Содержание

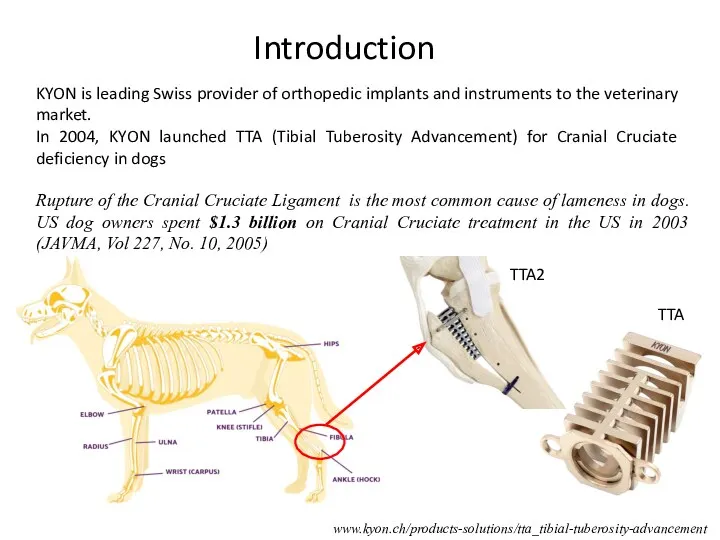

- 2. Introduction Rupture of the Cranial Cruciate Ligament is the most common cause of lameness in dogs.

- 3. Motivation 1st generation of KYON TTA is in CP-4 Titanium. Advantages of using a Mg-alloy (MgAl3Zn1

- 4. Motivation www.biotronik.com/en-de/products/coronary/magmaris Magnezix® screw from Syntelllix

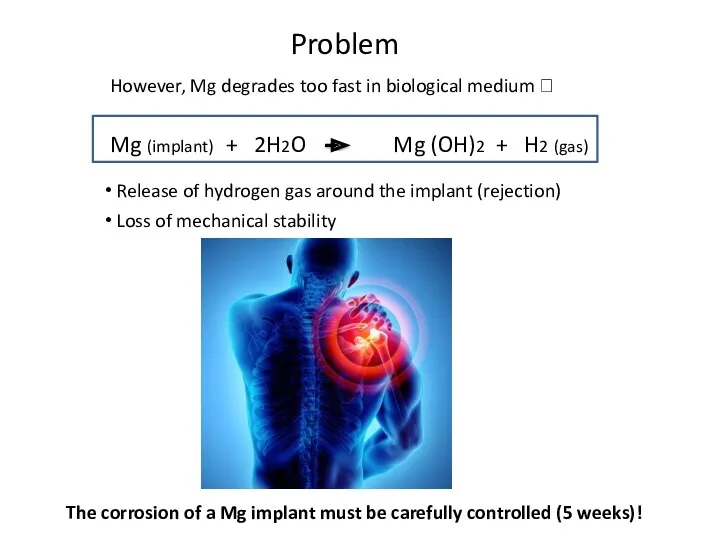

- 5. Problem However, Mg degrades too fast in biological medium ? The corrosion of a Mg implant

