Содержание

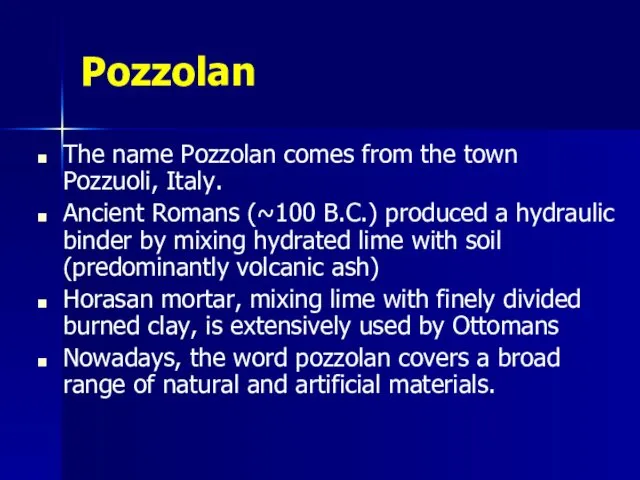

- 2. Pozzolan The name Pozzolan comes from the town Pozzuoli, Italy. Ancient Romans (~100 B.C.) produced a

- 3. Pozzolan a material that, when used in conjunction with portland cement, contributes to the properties of

- 4. Pozzolan Siliceous or aluminous material, which in itself possesses little or no cementitious value but will,

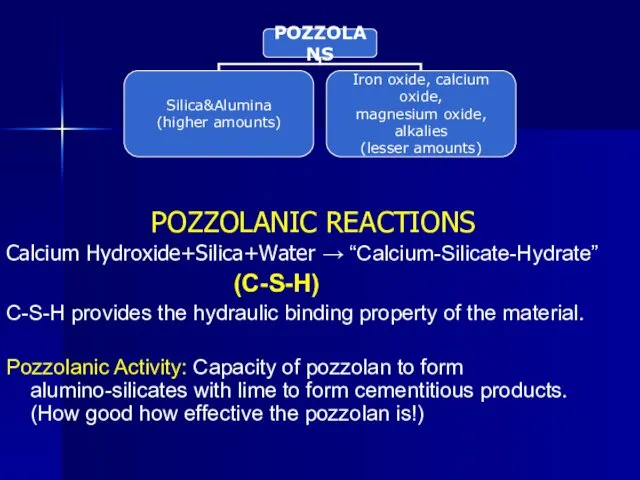

- 5. POZZOLANIC REACTIONS Calcium Hydroxide+Silica+Water → “Calcium-Silicate-Hydrate” (C-S-H) C-S-H provides the hydraulic binding property of the material.

- 6. FACTORS THAT AFFECT THE ACTIVITY OF POZZOLANS 1) SiO2 + Al2O3 + Fe2O3 content 2) The

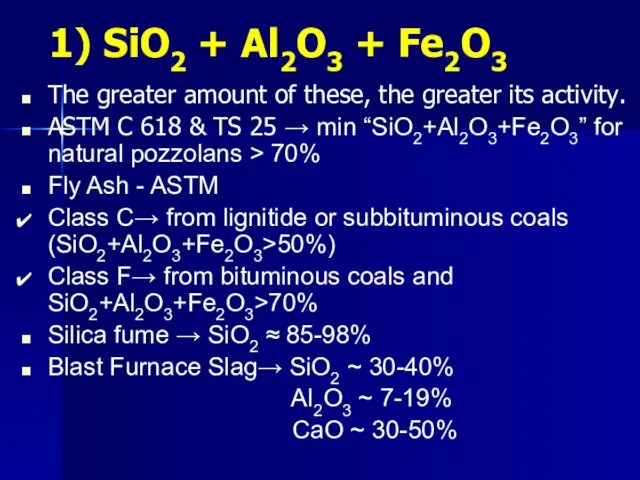

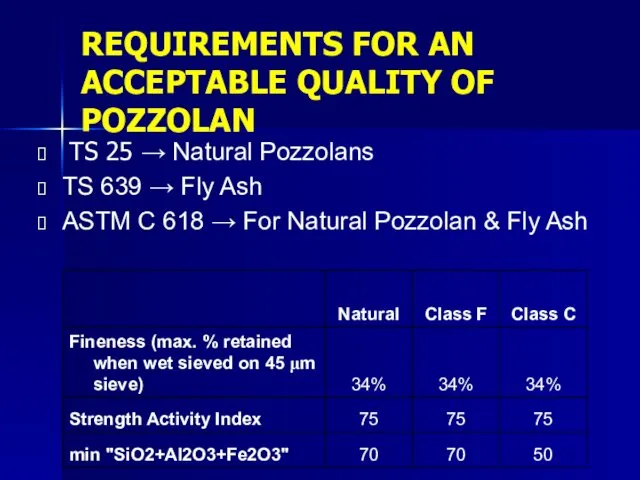

- 7. 1) SiO2 + Al2O3 + Fe2O3 The greater amount of these, the greater its activity. ASTM

