Содержание

- 2. Daikin Single G-type Screw Compressor G - Type Single Screw R134a Up to 90 KW120 Hp

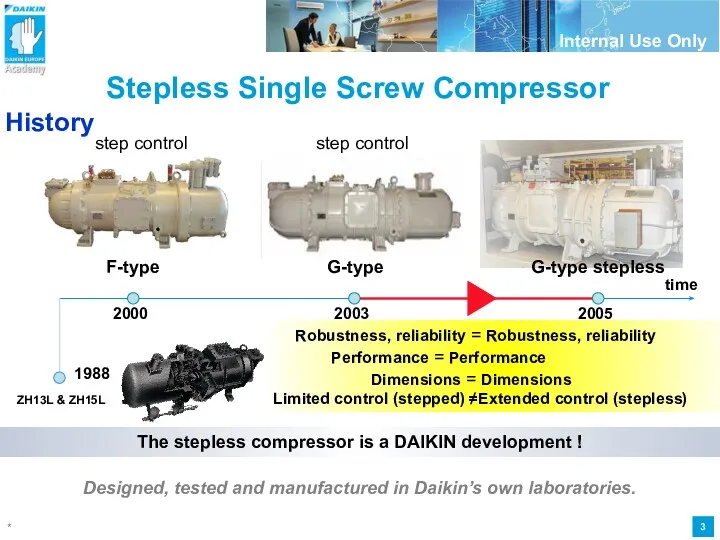

- 3. Stepless Single Screw Compressor History F-type G-type G-type stepless 2005 2003 2000 time Robustness, reliability =

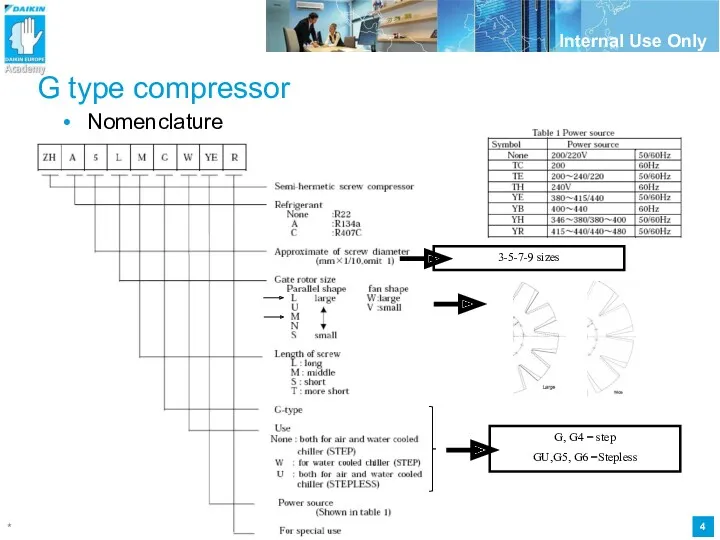

- 4. G type compressor Nomenclature G, G4 = step GU,G5, G6 =Stepless 3-5-7-9 sizes

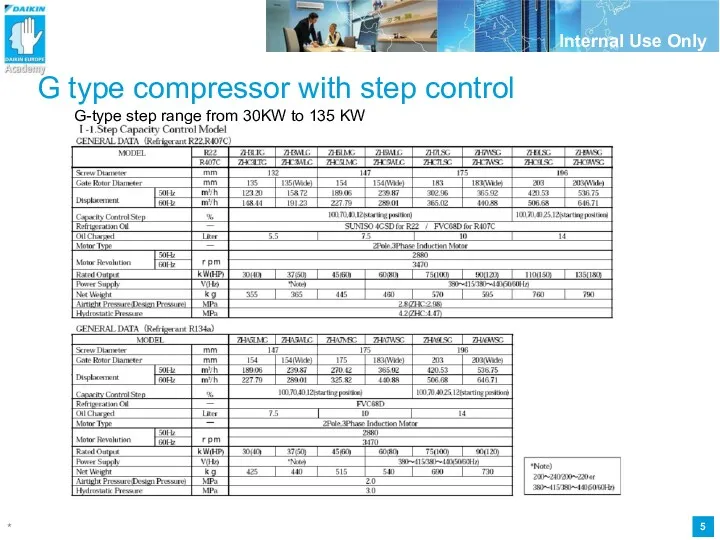

- 5. G type compressor with step control G-type step range from 30KW to 135 KW

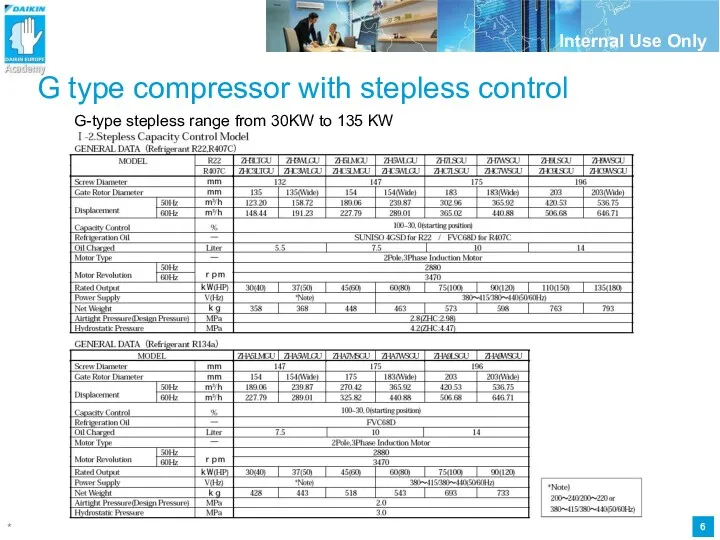

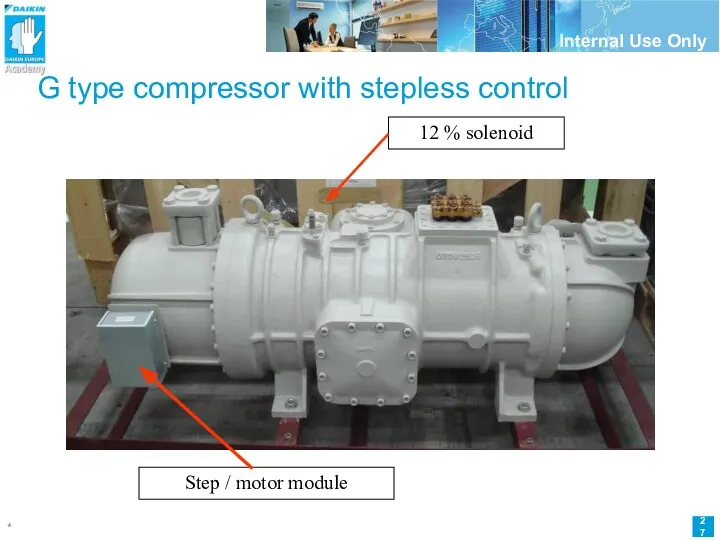

- 6. G type compressor with stepless control G-type stepless range from 30KW to 135 KW

- 7. The single, mono or globoïd screw Closed end Open end Satelite Or Gate Rotor = Special

- 8. Gate rotor and gate rotorshaft

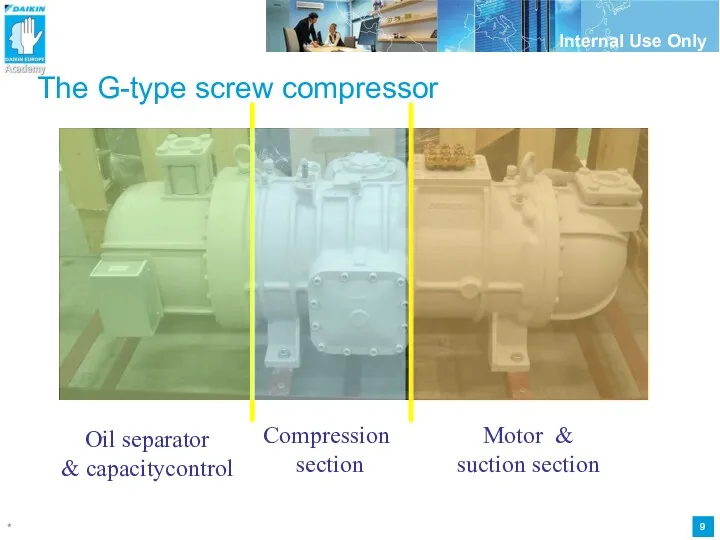

- 9. The G-type screw compressor Motor & suction section Compression section Oil separator & capacitycontrol

