Содержание

- 2. Our Products Trade Names

- 3. MoldWiz® Process Aid Additives for Thermoplastics

- 4. Process Aid Additives available in: powder, pellet, liquid Proprietary formulations manufactured in the USA 100% active

- 5. Process Aid Additives Release Flow Scratch & Mar Reduction Dispersion Coefficient of Friction Unique Formulations Focused

- 6. The Value of MoldWiz® Additives Rheology & Processing Higher MFI Better Flow / Cavity Fill Improved

- 7. Improved Surface Luster On Molded Part Elimination of Flow Lines Elimination of Hair-Line Stress Cracks Stronger

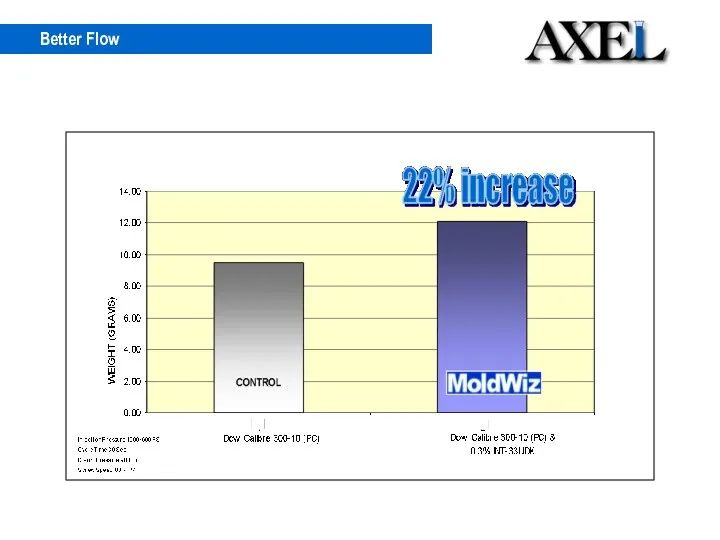

- 8. Better Flow

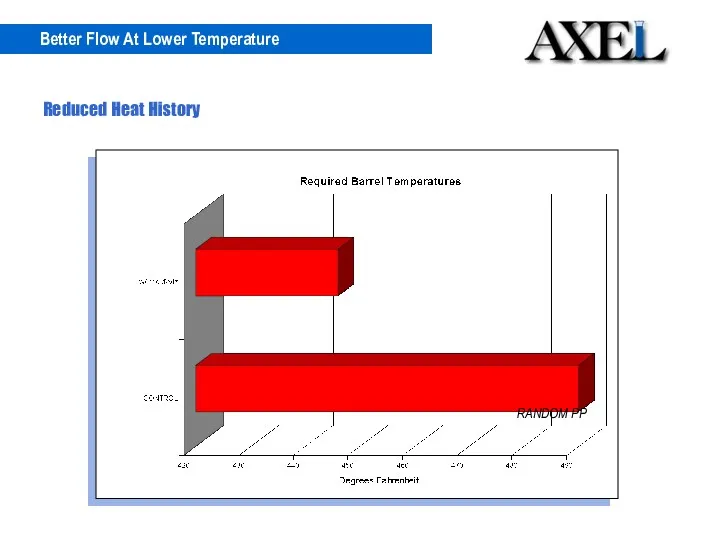