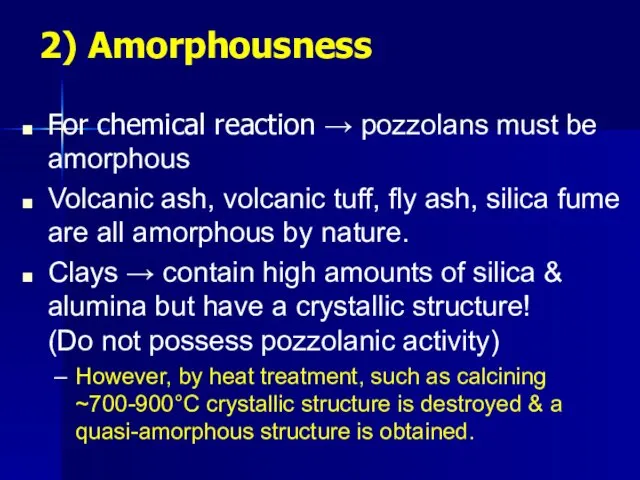

- 8. 2) Amorphousness For chemical reaction → pozzolans must be amorphous Volcanic ash, volcanic tuff, fly ash,

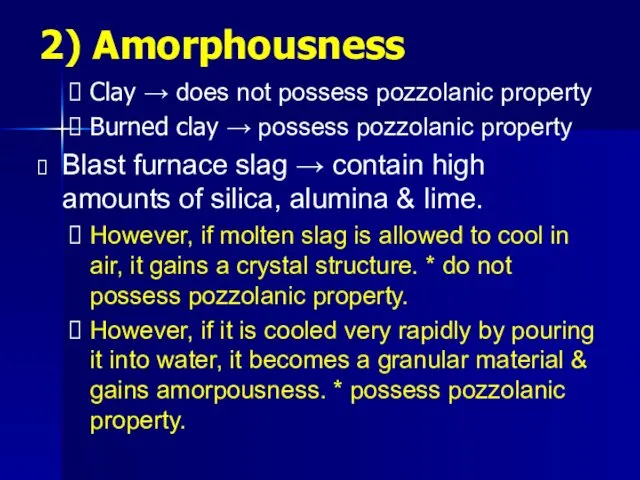

- 9. Clay → does not possess pozzolanic property Burned clay → possess pozzolanic property Blast furnace slag

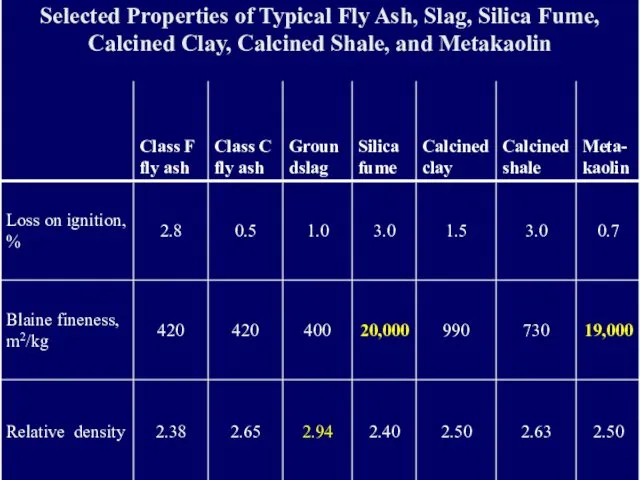

- 10. 3) Fineness Pozzolanic activity increases as fineness increases. Volcanic ash, rice husk ash, fly ash, condensed

- 11. DETERMINATION OF POZZOLANIC ACTIVITY Pozzolanic activity is determined by “strength activity indexes” Six mortar cubes are

- 12. Compressive testing at 7 or 28 days Strength Activity Index (SAI) =A/B*100 A=f’c of test mixture

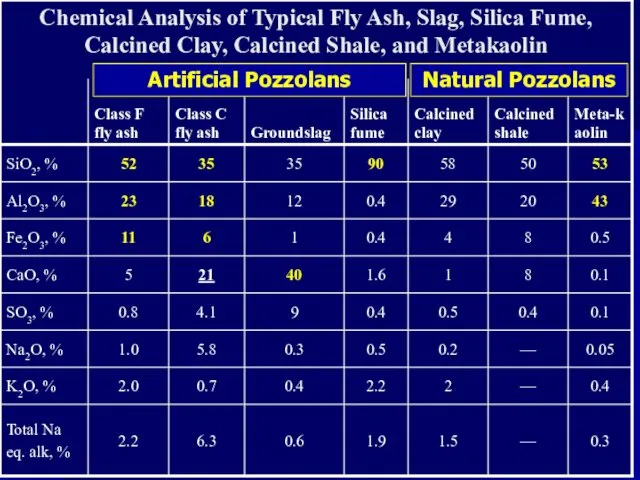

- 13. CHEMICAL COMPOSITION OF POZZOLANS Silica Fume is mostly SiO2 G. G. Blast Furnace Slag→ high amounts