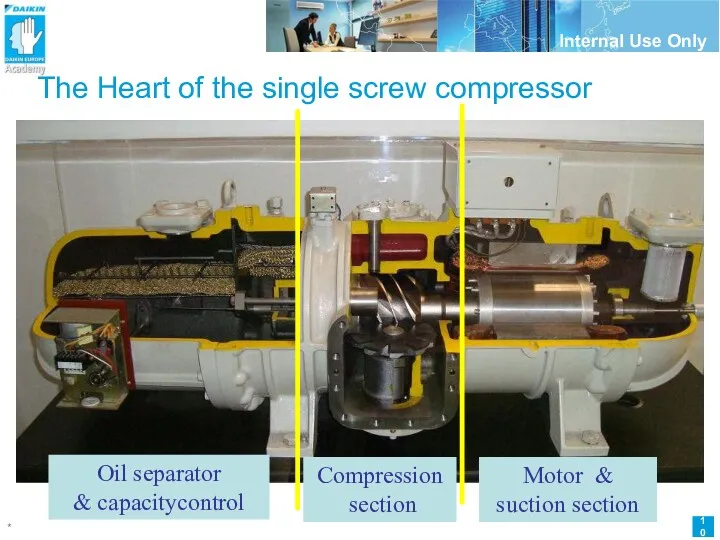

- 10. The Heart of the single screw compressor Motor & suction section Compression section Oil separator &

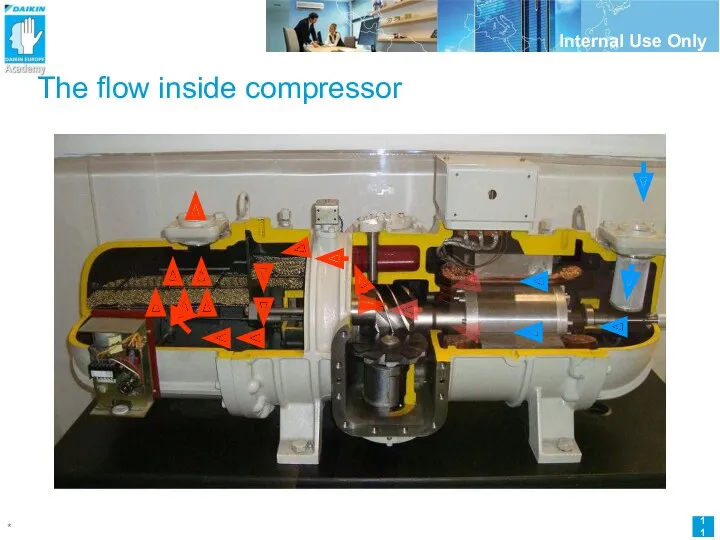

- 11. The flow inside compressor

- 12. Compression Principle

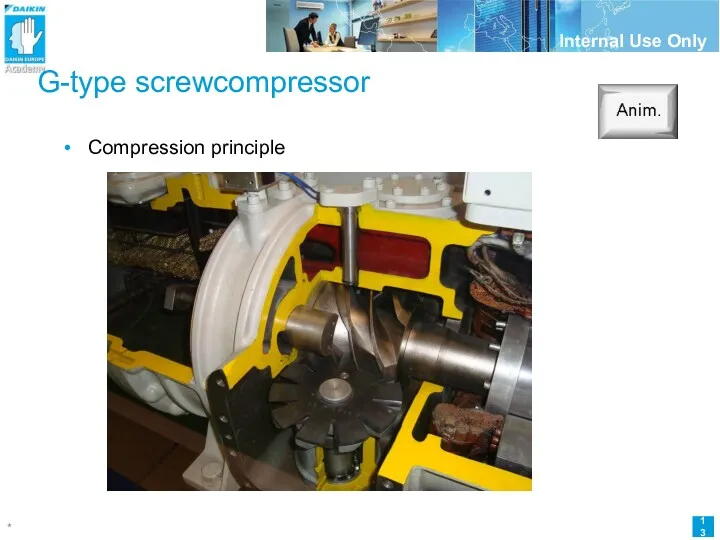

- 13. G-type screwcompressor Compression principle

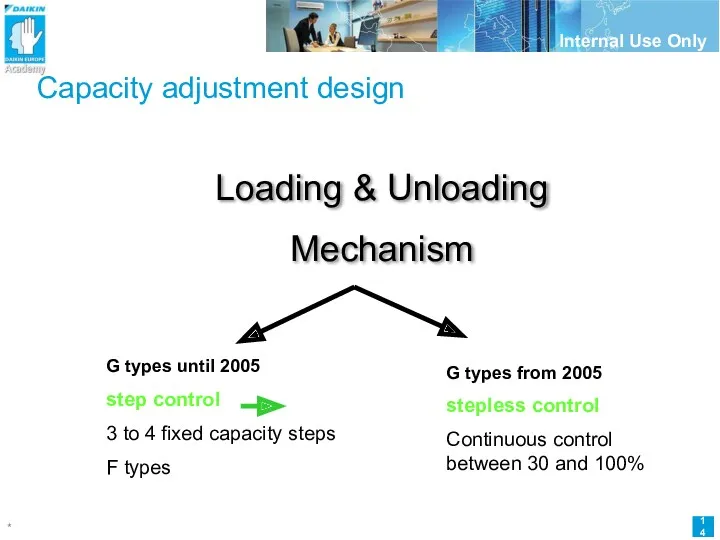

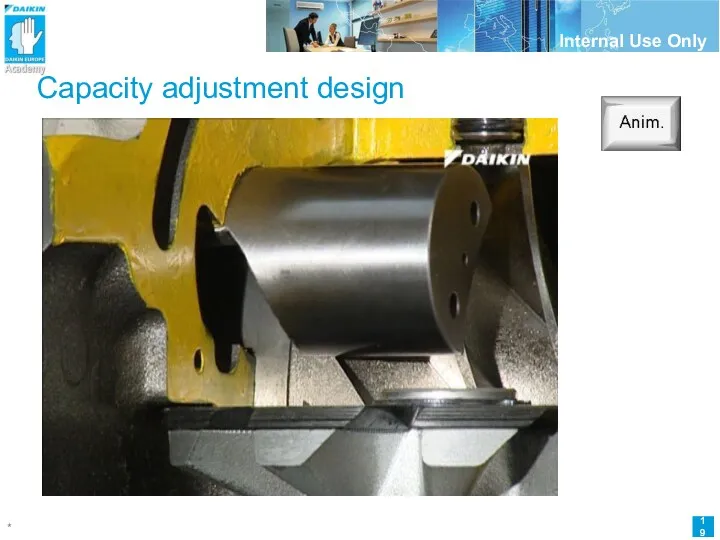

- 14. Capacity adjustment design Loading & Unloading Mechanism G types until 2005 step control 3 to 4

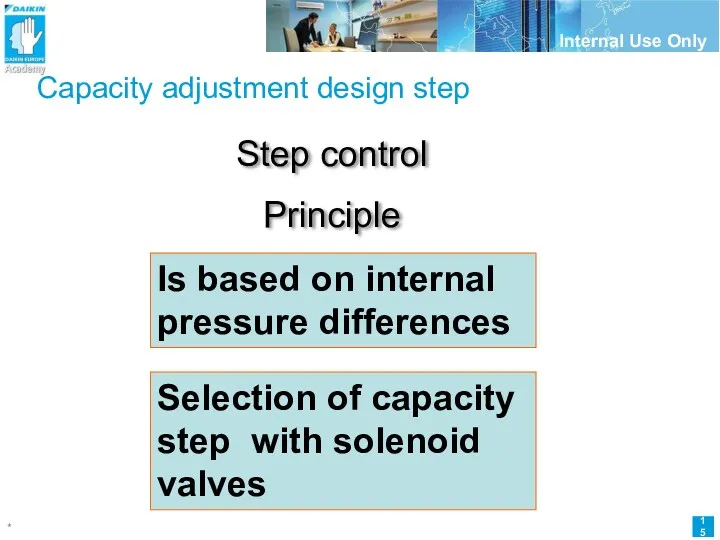

- 15. Capacity adjustment design step Step control Principle Is based on internal pressure differences Selection of capacity