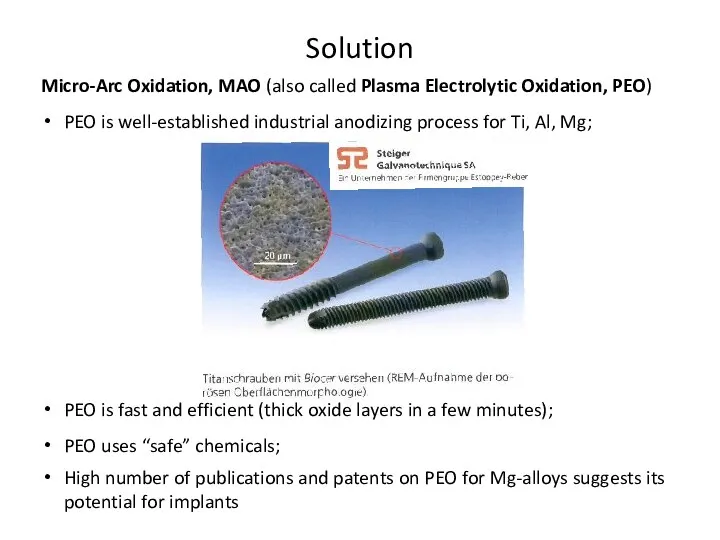

- 6. Solution

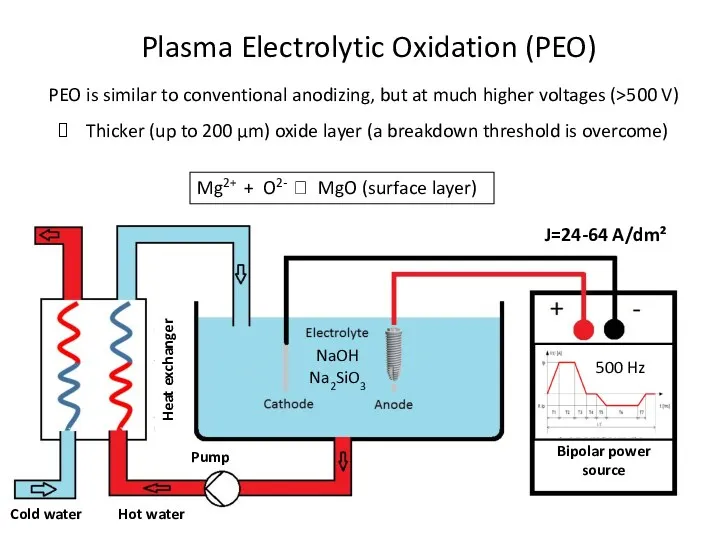

- 7. Plasma Electrolytic Oxidation (PEO) PEO is similar to conventional anodizing, but at much higher voltages (>500

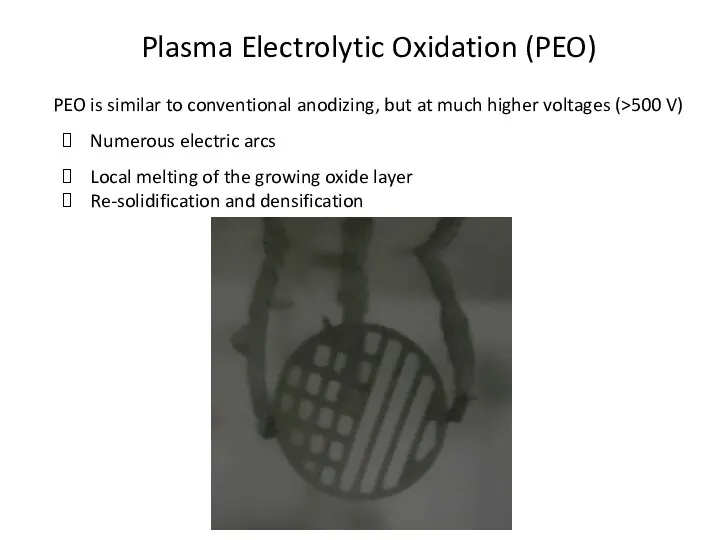

- 8. Plasma Electrolytic Oxidation (PEO) PEO is similar to conventional anodizing, but at much higher voltages (>500

