Содержание

- 2. Outline Introduction Applications Passive structures Sensors Actuators Future Applications MEMS micromachining technology Bulk micromachining Surface micromachining

- 3. What are MEMS? (Micro-electromechanical Systems) Fabricated using micromachining technology Used for sensing, actuation or are passive

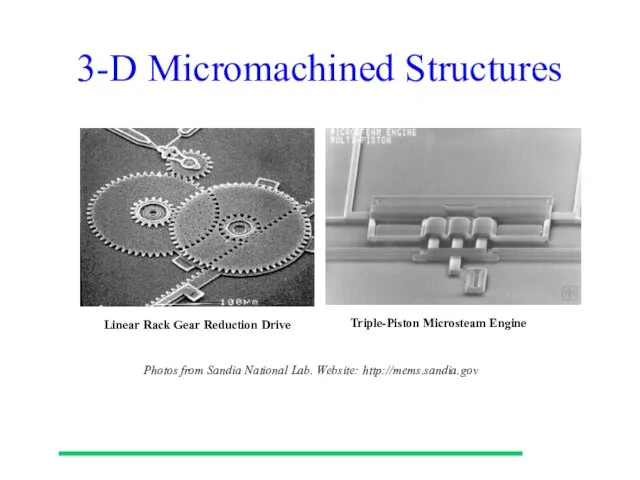

- 4. 3-D Micromachined Structures Linear Rack Gear Reduction Drive Triple-Piston Microsteam Engine Photos from Sandia National Lab.

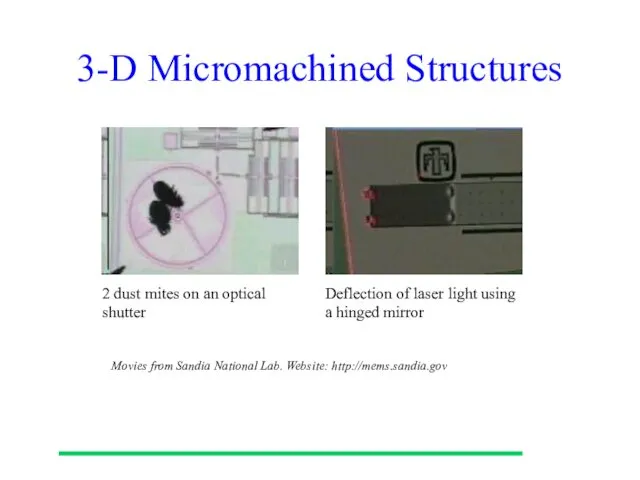

- 5. 3-D Micromachined Structures Movies from Sandia National Lab. Website: http://mems.sandia.gov 2 dust mites on an optical

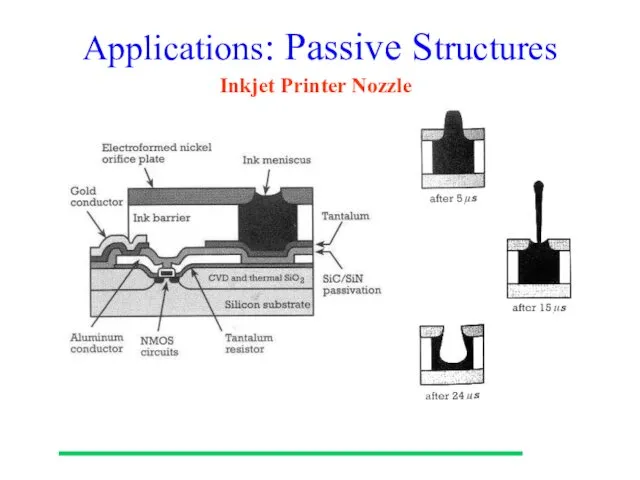

- 6. Applications: Passive Structures Inkjet Printer Nozzle

- 7. Applications: Sensors Pressure sensor: Piezoresistive sensing Capacitive sensing Resonant sensing Application examples: Manifold absolute pressure (MAP)