- 16. step control/essential parts Capacity solenoid valves 12 12

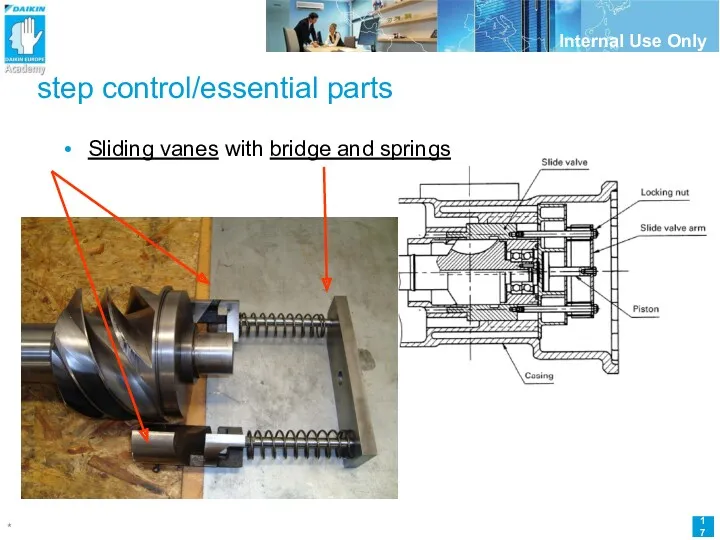

- 17. step control/essential parts Sliding vanes with bridge and springs

- 18. step control/essential parts Slide vane bridge with capacity cylinder/piston

- 19. Capacity adjustment design

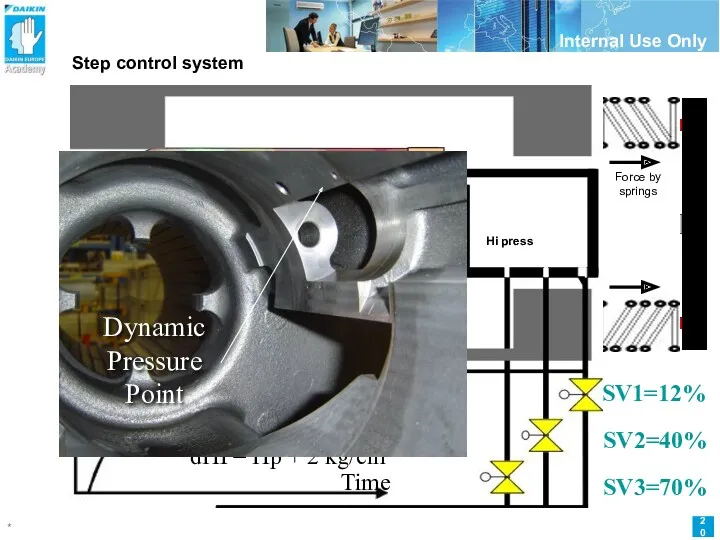

- 20. SV1=12% SV2=40% SV3=70% Step control system Energized = open ! Spacer Low pressure side Screw rotor

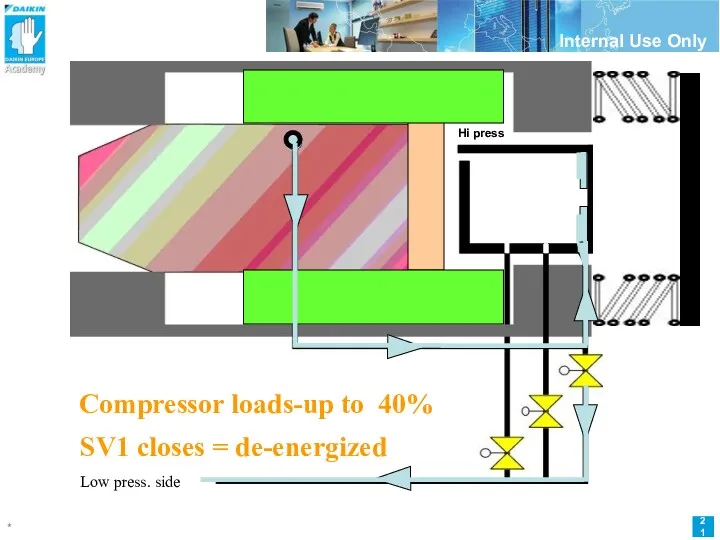

- 21. Compressor start Compressor loads-up to 40% SV1 closes = de-energized 12% capacity Hi press Low press.

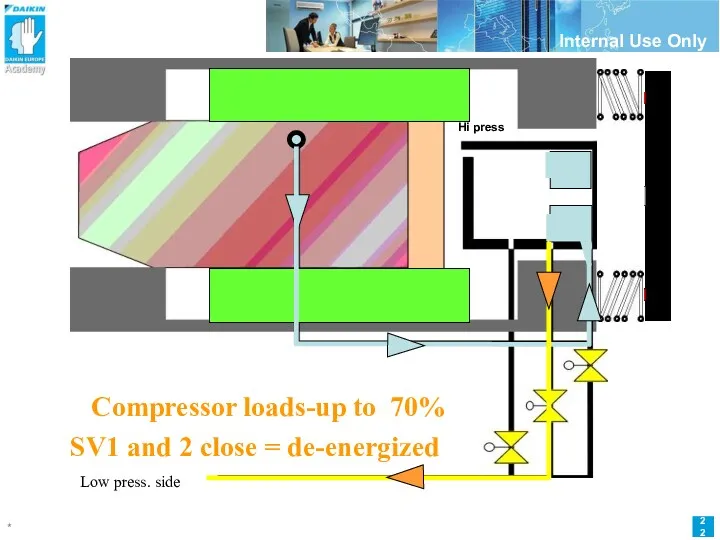

- 22. Compressor loads-up to 70% SV1 and 2 close = de-energized 40% capacity Hi press Low press.

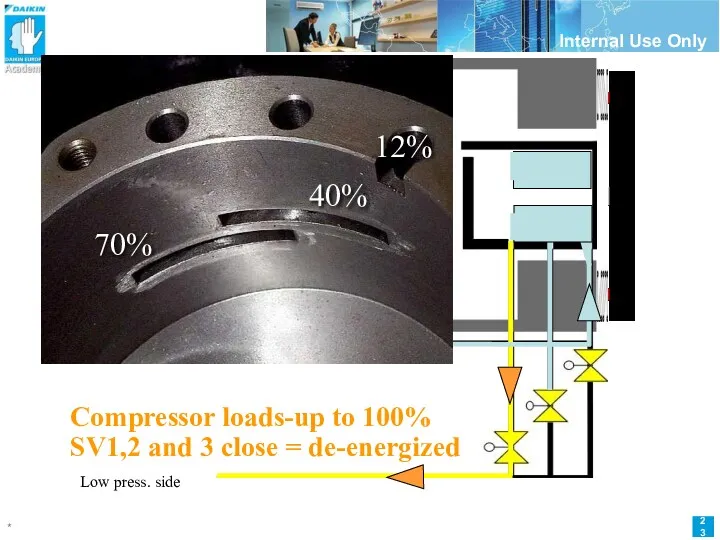

- 23. Compressor loads-up to 100% SV1,2 and 3 close = de-energized 70% capacity Low press. side

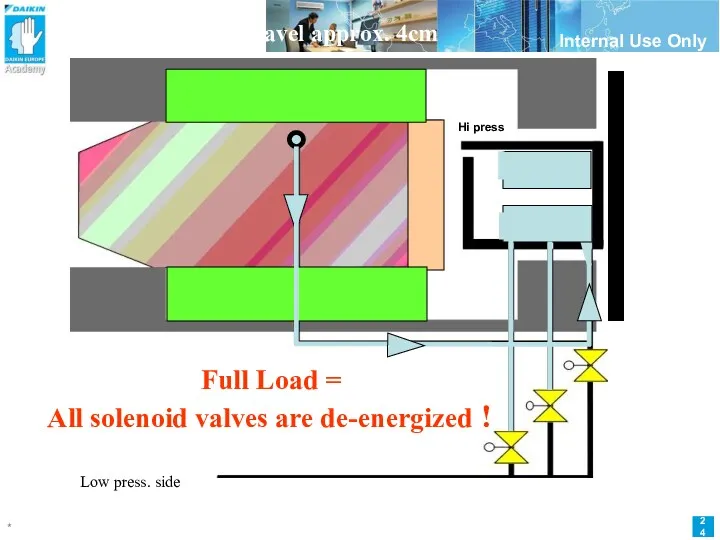

- 24. Full Load = All solenoid valves are de-energized ! Full travel approx. 4cm Low press. side

- 25. Capacity adjustment design stepLESS Stepless control Principle Is based on internal pressure differences Regulation of stepless