- 14. Natural Pozzolans Artificial Pozzolans

- 15. SILICA FUME FLY ASH GRANULATED BLAST FURNACE SLAG

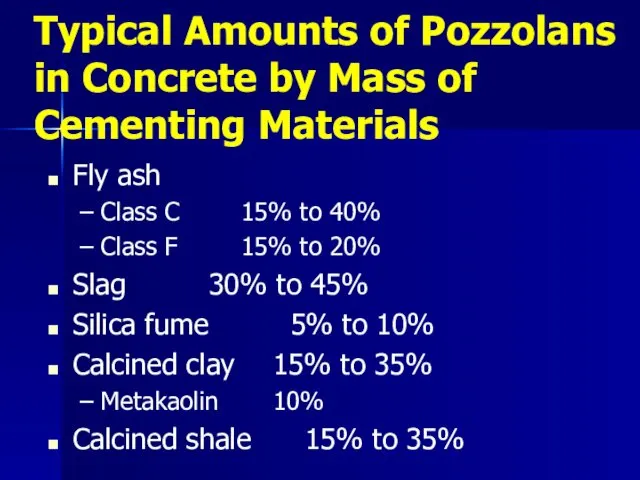

- 17. Typical Amounts of Pozzolans in Concrete by Mass of Cementing Materials Fly ash Class C 15%

- 18. REQUIREMENTS FOR AN ACCEPTABLE QUALITY OF POZZOLAN TS 25 → Natural Pozzolans TS 639 → Fly

- 20. Скачать презентацию

Экологическое воспитание дошкольников.

Экологическое воспитание дошкольников. Фізична природа, фізичні механізми взаємодії іонізуючого випромінювання з речовиною

Фізична природа, фізичні механізми взаємодії іонізуючого випромінювання з речовиною Художественное творчество Елочки для волшебного леса Руководитель кружка воспитатель: Рудь С. П.

Художественное творчество Елочки для волшебного леса Руководитель кружка воспитатель: Рудь С. П. викторина Лабиринты химии

викторина Лабиринты химии Информационный центр ОАО Машиностроительный завод

Информационный центр ОАО Машиностроительный завод Алгоритм и его формальное исполнение

Алгоритм и его формальное исполнение Мастер-класс Новогодняя игрушка Шапочка

Мастер-класс Новогодняя игрушка Шапочка Устройство компьютера

Устройство компьютера Жизнь и быт городских жителей России 19-го века

Жизнь и быт городских жителей России 19-го века Увлечение моей мамы

Увлечение моей мамы Бауыр және өт жолдары, ұйқы безі ауруларын тағаммен емдеу және емдік дене шынықтыру

Бауыр және өт жолдары, ұйқы безі ауруларын тағаммен емдеу және емдік дене шынықтыру Адаптация Вашего ребенка к школе

Адаптация Вашего ребенка к школе Componente şi circuite electronice pasive - CCEP

Componente şi circuite electronice pasive - CCEP Периодизация изменения отношения общества к лицам с ограниченными возможностями здоровья

Периодизация изменения отношения общества к лицам с ограниченными возможностями здоровья Темы в мировой литературе

Темы в мировой литературе Проект Необъятный космос

Проект Необъятный космос Выступление на РМО. Тема: Создание проблемной ситуации на этапе мотивации урока-исследования.

Выступление на РМО. Тема: Создание проблемной ситуации на этапе мотивации урока-исследования. Теорема Пифагора. Шаржи

Теорема Пифагора. Шаржи Скандинавская мифология

Скандинавская мифология Дидактическая игра с использованием ИКТ Сложи слова.

Дидактическая игра с использованием ИКТ Сложи слова. Picture description

Picture description Организация туриндустрии. Услуги предприятий питания. Виды питания

Организация туриндустрии. Услуги предприятий питания. Виды питания Проектная исследовательская работа Наши бабушки

Проектная исследовательская работа Наши бабушки Экономическая оценка деятельности агрегатного участка для автомобиля Урал 4320 в условиях

Экономическая оценка деятельности агрегатного участка для автомобиля Урал 4320 в условиях Хранимые процедуры

Хранимые процедуры Радиоактивность. Модели атомов

Радиоактивность. Модели атомов Органический мир в океане

Органический мир в океане Название проекта. Дополнительная информация

Название проекта. Дополнительная информация