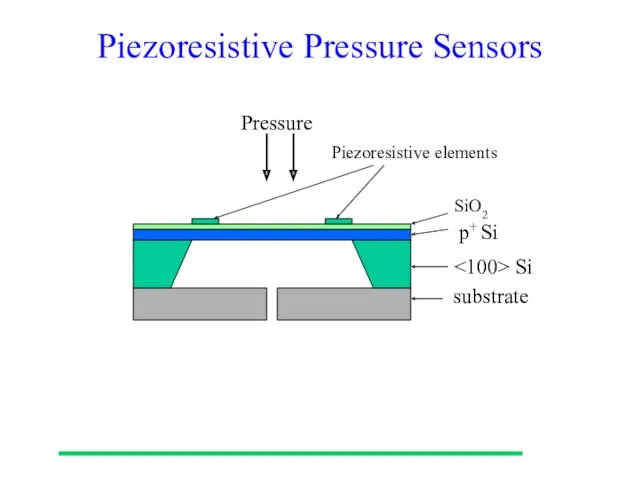

- 8. Piezoresistive Pressure Sensors

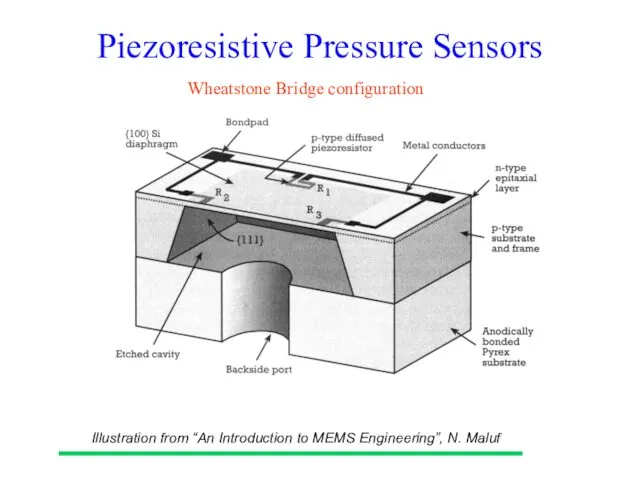

- 9. Piezoresistive Pressure Sensors Wheatstone Bridge configuration Illustration from “An Introduction to MEMS Engineering”, N. Maluf

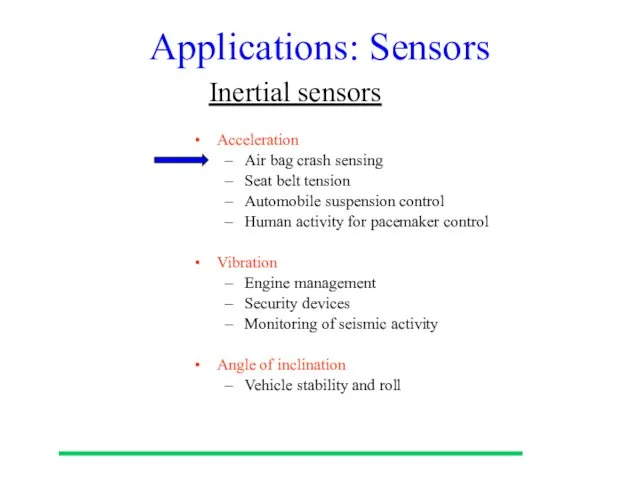

- 10. Applications: Sensors Acceleration Air bag crash sensing Seat belt tension Automobile suspension control Human activity for

