Содержание

- 2. Two Dominant Microsystems Fabrication Technologies Surface Micromachining Bulk Micromachining Robert Bosch GmbH Sandia National Laboratories IBM

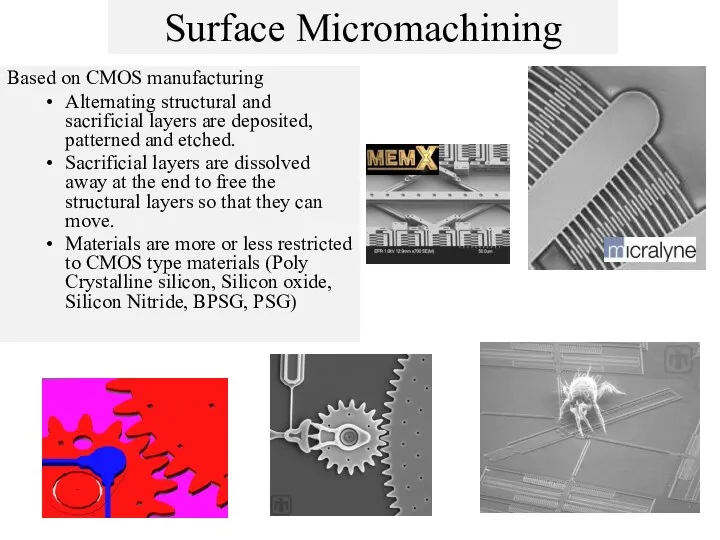

- 3. Surface Micromachining Based on CMOS manufacturing Alternating structural and sacrificial layers are deposited, patterned and etched.

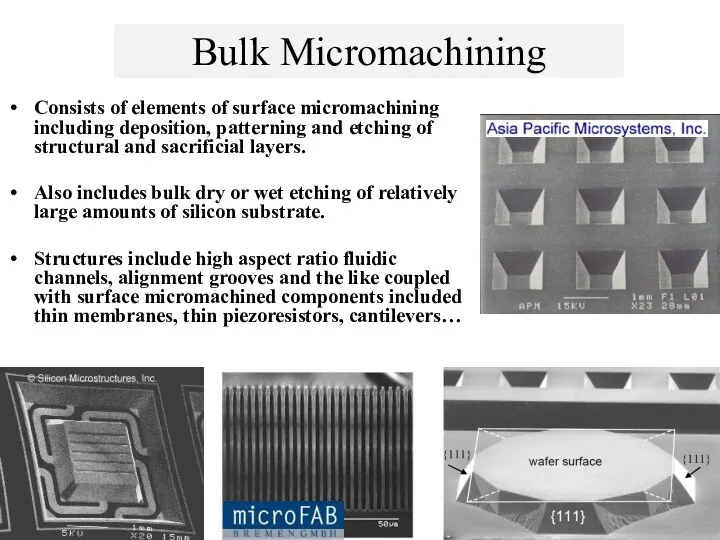

- 4. Bulk Micromachining Consists of elements of surface micromachining including deposition, patterning and etching of structural and

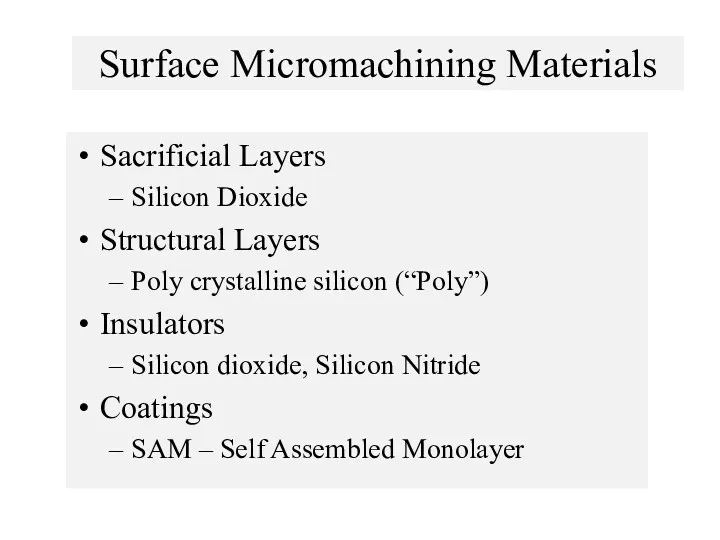

- 5. Surface Micromachining Materials Sacrificial Layers Silicon Dioxide Structural Layers Poly crystalline silicon (“Poly”) Insulators Silicon dioxide,

- 6. Surface Micromachining Process Outline Obtain Silicon Crystal Wafers Deposit (or grow) thin film material Pattern (Photo

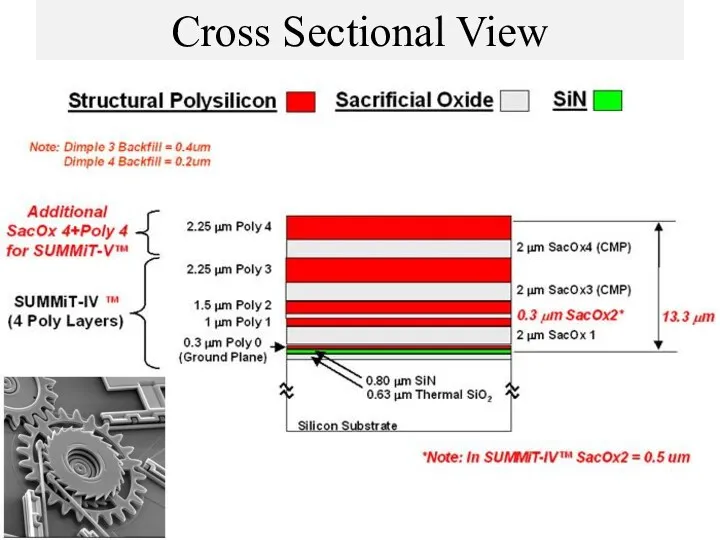

- 7. Cross Sectional View

- 8. Surface Micromachining Process Start with a Silicon Crystal Substrate Slice and Polish to create wafers Ingot

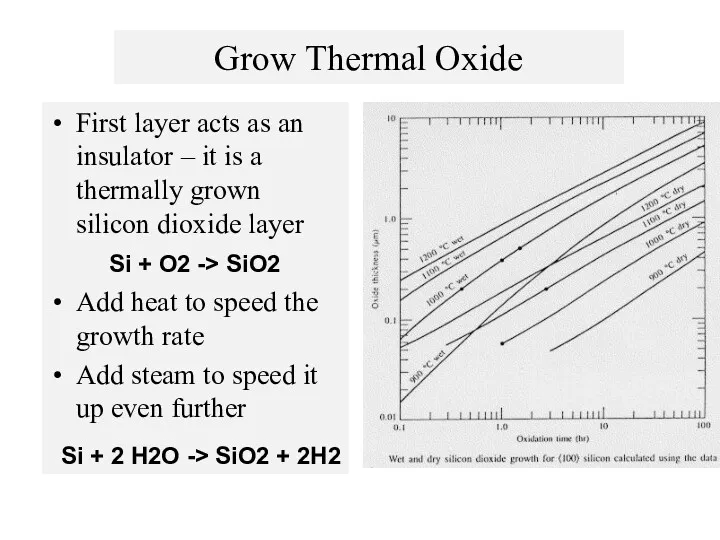

- 9. Grow Thermal Oxide First layer acts as an insulator – it is a thermally grown silicon

- 10. MEMS deposition technology can be classified in two groups: Depositions that happen because of a chemical

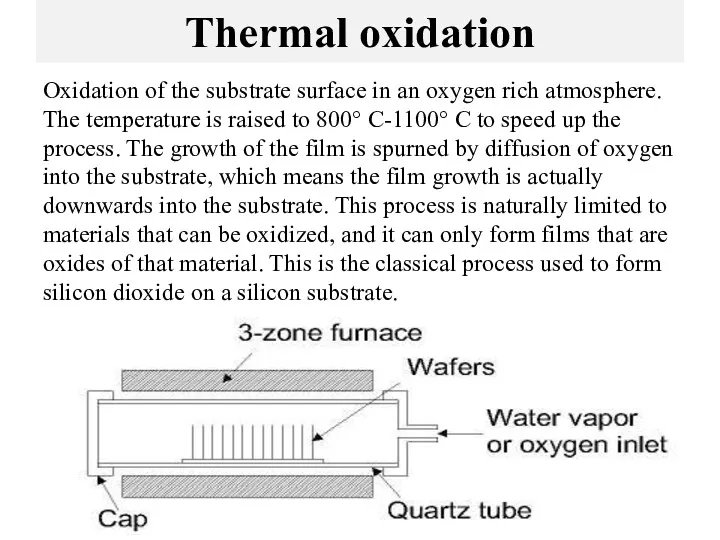

- 11. Thermal oxidation Oxidation of the substrate surface in an oxygen rich atmosphere. The temperature is raised

- 12. Evaporation In evaporation the substrate is placed inside a vacuum chamber, in which a block (source)