- 9. RANDOM PP Better Flow At Lower Temperature Reduced Heat History

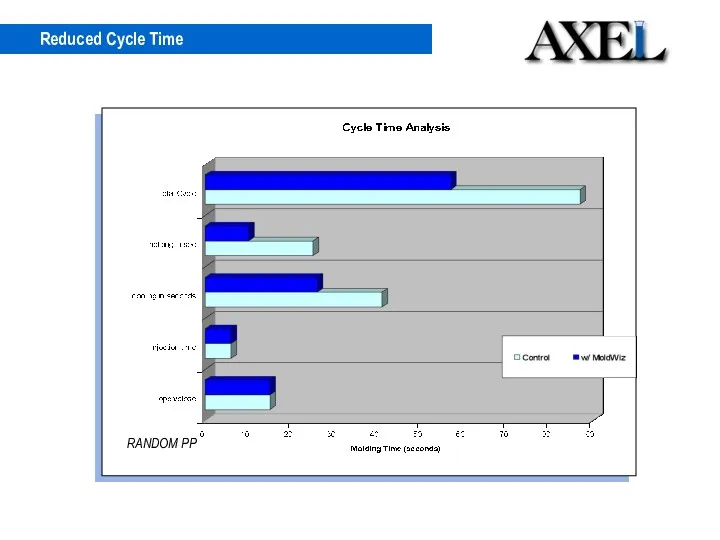

- 10. RANDOM PP Reduced Cycle Time

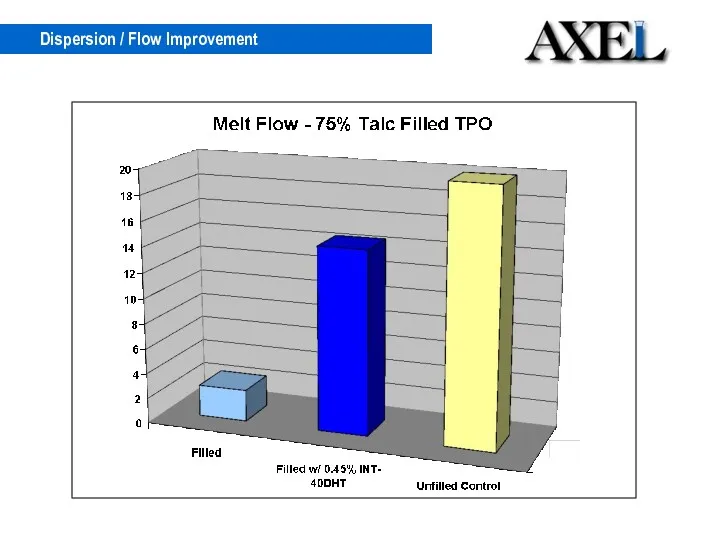

- 11. Dispersion / Flow Improvement

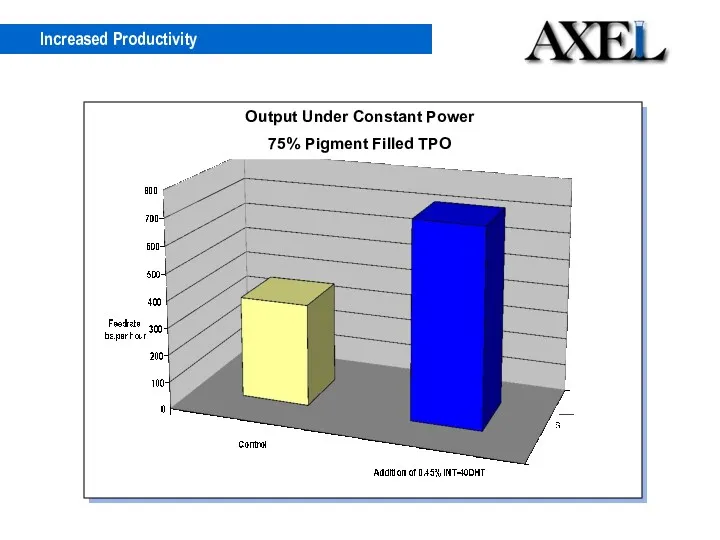

- 12. Output Under Constant Power 75% Pigment Filled TPO Increased Productivity

- 13. Key Products PROCESS AID ADDITIVES

- 14. INT-33LCA FLOW & RELEASE Thin Walled Parts Large Mold Cavities Better Flow Better Release TPO, PP,

- 15. REDUCED COEFFICIENT OF FRICTION Safe for Food Contact TPO, PP, PE INT-33LCA

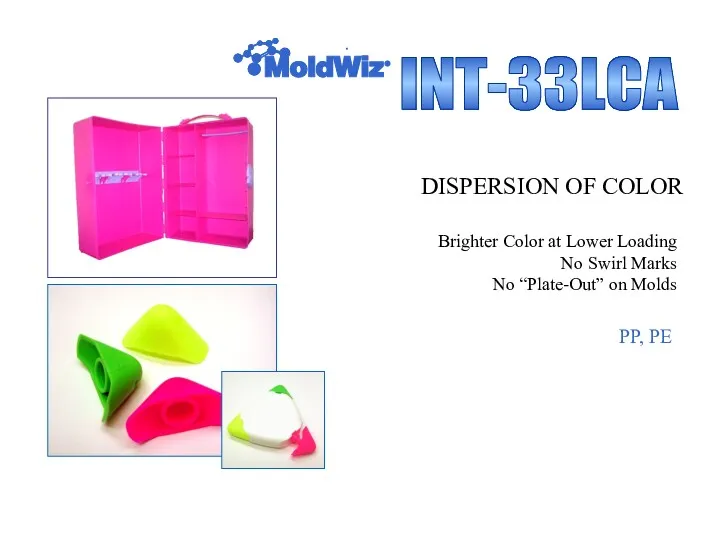

- 16. Brighter Color at Lower Loading No Swirl Marks No “Plate-Out” on Molds DISPERSION OF COLOR PP,