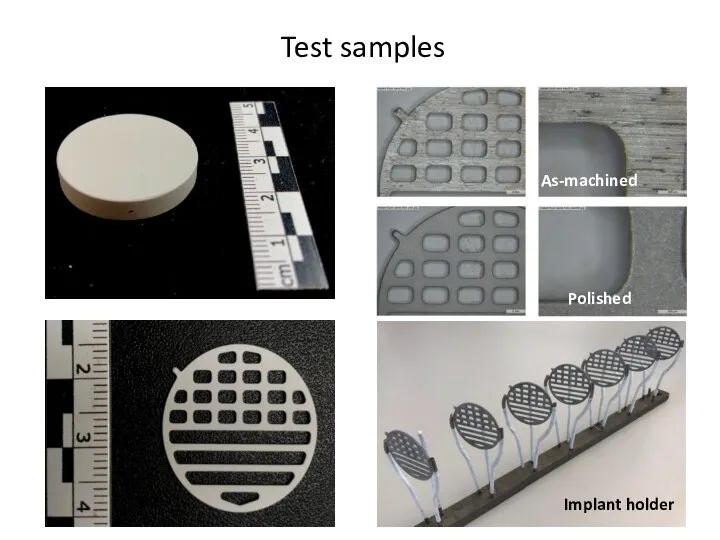

- 9. Test samples Implant holder

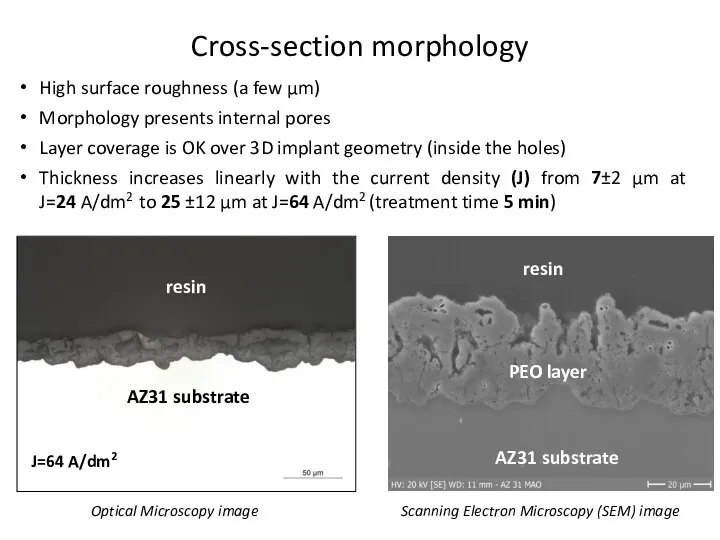

- 10. Cross-section morphology High surface roughness (a few µm) Morphology presents internal pores Layer coverage is OK

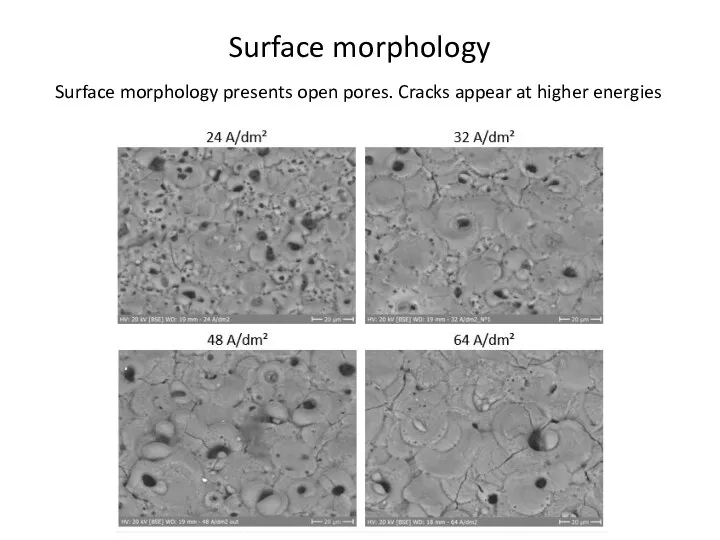

- 11. Surface morphology Surface morphology presents open pores. Cracks appear at higher energies

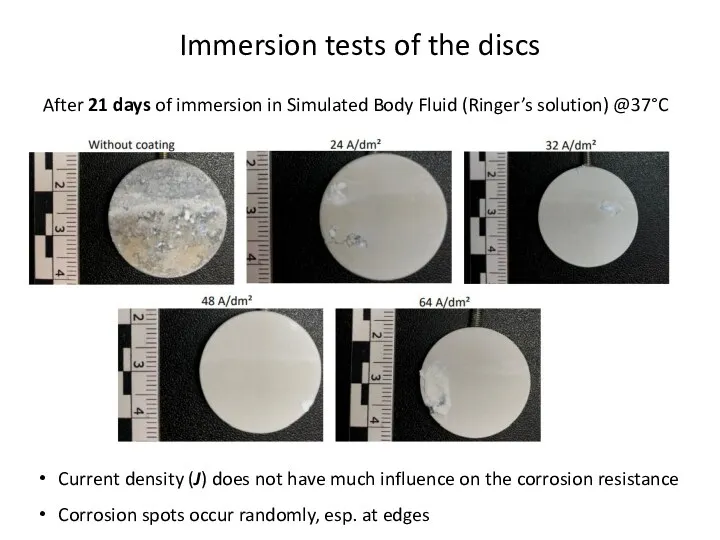

- 12. Immersion tests of the discs After 21 days of immersion in Simulated Body Fluid (Ringer’s solution)