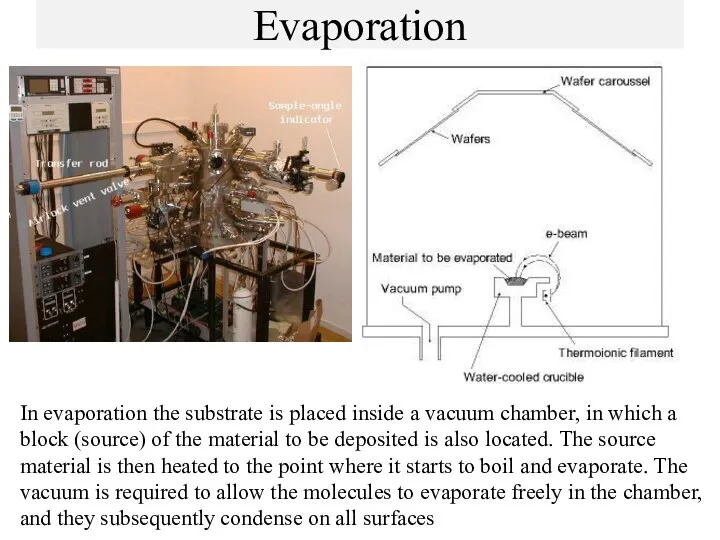

- 13. Sputtering The substrate is placed in a vacuum chamber with the source material, named a target,

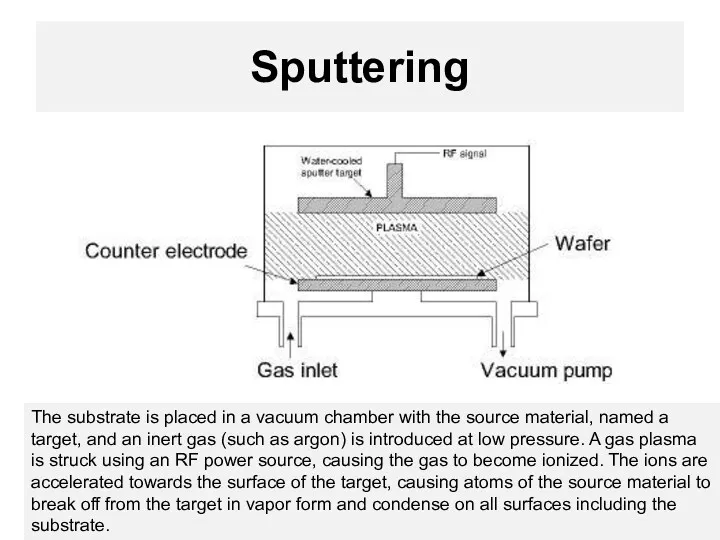

- 14. Casting In this process the material to be deposited is dissolved in liquid form in a

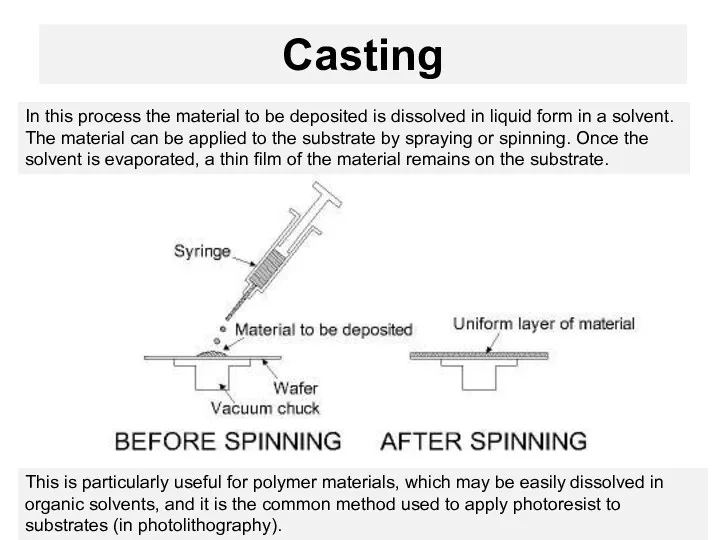

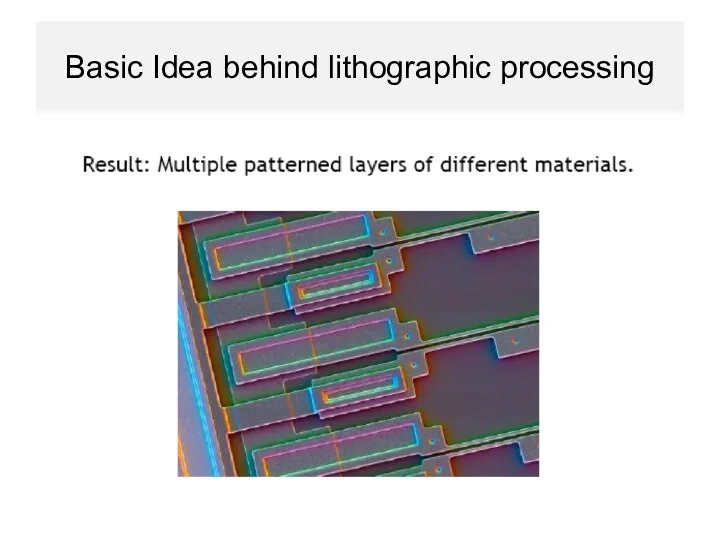

- 15. Basic Idea behind lithographic processing

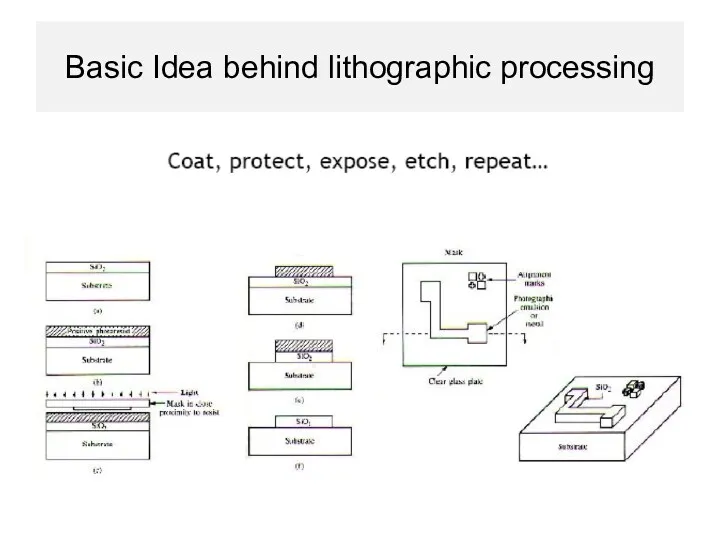

- 16. Basic Idea behind lithographic processing

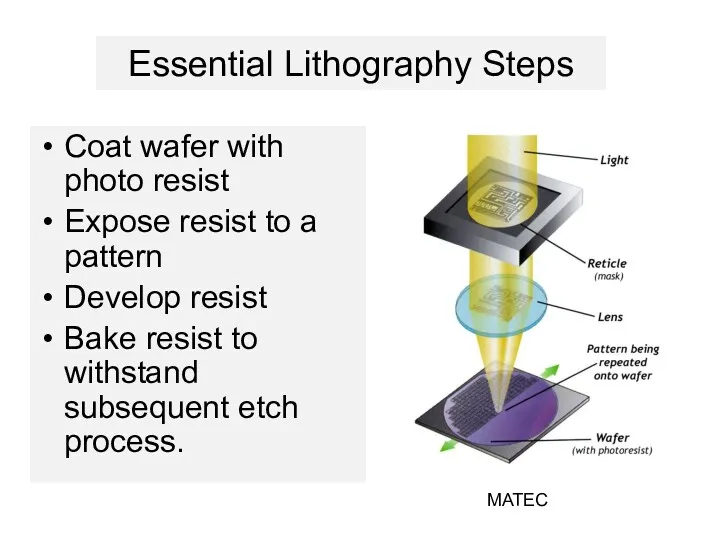

- 17. Essential Lithography Steps Coat wafer with photo resist Expose resist to a pattern Develop resist Bake