- 17. INT-35PRC Good Release No Tackiness On Part TPE

- 18. FILL & RELEASE TPU TPE Crystal PS TPR Clean Release NO Printing or Bonding Problems NO

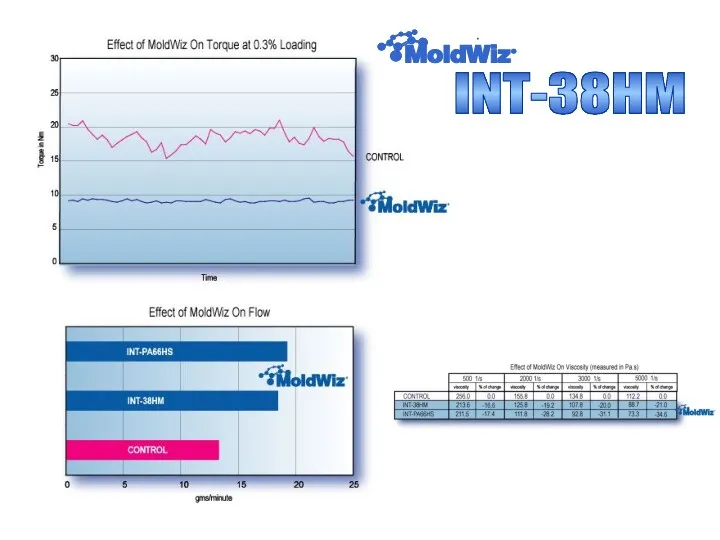

- 19. NYLON all grades including glass filled Improved Flow Lower Torque Consistent Torque Easy Release INT-38HM

- 20. INT-38HM

- 21. INT-PA33FRK Improved Flow - hard to fill Reduction in heat to eliminate discoloration Maintain/Improve whiteness Improve

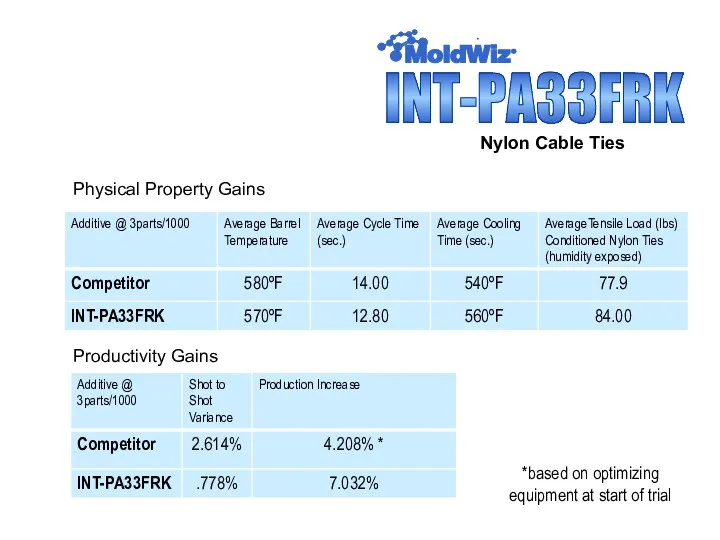

- 22. INT-PA33FRK Nylon Cable Ties Productivity Gains Physical Property Gains *based on optimizing equipment at start of

- 23. INT-66PV Use More Regrind, Less Virgin Resin Better Incorporation of Additives Less Buildup on Molds Easier