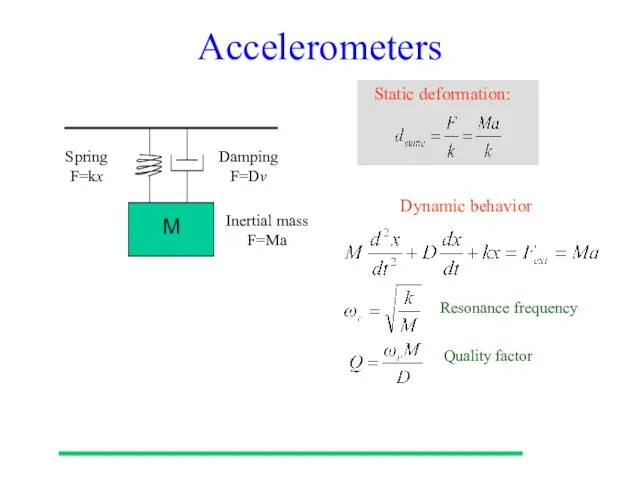

- 11. Accelerometers

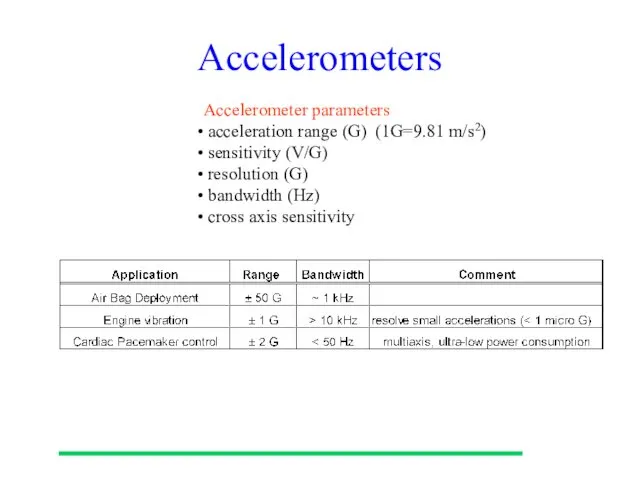

- 12. Accelerometers Accelerometer parameters acceleration range (G) (1G=9.81 m/s2) sensitivity (V/G) resolution (G) bandwidth (Hz) cross axis

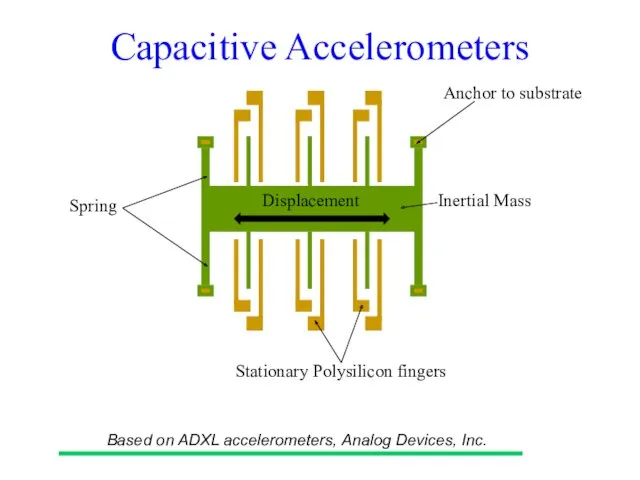

- 13. Capacitive Accelerometers Stationary Polysilicon fingers Based on ADXL accelerometers, Analog Devices, Inc. Spring Inertial Mass Anchor

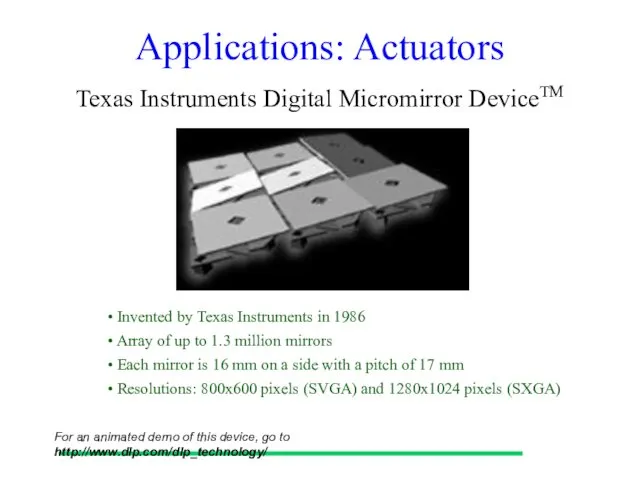

- 14. Applications: Actuators Texas Instruments Digital Micromirror DeviceTM Array of up to 1.3 million mirrors Invented by

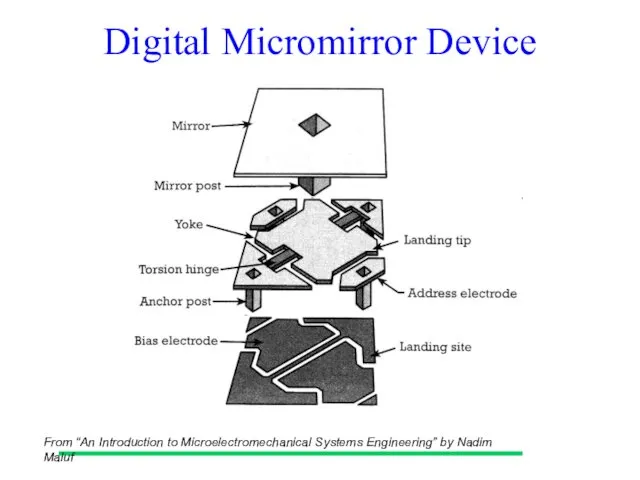

- 15. Digital Micromirror Device From “An Introduction to Microelectromechanical Systems Engineering” by Nadim Maluf