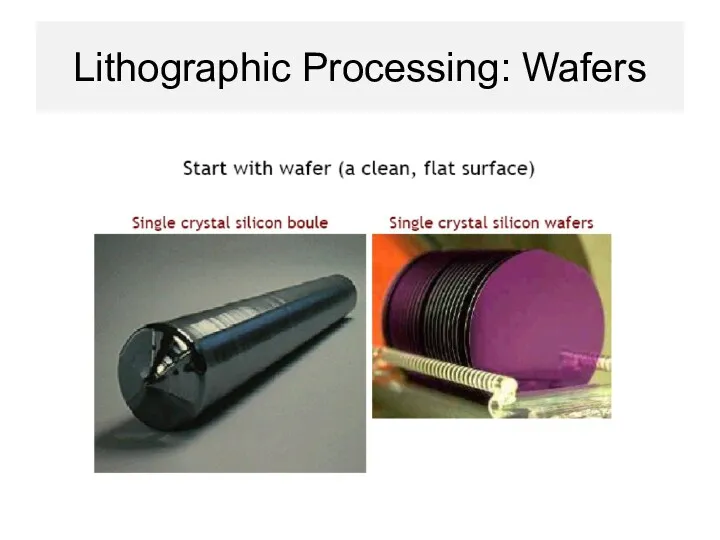

- 18. Lithographic Processing: Wafers

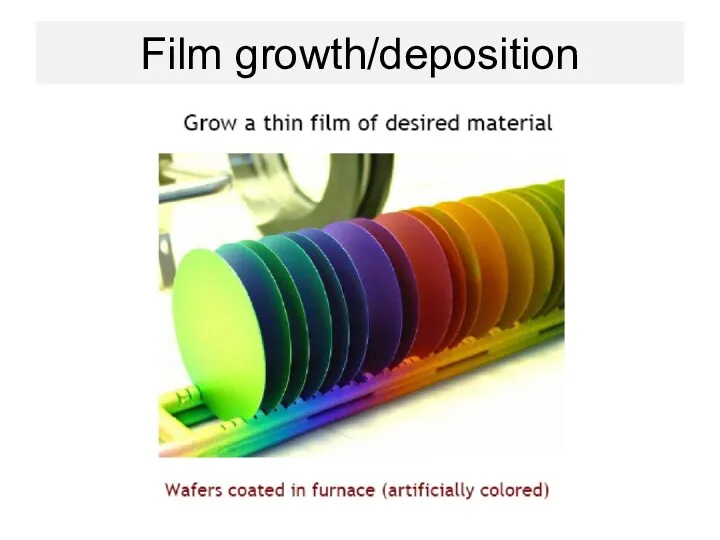

- 19. Film growth/deposition

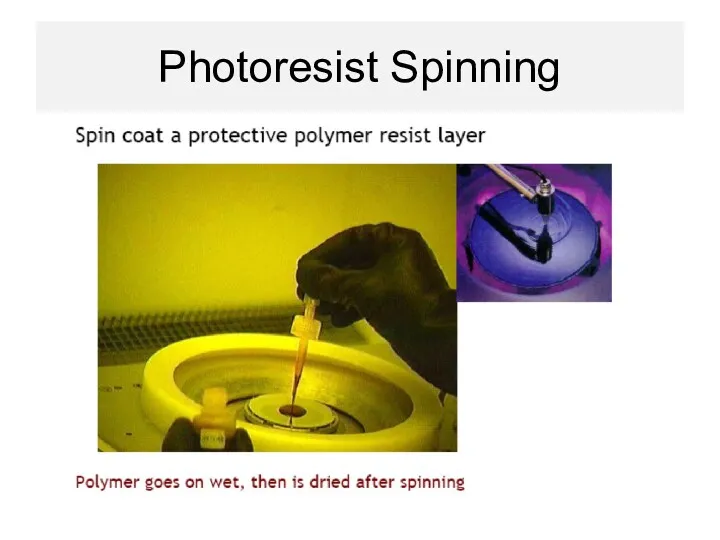

- 20. Photoresist Spinning

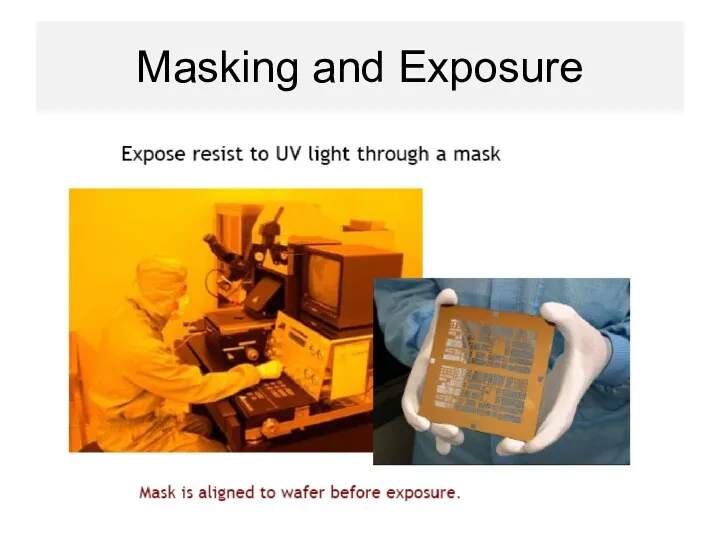

- 21. Masking and Exposure

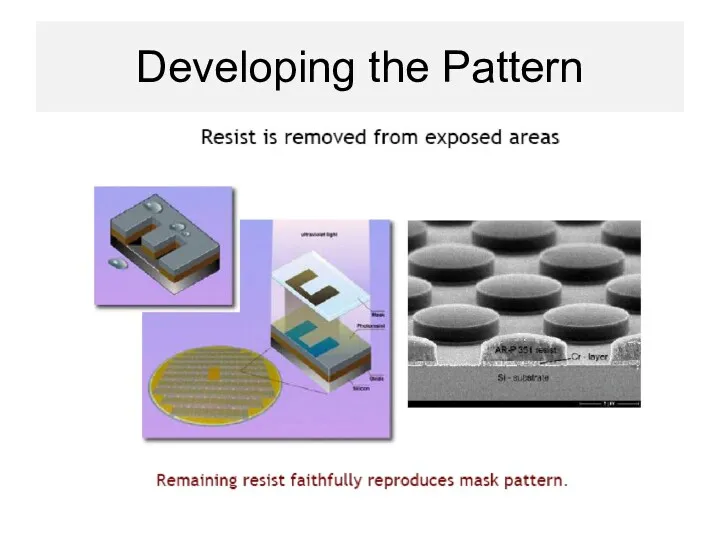

- 22. Developing the Pattern

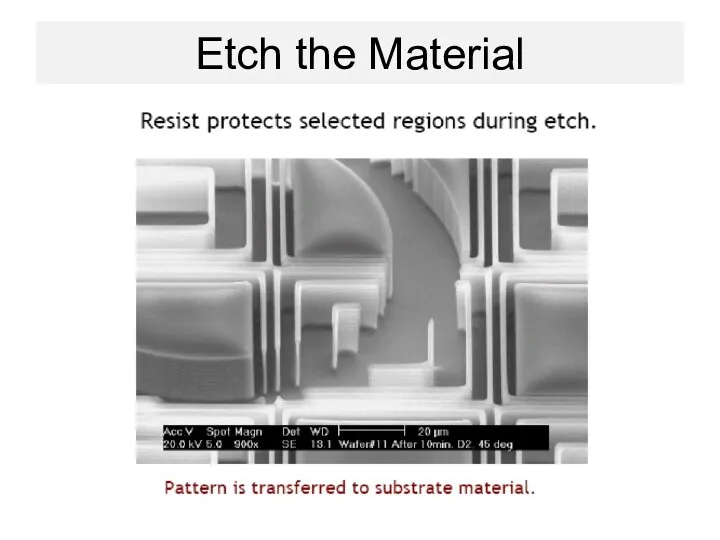

- 23. Etch the Material

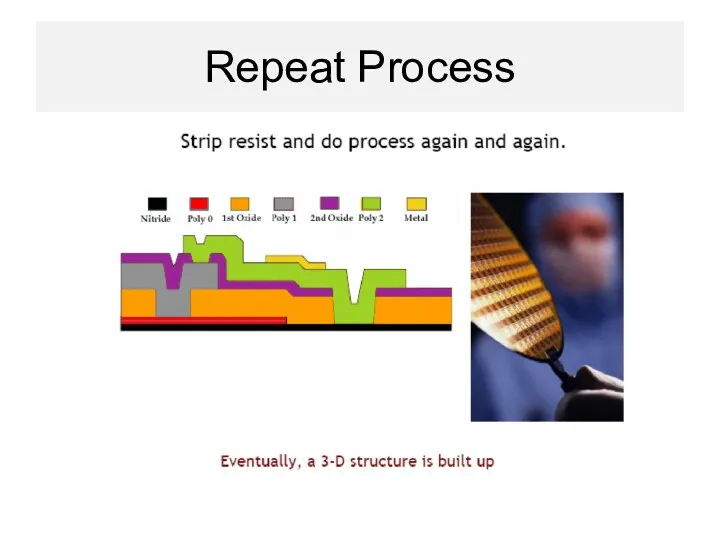

- 24. Repeat Process

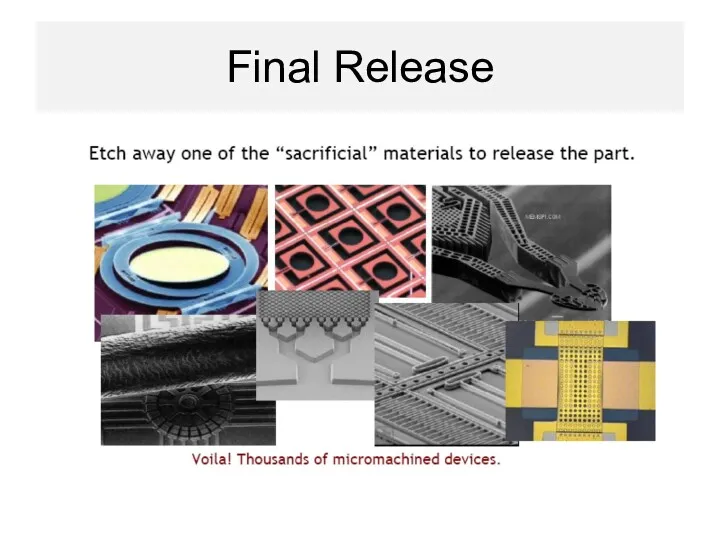

- 25. Final Release

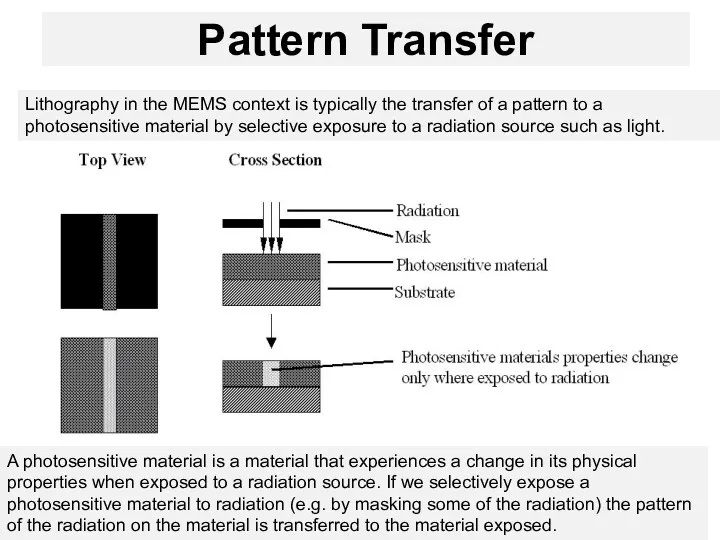