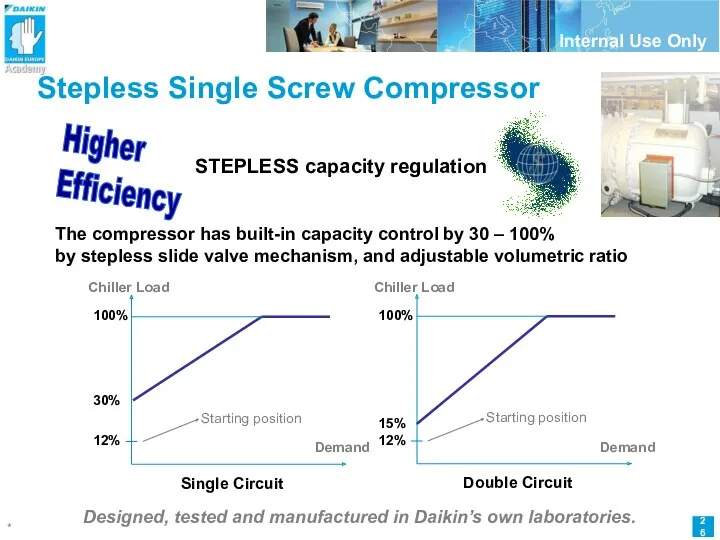

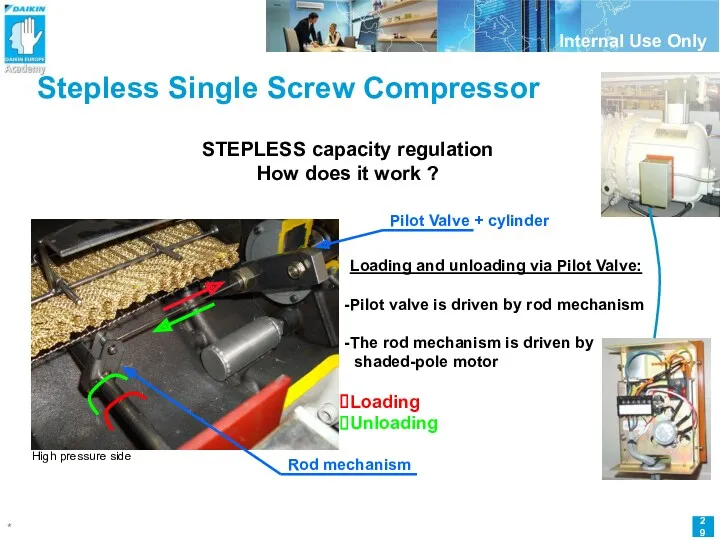

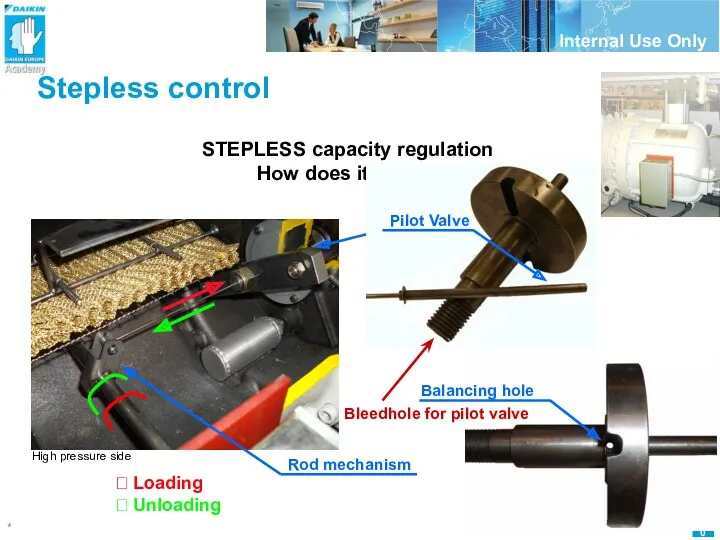

- 26. Stepless Single Screw Compressor STEPLESS capacity regulation Designed, tested and manufactured in Daikin’s own laboratories. Higher

- 27. G type compressor with stepless control Step / motor module 12 % solenoid

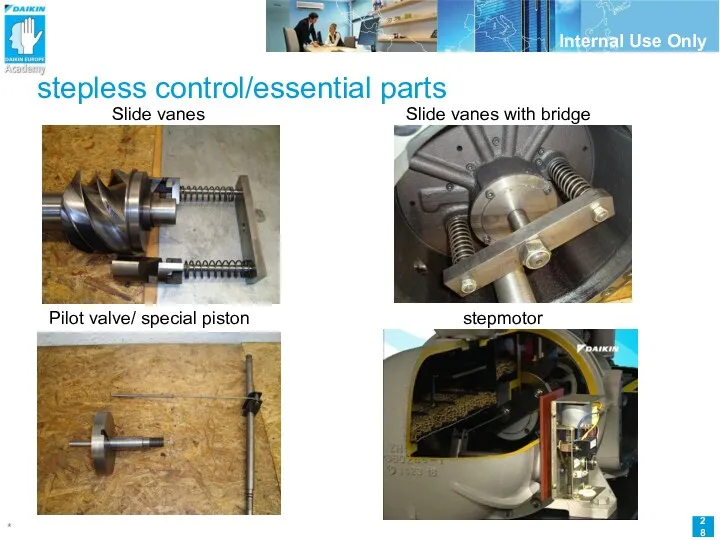

- 28. stepless control/essential parts Slide vanes Slide vanes with bridge Pilot valve/ special piston stepmotor

- 29. Stepless Single Screw Compressor STEPLESS capacity regulation How does it work ? Loading and unloading via

- 30. Stepless control STEPLESS capacity regulation How does it work ? Rod mechanism High pressure side Pilot

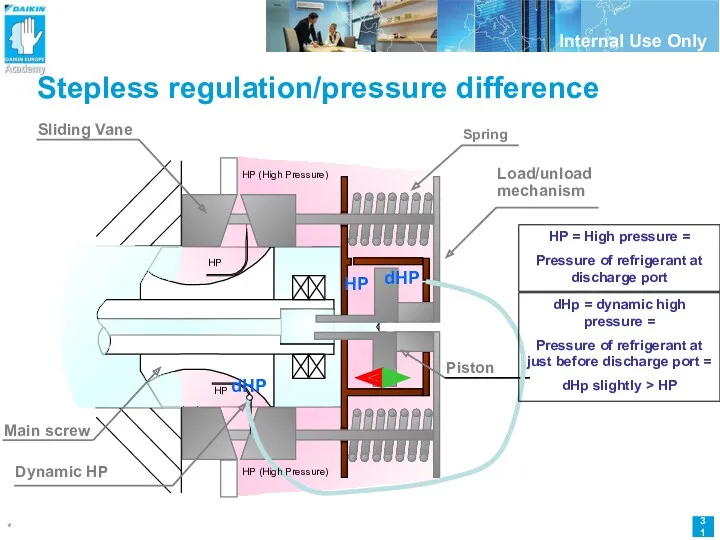

- 31. Stepless regulation/pressure difference HP (High Pressure) Main screw Sliding Vane Load/unload mechanism Piston HP HP Spring

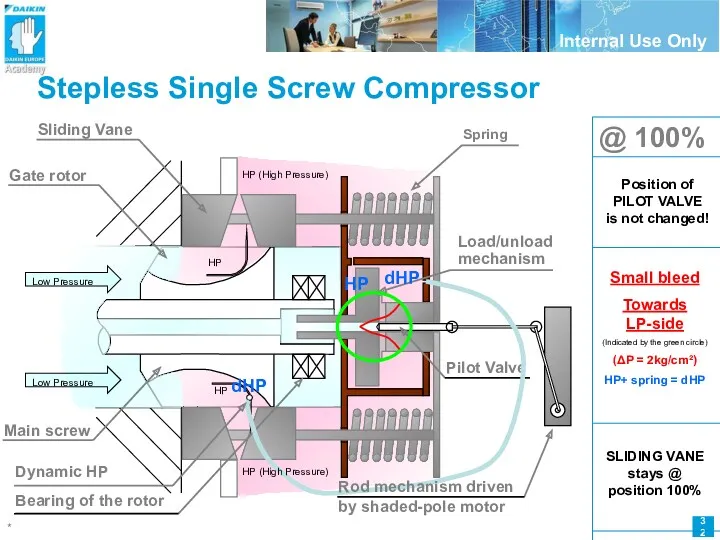

- 32. Stepless Single Screw Compressor HP (High Pressure) Low Pressure Gate rotor Main screw Sliding Vane Load/unload