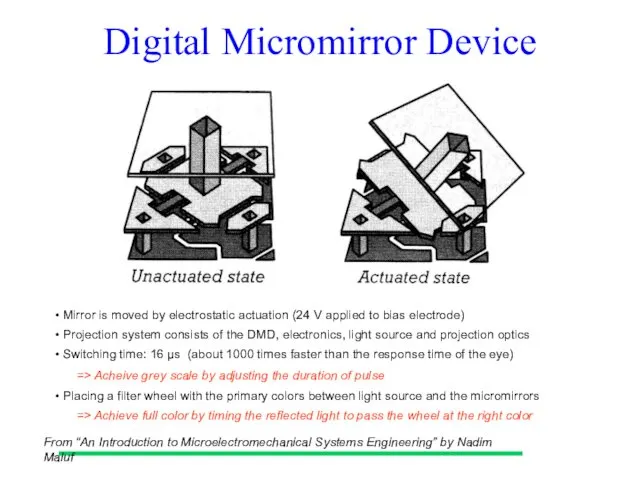

- 16. Digital Micromirror Device From “An Introduction to Microelectromechanical Systems Engineering” by Nadim Maluf => Acheive grey

- 17. Some future applications Biological applications: Microfluidics Lab-on-a-Chip Micropumps Resonant microbalances Micro Total Analysis systems Mobile communications:

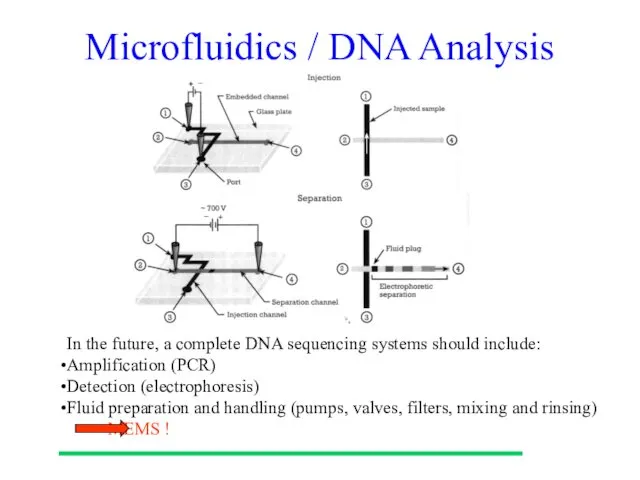

- 18. Microfluidics / DNA Analysis

- 19. Basic microfabrication technologies Deposition Chemical vapor deposition (CVD/PECVD/LPCVD) Epitaxy Oxidation Evaporation Sputtering Spin-on methods Etching Wet