- 26. Pattern Transfer Lithography in the MEMS context is typically the transfer of a pattern to a

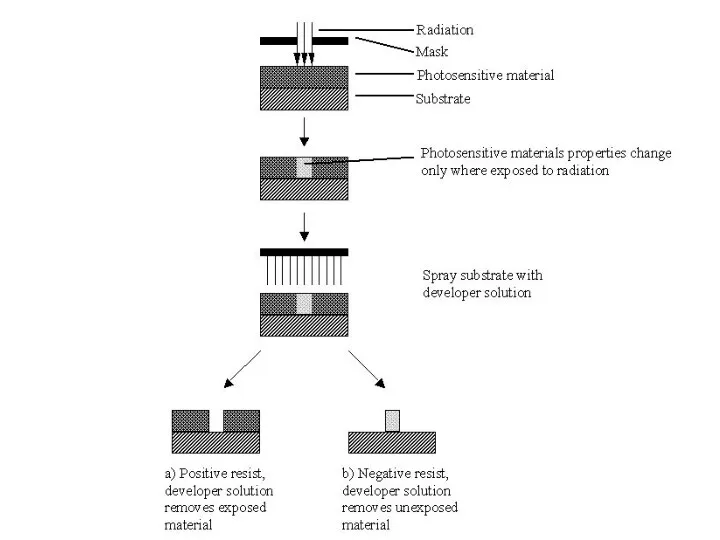

- 27. Resist When resist is exposed to a radiation source of a specific a wavelength, the chemical

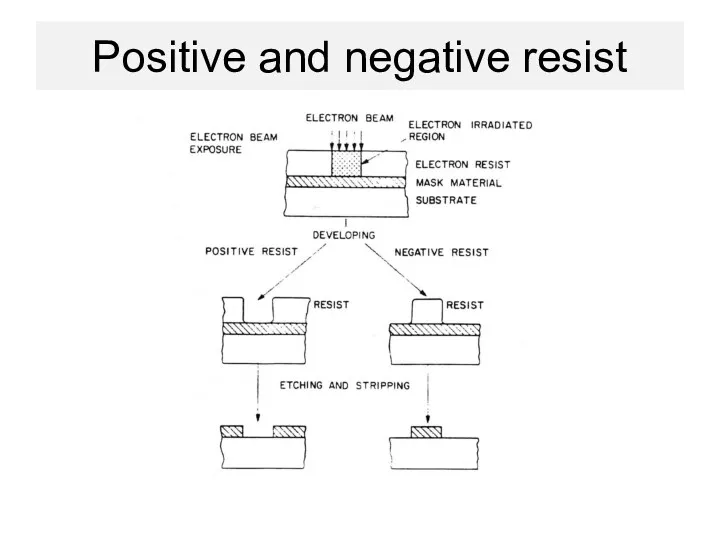

- 29. Positive and negative resist

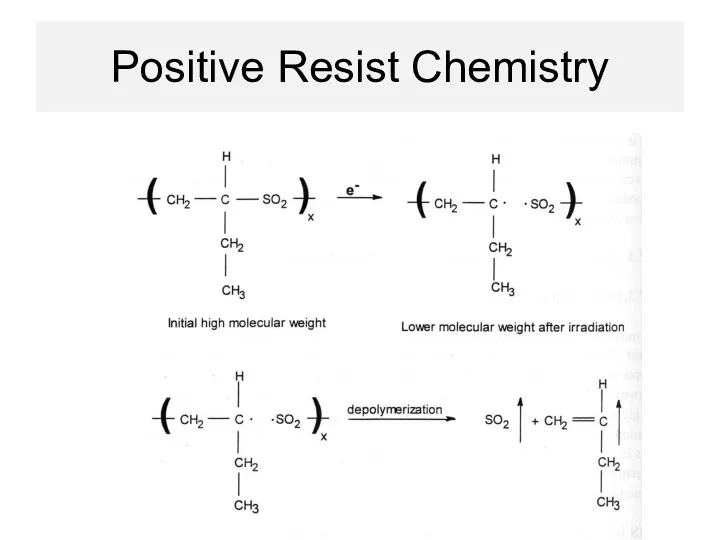

- 30. Positive Resist Chemistry

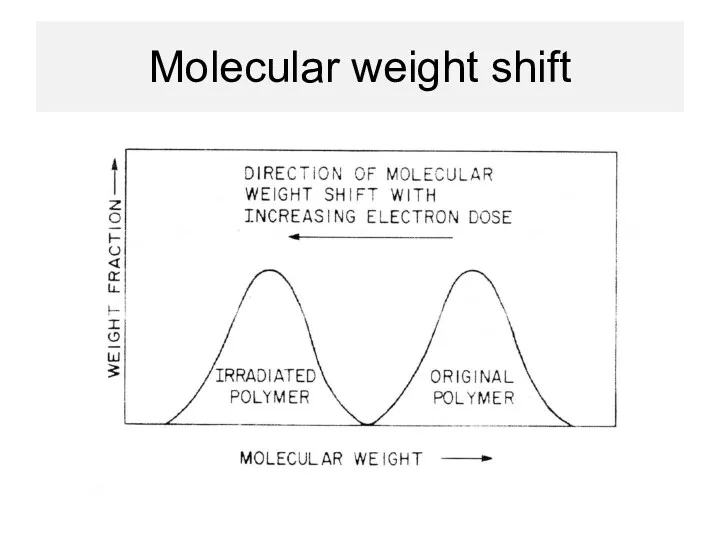

- 31. Molecular weight shift

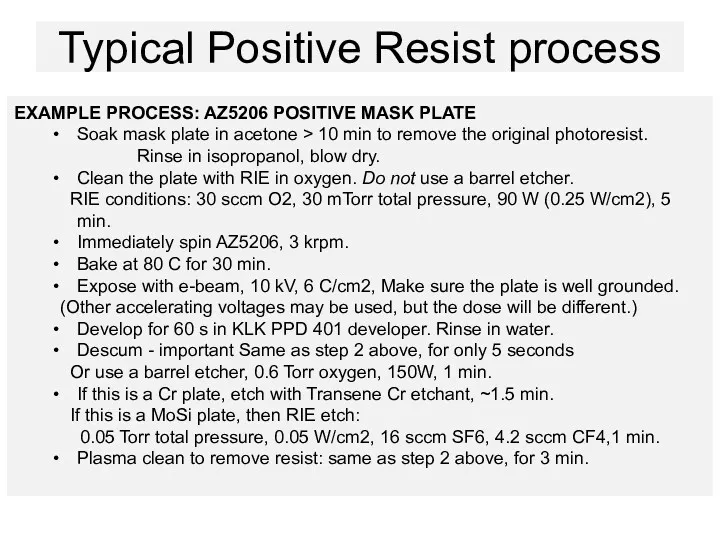

- 32. Typical Positive Resist process EXAMPLE PROCESS: AZ5206 POSITIVE MASK PLATE Soak mask plate in acetone >