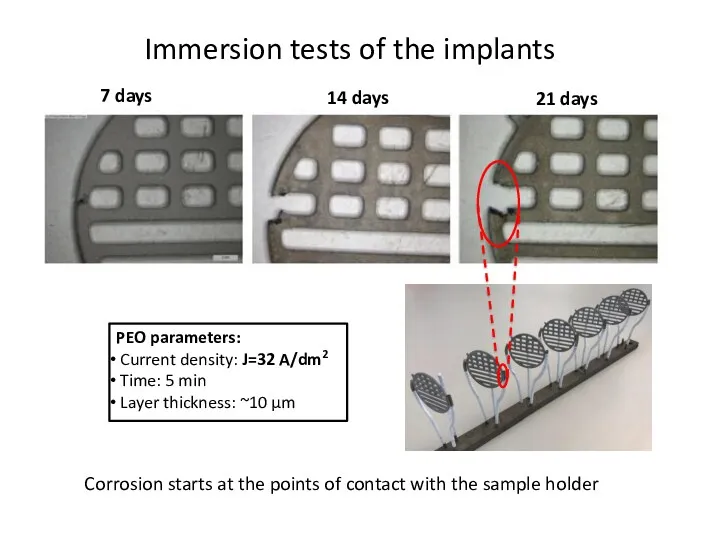

- 13. Immersion tests of the implants

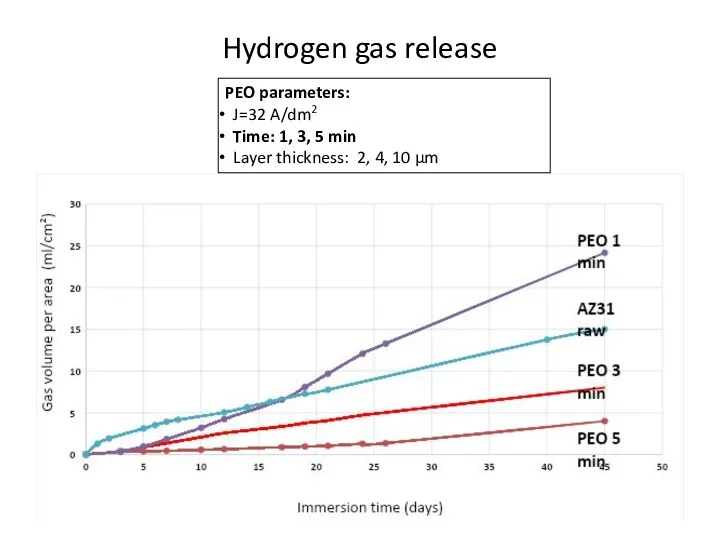

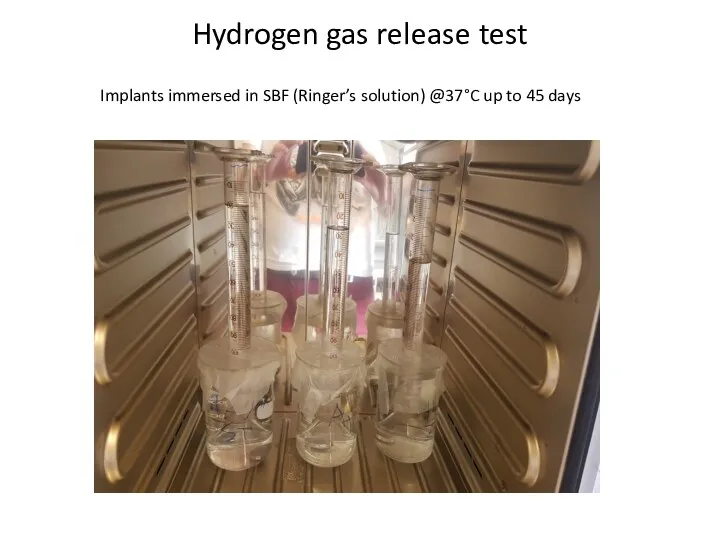

- 14. Hydrogen gas release PEO parameters: J=32 A/dm2 Time: 1, 3, 5 min Layer thickness: 2, 4,