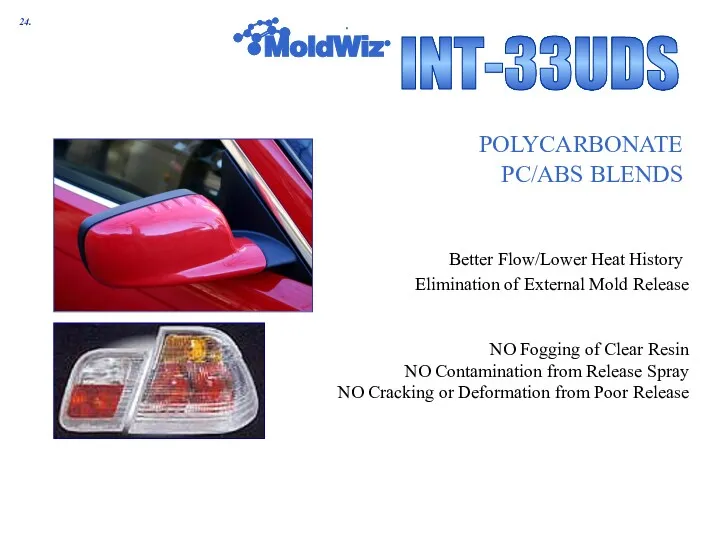

- 24. PC/ABS BLENDS Elimination of External Mold Release NO Fogging of Clear Resin NO Contamination from Release

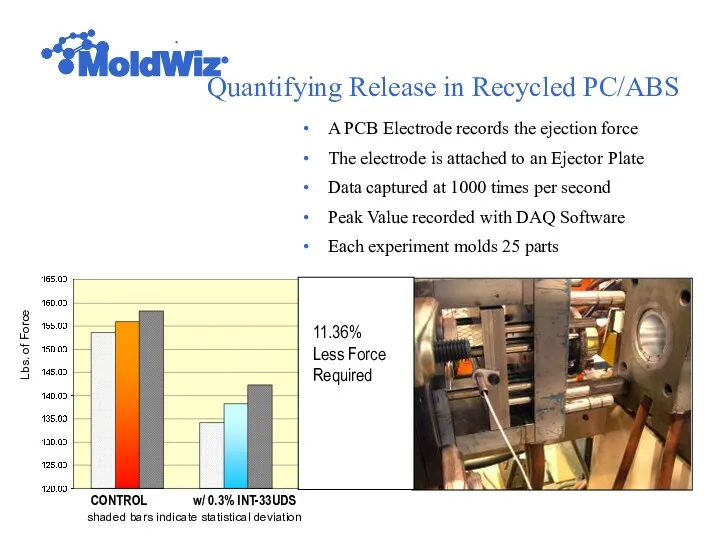

- 25. CONTROL A PCB Electrode records the ejection force The electrode is attached to an Ejector Plate

- 26. PROCESS AID ADDITIVES New Developments

- 27. INT-701TPD Automotive TPO Scratch & Mar Reduction Also Aids Flow & Release

- 28. INT-701TPD Improved Flow - deep draw hard to fill Reduction in heat to eliminate resin burning

- 29. INT-701TPD PP Storage Containers Productivity Gains Estimated Savings/ Part at Machine Hour Rate of $100/hr. Also…Energy

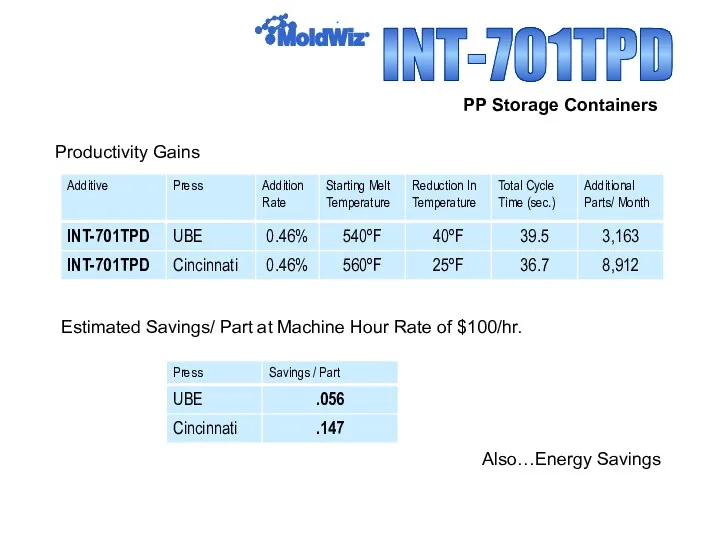

- 30. INT-35CPD INT-41TPD 4000 1/s 6000 1/s 9000 1/s * HDPE:7.45g/10 minutes HDPE* with 0.5% loading of