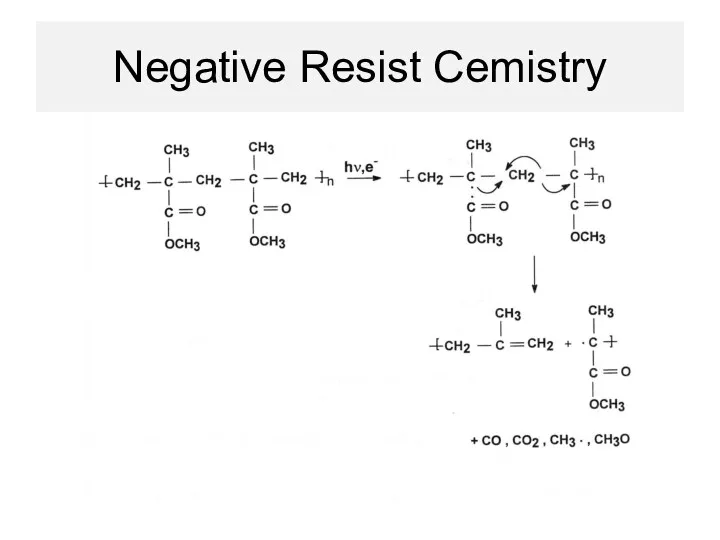

- 33. Negative Resist Cemistry

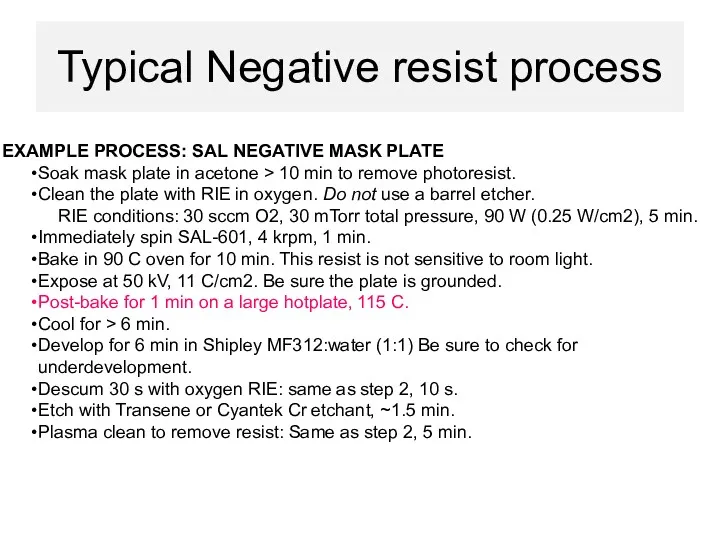

- 34. Typical Negative resist process EXAMPLE PROCESS: SAL NEGATIVE MASK PLATE Soak mask plate in acetone >

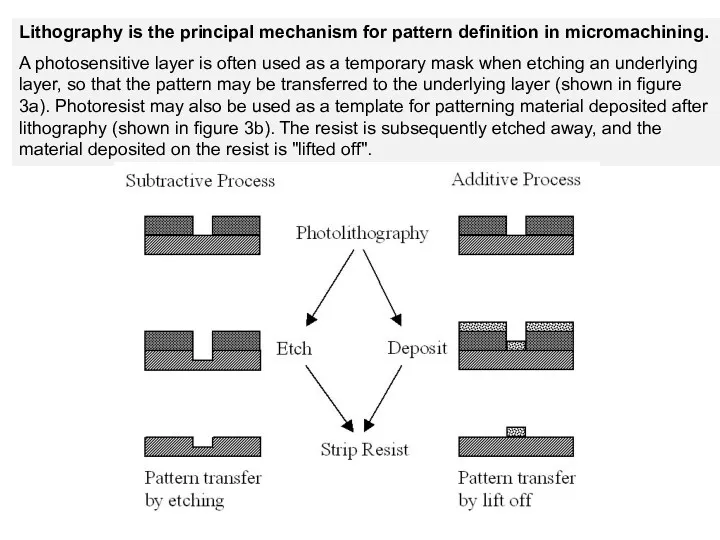

- 35. Lithography is the principal mechanism for pattern definition in micromachining. A photosensitive layer is often used

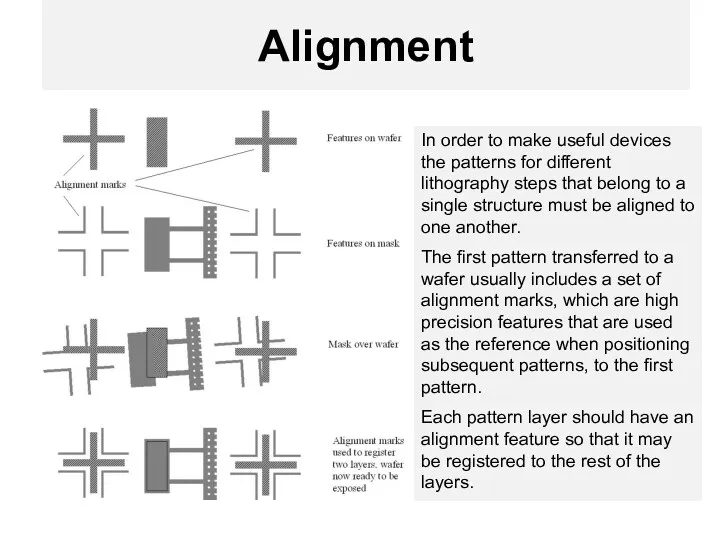

- 36. Alignment In order to make useful devices the patterns for different lithography steps that belong to

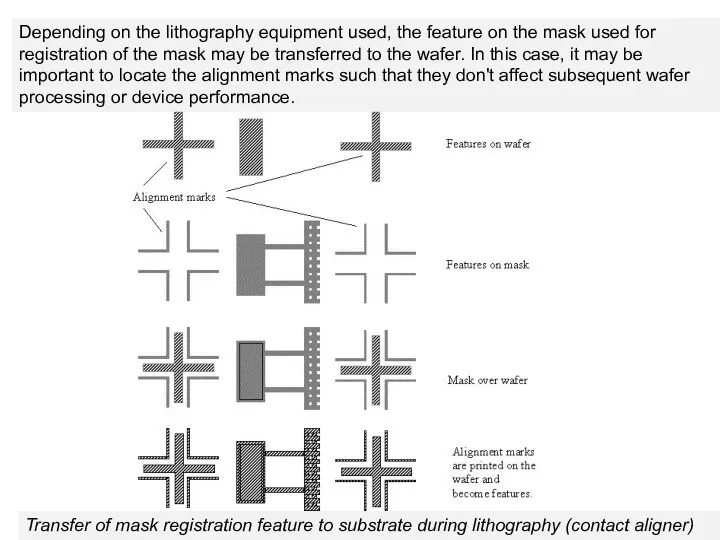

- 37. Depending on the lithography equipment used, the feature on the mask used for registration of the

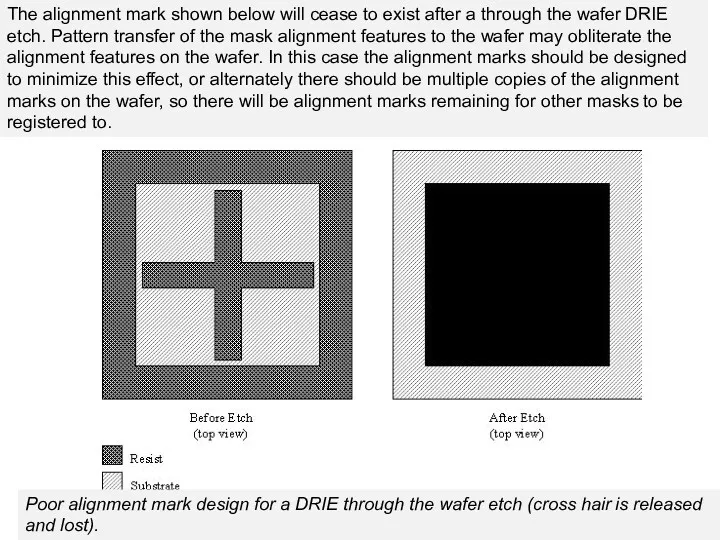

- 38. Poor alignment mark design for a DRIE through the wafer etch (cross hair is released and

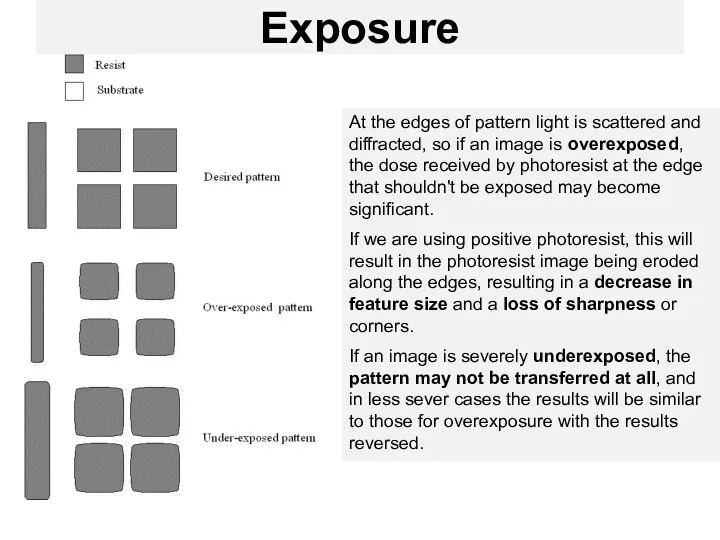

- 39. Exposure At the edges of pattern light is scattered and diffracted, so if an image is

- 40. The Lithography Module Dehydration bake - dehydrate the wafer to aid resist adhesion. HMDS prime -

- 41. Etching In order to form a functional MEMS structure on a substrate, it is necessary to