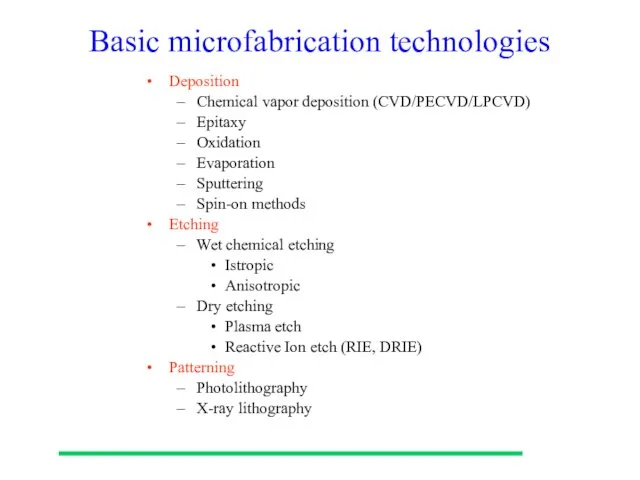

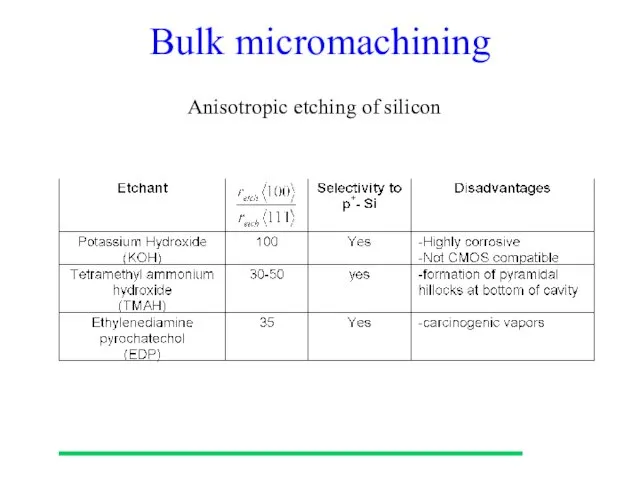

- 20. Bulk micromachining Anisotropic etching of silicon

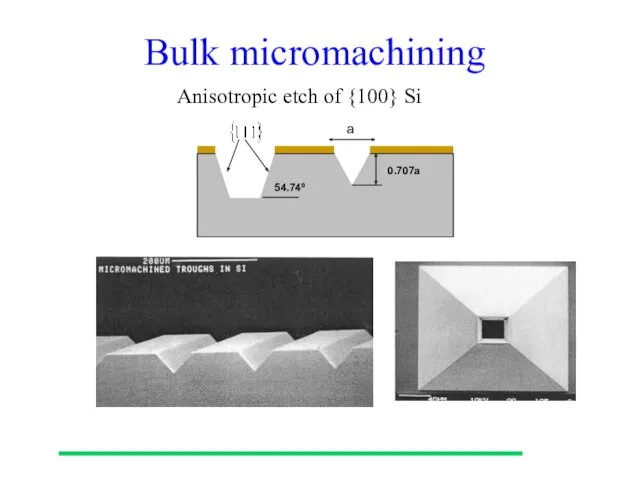

- 21. Bulk micromachining Anisotropic etch of {100} Si 54.74º a 0.707a

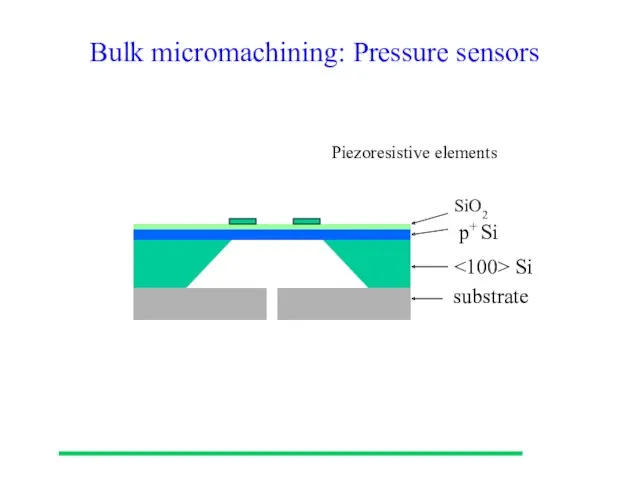

- 22. Bulk micromachining: Pressure sensors Piezoresistive elements SiO2 p+ Si Si

- 23. Surface Micromachining substrate Important issues: selectivity of structural, sacrificial and substrate materials stress of structural material

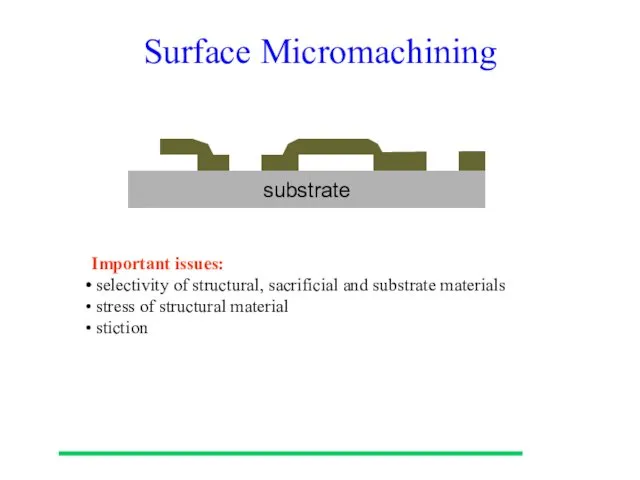

- 24. Surface Micromachining Most commonly used materials for surface micromachining: substrate: silicon sacrificial material: SiO2 or phosphosilicate

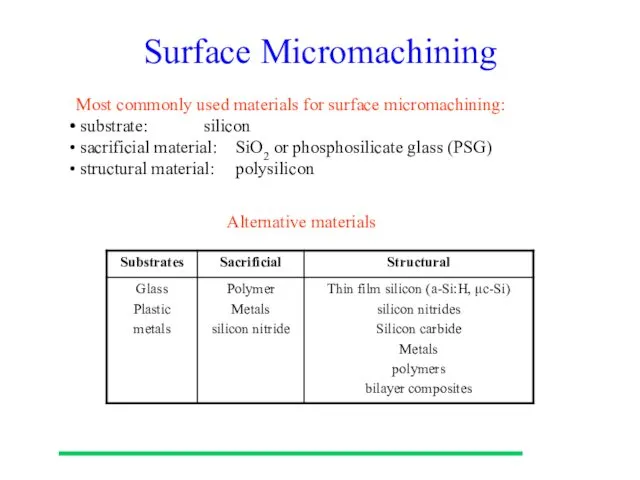

- 25. Surface Micromachining Polysilicon deposited by LPCVD (T~600 ºC) usually has large stress High T anneal (600-1000