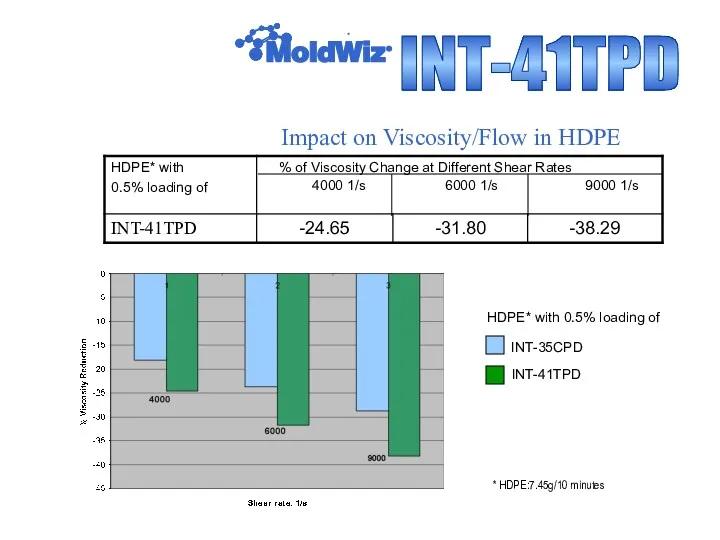

- 32. Скачать презентацию

Как вести себя рядом с энергообъектами

Как вести себя рядом с энергообъектами Жизненный и творческий путь Афанасия Афанасьевича Фета. (1820г.-1892г.)

Жизненный и творческий путь Афанасия Афанасьевича Фета. (1820г.-1892г.) Тези до законопроектів щодо запровадження накопичувальної системи пенсій

Тези до законопроектів щодо запровадження накопичувальної системи пенсій Универсальные семейные ценности

Универсальные семейные ценности Работа с учетными записями пользователей в Windows. 10 подробное руководство

Работа с учетными записями пользователей в Windows. 10 подробное руководство Светлая Пасха. История и традиции

Светлая Пасха. История и традиции Занятие 2 Тема 2 Управление ТС в штатных ситуациях

Занятие 2 Тема 2 Управление ТС в штатных ситуациях Страхование спортсменов

Страхование спортсменов Сказочный городок

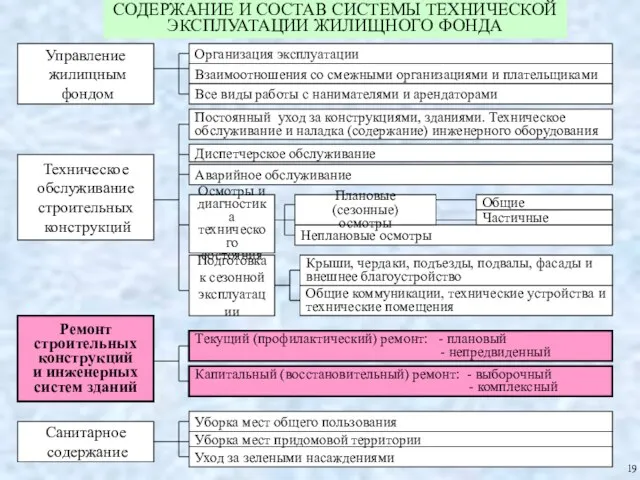

Сказочный городок Основные положения по организации и производству ремонтно-строительных работ

Основные положения по организации и производству ремонтно-строительных работ Электронное строение атома. 11 класс.

Электронное строение атома. 11 класс. Этикет. История этикета

Этикет. История этикета Техническая эксплуатация сооружений и устройств путевого хозяйства

Техническая эксплуатация сооружений и устройств путевого хозяйства Сказочный город

Сказочный город Коммерческое предложение. Онлайн-касса Эвотор

Коммерческое предложение. Онлайн-касса Эвотор Неметаллы

Неметаллы Чрезвычайные ситуации химического характера

Чрезвычайные ситуации химического характера Распознавание пластмасс и волокон. Лабораторная работа

Распознавание пластмасс и волокон. Лабораторная работа История создания термометра

История создания термометра Автоматизация и ее применение

Автоматизация и ее применение Художники Марий Эл

Художники Марий Эл Презентация География в танце

Презентация География в танце История и методы изучения клетки. Клеточная теория

История и методы изучения клетки. Клеточная теория Даниил Гранин

Даниил Гранин презентация Фосфор, соединения фосфора

презентация Фосфор, соединения фосфора Социальная политика государства и управление социальным развитием организации (Россия и Сингапур)

Социальная политика государства и управление социальным развитием организации (Россия и Сингапур) Игил - Исламское государство

Игил - Исламское государство Эрзянский народный зимний календарь

Эрзянский народный зимний календарь