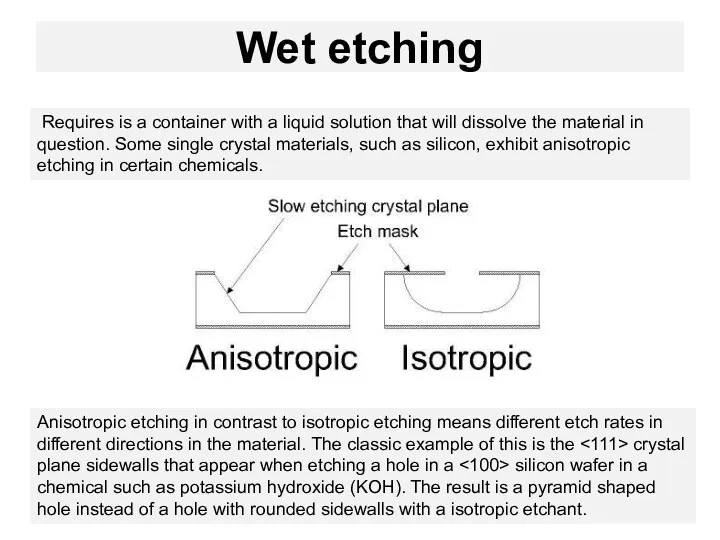

- 42. Wet etching Requires is a container with a liquid solution that will dissolve the material in

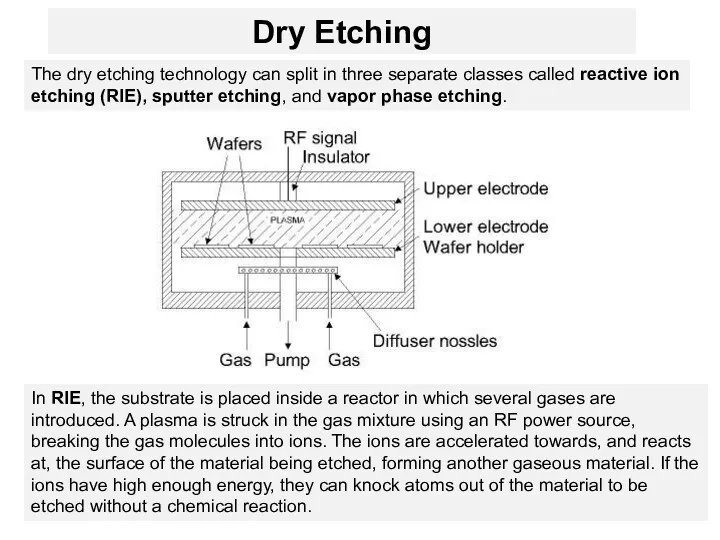

- 43. Dry Etching In RIE, the substrate is placed inside a reactor in which several gases are

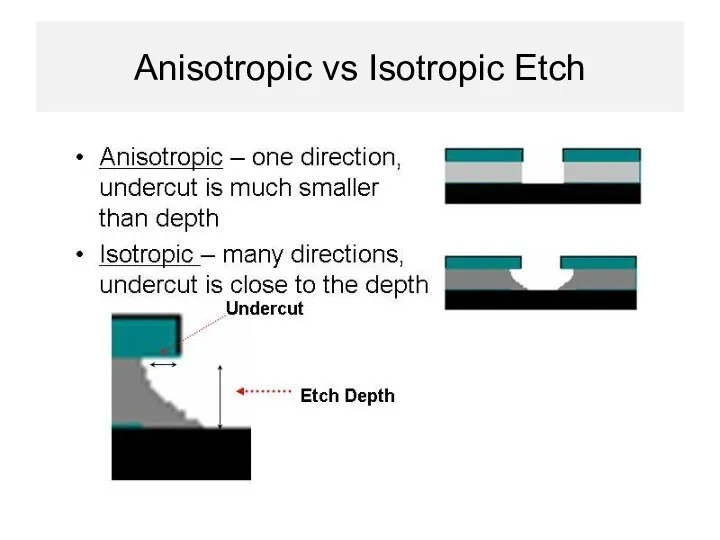

- 44. Anisotropic vs Isotropic Etch

- 45. Wet (Isotropic) Etch

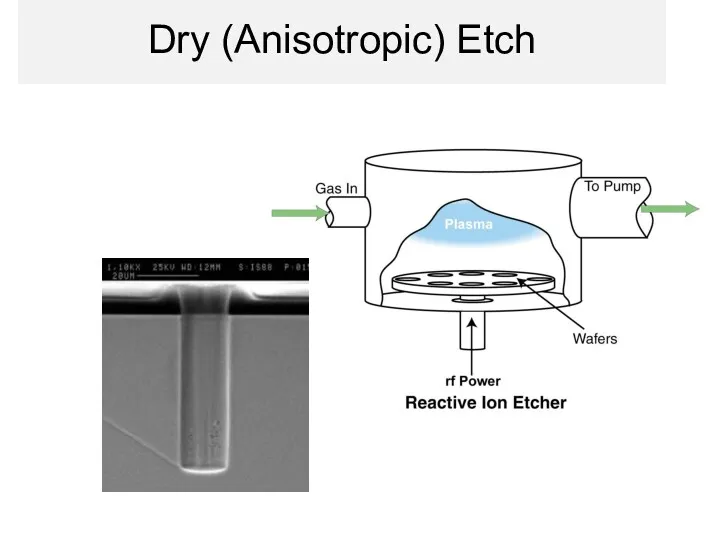

- 46. Dry (Anisotropic) Etch

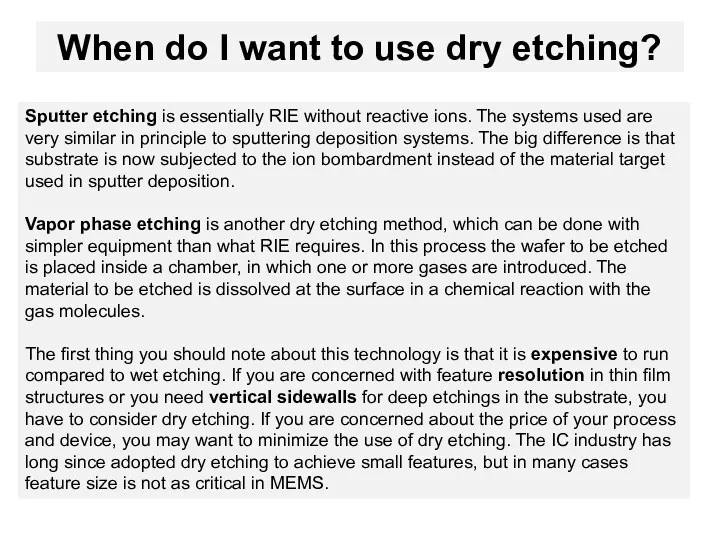

- 47. Sputter etching is essentially RIE without reactive ions. The systems used are very similar in principle

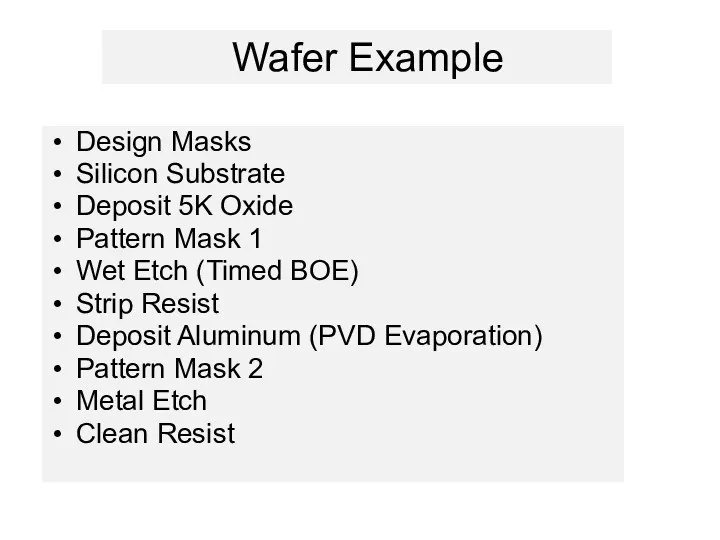

- 48. Wafer Example Design Masks Silicon Substrate Deposit 5K Oxide Pattern Mask 1 Wet Etch (Timed BOE)