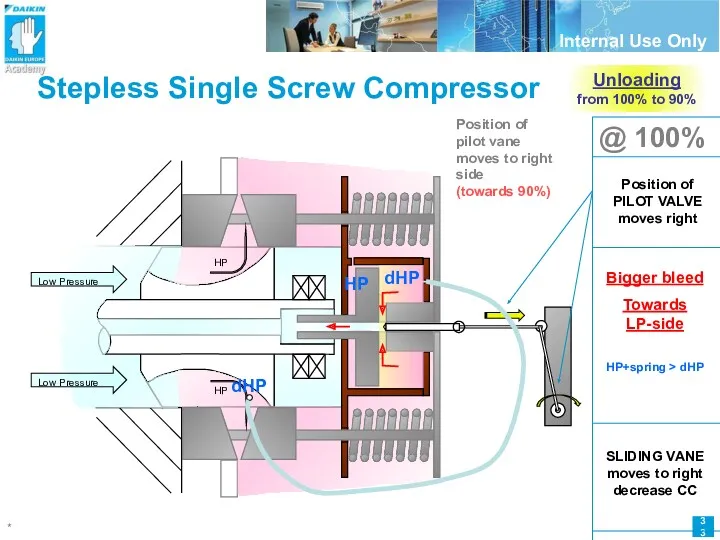

- 33. Stepless Single Screw Compressor @ 100% Position of pilot vane moves to right side (towards 90%)

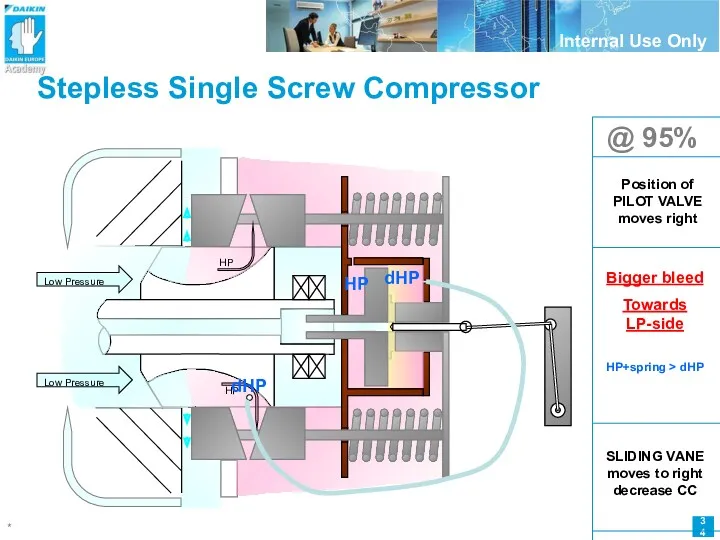

- 34. Stepless Single Screw Compressor @ 95% Low Pressure HP HP Low Pressure dHP dHP HP Bigger

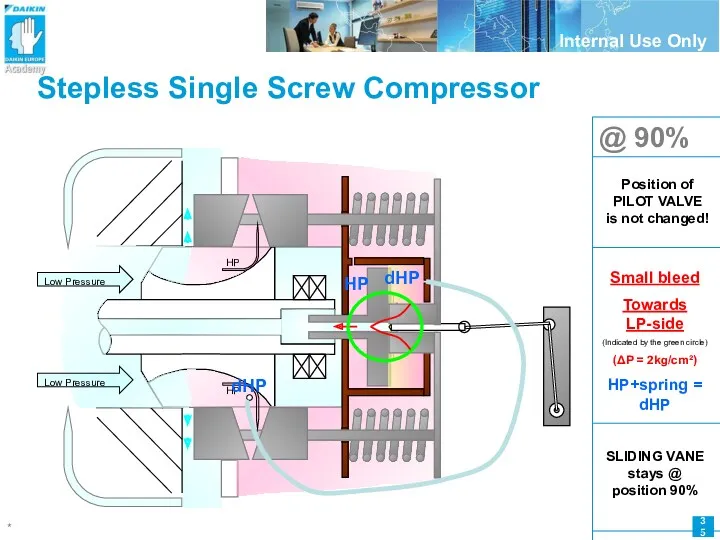

- 35. Stepless Single Screw Compressor @ 90% Low Pressure HP HP Low Pressure Small bleed Towards LP-side

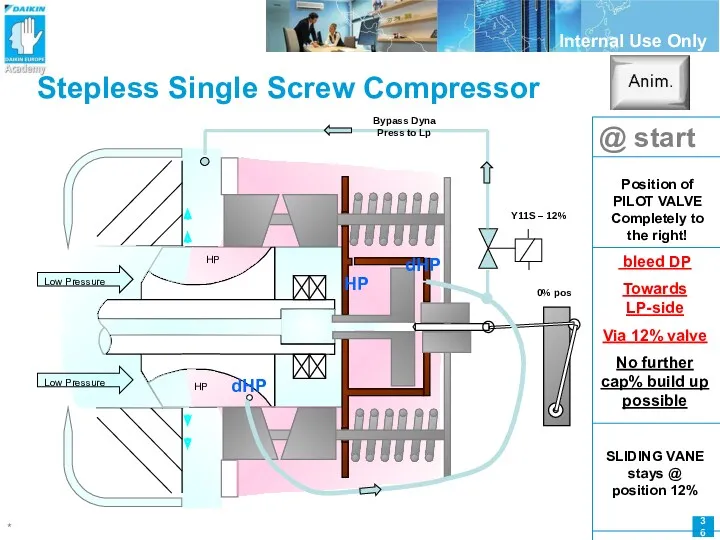

- 36. Stepless Single Screw Compressor @ start Low Pressure HP HP Low Pressure bleed DP Towards LP-side

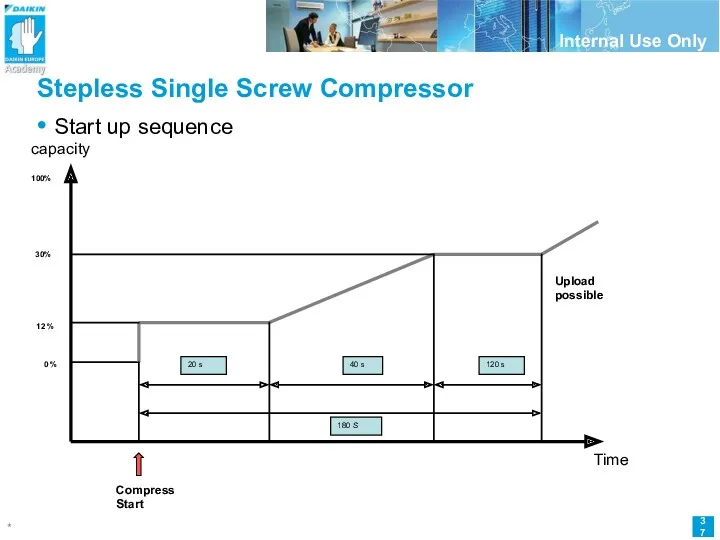

- 37. Stepless Single Screw Compressor 12 % 30% Upload possible 0 % 20 s 40 s 120

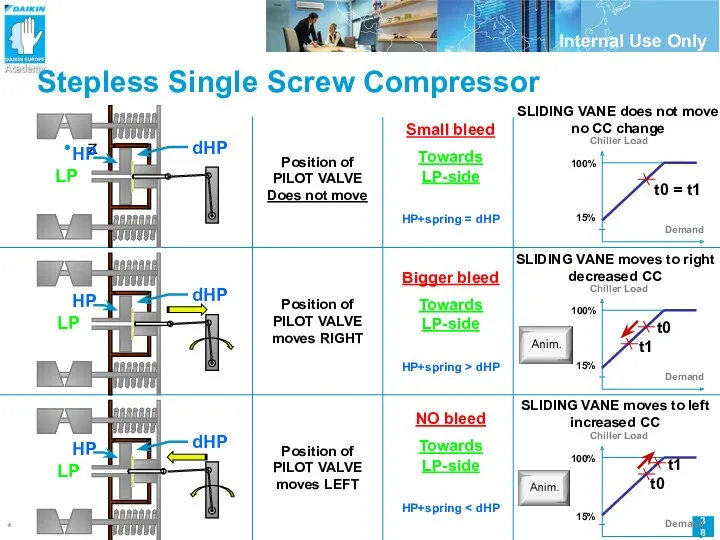

- 38. Stepless Single Screw Compressor z Position of PILOT VALVE moves RIGHT Position of PILOT VALVE moves