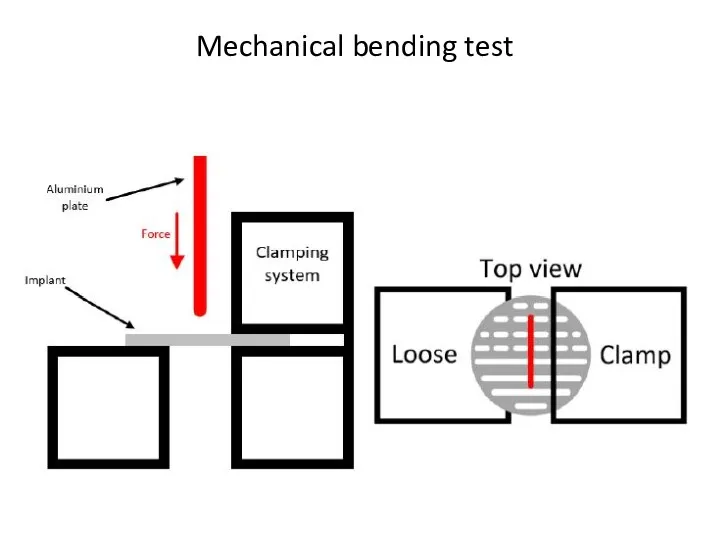

- 15. Mechanical bending test

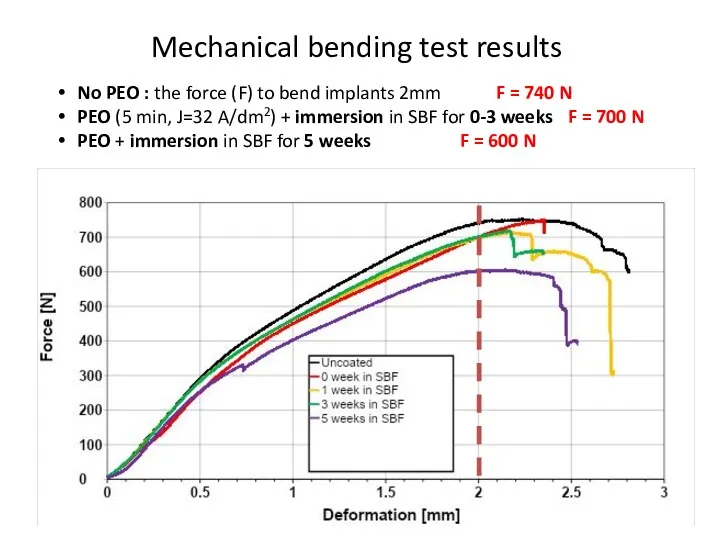

- 16. Mechanical bending test results No PEO : the force (F) to bend implants 2mm F =

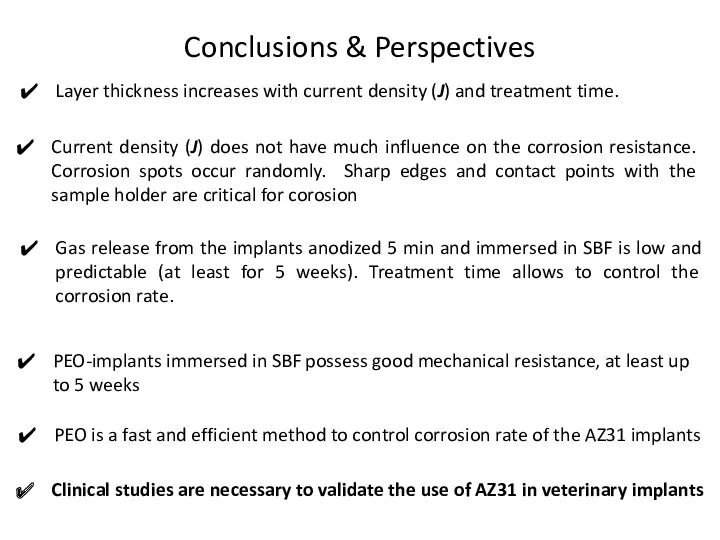

- 17. Conclusions & Perspectives Layer thickness increases with current density (J) and treatment time. Current density (J)