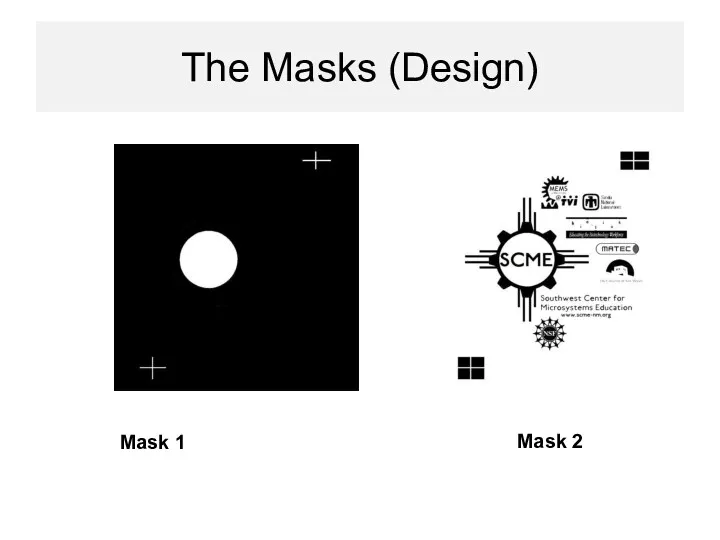

- 49. The Masks (Design) Mask 1 Mask 2

- 50. Bare Silicon Start with Bare Crystalline Silicon

- 51. Deposit Oxide Thermally grow 5K Angstroms of Oxide

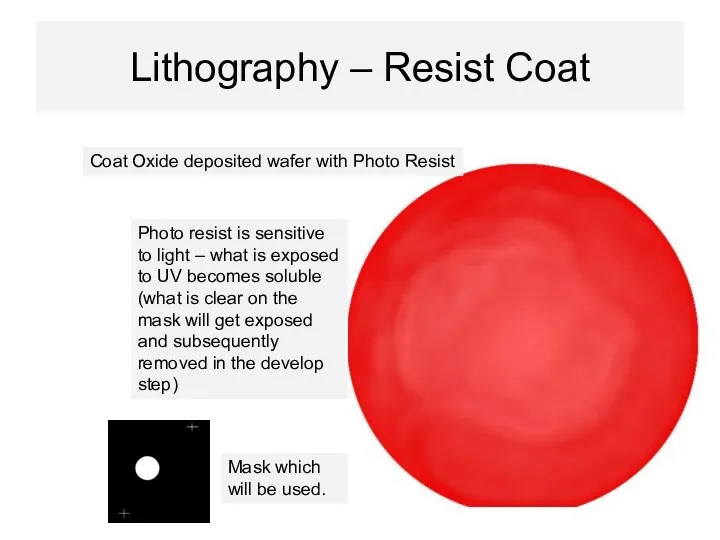

- 52. Lithography – Resist Coat Coat Oxide deposited wafer with Photo Resist Photo resist is sensitive to

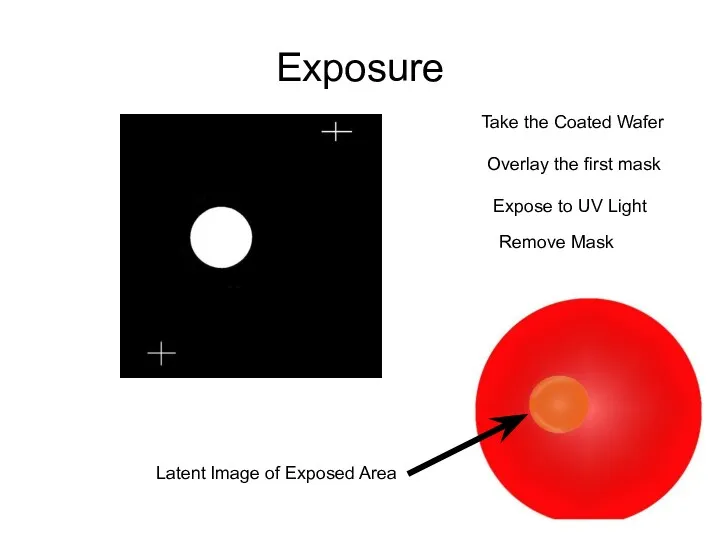

- 53. Exposure Take the Coated Wafer Overlay the first mask Expose to UV Light Remove Mask

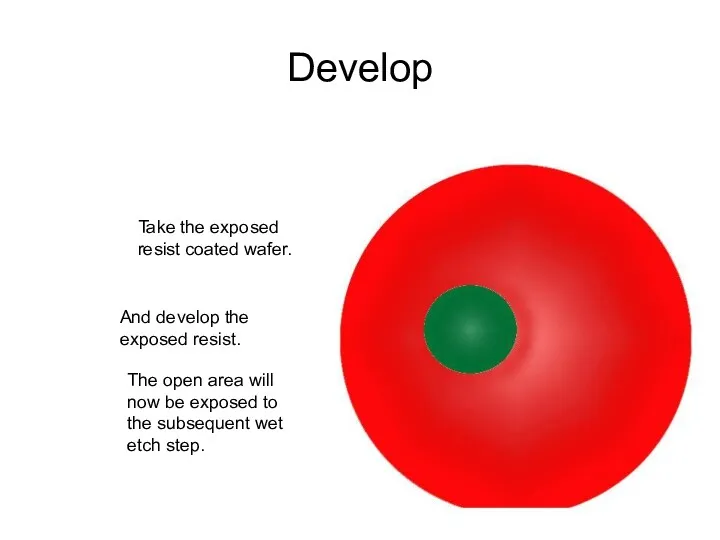

- 54. Develop Take the exposed resist coated wafer. And develop the exposed resist. The open area will

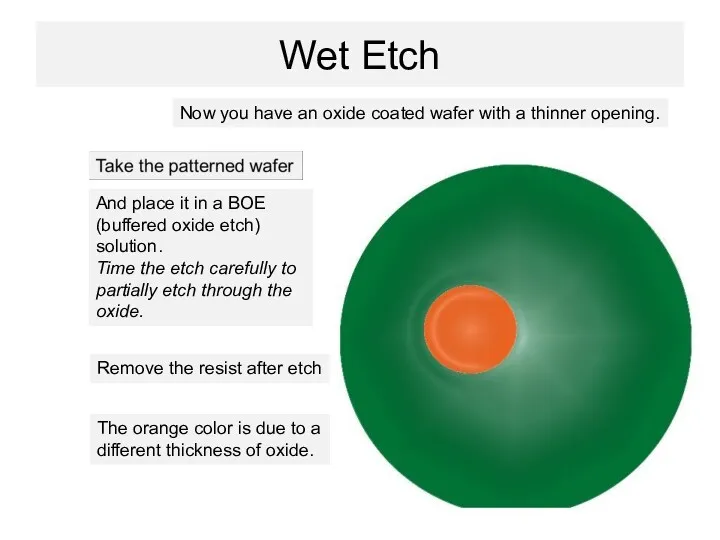

- 55. Wet Etch The orange color is due to a different thickness of oxide. Now you have

- 56. Deposit Aluminum Start with the etched oxide wafer.

- 57. Mask 2 – Pattern & Etch Aluminum Expose with UV Light

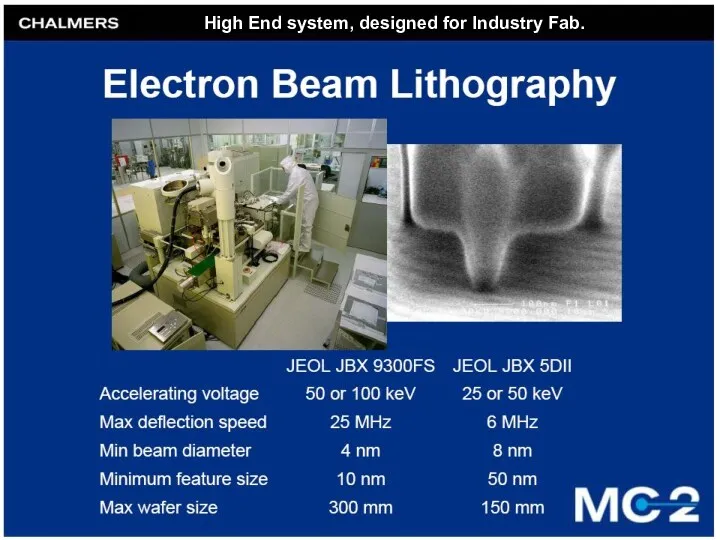

- 58. Electron Beam Lithography

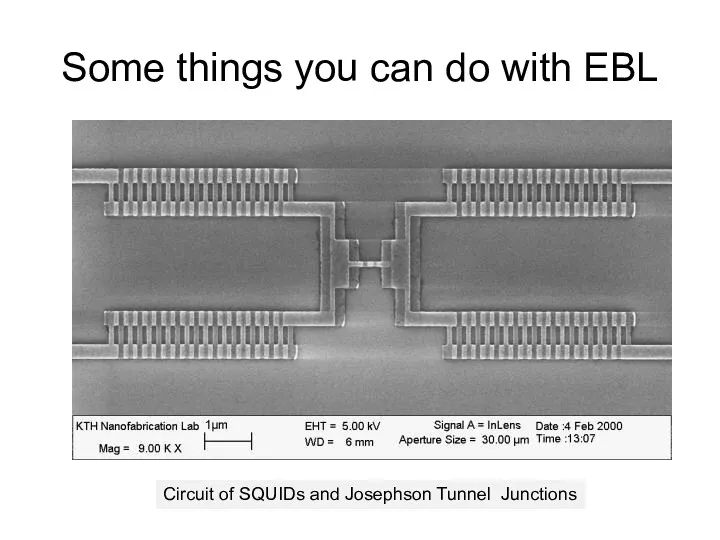

- 59. Some things you can do with EBL Circuit of SQUIDs and Josephson Tunnel Junctions