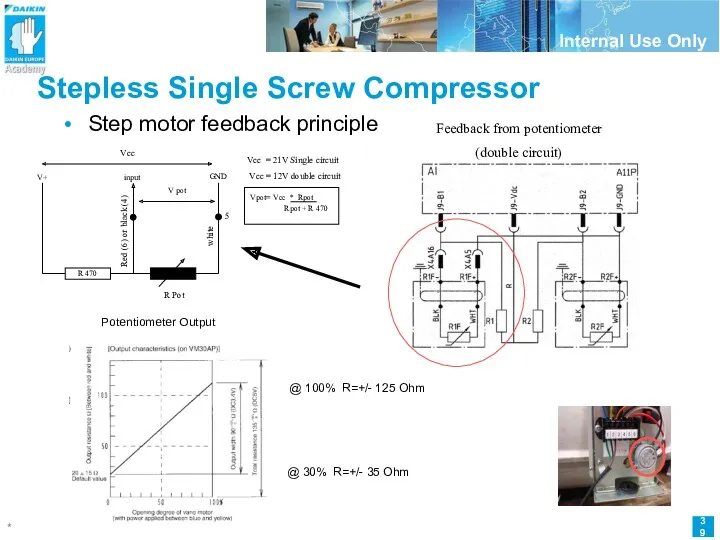

- 39. Stepless Single Screw Compressor Step motor feedback principle Feedback from potentiometer (double circuit) R 470 R

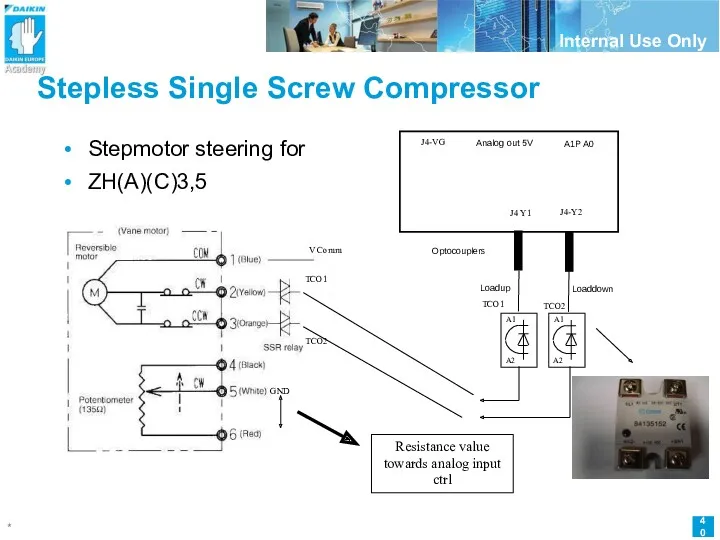

- 40. Stepless Single Screw Compressor Stepmotor steering for ZH(A)(C)3,5 TCO1 TCO2 J4-VG J4 Y1 J4-Y2 TCO1 TCO2

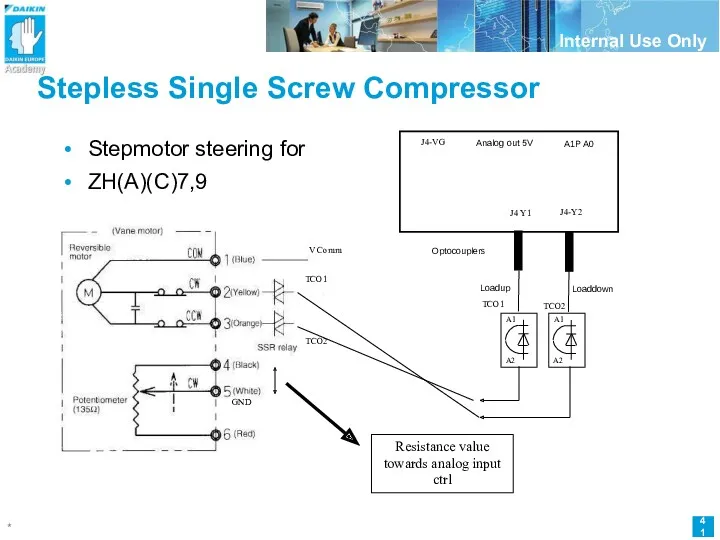

- 41. Stepless Single Screw Compressor Stepmotor steering for ZH(A)(C)7,9 TCO1 TCO2 J4-VG J4 Y1 J4-Y2 TCO1 TCO2

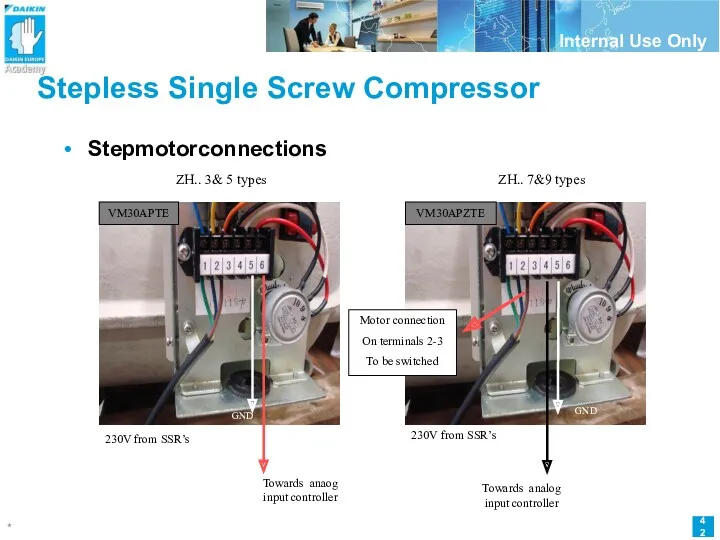

- 42. Stepless Single Screw Compressor Stepmotorconnections ZH.. 7&9 types ZH.. 3& 5 types Towards anaog input controller

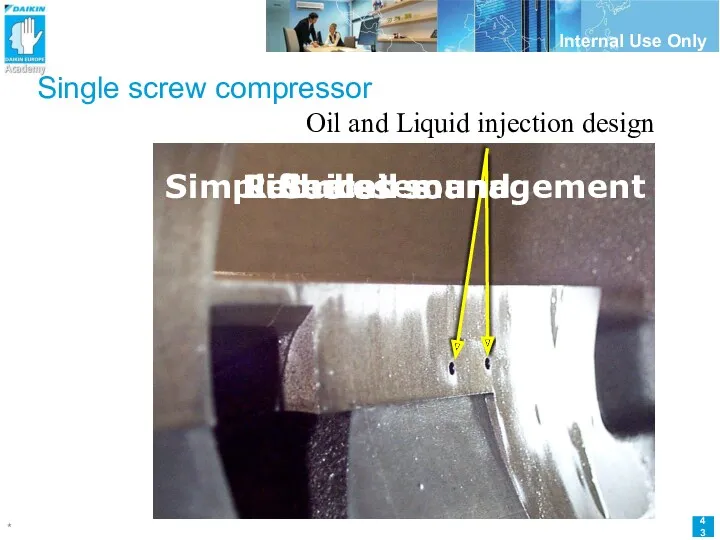

- 43. Oil and Liquid injection design Seals Cools Lubricates Reduces sound Simplified oil management Single screw compressor

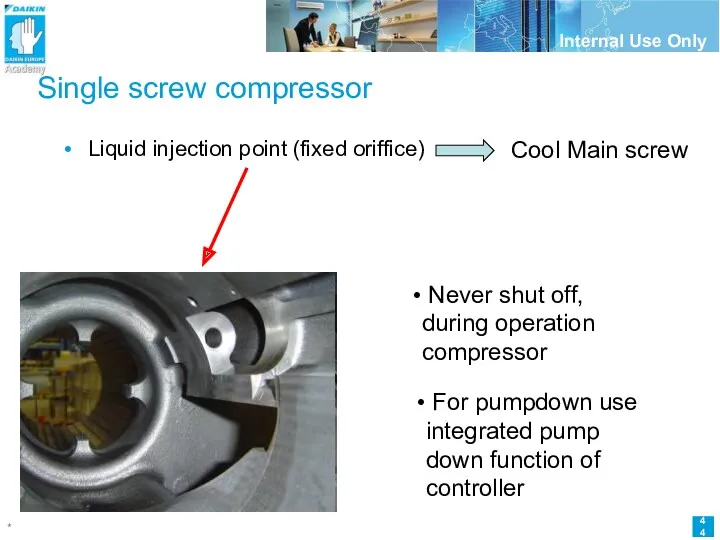

- 44. Single screw compressor Liquid injection point (fixed oriffice) Cool Main screw Never shut off, during operation