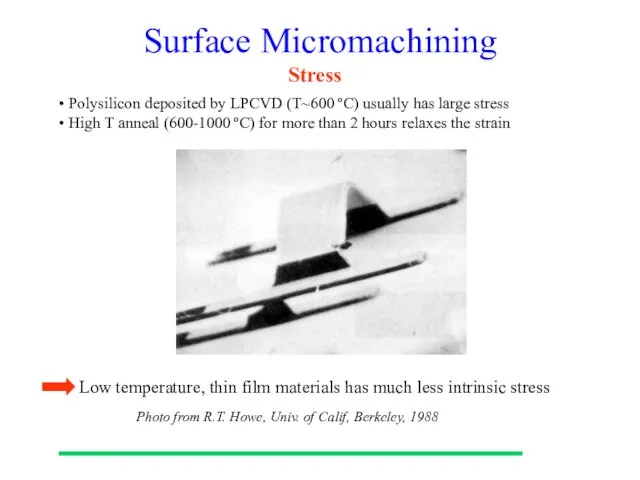

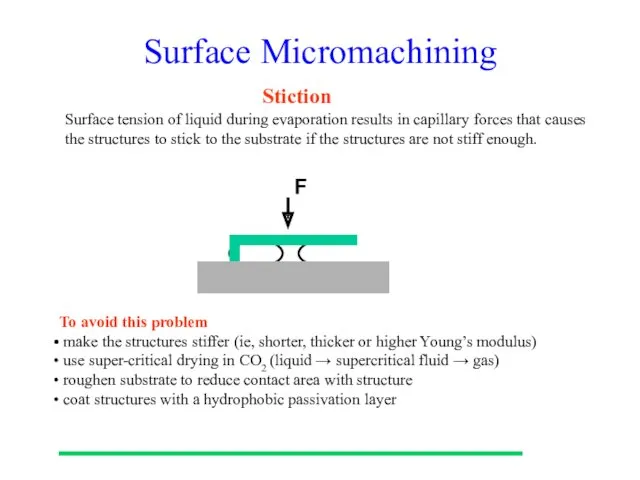

- 26. Surface Micromachining Surface tension of liquid during evaporation results in capillary forces that causes the structures

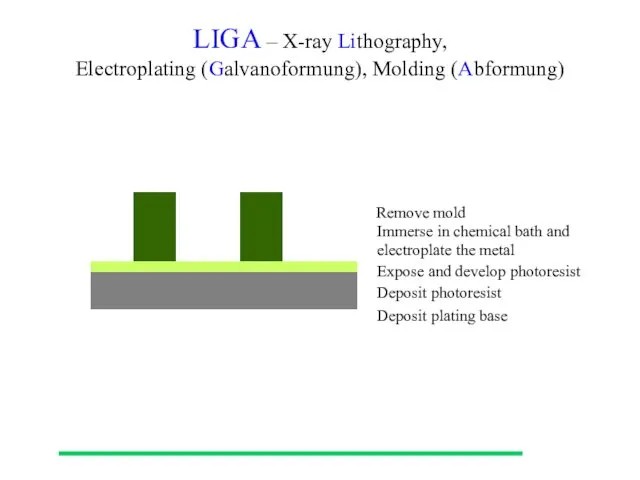

- 27. LIGA – X-ray Lithography, Electroplating (Galvanoformung), Molding (Abformung) Deposit plating base Deposit photoresist Expose and develop