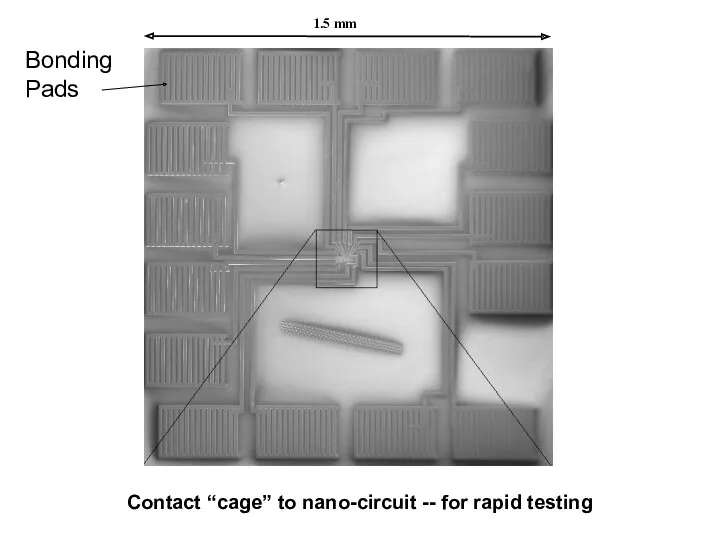

- 60. 1.5 mm Contact “cage” to nano-circuit -- for rapid testing Bonding Pads

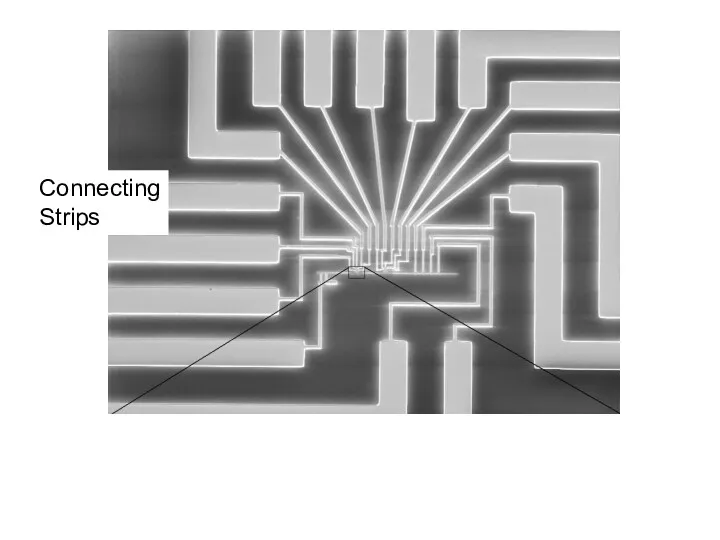

- 61. Connecting Strips

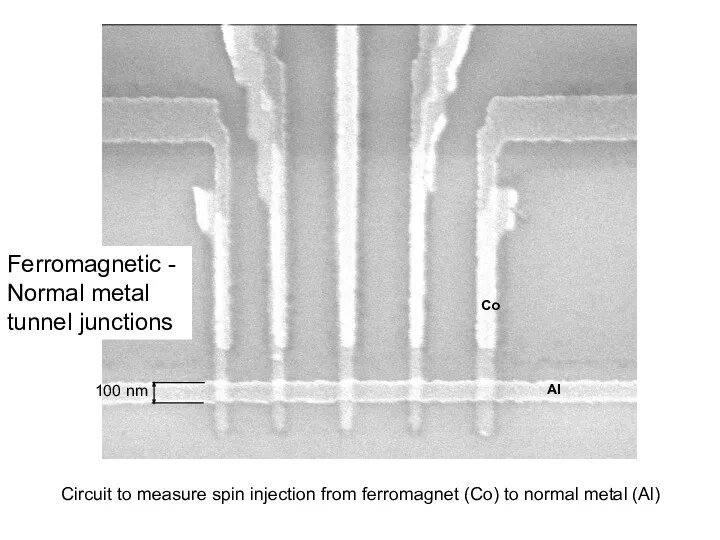

- 62. 100 nm Al Co Circuit to measure spin injection from ferromagnet (Co) to normal metal (Al)

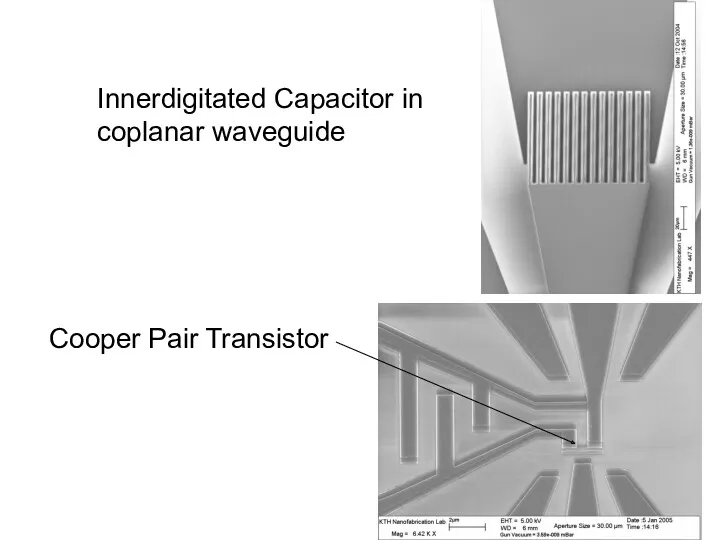

- 63. Innerdigitated Capacitor in coplanar waveguide Cooper Pair Transistor

- 64. High End system, designed for Industry Fab.

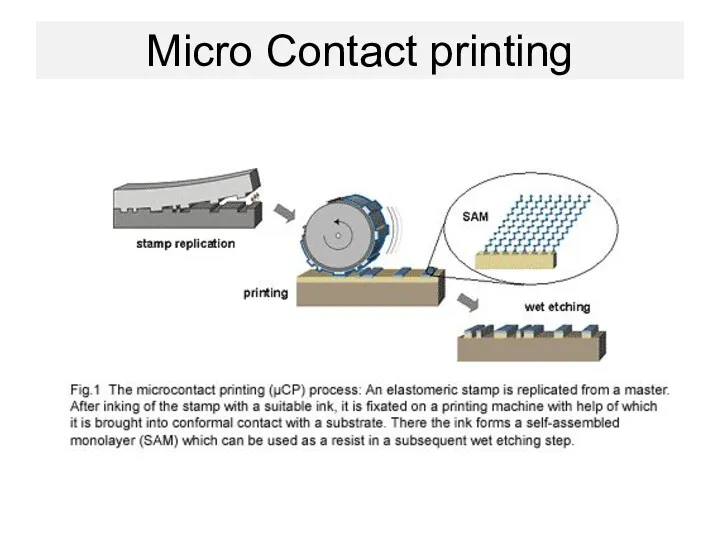

- 65. Micro Contact printing

- 67. Скачать презентацию

Impressionism. Claude Monet

Impressionism. Claude Monet Лекція 18 new

Лекція 18 new Денсаулықты кешенді бағалау денсаулық критерилері және денсаулық топтарын құрастыру

Денсаулықты кешенді бағалау денсаулық критерилері және денсаулық топтарын құрастыру Жилищный фонд, его виды. Переустройство и перепланировка жилых помещений. Жилищный надзор и жилищный контроль

Жилищный фонд, его виды. Переустройство и перепланировка жилых помещений. Жилищный надзор и жилищный контроль 75 лет Великой Победы!

75 лет Великой Победы! Промышленная безопасность

Промышленная безопасность Радіоелектронний захист ЗРЛ. Методи захисту від активних перешкод (Заняття №5.2)

Радіоелектронний захист ЗРЛ. Методи захисту від активних перешкод (Заняття №5.2) Тепловые методы увеличения нефтеотдачи

Тепловые методы увеличения нефтеотдачи Процесс очистки внутренней полости нефте- и нефтепродуктопроводов

Процесс очистки внутренней полости нефте- и нефтепродуктопроводов Нефтяная промышленность Киргизии

Нефтяная промышленность Киргизии материал к уроку Электромагнитные колебания.История открытия. 11 класс .профильный курс.Лекция с использованием презентации.

материал к уроку Электромагнитные колебания.История открытия. 11 класс .профильный курс.Лекция с использованием презентации. Монашество. Иоанн Шанхайский

Монашество. Иоанн Шанхайский City Tour Tbilisi 35 lari

City Tour Tbilisi 35 lari Дети моей группы Звёздочки

Дети моей группы Звёздочки Введение. Элементная база электронных устройств. Лекция 1

Введение. Элементная база электронных устройств. Лекция 1 Отопление зданий

Отопление зданий Женские лица российской прозы

Женские лица российской прозы Незабываемое поздравление для мужчин

Незабываемое поздравление для мужчин Классный час по теме: Государственные символы России

Классный час по теме: Государственные символы России Урок по теме Спирты

Урок по теме Спирты Тренажер по русскому языку Родовые окончания имён прилагательных

Тренажер по русскому языку Родовые окончания имён прилагательных Нейрогуморальная регуляция полового процесса

Нейрогуморальная регуляция полового процесса Мини-музей в ДОУ

Мини-музей в ДОУ Детские праздники и дни рождения Лазертаг

Детские праздники и дни рождения Лазертаг История развития тифлопедагогики

История развития тифлопедагогики Архитектурные памятники Липецкой области

Архитектурные памятники Липецкой области Родительское собрание Первые школьные отметки

Родительское собрание Первые школьные отметки Спортсмены-паралимпийцы Оренбургской области

Спортсмены-паралимпийцы Оренбургской области