- 18. The END

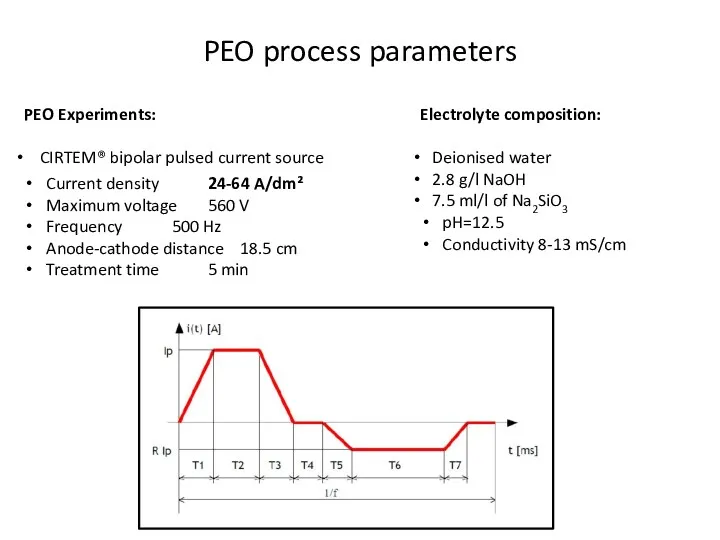

- 19. PEO process parameters Current density 24-64 A/dm² Maximum voltage 560 V Frequency 500 Hz Anode-cathode distance

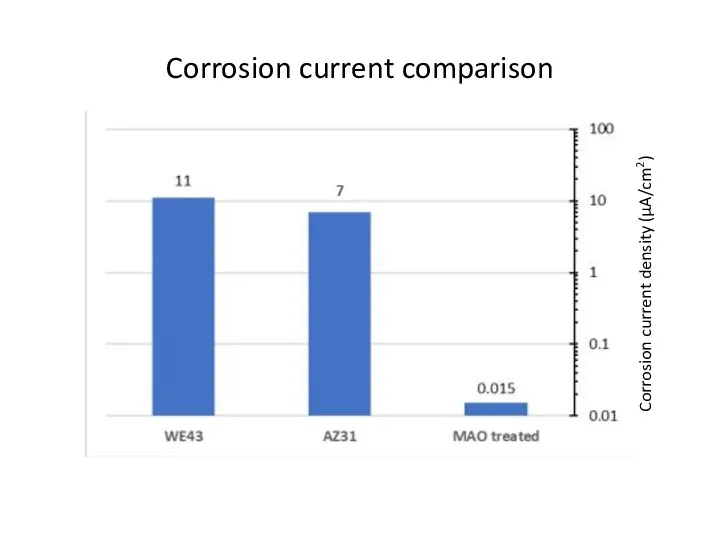

- 20. Corrosion current comparison Corrosion current density (µA/cm2)

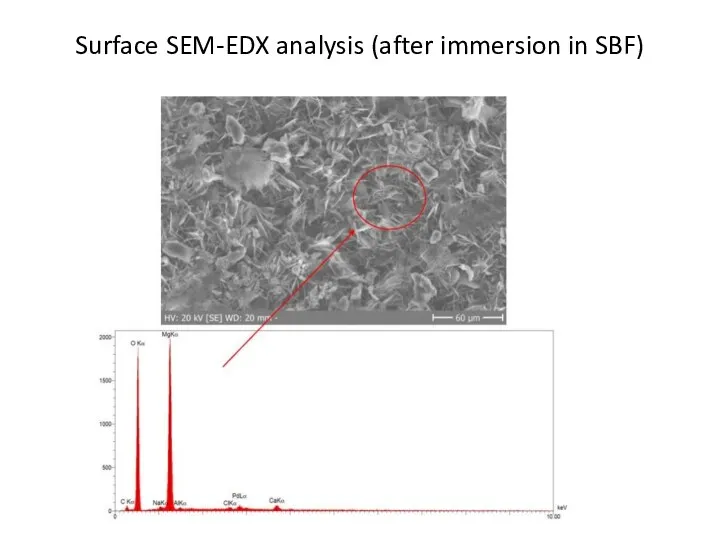

- 21. Surface SEM-EDX analysis (after immersion in SBF)

- 22. Hydrogen gas release test Implants immersed in SBF (Ringer’s solution) @37°C up to 45 days

- 24. Скачать презентацию

Основы микроэлектроники

Основы микроэлектроники Первая помощь при черепно-мозговой травме, травме груди, травме живота, при травме в области таза, при повреждениях позвоночника

Первая помощь при черепно-мозговой травме, травме груди, травме живота, при травме в области таза, при повреждениях позвоночника Презентация к внеклассному мероприятию Мисс математика

Презентация к внеклассному мероприятию Мисс математика Фирма в теории организации рынков

