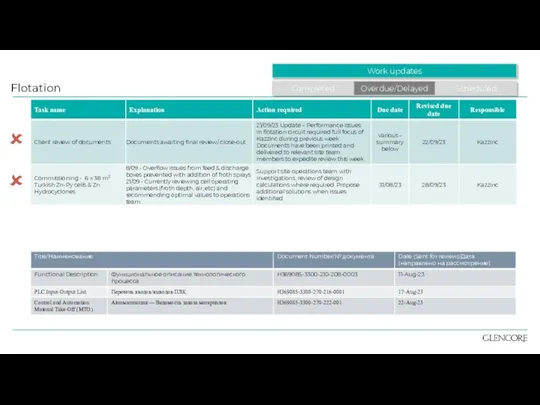

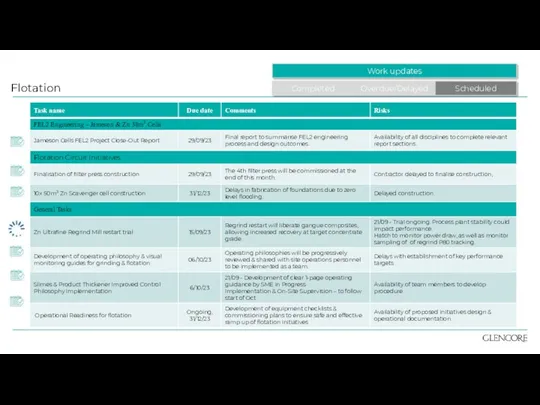

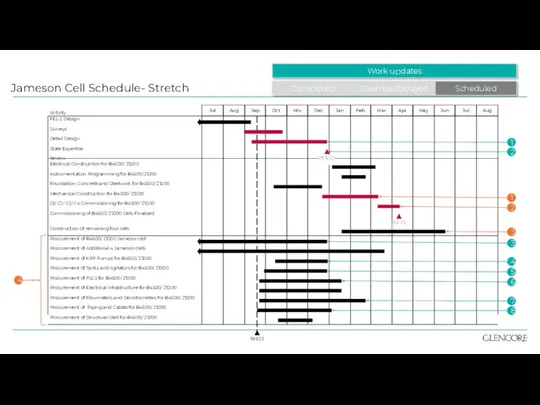

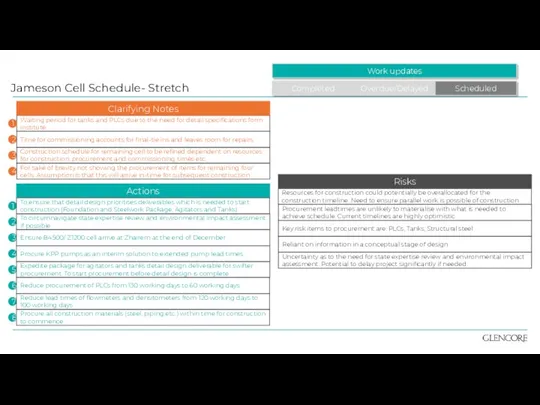

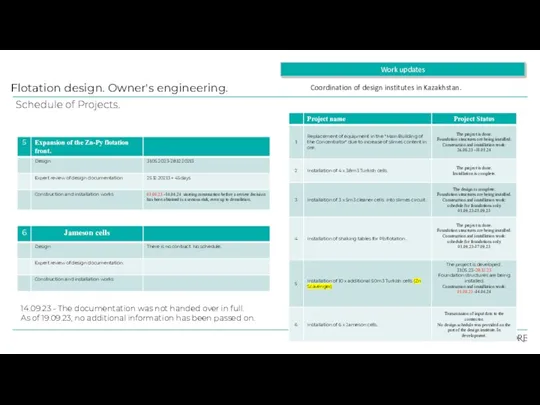

Jameson Cell Schedule- Stretch

Jul

Aug

Sep

Oct

Nov

Dec

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Procurement of Additional 4 Jameson cells

