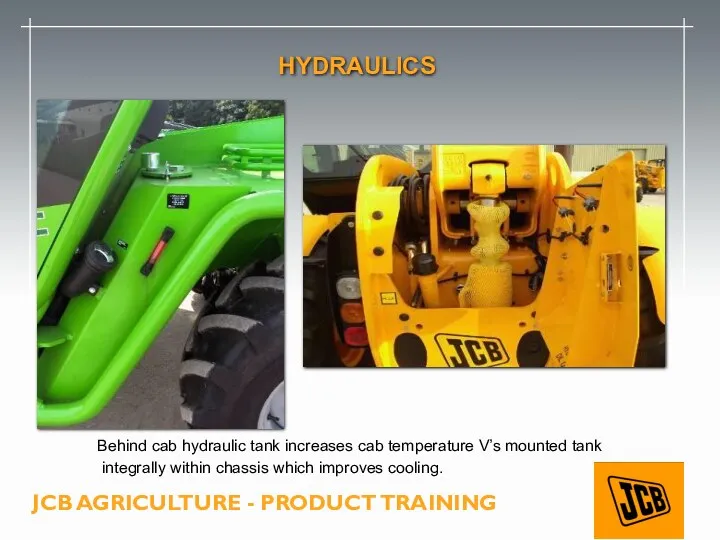

- 33. CAB • Poor grab handles and narrow door way make access difficult Large modern cab with

- 34. CAB Wide door access and longer cab with improved leg room

- 35. CAB Limited access to the floor pedals due to the wheel arch Large floor area with

- 36. CAB Dated lay out V’s Modern automotive design.

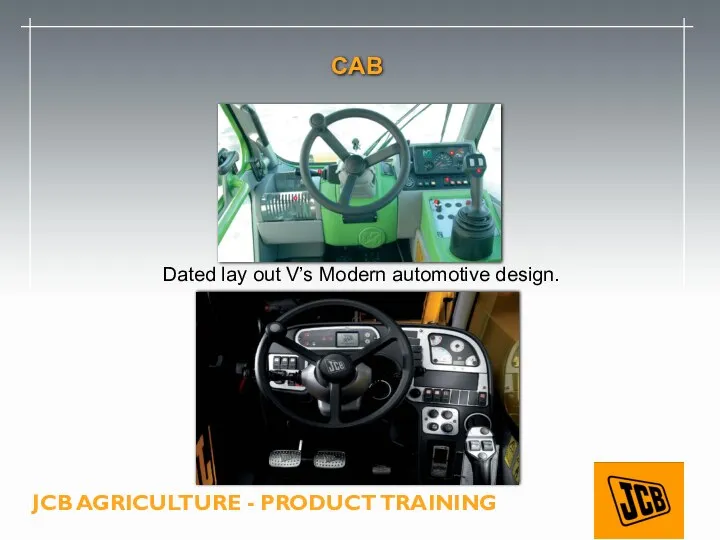

- 37. CAB Merlo cab interior looks exceptionally basic and sparse in comparisons to JCB ‘automotive style’ cab

- 38. LMI Dash mounted LMI V’s cab pillar, in line of sight mounted. Non progressive LMI V’s

- 39. CAB Poor visibility to the front carriage due to the ring of steel when fully retracted

- 40. CAB Fixed rear fender V’s rotates with wheel for increased visibility.

- 42. Скачать презентацию

Тест по информатике

Тест по информатике Применение свай при строительстве в вечной мерзлоте

Применение свай при строительстве в вечной мерзлоте презентация к уроку литературного краеведения по изучению творчества Бехтерева

презентация к уроку литературного краеведения по изучению творчества Бехтерева Применение Вооруженных Сил Российской Федерации в борьбе с терроризмом

Применение Вооруженных Сил Российской Федерации в борьбе с терроризмом Внутреннее устройство компьютера

Внутреннее устройство компьютера Где находится/ находятся …?

Где находится/ находятся …? Көкөністер мен жемістердің пестицидтермен, нитраттармен және ГМО-мен ластануы

Көкөністер мен жемістердің пестицидтермен, нитраттармен және ГМО-мен ластануы Шаблон презентации Лето

Шаблон презентации Лето Рождественский сочельник

Рождественский сочельник Наладка шлифовальных станков

Наладка шлифовальных станков социализация личности и откл поведение

социализация личности и откл поведение Принцип метода ЭКГ. Показания. Отведения. Нормальная ЭКГ. Электрическая ось сердца

Принцип метода ЭКГ. Показания. Отведения. Нормальная ЭКГ. Электрическая ось сердца Картотека загадок по лексической теме Дикие животные

Картотека загадок по лексической теме Дикие животные Декоративный рисунок. 4 класс

Декоративный рисунок. 4 класс Аппликация Павлин.

Аппликация Павлин. урок 13.04

урок 13.04 Возникновение и распад империи Карла Великого

Возникновение и распад империи Карла Великого Электронда есептеуіш машиналардың кезеңдері. ДК сәулетінің замануи даму бағыттары

Электронда есептеуіш машиналардың кезеңдері. ДК сәулетінің замануи даму бағыттары Лувр – палац-музей з світовим ім'ям

Лувр – палац-музей з світовим ім'ям Человек на войне 7 класс ИЗО

Человек на войне 7 класс ИЗО Актуальность. Примеры формулировок

Актуальность. Примеры формулировок Предварительно-напряженные листовые металлические конструкции

Предварительно-напряженные листовые металлические конструкции Презентация к уроку истории Путешествие в средневековый город

Презентация к уроку истории Путешествие в средневековый город Рабочее время

Рабочее время Межкультурная коммуникация. Формы коммуникации при межкультурном взаимодействии

Межкультурная коммуникация. Формы коммуникации при межкультурном взаимодействии Общественный строй Древней Руси

Общественный строй Древней Руси Операторы и выражения

Операторы и выражения Сечение. Фигура сечения на чертеже

Сечение. Фигура сечения на чертеже