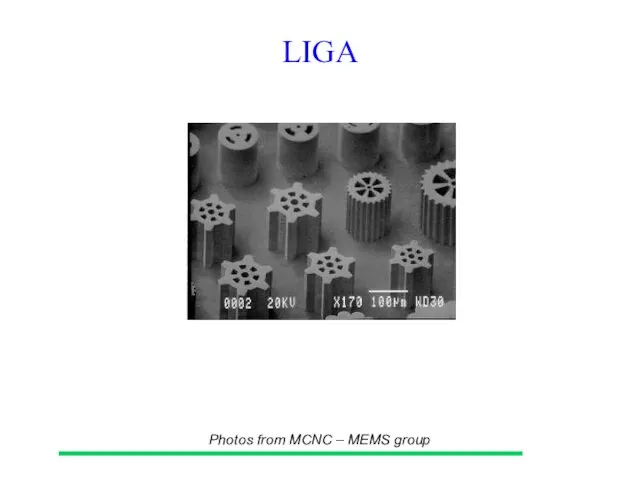

- 28. LIGA Photos from MCNC – MEMS group

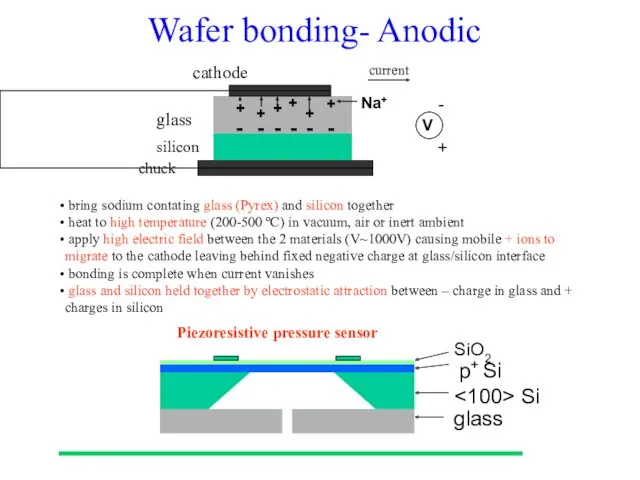

- 29. Wafer bonding- Anodic bring sodium contating glass (Pyrex) and silicon together heat to high temperature (200-500

- 30. Summary: MEMS fabrication MEMS technology is based on silicon microelectronics technology Main MEMS techniques Bulk micromachining

- 31. Thin-film MEMS Thin films allows: Low-temperature processing Large area, low cost, flexible or biocompatible substrates Possibility

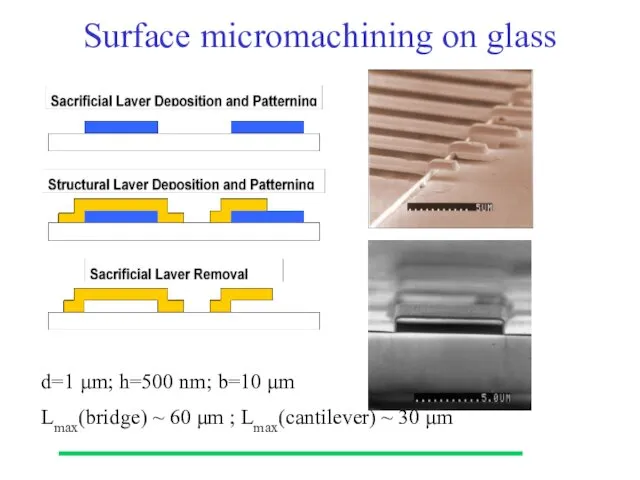

- 32. d=1 μm; h=500 nm; b=10 μm Lmax(bridge) ~ 60 μm ; Lmax(cantilever) ~ 30 μm Surface

- 33. Electrostatic force between gate and counter-electrode Electrostatic force is always attractive Electrostatic Actuation

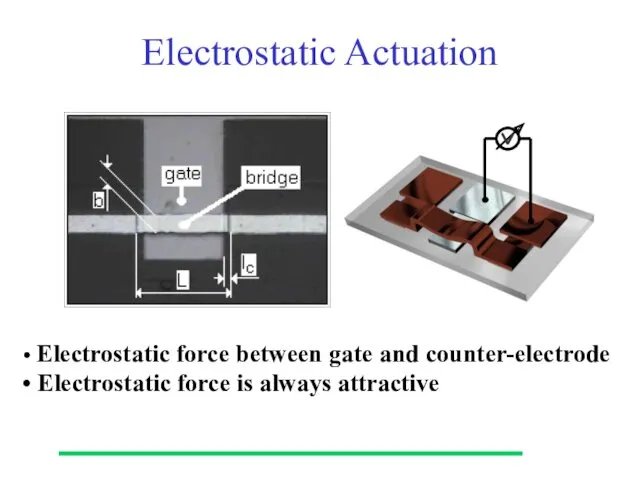

- 34. A laser beam is focused on the structure and the reflected light is collected with an