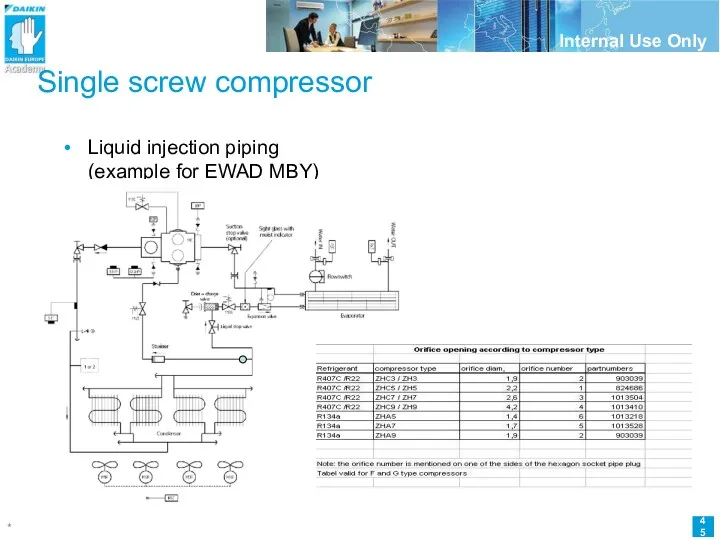

- 45. Single screw compressor Liquid injection piping (example for EWAD MBY)

- 46. Single screw compressor Periodic Inspection

- 47. Single screw compressor - Inspection Periodic Inspection - Check points Insulation Resistance of the Motor. Inspection/Changement

- 48. Single screw compressor - Inspection Check points Insulation Resistance of the Motor. After 1year of operation.

- 49. Single screw compressor - Inspection Check points Inspection/Changement of the Refrigerant Oil. Take a oil sample

- 50. Single screw compressor - Inspection Oil drain ports

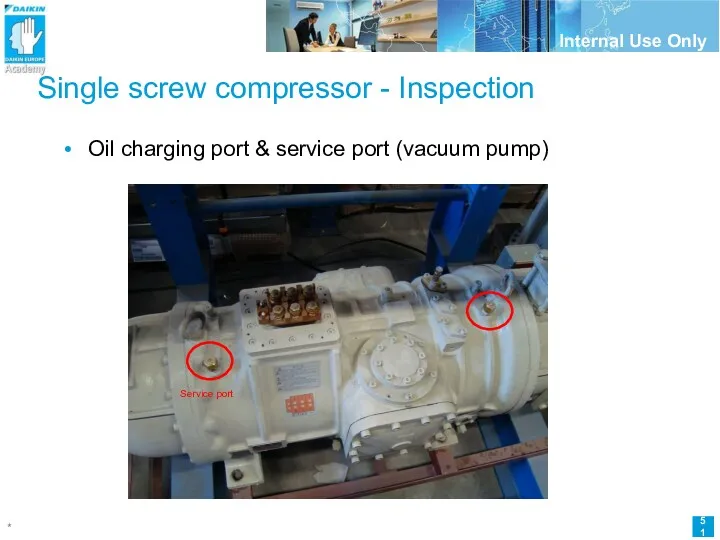

- 51. Single screw compressor - Inspection Oil charging port & service port (vacuum pump) Service port

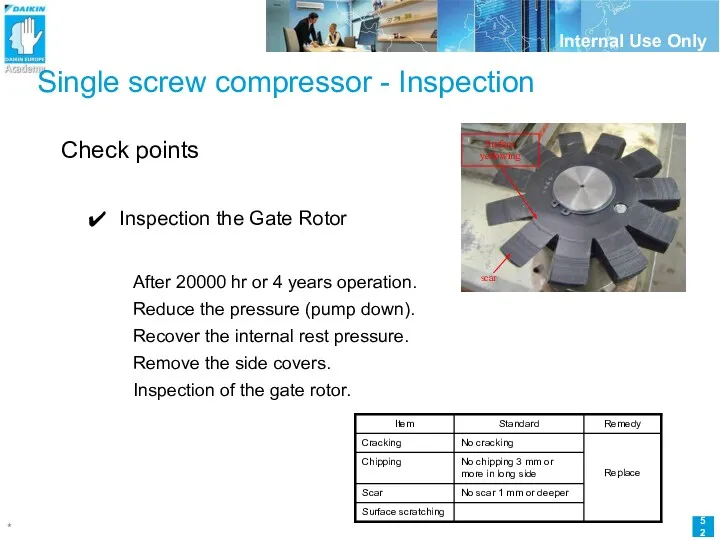

- 52. Single screw compressor - Inspection Check points Inspection the Gate Rotor After 20000 hr or 4

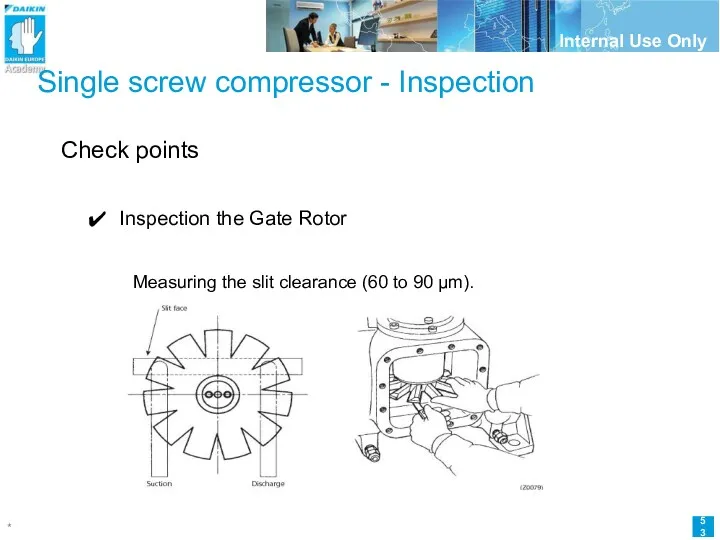

- 53. Single screw compressor - Inspection Check points Inspection the Gate Rotor Measuring the slit clearance (60

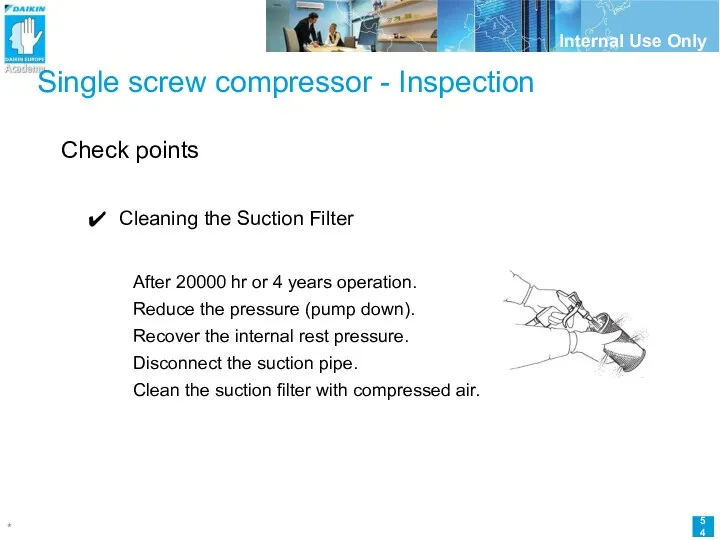

- 54. Single screw compressor - Inspection Check points Cleaning the Suction Filter After 20000 hr or 4

- 55. Single screw compressor Overhaul

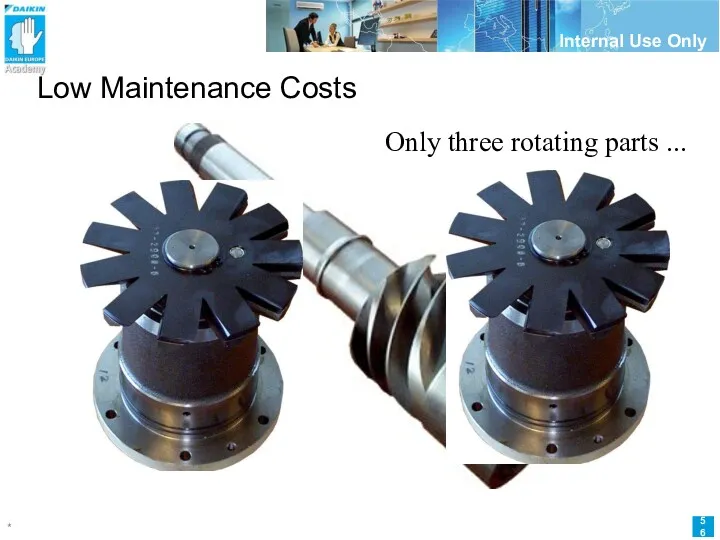

- 56. Low Maintenance Costs Only three rotating parts ...