Procurement of Electrical

Infrastructure for B4500/ Z1200

Procurement of B4500/ Z1200 Jameson cell

Procurement of Flowmeters and Densitometers for B4500/ Z1200

Procurement of KPP Pumps for B4500/ Z1200

Procurement of Piping and Cables for B4500/ Z1200

11.4.24

C1/ C2/ C3/ C4 Commissioning for B4500/ Z1200

Mechanical Construction for B4500/ Z1200

Foundation, Concrete and Steelwork for B4500/ Z1200

Electrical Construction for B4500/ Z1200

State Expertise Review

29.12.23

Detail Design

Instrumentation Programming for B4500/Z1200

Surveys

FEL-2 Design

19.9.23

Commissioning of B4500/ Z1200 Cells Finalised

Procurement of Tanks and Agitators for B4500/ Z1200

Construction of remaining four cells

Procurement of PLCs for B4500/ Z1200

Procurement of Structural Stell for B4500/ Z1200

Activity

1

4

3

4

2

1

2

3

5

6

7

8

Источник 1 (глаголь22.рф)

Источник 1 (глаголь22.рф) Область познания-экспериментирование

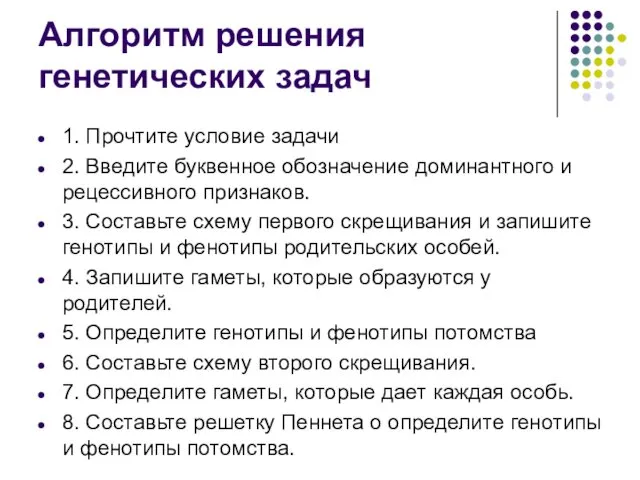

Область познания-экспериментирование Алгоритм решения генетических задач

Алгоритм решения генетических задач Көбіктер және оларды алу әдістері

Көбіктер және оларды алу әдістері Социально-педагогические технологии консультирования

Социально-педагогические технологии консультирования моя презентация

моя презентация Родительское собрание на тему ФГОСы

Родительское собрание на тему ФГОСы Наглядное пособие

Наглядное пособие Цифровые комбинационные устройства. Тема 4.2

Цифровые комбинационные устройства. Тема 4.2 Дети и война

Дети и война Морфологический анализ слова

Морфологический анализ слова Программы и фонды для мероприятия

Программы и фонды для мероприятия Обоснование параметров и разработка технических средств и технологии бурения направленных скважин из горных выработок

Обоснование параметров и разработка технических средств и технологии бурения направленных скважин из горных выработок Презентация к вводному занятию Волшебная страна бисера.

Презентация к вводному занятию Волшебная страна бисера. Самостійна робота учнів - засіб розвитку пізнавальної активності і творчого мислення

Самостійна робота учнів - засіб розвитку пізнавальної активності і творчого мислення Кәмпит бұл-қанттан

Кәмпит бұл-қанттан Сказка о том, как Лягушонок научился гудеть, как пароход. Постановка и автоматизация звука [Ы]

Сказка о том, как Лягушонок научился гудеть, как пароход. Постановка и автоматизация звука [Ы] What is Marketing Management?

What is Marketing Management? Реализация мероприятий в области информационных технологий

Реализация мероприятий в области информационных технологий Речевые игры для детей от 3-х лет.

Речевые игры для детей от 3-х лет. Виниловые обои

Виниловые обои презентация Службы района

презентация Службы района Keys_Poklevochka_1

Keys_Poklevochka_1 Синичкин день. Народный календарь.

Синичкин день. Народный календарь. Применение данных каротажа в процессе бурения с использованием комплексных приборов LWD121-2ННК-ГГКЛП и LWD172-2ННК-ГГКЛП-3Г

Применение данных каротажа в процессе бурения с использованием комплексных приборов LWD121-2ННК-ГГКЛП и LWD172-2ННК-ГГКЛП-3Г Страшный суд

Страшный суд Назначение и устройство токарно-винторезного станка ТВ-6

Назначение и устройство токарно-винторезного станка ТВ-6 Проблемы российского образования в современных условиях

Проблемы российского образования в современных условиях