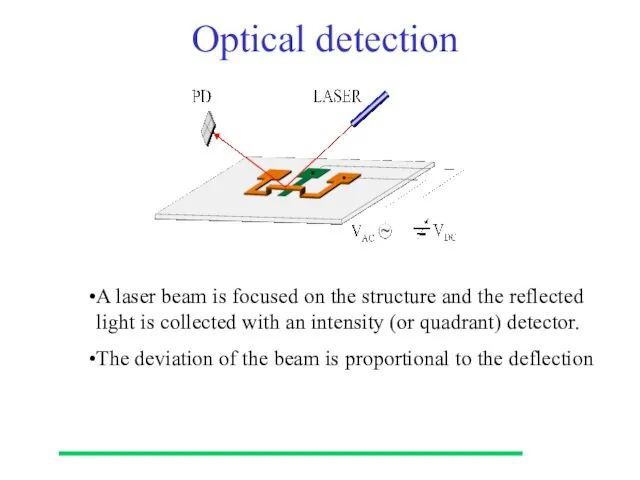

- 35. Optical detection of electrical actuation Resonance is inversely proportional to square of the length 20 MHz

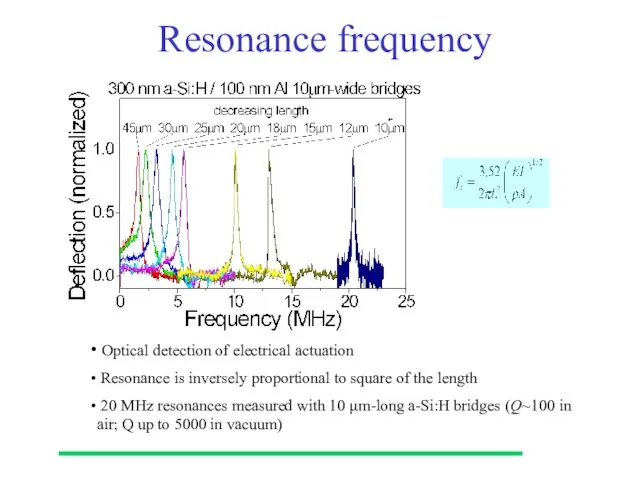

- 37. Скачать презентацию

Презентация 8 Марта - праздник мам!

Презентация 8 Марта - праздник мам! Квартирная электропроводка. 8 класс

Квартирная электропроводка. 8 класс Игры и игровые упражнения в логопедической работе с детьми. Развитие мелкой моторики рук

Игры и игровые упражнения в логопедической работе с детьми. Развитие мелкой моторики рук Основы технической диагностики. Общие требования по безопасности промышленных объектов, установленные законами РФ

Основы технической диагностики. Общие требования по безопасности промышленных объектов, установленные законами РФ Методы изучения генетики человека

Методы изучения генетики человека Итоги о проделанной работе районного методического объединения воспитателей дошкольных образовательных организаций

Итоги о проделанной работе районного методического объединения воспитателей дошкольных образовательных организаций Транзисторы и тиристоры

Транзисторы и тиристоры Великдень. Куличи на Пасху

Великдень. Куличи на Пасху Презентация Разделение неоднородный смесей.

Презентация Разделение неоднородный смесей. Ырғақ бұзылыстары

Ырғақ бұзылыстары Организация деятельности приёмной Апатитского городского суда

Организация деятельности приёмной Апатитского городского суда Коллективный проект Перемена

Коллективный проект Перемена Презентация к уроку технология 4 класс с творческими проектами детей. Тема Дизайн календаря

Презентация к уроку технология 4 класс с творческими проектами детей. Тема Дизайн календаря Космический аналог ядерной угрозы

Космический аналог ядерной угрозы Культура Беларуси в XIV - первой половине XVI в. Образование белорусской народности. Происхождение названия Белая Русь

Культура Беларуси в XIV - первой половине XVI в. Образование белорусской народности. Происхождение названия Белая Русь Общая психология

Общая психология Світове господарство та тенденції його розвитку

Світове господарство та тенденції його розвитку Землеройно-транспортные машины

Землеройно-транспортные машины тренажёры Диск

тренажёры Диск Зелёный ад

Зелёный ад Степени повреждения и категории технического состояния промышленных и производственных зданий и их характерные признаки

Степени повреждения и категории технического состояния промышленных и производственных зданий и их характерные признаки Ғылым тілі

Ғылым тілі Моделирование и формализация. Система управления базами данных

Моделирование и формализация. Система управления базами данных образец

образец Методические разработки уроков

Методические разработки уроков Краткий тезаурус по ВВЭР-1200

Краткий тезаурус по ВВЭР-1200 На юге Европы. Греция и Италия

На юге Европы. Греция и Италия Парентеральный путь введения лекарственных средств в организм

Парентеральный путь введения лекарственных средств в организм