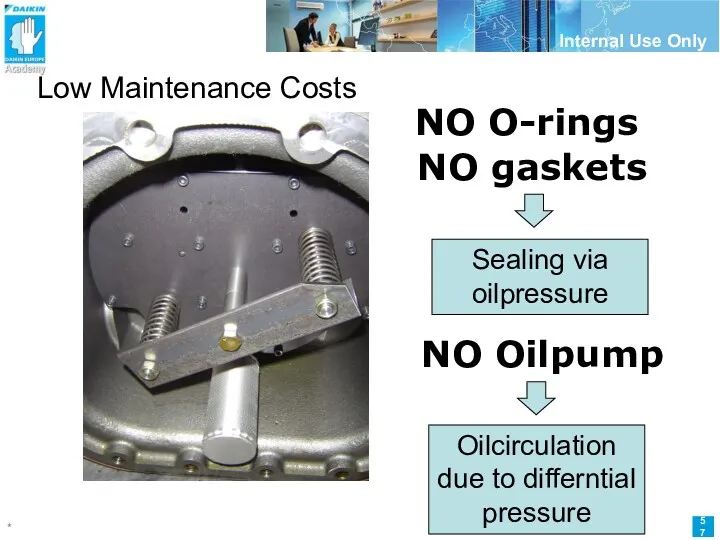

- 57. Low Maintenance Costs … and two sliding parts NO O-rings NO gaskets NO Oilpump

- 58. Single Screw Compressor - Overhaul Overhaul (see service manual Si50-402A) Overhaul interval:40.000 hrs or 7 years,

- 59. Single Screw Compressor - Overhaul Overhaul Instructions Chart (See Service Manual SiE50-402A) 1. Disassembly and Inspection

- 60. Single Screw Compressor - Overhaul Overhaul Instructions Chart(See Service Manual SiE50-402A) 2. Replacing The Bearing Remove

- 61. Single Screw Compressor - Overhaul Overhaul Instructions Chart (See Service Manual SiE50-402A) 3. Final Assembly Assemble

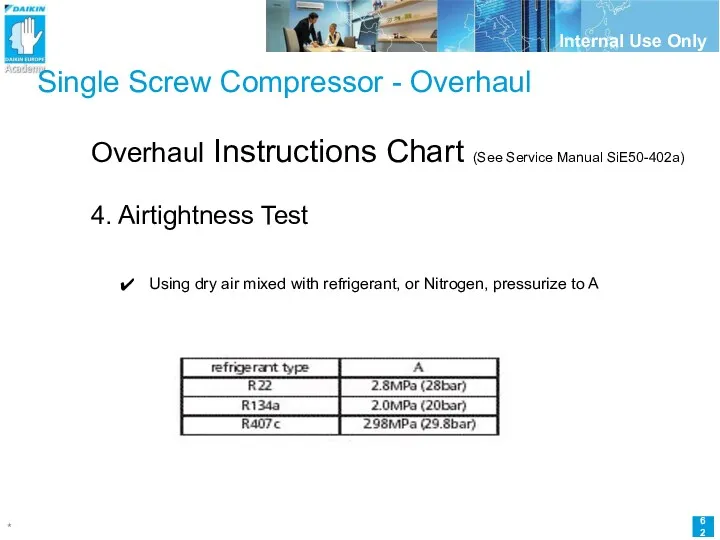

- 62. Single Screw Compressor - Overhaul Overhaul Instructions Chart (See Service Manual SiE50-402a) 4. Airtightness Test Using

- 63. Single Screw Compressor - Overhaul Overhaul Instructions Chart (See Service Manual SiE50-402a) 5. Charging Oil Charge

- 64. Single Screw Compressor - Overhaul Overhaul Instructions Chart (See Service Manual SiE50-402a) 6. Caution in Test

- 65. Single Screw Compressor – Overhaul pics

- 67. Скачать презентацию

Биполярные транзисторы

Биполярные транзисторы Групповое занятие по коррекции устной и письменной речи у младших школьников.

Групповое занятие по коррекции устной и письменной речи у младших школьников. Кем я вижу себя через 7 лет. Ващев Евгений

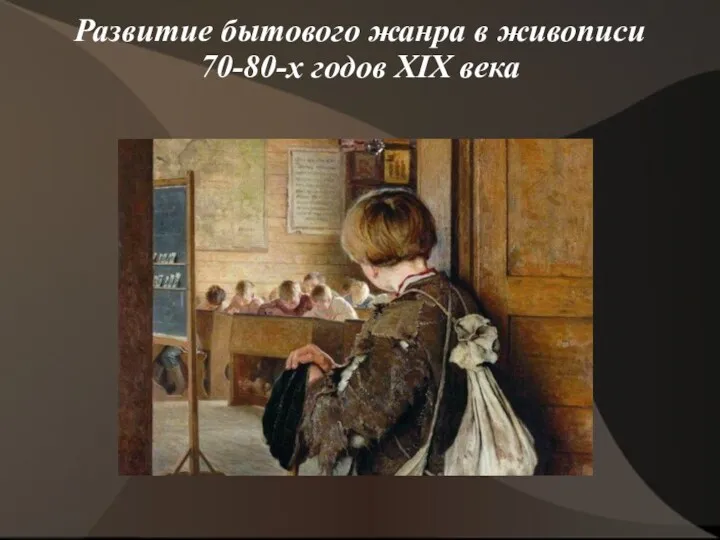

Кем я вижу себя через 7 лет. Ващев Евгений Презентация 11. Бытовой жанр в живописи 70-80-х годов

Презентация 11. Бытовой жанр в живописи 70-80-х годов Договорные отношения в туристической деятельности. Тема 4

Договорные отношения в туристической деятельности. Тема 4 Самоуправление- важнейший компонент воспитательной системы школы

Самоуправление- важнейший компонент воспитательной системы школы Розвиток мовлення 4 клас ІІ семестр

Розвиток мовлення 4 клас ІІ семестр Основные производственные процессы в тепловодном карповом прудовом хозяйстве

Основные производственные процессы в тепловодном карповом прудовом хозяйстве Walk, crawl, stagger

Walk, crawl, stagger Современные информационно-управляющие системы в управлении движением на железнодорожном транспорте

Современные информационно-управляющие системы в управлении движением на железнодорожном транспорте Природоведение. Урок знакомства.

Природоведение. Урок знакомства. Емдік тамақтандыру. Анемия. Қызба. Оттегі терапия

Емдік тамақтандыру. Анемия. Қызба. Оттегі терапия Специфика исследований в бизнесе и менеджменте

Специфика исследований в бизнесе и менеджменте Опухоли, опухолеподобные поражения и кисты слюнных желез. Клиника, диагностика, лечение. (Лекция 7)

Опухоли, опухолеподобные поражения и кисты слюнных желез. Клиника, диагностика, лечение. (Лекция 7) Резные кружева. Русская домовая резьба

Резные кружева. Русская домовая резьба Красный основной соус и его производные

Красный основной соус и его производные Поздравление мамам

Поздравление мамам Pour rire sans reflechir

Pour rire sans reflechir Канальное кодирование. Основы помехоустойчивого кодирования

Канальное кодирование. Основы помехоустойчивого кодирования Склейка Ландыши

Склейка Ландыши Физминутка для глаз Звездочет

Физминутка для глаз Звездочет Использование игровых методов при принятии решений в условиях риска и неопределенности понятие об игровых методах. Тема 8

Использование игровых методов при принятии решений в условиях риска и неопределенности понятие об игровых методах. Тема 8 Вопросы репродуктивного здоровья, современные методы обследования и лечения бесплодия

Вопросы репродуктивного здоровья, современные методы обследования и лечения бесплодия Универсальные семейные ценности

Универсальные семейные ценности Интерактивная игра-викторина по русским народным сказкам для детей старшего дошкольного возраста с ОИН

Интерактивная игра-викторина по русским народным сказкам для детей старшего дошкольного возраста с ОИН Оборудование и технология для гибридной лазерно-дуговой сварки сталей и алюминиевых сплавов

Оборудование и технология для гибридной лазерно-дуговой сварки сталей и алюминиевых сплавов Готовимся к ЕГЭ по биологии. Презентация – практикум по подготовке к успешному выполнению задания С5

Готовимся к ЕГЭ по биологии. Презентация – практикум по подготовке к успешному выполнению задания С5 Псков. Мастеровой. Гости праздника

Псков. Мастеровой. Гости праздника