Фирма в теории организации рынков Поражение нервной системы при ВИЧ инфекции

Поражение нервной системы при ВИЧ инфекции Онкогенные вирусы

Онкогенные вирусы Трудовое воспитание детей

Трудовое воспитание детей Обработка конических поверхностей

Обработка конических поверхностей презентация урока-практикума по темеБелки в 10 классе

презентация урока-практикума по темеБелки в 10 классе Image comparison

Image comparison Cтрессовые расстройства в стоматологии (Дентофобия)

Cтрессовые расстройства в стоматологии (Дентофобия) Law of person

Law of person Проект Дорожная азбука Диск

Проект Дорожная азбука Диск Let’s play ball with the future play

Let’s play ball with the future play Финансовое управление администрации МОГО Ухта

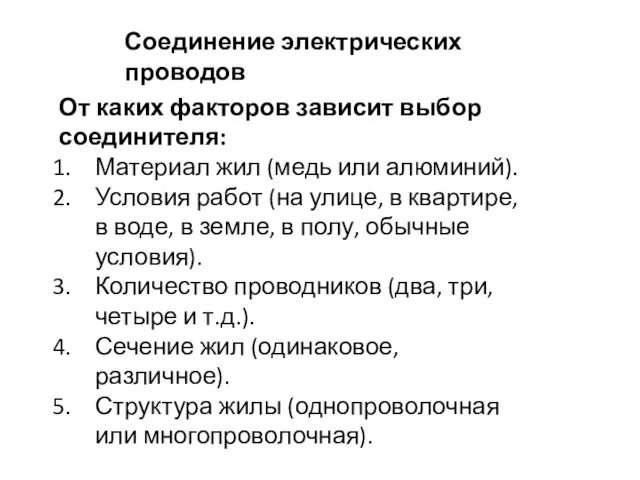

Финансовое управление администрации МОГО Ухта Соединение проводов и жил кабелей

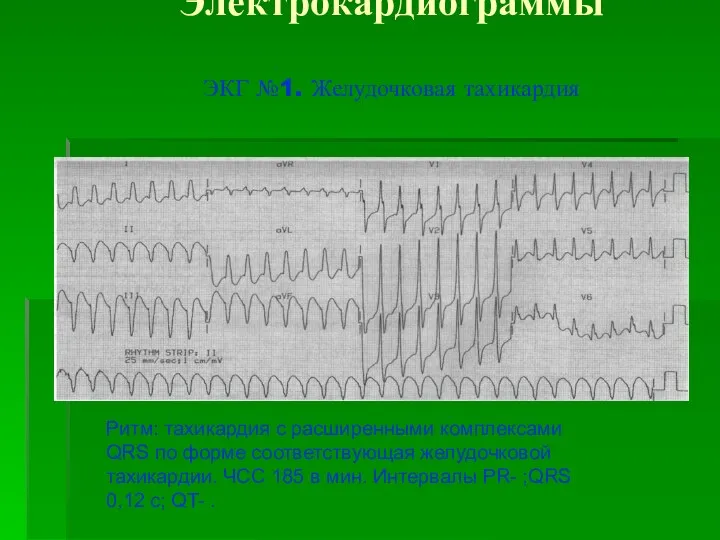

Соединение проводов и жил кабелей ЭКГ при аритмиях

ЭКГ при аритмиях Презентация Мой друг ВЕЛОСИПЕД

Презентация Мой друг ВЕЛОСИПЕД Среды обитания организмов

Среды обитания организмов Общие сведения по холодному и горячему водоснабжению. Системы и схемы водопроводов (Тема 1)

Общие сведения по холодному и горячему водоснабжению. Системы и схемы водопроводов (Тема 1) Санкт-Петербургская городская Масленица

Санкт-Петербургская городская Масленица Математический анализ

Математический анализ Отрезок. Длина отрезка. Прямая. Луч. 5 класс

Отрезок. Длина отрезка. Прямая. Луч. 5 класс Ученый и врач Владимир Михайлович Бехтерев

Ученый и врач Владимир Михайлович Бехтерев Изготовление домашнего халата

Изготовление домашнего халата Урок по природоведению на тему Почва

Урок по природоведению на тему Почва Кемеровская область

Кемеровская область Приемы фантазирования в коммуникативной деятельности и ознакомлении с художественной литературой старших дошкольников.

Приемы фантазирования в коммуникативной деятельности и ознакомлении с художественной литературой старших дошкольников.